JT-SLT-1400FA Fully Automatic Thermal Paper Roll Slitting Packaging Machine

- Fully automatic intelligent machine line for thermal cash rolls.

- More till roll output capacity in 8h

- No need dedicated operator, labor cost -95%

- Core feeder, slitter rewinder, conveyor, packager

- Optional inline printing and buffer

- Specification

- Video

- Finished Goods

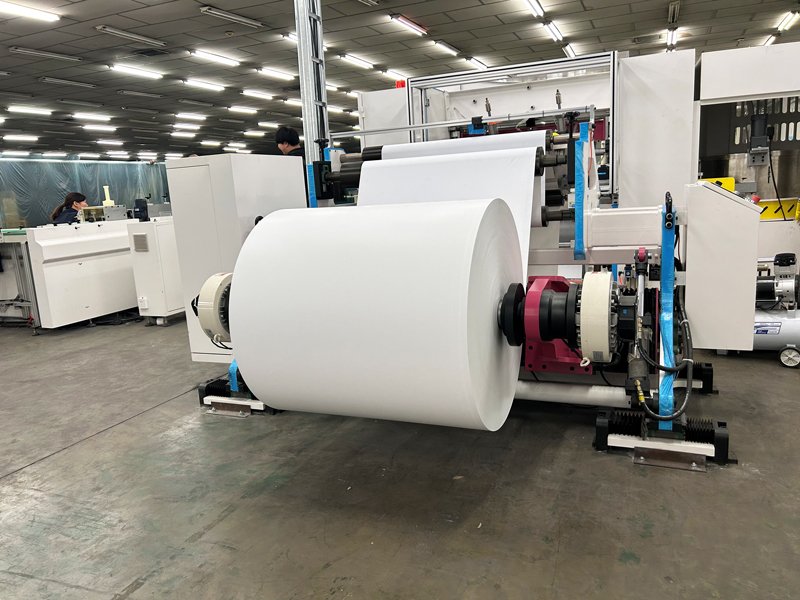

- In Asia Pulp & Paper

PARAMETERS

| Item | JT-SLT-1400FA Fully Automatic Thermal Paper Roll Slitting Packaging Machine |

| Unwinding Width | 1400mm |

| Unwinding Diameter | 1200mm |

| Max. Rewinding Diameter | 300mm |

| Min. Slit Width | 15mm |

| Max. Speed | 300m/min |

| Unwinding Shaft | 3” air expanding shaft |

| Rewinding Shaft | 0.5”, 1” are available (or as your request) |

| Voltage | 3 phase, 380V, 50Hz |

| Torque | 100Nm |

| Power | 20Kw |

| Weight | 4000Kg |

| Overall Dimensions (L*W*H) | 5500mm x 2200mm x 1880mm |

| SPECIFICATIONS |

| JT-SLT-1400FA Fully Automatic Thermal Paper Roll Slitting Packaging Machine is able to make thermal receipt paper roll, ATM roll, ECG roll, carbonless copy paper roll, POS till roll, adding machine roll, etc. |

| FEATURES |

| Siemens PLC and MCGS touch control screen, all the parameters can be set on the screen. |

| Master motor is Siemens Inverter Motor, controlled by Inovance AC drive. |

| Shaftless unwind stand, hydraulic driven automatic jumbo roll loading. |

| Ultrasonic web guide for printed paper. |

| Automatic vacuum core sucker. (Patented) |

| Upper and lower circular knives shear cutting. |

| Automatic tucker quickly triggers rewinding. |

| 2 sets loadcell sensor and fully automatic tension controller for constant tension control. |

| Rotary encoder measures slit length automatically. |

| 90° vertical lay-on roller and banana roller ensures no overlapping problem. |

| Automatic finishing line: breaker, hammer, and conveyor. |

| Automatic Hot Shrink Packager (Another packing method available) |

Fully Automatic Thermal ATM Paper Roll Slitting Packaging Machine

Last Update Time:22/12/2023

In 2019, many potential customers asked us whether we can supply a fully automatic thermal ATM paper roll slitting packaging machine.

Because so many potential customers have such hidden demand, we Jota decided to develop a fully automatic thermal ATM paper roll slitting packaging machine in 2020.

Due to the COVID-19 epidemic, Jota could only officially start work in March 2020.

Jota fully automatic thermal paper slitter rewinder research and development just started in early April 2020.

After 6 months of hard work, we Jota finally released our own type of fully automatic thermal ATM paper roll slitting packaging machine.

With JT-SLT-1400FA, from core feeding to till roll packing, one-stop thermal paper roll production can be realized.

JT-SLT-1400FA paper slitting machine can produce 23,0000-35,000 pcs 57mm x 50mm till roll in 8h, no need dedicated operator.

Some of the freshmen don’t know how to do or how to solve the issue when operating our slitting machine then we made a page for frequent troubleshooting and solution. Kindly check this page

For better assist you in better understanding this newly released fully automatic thermal ATM paper roll slitting packaging machine

Let us introduce it part by part according to its running process, please watch the following demo video first for reference.

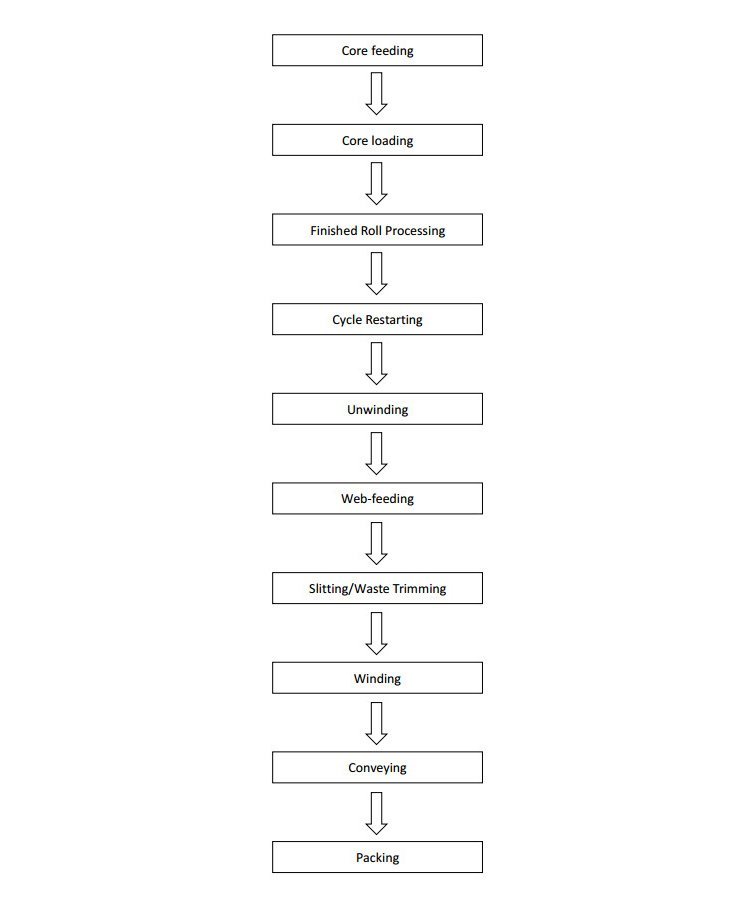

The thermal paper slitting machine’s running process mainly includes:

