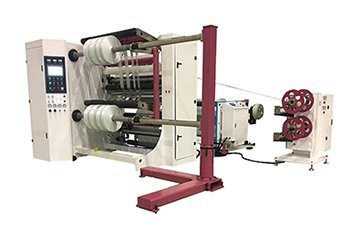

Leading Thermal Paper Slitter Rewinder Machine Manufacturer

- Special designed for making coreless thermal paper rolls

- Same configuration with JT-SLT-900

- Small size and economic

- Works for most used thermal paper roll

900mm Coreless Type Thermal Paper Slitting Rewinding Machine

900mm Coreless Type Thermal Paper Slitting Rewinding Machiner is always Jota’s core product from the very beginning.

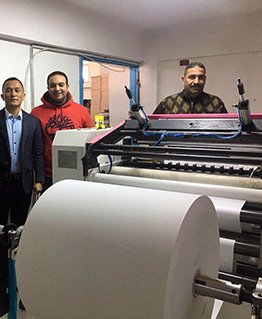

Jota thermal paper slitting machine’s iconic clients include Navigator, SS Labels, K.M.S Group, etc.

When you are shopping in the supermarket or having dinner at a restaurant and swiping your credit card, there is a small cash roll of paper, which is very popular nowadays. It is thermal reception paper or thermal cash register receipt paper. There is a great demand for this kind of paper in the current market, and it penetrates all aspects of your life. Therefore, the thermal paper slitting converting should be a good business for you, it is with a small investment and quick return.

As a professional thermal paper slitter rewinder machine supplier, after 20 years of industry precipitation, we could now provide a full set of thermal paper cashier receipt solutions chain from A to Z, from base thermal paper mother roll, paper core (plastic core), thermal paper slitter rewinder Machine, thermal paper printing machine, cash roll finishing wrapping line, and packaging film, we could provide a full set of professional solutions.

Submit your requirements now, we will recommend a suitable thermal roll slitting machine to you.

Jota Machinery: Your Trustworthy Thermal Paper Slitting Rewinding Supplier in China

Jota is a reliable thermal paper slitter rewinder supplier, we have our own factory and CNC center.

We are able to offer a one-stop solution for your thermal paper roll business.

To OEM your desired thermal paper roll machine, please submit your request to get a quote.

Machining Material

- Visible high-quality components

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi

- Self-supporting CNC processed sheet metal, precision parts

- Assembly raw materials provided by long-term cooperation suppliers

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Factory

- Customer

- Specs

| Max. Unwinding Width | 900mm |

| Max. Unwinding Diameter | 1000mm |

| Max. Rewinding Diameter | 300mm |

| Min. Slitting Width | 25mm |

| Max. Machine Speed | 150m/min |

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

900mm Coreless Type Thermal Paper Slitting Rewinding Machine

Are you a buyer in the paper products and production industry, searching for the best coreless paper slitting winding machine and other spares for effective performance?

And do you need full information on the same, so that you stand a chance to get the best thermal paper roll machines?

Well, that is very correct, you need a thorough outstanding and brilliance while selecting the most appropriate thermal paper slitter rewinder, distinctive, and potent machinery parts.

Therefore, even if you are new to thermal paper slitting rewinding machines, these frequently asked questions will be an eye-opener, hence ensuring that you choose the best 900mm coreless type thermal paper slitting rewinding machine for your needs.

What is a slitting rewinding machine and how does it function?

A thermal paper slitter rewinder is a machine that involves unrolling a big master roll of material on a series of calculated rewinding rolls and blades placed into your defined length and width.

900mm coreless type thermal paper slitting rewinding machine works by using three primary types of slitting: shear slitting, score slitting, and razor slitting. The score is also known as crush slitting, so you do not get confused. The knife differentiates every type, blade or gadget used when cutting.

900mm coreless type thermal paper slitting rewinding machine usually consists of three distinctive parts; the slitter, the rewind, and the unwind.

By feeding a massive roll of material depending on your specifications via the slitter rewinder unwind, your substance will develop before ending up in slits of various widths.

The material will, after that, get rewound into cores of numerous widths.

How can one describe thermal paper roll products?

900mm coreless type thermal paper slitting rewinding machine has uncomplicated loading and unloading of rewinding a rotating machine element (shaft) for increased production but with lesser downtime.

It, therefore, means that several unwind stations will have the opportunity to get multiple rolls such as multiply and adding machine rolls for billing, teleprinter, and so on.