- Plastic core feeding

- Plastic core loading

- Finished roll processing

- Cycle restarting

- Jumbo roll unwinding

- Web-feeding

- Slitting/waste trimming

- Finished roll winding

- Finished roll conveying

- Finished roll packing

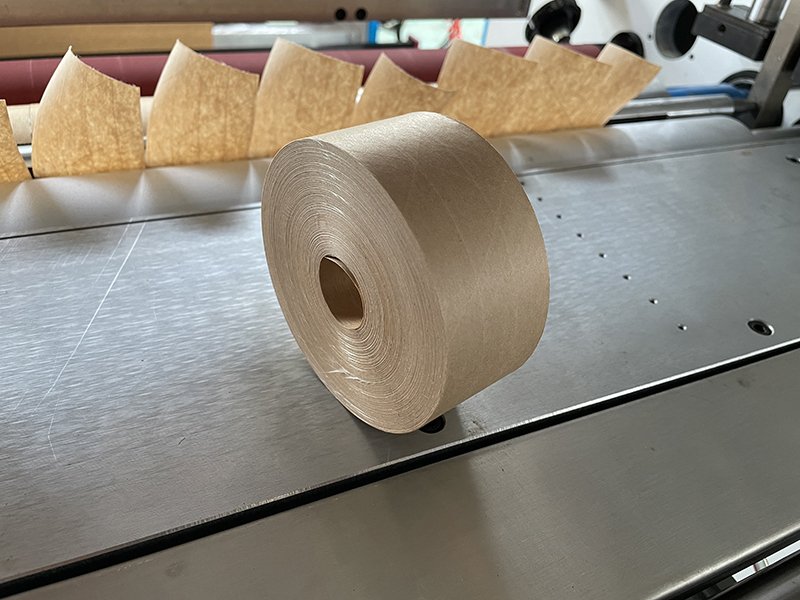

Core feeding is completed by an automatic core feeder.

As long as the plastic core is placed in the bowl in advance, the core feeder will automatically push the plastic core to the core staging conveyor.

Automatic core hooper running video

After the plastic core is pushed to the core staging conveyor, the vacuum core sucker will suck up the core and move it forward to the rewinding station.

When the core sucker moves forward, the front crossbar pushes the last cycle till rolls to the finished roll processing station, and these sucked cores are also placed on the rewinding station at the same time.

After placing the cores, the vacuum core sucker moves backward to the initial position, and a rider roller presses down on the finished till roll.

Then the automatic tail cutting gluing unit cuts off the finished rolls’ tails and applies glue, the rider roller starts rotating, the glue follows the rider roller’s rotation and evenly adheres to the thermal paper’s inner layer, and the till rolls are sealed.

After the till rolls are sealed, the paper slitting machine automatically starts the next rewinding.

A full cycle winding mainly includes the steps of:

- Unwinding

- Web-feeding

- Slitting

- Winding

- Waste discharging

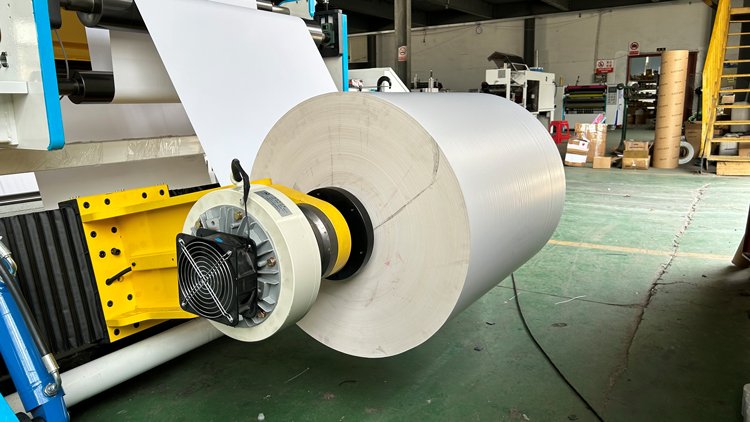

JT-SLT-1400FA introduces a shaftless unwind stand, with it, no need to put the unwinding shaft into the jumbo roll, a little time could be saved;

Shaftless Unwind Stand

With hydraulic driven automatic jumbo roll loading system, max. weight capacity of 3 tons, which can be controlled by remote control, it greatly saves the operator’s physical strength;

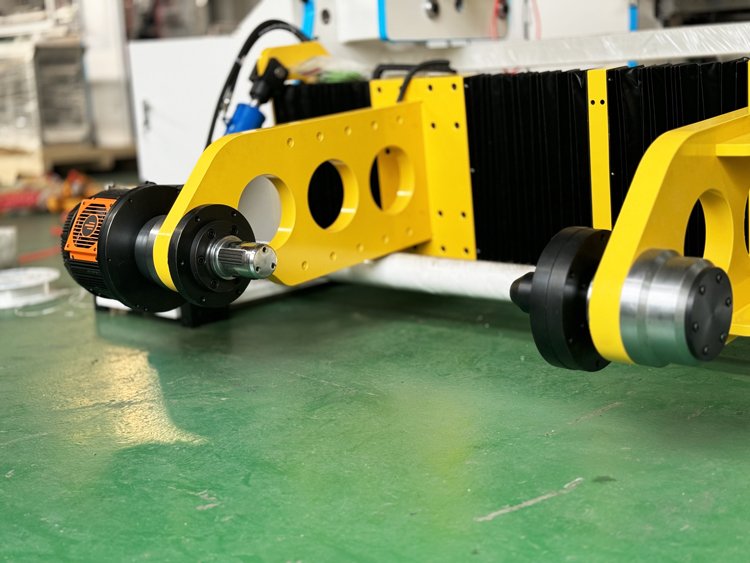

What’s more, the unwinding shaft equips with a magnetic powder brake for tension control, magnetic powder brake is very important for keeping constant tension in the whole process.

After all, constant tension is the most influential factor for the slitter rewinder machine.

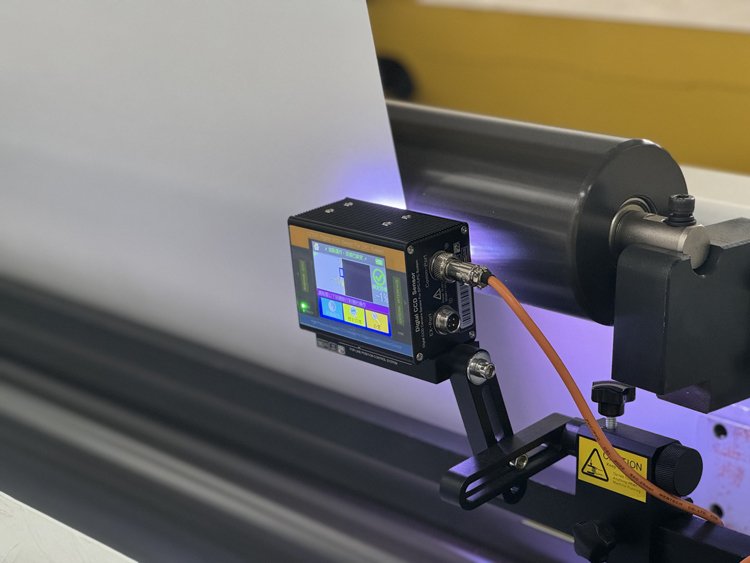

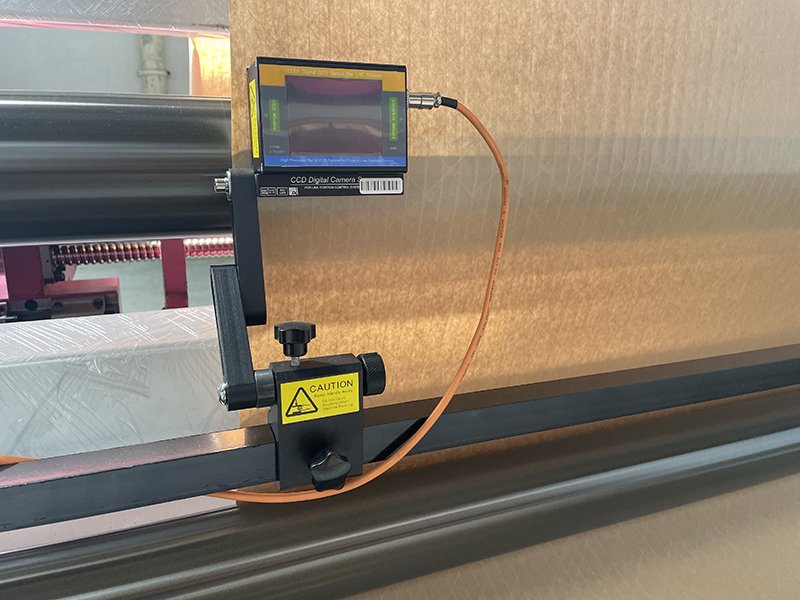

The web-feeding part equips with an ultrasonic web guiding system, this web guiding system can monitor the deviation of the web’s forwarding automatically.

Edge Position Controller

With this system, the web accurately enters the slitting section, ultimately ensuring the slit width accuracy and avoiding material waste.

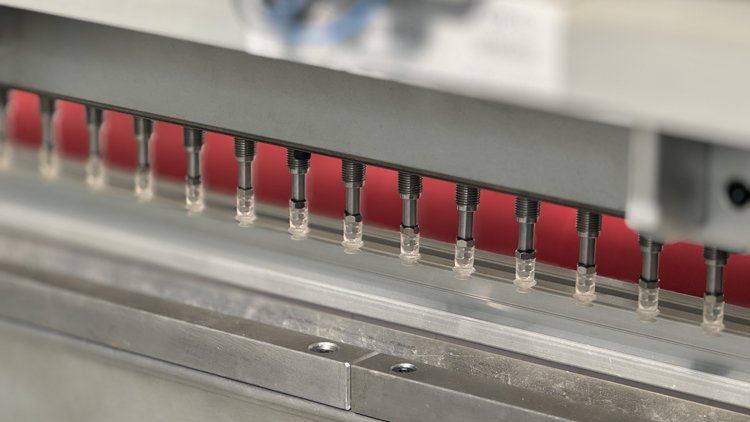

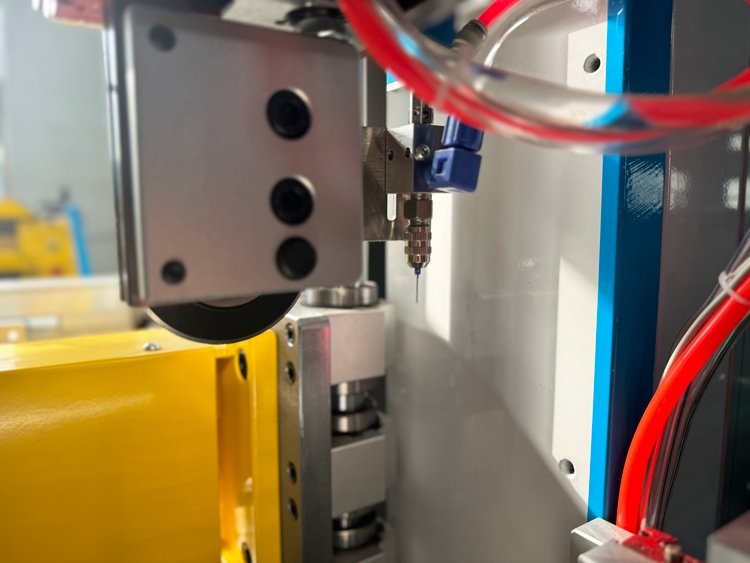

In the slitting part, the upper and lower round knives shear cutting is applied, shear cutting can guarantee the slitting accuracy to the greatest possible extent, avoid problems such as burrs, and will not affect the finished till rolls’ appearance.

In order to reduce your operation time and improve your efficiency, Jota Machinery also could supply a fully automatic knife positioning system for your slitter rewinder.

All the slitting width could be automatic setup on the touch screen.