- Rewinding unit

For proper bracing, one shaft should be inserted in the cores before being supported between 2 driven drums ( rollers)for rigidity.

- Slitting cum trimming unit

Typically, the unit has eight sets of rotary for the bottom and top cutters alongside spacers for slitting the web, reaching seven rolls of trimming on the two-edged.

Center slitting and edge trimming is usually done with female and male cutters. The two blades are correctly fitted for a perfect web cut and alloy.

- Unwind

A typical unwind station for paper reel in measurements is up to 1000 mm dia and is placed on a mechanical shaft with supplies for balancing the draw unit for correctness.

In the end, one mechanical brake is offered a dancing roller for traction control.

Where exactly are thermal paper roll rewinder machines used, and are there any features or merits?

When it comes to putting 900mm coreless type thermal paper slitting rewinding machine into work, a thermal paper roll slitting rewinding machine produces the following;

Rolls of thermal paper, lottery, medical record paper, cash register paper, ATM receipt, POS, paper, fax paper, and computer bill.

The advantage of this kind of model is that it can work with both coreless paper roll and core.

The cost of cored roll typically reduces In the absence of a plastic core of paper rolls and paper core, and their features include;

- Auto tension control

- Accurate slitting, proper edge slitting, and a breakneck speed.

- The ability to rewind paper without a core.

- Unplanned adjustment in tightening of the paper rolls.

- Stocked with flattened rollers besides complete separation.

The main objective is to improve the quality of print. Thermal printers are known to create durable and more quality images than impact printers.

Thermal paper rolls also produce long-lasting and clear images that are more resistant to several factors like UV rays, soils, and climates.

Images resulting from thermal images are more readable since there is no ink for streaking.

What are the different varieties of paper-slitting machines?

In general, they include; core cutting machine, thermal paper cutting machine, label machine, threading machine, thermal paper packaging machine and several types of automatic packaging assembly and packaging equipment.

The Jota machinery saves on labor and ease operations plus does away with the requirement for the workforce and can thus automatically split and pack.

That, in turn, reduces the production cost of a small paper roll with a significant margin. Our slitting rewinding machines are flexible in operation, plus the requirements are convertible.

The machines have very high automation for elite processing efficiency.

The device also contains a compact and robust body hewn out of steel and is a slightly thicker substance when compared with other materials.

We guarantee that the service life will serve you for longer than you expect.

These machines are; a 900mm coreless type thermal paper slitting rewinding machine, a Cash register paper slitting machine, a Full automatic label production line, and a Semi-automatic slitting machine.

What are the step-by-step production process of the thermal paper roll coreless slitting rewinding?

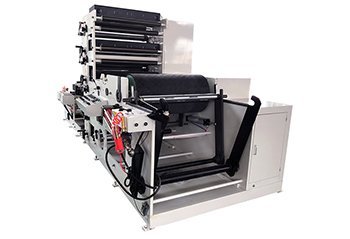

- Thermal paper inline printing slitting machine

Fast-moving paper roll rewinding and slitting process. Perfect for the production of ATM banks, lottery ticket rolls, receipt rolls, cash register rolls, POS rolls e.t.c

- Thermal paper packaging machine

Rapid automation production of thermal paper roll packaging. Effective for producing ATM rolls packaging, POS rolls, lottery ticket rolls, cash register rolls.

Depending on the needs of production, thermal paper packaging machines require proper matching function and device. Its constituents come from select countries like Germany and Japan for sustainable and efficient production stability.

- Thermal paper slitting rewinding machine

Fast-moving semi-automatic paper roll slitting and rewinding process. Fitting for production of the following; lottery ticket rolls, ATM bank receipts, cash register rolls, POS rolls, and others.

Auto paper cutting, slitting, rewinding semi-core loader, and auto gluing can quickly be finished in a single line.

- Full-automatic label slitter rewinder packaging line

Swift automatic production of coreless label rolls and label rolls, acceptable for coreless label rolls and label rolls, tail stick, slitting, packaging, arranging, can be completed in one line.

- Full-automatic slitter rewinder packaging line

Production of coreless thermal rolls is of great speed and is appropriate for arranging, printing, slitting, tail stick and packaging. All these processes can be accomplished in one line.

- Fallout label converting

The turret rewinder has a paper core loading system that operates in a non-stop rewinding with flexo printing, shrink park, rotary die, and grouping, all in an individual production line.

Numerous low-priced ATM paper roll machines are currently present in the market; why should we buy from you?