Automatic Knife Positioning System

In the winding part, Jota assembler installs automatic tucker for this 1400mm thermal paper slitter machine, automatic tucker can quickly tuck the tail, then triggers the winding;

The vertical 90-degree lay-on roller and the web spreader roller/banana roller’s combination can effectively avoid the overlapping problem;

With the addition of a precision pressure regulator, it is easy to adjust the winding tightness freely.

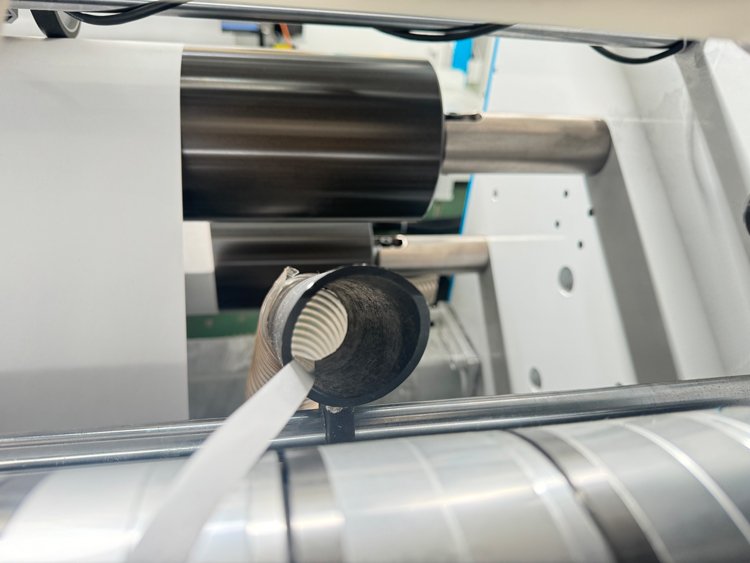

In the waste trimming part, the JT-SLT-1400FA paper slitting machine has a special waste outlet.

Connect the hose to the waste outlet, all the waste edges pass through the hose with the siphon fan’s huge vacuum suction.

Waste Outlet

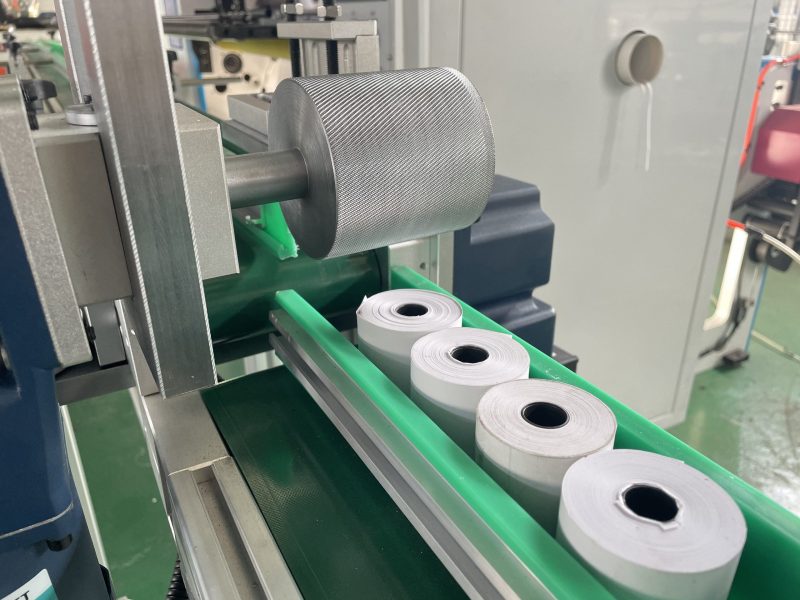

Finished roll processing’s last step is ejecting the finished rolls onto the conveyor belt, when the finished rolls are ejected onto the conveyor belt, the finished roll conveying begins.

After the finished till rolls are broken apart by cylindrical roller and flattened by the small press, the finished till rolls’ edges become neater, then they are about to enter the downstream packing.

Regarding the packing process, the 1st step is pushing the two rows of finished rolls between the upper and lower heat-shrinkable films.

The sealing knife will cut the heat-shrinkable film to a certain size, wrap the two rows of finished rolls before entering the heat shrink tunnel.

Two rows of finished rolls are sealed in the heat shrink tunnel after heating and shrinking.

In this way, small till rolls packed with the heat-shrinkable film is produced.

Some clients also inquired about thermal paper roll slitting machines with inline printing functions, our Jota engineers took this requirement into consideration when designing this slitter.

Our Jota engineers have innovatively designed a buffer/accumulator for the printing station, ensuring that the printing station can be integrated into the whole thermal paper production line.

After all, printing is continuous, while the slitting and rewinding process is discontinuous, and jumbo roll running will stop for a while at intervals.

Due to this reason, the buffer/accumulator is quite essential for filling those time intervals.

Buffer/Accumulator

For more details about this inline printing function integration, please send us an inquiry on this website, offer your Email address, we can get in touch with you soon.

Of course, we Jota manufacture other kinds of thermal paper slitting machines, i.e

- 2 layers thermal paper slitting machine

- Economical model thermal roll slitting machine

- High-end thermal cash register paper roll slitting machine

You can choose different models according to your budget and requirements

About the ending of the Fed, we take a video to show the difference between fully automatic thermal paper slitting machines and semi-automatic types.

This video is uploaded to our YouTube channel.

Thermal Paper Slitting Machine FAQ Guide

- What is a thermal paper slitting machine?

- How do I operate a thermal paper slitting machine?

- Why should I have a slitting machine in my paper mill business?

- What are the parameters of a fully automatic thermal ATM paper roll slitting packaging machine.?

- Who are the leading slitting machine manufacturers?

- What should I consider when determining the slitting machine price?

- What are the specifications and features of the slitter?

- What after-sale services do you offer for slitting machines?

- What should I consider when choosing the winding methods and slitting methods for my automatic thermal paper slitter rewinder?

- What are some of the considerations I should put in mind when carrying out slitter machine maintenance?

What is a thermal paper slitting machine?

A thermal paper slitting machine is a machine that is used in making fine paper rolls.

The fine paper is impregnated with a chemical that changes color when exposed to heat.

Slitting machines are ideal and specifically used in making thermal-sensitive paper.

Thermal sensitive paper is used in machines such as:

- Bus ticketing

- Point of sale (POS) billing rolls

- Air tick ticketing

- Parking ticketing

- Automated Teller Machines (ATMs)

- Fax Machines

- Medical reports

- Pay-in slips.

- Credit card charge slips.

The list of products that you can use your slitter rewinder for is endless.

All our slitting machines are designed to meet your standards and specification.

This depends on what you are planning to use the machine for.

We have designed a heavy-duty thermal paper slitter rewinder machine, especially for thermal sensitive paper.

We do this while ensuring high-quality equipment for longer durability. This is due to its accurate slitting and rewinding qualities.

It ensures the perfect slitting of rolls with consistent, flawless results and constant line speed.

It is available in an adaptable model to suit your requirement. Our machine is available in rewinder.

At Jota Machinery, we are renowned for our accurate machines.

Fully automated thermal paper slitting machine work at a higher speed by AC Frequency Inverter Motor.

This minimizes the time required for production and lead time. Jota Machinery ensures perfect slitting of rolls with consistent flawless quality and constant line speed.

We manufacture machines depending on your preferences. You can reach us for customized designs of your machines.

Contact us for more information on our machines.

You can also visit our factory or liaise with our agents for product prototypes.

If you need training for the operation of the slitting machine, you can also reach us.

How do I operate a thermal paper slitting machine?

At Jota Machinery, we ensure that we give you comprehensive guidance on how to operate our fully automatic thermal ATM paper roll slitting packaging machine..

We have the option of dispatching our technicians to your location.

You can also send your technicians to our factories in China.

This is ideal in making them understand the operation of the thermal paper slitting machine.

The fully automatic type is a new design from Jota Machinery.

From core feeding to till roll packing, one-stop thermal paper production can be realized.

The running process of a JT-SLT-1400FA include:

- Plastic core feeding

- Plastic core loading

- Finished roll processing.

- Cycle restarting

- Jumbo roll unwinding

- Web-feeding

- Slitting or waste trimming

- Finished roll winding.

- Finished roll conveying.

- Finished roll packing.

Plastic Core Feeding

1400mm slitting machine comes equipped with an automatic core feeder.

The core feeder is used to push the plastic core or paper core to the core staging conveyor.

The plastic core is usually placed in the bowl in advance.

It is important that you use the correct plastic core that aligns with your slitter machine.

This ensures that it aligns correctly with the core feeder.

Ensure also that the core staging conveyor is not clogged up.

This is to achieve a smooth push of the plastic core by the core feeder.

The vacuum core sucker will suck up the core and move it forward to the rewinding station.

This is after the core is pushed to the core staging conveyor.

All these processes are fully automated. It will save your paper mill timer and labor required to do these tasks.

We also support customized.

The customization of the plastic core feeding includes an increase in the size of the bowl.

A bigger bowl means a bigger core that increases the capacity of your slitting machine.

Plastic Core Loading

The plastic core loading process happens after the core has been sucked up by the vacuum core sucker.

It is then moved forward to the rewinding station.

The plastic core loading process involves a couple of mechanisms that involve several steps.

These steps include:

- The core sucker moves forward.

- The front crossbar pushes the last cycles till roll to the finished roll processing station.

- The sucked cores are also placed on the rewinding station at the same time.

- After placing the cores, the vacuum core sucker moves backward to the initial position.

- A rider roller presses down on the finished till roll.

After the roller has been pressed down on the finished roll, it goes to the finished roll processing.

Here, the automatic tail cutting gluing units cuts off the finished roll’s tail.

The automatic tail cutting gluing unit also applies glue to the cut rolls.

After the application of glue, the rider roller starts rotating. The glue is applied evenly as it follows the rider roller’s rotation. It evenly adheres to the thermal paper’s inner layer, and the till rolls are sealed.

Cycle Restarting

After the till rolls are sealed, the thermal paper slitting machine starts the next winding.

Ensure that the seals are well closed and in place.

This will ensure that the machine works perfectly. If the rolls are not sealed correctly, the next winding cannot start automatically.

Jumbo Roll Unwinding

Our fully automatic thermal paper slitting machine has a shaftless unwind stand.

This is an upgrade compared to the previous designs.

This feature is particularly important.

You will not need to put the unwinding shaft into the jumbo roll.

Automatic unwinding will save you money that you would have used on labor.

It helps save you operating costs and time.

The fully automatic thermal paper slitting machine unwinding shaft is equipped with a magnetic powder brake.

The unwinding section of a paper slitting machine is where the jumbo paper roll is winded. The reason for the unwinding is to ready the paper roll for slitting.

The magnetic powder break is used for tension control. The magnetic powder brake is very important for keeping constant tension in the whole process.

Constant tension is the most influential factor for the thermal paper slitter rewinder machine.

The tension control is the most important part of Jota’s thermal paper slitting machine.

With the existence of the automatic tension control, the whole running process tension is constant, the winding effect can be guaranteed.

Our slitting machines use the latest technology in tension control.

The tension control is monitored electronically. Our paper roll cutting machines come equipped with a digital touch screen.

You can use it in controlling the tension. It also can be used in giving out diagnoses of the cutting.

Web-Feeding

The web-feeding part equips with an ultrasonic web guiding system, this web guiding system can monitor the deviation of the web’s forwarding automatically.

The web feeding section is where the jumbo paper roll enters the slitting section.

It consists of rollers that hold the web of paper and direct it to the slitter head.

The web is held at a constant angle and tension.

This is to ensure that the web does not break or deform.

We ensure that the web feeding for our automatic thermal paper slitting machines is one hundred percent automated.

They are fitted with an ultrasonic edge sensor and edge position controller.

Ultrasonic edge sensor helps guide the web into the slitting chamber.

It also ensures that the jumbo paper roll gets clean cuts and is aligned with the round disc cutters.

The edge position controller is used to guide the jumbo roll into the slitter head.

It also ensures that the thermal paper roll does not deviate from its position.

With this system, the web accurately enters the slitting section. It also ultimately ensures the slit width accuracy and avoids material waste.

Slitting Or Waste Trimming

The slitter stage or section of the thermal paper slitting machine is very important.

It largely determines the size, shape, and quality of the paper rolls.

Here, the actual separation of the web into multiple smaller slits occurs. This is achieved by setting the blades to the required specifications.

The slitter head is the main component in the slitting section.

This holds the round disc cutters into place. The round disc cutters can be either rotating discs or static.

The type of the pneumatic cutters depends on your specifications.

The series of round disk cutters cut the web of paper into desirable sizes.

The cutting method that our thermal roll slitting machine applies is shear cutting.

Here, bottom-placed round disc cutters work with an upper round disc cutter.

They work in tandem and produce a scissor-like cut. It produces very clean cuts of very high quality.