This is a very highbrow question, and as Jota, we answer that it is true that you will get many machines in many different places.

Nevertheless, it is equally challenging to find a long-lasting machine that will serve you for years. You need a device that effectively performs a professional design, and working stability.

Therefore, in all these, durability is an essential factor. Besides, there has been an enormous market transition in the past decade.

Meaning it is no longer possible to produce everything at a low price because, for instance, low price equals low quality, and there is no negotiation on that.

Alternatively, you can look at this scenario;

You can not compare the cost you will incur if a rewinder/slitter breaks every month, and in another case, it breaks once per year.

A monthly breakage means you pay for the repairs every month, while an annual wreck only implies that you will incur the cost once per year.

Do you get the point?

Regarding quality control, what does your company do?

Apart from paying attention to quality control from the start to the end, we also thoroughly check and test before any shipment.

Our commitment is to offer excellent product quality, prompt delivery, and competitive pricing.

We hold fast to a modern venture management model, assuring product processing accuracy while producing in bulk. Jota is always on the run with constant innovation, establishing a robust foundation for long-term engagements.

Can you describe your relationship with the public regarding your machines?

Jota machinery has a quality assurance system that is firmly established. We are founded on integrity, embracing hard-won honors and sincerity.

We appreciate our customers and other potential buyers from different parts of the world for continuous support and long-term engagement.

We sell our products worldwide because of our favors from both new and old customers regarding our after-sales services.

Our forever goal is to form the best cooperative relationship with our clients and provide them with satisfactory and qualified products.

We also adhere to customer-aligned principles and strive to meet their requirements.

From logistics and distribution to strict material selection, our complete service ensures that customers’ choice is safe, efficient, and convenient.

Why choose Jota Machinery other than industries in the same field?

Jota Machinery takes pride in innovative design concepts and rigorous manufacturing processes.

With many years of experience, we always focus on the unique production of thermal paper roll coreless slitting rewinding machines and packaging technology.

We are not dependent on innovation but instead implement patent strategies with a solid and professional team of software development programming.

We depend on genuine import core components, all-around spare parts precision processing, and independent research development of verified patent technology.

Jota Machinery also ensures the quality of strict rules of the ISO9001 international quality management system.

Do you conduct any inspections before delivery?

Jota Machinery follows the utmost seven steps to ensure that buyers get the best.

- We run a test to ensure that all data is right. Meaning every action command should be correct.

- We inspect the complexion and appearance of our machines, paint quality, welding procedure, among others. After reforming and rectifying, the inspection department is responsible for confirming the quality of the final product.

- Besides the rectification, we hold quality assurance engineers responsible for any defect detected before product delivery.

- The technical department put together the list for delivery in advance according to the time of delivery.

- Our storehouse experts must prove the content of the delivery list.

- Jota production department is in charge of loading details and goods packages. 7. Following a thorough general inspection, our quality assurance engineer will confirm before signing all the requirements of the product delivery protocol. After that, the technician will provide a shipping list requirement to ensure that you get the best of the best.

What size of thermal paper roll products do you produce?

To start with, thermal paper roll products have various uses, including cash registers, thermal printers, and credit card terminals inside the retail, gaming, catering, hospitality sectors, and the government.

When the paper goes via a thermal printer, print head heat causes the chemical coating to activate, forming a high image definition.

Contrasting to regular paper, the process employs heat when starting a chemical reaction inside the paper.

Meaning,

It will not need a toner or a ribbon; hence it becomes more manageable compared to other options.

As one of the top leading 900mm coreless type thermal paper slitting rewinding machine industries globally, our company offers a wide range of different sizes and qualities at highly affordable prices.

Our regular thermal paper roll width ranges as follows; 78mm, 4mm, 78mm, 57mm, and 80mm, but the list is long to navigate before choosing.

What is the future of the 900mm coreless type thermal paper slitting rewinding machine at Jota?

With emerging technology such as the invention of artificial intelligence, industrial robots, and machine learning, we at Jota are already adopting technological advancements with the aim of improving on services, but most importantly quality products to our clients. With the ability to manufacture a range of machines above 20, we comprise a convocation of units and a CNC focal point, with the best machine quality at your order.

We are a widely applied and brand standard 900mm coreless type thermal paper slitting rewinding machine for label die cutting machine, Automatic facial tissue making machine, Flexo printing machine, Fully automatic tissue paper roll making machine, Slitting Rewinding Machine, and many more.