Shear cutting can guarantee to slit accuracy to the greatest possible extent. It is also important in avoiding problems such as burrs and will not affect the finished till rolls’ appearance.

Finished Roll Winding.

At this section, the silted paper roll is rewound into smaller cores on the rewinder stand.

This is done to the recommended or desired length. The thermal paper slitting machine has different configurations that depend on the desired hardness of the final role.

This can be adjusted as you produce different types of paper.

Finished Roll Conveying.

Our new thermal paper roll cutting machine has been installed with an automatic tucker.

The winding tucker is in the winding part.

It is also fitted with a vertical 90-degree lay-on roller and the web spreader roller/banana roller’s combination.

This helps the fully automatic thermal paper slitting machine effectively avoid overlapping problems.

With the addition of a precision pressure regulator, it is easy to adjust the winding tightness freely.

This ensures that the slit paper rolls winds up tightly.

Here the finished roll is ejected onto the conveyor belt. When the finished rolls are ejected onto the conveyor belt, the finished roll conveying begins.

We have installed a cylindrical roller onto our paper slitting machine.

The cylindrical roller is used to break the finished till rolls apart.

The finished till rolls are also flattened by a small press to get a neat edge.

After this step, the till rolls are then pushed to the downstream packing which is at the end of the fully automatic thermal paper slitting machine.

The slitter that we produce is equipped with rollers that keep the slit sections separately.

The rollers are mostly just after the slitter head. This is important, especially in avoiding the slitted sections form interweaving.

The interweaving will affect the quality.

Waste Outlet

We have equipped our slitting machine with a special waste outlet.

For the waste outlet to work perfectly, you need to connect the hose to the waste outlet.

All the waste edges pass through the hose with the siphon fan’s huge vacuum suction.

Finished Roll Packing

The last step in the running process is the finished roll packing. The first step is pushing the two rows of finished rolls between the upper and lower heat-shrinkable films.

The heat-shrinkable film is cut into size using the sealing knife.

It wraps the two rows of finished rolls before entering the heat shrink tunnel.

Two rows of finished rolls are sealed in the heat shrink tunnel after heating and shrinking.

The end results of this process are small cash register rolls packed with the heat-shrinkable film.

This ensures that the product can be sold in the retail market without having to unpack the till rolls.

At the time being, our slitting machines do not have printing capabilities. For inquiries and clarification on this, kindly call us.

We have flexible and open-minded designers and engineers whom you can talk in for your design specifications.

You can configure the thermal paper slitting machine to include a printer at the end of the machine.

For more details about this inline printing function integration, please send us an inquiry on our website.

You can offer your Email address; we can get in touch with you.

Why should I have a slitting machine in my paper mill business?

A cash register paper roll slitting machine is an important machine in any paper mill business.

At Jota Machinery, we always ensure that our products and machinery enhance efficiency.

Our machine is manufactured using the latest technology.

There are several reasons that warrant you to have a slitting machine in your business. Some of these reasons include:

Our thermal paper slitting machines are efficient.

We guarantee you efficiency in using our thermal paper slitting machines.

Unlike manual paper-slitting machines, automatic ones are fast.

From core feeding to till roll packing, one-stop thermal paper production can be realized.

The fully automatic thermal paper slitting machine will enhance your product lead times.

You will also be able to take multiple orders from your customers. This is because our machines can handle more output in less time.

You also need a single setup for our thermal paper slitting machine. this is because it works as a conveyor.

All the systems are automated thus enhancing efficiency and less engagements with the thermal paper slitter machine.

Equipped with the latest thermal paper slitting machine technology.

Jota’s fully automatic thermal paper slitting machine is equipped with the latest technology in the market.

We have ensured that the thermal paper slitting machine serves you per your specifications.

We have incorporated additions such as ultrasonic edge sensor and edge position controller.

This ensures that you get a smooth and precise cut on your thermal jumbo paper roll.

The thermal paper slitting machine is also equipped with a wastage outlet.

The wastage outlet ensures that all the debris from slitting is removed from the thermal paper slitting machine.

This protects it from clogging.

All the parts of our new fully automatic thermal paper slitting machine are aligned to work in tandem.

The machines work as a conveyor. This ensures that the product is standardized.

Our thermal paper slitting machines are cost-effective.

At Jota Machinery, we regard your budget. We ensure that our thermal paper slitting machines are affordable.

This subsequently will guarantee you profitable margins for your paper mill business.

The affordability of our thermal paper slitting machines also ensures that you save operating costs.

The fully automatic thermal paper slitting machine is fully automated. This means that you will save cost associated with manual operations.

You will need fewer personnel to operate the fully automatic thermal paper slitting machine.

The machine will also save you the time required to produce large quantities of thermal paper rolls. Increased lead times mean more customers at your doorstep.

Fully automatic thermal paper slitting machine with a centralized master control

All the components of our machine are integrated with the master control.

This gives you freedom on adjusting the speed, torque, and tension of the slitting machine.

Other advantages of having a master control include:

- Easy roll profile optimization

- Automatic start and stop configurations.

- Product receipt capabilities lead to efficiency in setting up orders and product consistency.

- Graphical and numeric set points

- Easy diagnostic modules.

- Merging of the drive hardware with the control equipment

- Flexible and easy to use system providing increased performance.

Flexibility in all your thermal paper needs

We ensure that our thermal paper slitting machine serves your specified needs.

Our automatic paper slitter can be configured to produce different types of thermal paper rolls.

Our machine supports different types of papers.

Some of the thermal paper rolls based on their constructions include:

- Conventional Thermal Paper: This has three layers, namely, the substrate, base coating, and active coating.

- Top-coated Thermal Paper Roll: It has the top coating in addition to three coatings of the conventional thermal paper.

- Synthetic-Base Thermal: It has an anti-static coat including the 4 coatings of top-coated thermal paper.

Each of these types of paper rolls has different features and durability.

They also differ in their resistance capability to the environment.

The synthetic-base thermal has the longest life span and best environmental resistance.

Some of the considerations that you should put in mind when selecting the right thermal paper to use include:

- Heat: thermal media is heat sensitive. This means that heat, light, and other types of environmental and storage conditions may affect the paper’s performance.

- Thickness: The thicker the material, the more durable and higher quality the paper is; however, it also means there is less paper on each roll. Make sure to consider this when making a purchase.

- Moisture: When exposed to moisture, there is some thermal paper that may not perform as expected, or there may be issues reading it.

You can reach to us for all your thermal paper slitting machine needs.

We will configure it to suit all your needs and specifications.

What are the parameters of a fully automatic thermal ATM paper roll slitting packaging machine?

Jota comes equipped with the latest technology.

Each machine is also of the highest quality.

We ensure continuous quality checks throughout our machine production processes.

These parameters include:

- Unwinding width of 1400mm

- An unwinding diameter of 1200mm

- The machine also comes with a maximum rewinding diameter of 300mm.

- A minimum slit width of 15mm. this ensures that you can produce thermal paper rolls for ATMs, POS systems, etc.

- For fast production, the slitter comes with a maximum speed of 300m/s.

- The unwinding shaft is equipped with a 3” air expanding shaft.

- At the same time, the rewinding shaft is equipped with a 0.5” or 1” shaft. The size of the rewinding shaft depends on your specifications.

- Our fully automatic thermal paper slitting machine comes with a voltage of 3 phase, 380V, and 50Hz, respectively. You can request configurations of the voltage to suit your country’s voltage regulations.

- The machine comes with a torque of 100Nm.

- Our machines are energy efficient. They come with a low power requirement of 20Kw.

- Slitter weigh 4000Kg.

- The overall dimension of the machine is 5500mm x 2200mm x 1880mm.

You can contact us if you need customized parameters for your thermal paper slitting machines. You can share with us your designs and the specific usage of your machines.

Who are the leading slitting machine manufacturers?

Jota Machinery is your go-to place for all things.

We are the number one JT-SLT-1400FA fully automatic thermal paper roll slitting packaging machine manufacturer.

Our client portfolio is global with positive reviews from our customers.

We strive to ensure that our slitting machines are standardized.

We adhere to global thermal paper slitting machine standards. Some of these standards include:

- American National Standards Institute (ANSI)

- China’s Compulsory Certification (CCC)

- National Fire Prevention Association (NFPA)

- Underwriters Laboratories, Inc. (UL)

- GB/T 13328-2005

- Instrument Society of America (ISA)

- Robotics Industry of America (RIA)

- ISO 17916:2016 standards.

- CE Approvals for Slitting Machine

- ROHS certificate for Europe Union market

What should I consider when determining the slitting machine price?

There are several things you should put into consideration when choosing a fully automatic thermal paper slitting machine.

The factors will determine its price. Some of these considerations include:

Application material to be used with the slitting machine.

Different paper slitting machines are used for different applications.

If you need a fully integrated thermal paper slitting machine, you will have to pay more.

Thermal paper slitting machines also have different capacities.

High-capacity slitting machines cost more than low-capacity ones.

High capacity means the ability to produce a high number of small size paper rolls.

How the machine is integrated also determines its price.

The type of thermal paper used with your automatic thermal paper slitting machine will also determine its price. Some of these application materials include:

- Slitting thermal paper

- Bond paper

- Cash register paper

- Fax paper

- Point of sale (POS) paper.

- Automatic Teller Machine (ATM) paper

- Other small ribbon rolls.

The specific use of the JT-SLT-1400FA fully automatic thermal paper roll slitting packaging machine can be customized.

Customization options may also lead to a slight increase in the overall price of your machine.

It is recommendable to liaise with our sales agents. They will be able to guide you in the best options that will suit your finances and business.

The configurations of the fully automatic thermal paper slitting machine.

The configurations of the paper slitting machine also will determine its price. The configurations include the working mechanisms of the paper slitting machine.

Customized configurations for your machine will likely lead to slightly higher prices.

We advise you to go through our product catalog before making your order.

This will help you in making the right decision when it comes to the thermal paper slitting machine configurations.

Some of the configurations that you can put in mind may include the mode of control of the thermal paper slitting machine.

You can also consider some configurations such as hydraulic driven automatic jumbo roll loading.

The parameters of the fully automatic thermal paper slitting machine.

The parameters of the JT-SLT-1400FA fully automatic thermal paper roll slitting packaging machine are an essential determinant of the overall price.

Parameters such as unwinding width and unwinding diameter will determine the overall price.

The lesser the parameters the lesser the overall price of your thermal paper slitting machine.

Some components such as the rewinding shaft and or the unwinding shaft can be customized.

This can be achieved through the increasing of the rewinding shaft.

An adjustment of the components will lead to slightly higher prices for your thermal paper slitter rewinder.

For more information on the parameters of JT-SLT-1400FA, contact us.

The quantity of thermal paper slitting machines bought.

At Jota Machinery, we can handle any number of slitting machines you need.

Be assured of a discount on orders that exceed two units.

At Jota Machinery, we are business-centric. If you are a startup, feel free to visit us.

There exist several other costs that you should be aware of that may influence the price of your machine. These costs may include:

- The taxes will be charged on your machine.

- The warehouse charges.

- Insurance charges for your on-transit cargo.

- Customs and duties.

- Payment transactions costs.

- Other unforeseen charges.

But you should worry not. At Jota Machinery we ensure you have a smooth sail.

We will assist you through your order and delivery process.

We will guide you from the order placement process to the delivery to your factory.

Feel free to call our customer care center for any inquiries regarding your order processing.

If you are not sure of certain payments contact us. you can also seek the help of professional freight forwarders or shipping agents.

Be assured that we always have your best interest at heart as a business. Feel free to engage us on any cost implications of your orders and purchases.

What are the specifications and features of the slitter?

Our slitting machines are available in different specifications.

We ensure that each of our thermal paper slitting machines meets your unique specifications. Some of these specifications include:

- Thermal receipt paper roll making thermal paper slitter.

- ATM roll-making thermal paper roll machines.

- ECG roll paper slitting machine.

- Carbonless copy paper rolls slitting machines.

- 2 Layers thermal cash register POS paper till roll making machine.

- Machine roll, among others.

Jota’s JT-SLT-1400FA fully automatic thermal paper roll slitting packaging machine also comes with specific features.

These features are specific to the slitting machine.

To fully utilize your machine, you should be conversant with its features.

The main features of include;

- A control panel powered by Siemens PLC and MCGS touch control screen. It allows centralized control of parameters.

- The master motor is also powered by Siemens Inventor Motor. The Siemens Inventor Motor is controlled by an Inovance AC drive. All these are the latest additions to your slitting machine.

- A shaftless unwind stand makes your machine truly automatic. You will need no personnel to drive or lift the jumbo roll to the slitter head area. This will save you time and costs associated with labor and back injuries.

- Be assured of an Ultrasonic web guide for jumbo roll paper. This ensures minimally wasted when it comes to slitting the web. It guides the web into the slitter head.

- Our automatic slitting machine has an automatic vacuum core sucker. The vacuum core sucker is used to suck up the core and move it forward to the rewinding station. Note that this is a future patented to the fully automatic type.

- Our slitting machine is also equipped with two sets of round disc cutters. These round disc cutters are in the upper and lower parts of the slitter head. They are used in the shear cutting of the web of paper or the parent roll.

- Check out our automatic tucker that ensures quick trigger rewinding. This feature ensures a continuous paper roll production process.

- The thermal paper slitting machines come with 2 sets of loadcell sensors and a fully automatic tension controller for constant tension control.

- The rotary encoder measures the slit length automatically.

- Another feature of our machine is a 90° vertical lay-on roller and banana roller that ensures no overlapping problem.

- The end of the conveyor belt is also an equally important step. The JT-SLT-1400FA fully automatic thermal paper roll slitting packaging machine designers put this in mind. The automatic finishing line is equipped with a breaker, hammer, and conveyor. All this serves to ensure that your final product quality is not compromised.

- We can customize the packaging section to include an automatic hot shrink packager. This you can request for it to be installed. We can also accommodate your own designs.

Contact us for any additional features that you would like on your thermal paper slitting machine. you can visit our website or contact our customer support services.

What after-sale services do you offer for slitting machines?

Your experience with Jota Machinery is not only limited to the purchase of a thermal paper slitting machine or its spare parts.

We believe in the provision of several sale services to our customers.

When we consider service, we look at the various elements which you can use to benefit either before purchasing or after receipt.

Throughout the lifecycle of your thermal paper slitting machine, we have spotted areas where we can include added value.

The after-sales service of a slitting machine is offered by our skilled team of employees. Some of the after-sales services that we do offer for machines include:

Consulting

Consultation services are available at Jota Machinery to ensure growth in production.

This can be achieved either directly from the Jota Machinery team or through the provision of access to the vast knowledge and expertise of our suppliers.

This after-sales service can be conducted in several ways to enhance thermal paper slitting machine operation. Consultancy can be applied to:

- Assessing the suitability for customer requirements.

- Advising on the efficiency of production of paper slitting machine.

- Identification of the most appropriate solutions for customer needs.

- Recommending the required maintenance actions for the thermal paper slitter rewinder.

- Optimizing and improving the production quality of the thermal paper slitting machines and their productivity.

Through our contacts or directly from Jota Machinery, we can offer consultancy of thermal paper slitting machines.

This will assist our customers to identify gaps that may be present and ways of improvement.

Workforce Training

A workforce that is empowered becomes very productive.

Therefore, your employees need to be given a thermal paper slitting machine which they need to operate with confidence.

Jota Machinery is always happy to offer on-site training. this can be carried out either by our local team or with the help of our key suppliers.

We can tailor your slitting machine to suit the various skills and levels of your company.

Trials and Evaluation

As an industrial company, you will always need assurance that your thermal paper slitting machine is working well.

The technology needs to ensure efficiency thus increasing input.

However, it is quite challenging for everyday operators to ascertain that the thermal paper slitting machine is functioning effectively.

Therefore, you require an expert’s view.

Jota machinery can facilitate the testing of your thermal paper slitting machine. it can also conduct evaluations of your needs to ensure that you come up with the best thermal paper slitting machine.

This after-sales service can be conducted on your premises by bringing a machine for testing.

Maintenance

You will have access to a team of professional technicians that will offer mechanical, control, and electrical support upon request.

Some of the maintenance after-sales services that Jota Machinery support team can help with include:

- Give breakdown maintenance support

- Perform installation and commissioning

- Complete part identification and reduction activity.

- Provide onsite maintenance

- Refurbishing of your

- Carrying out scheduled on-site audits and maintenance of activities for thermal paper slitting machine. this will serve as part of preventive maintenance service.

Get in touch with us today and discover how your company can benefit from the Jota Machinery experience.

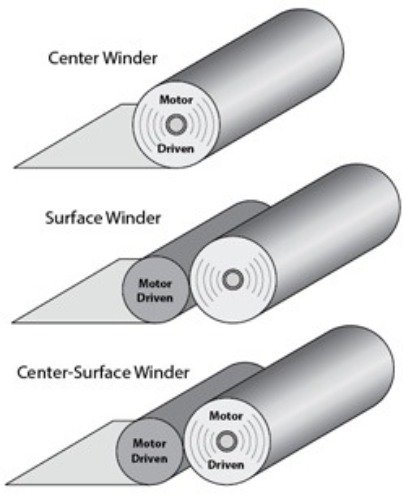

What should I consider when choosing the winding methods and slitting methods for my automatic thermal paper slitter rewinder?

The winding process is an important process when it comes to thermal paper slitting machines.

This is the process where the slitted jumbo paper roll is wound into smaller rolls.

It is an important step of any thermal paper slitting machine because it determines the product quality.

Different end products such as ATM rolls, POS rolls or Paper rolls will determine the type of rewinder you use.

There are other factors that you should also consider when selecting a good winding type. These factors include the core size, the type of material, and the weight of the finished roll.

A bigger core size will demand a bigger winding type.

This is usually ideal for bigger paper-slitting machines.

On the other hand, courser material will require a different configured thermal paper slitting machine.

The weight of the finished roll will also determine the winding methods that you will use.

This is because heavy finished rolls require heavy-duty winding methods.

Some of the commonly used winding methods include:

- Surface winding; it is a preferred method when producing large jumbo rolls. It is easy to set up and operate.

- Center winding: this is a type of winding that is controlled at the core. It is preferable when dealing with composite materials such as nonwovens, plastic films, and heavy sheets.

- Centre surface winding: the center surface works in hardening the roll in the desired profile. It is preferable when you need thermal paper rolls with large diameters.

What are some of the considerations I should put in mind when carrying out thermal paper slitter machine maintenance?

Different thermal paper slitting machines require different maintenance protocols.

This is because they are all configured differently.

Adhere to all safety protocols before the start of maintenance procedures on your thermal paper slitting machine.

Use our operators’ manual to guide you.

This will help you in not making grave mistakes when cleaning the machine. it also ensures that you avoid minor and major accidents.

The common maintenance procedure for include:

- First, you should switch off the machine. Put a safety lock on the power source. This will ensure that no one can switch on the machine when it is under maintenance.

- Inspect all the parts. Look for any loose or broken parts. For the moving parts such as the rollers and the round disc cutters, check the levels of lubrication.

- Check off all the issues following the maintenance manual.

- Clean the rollers and all the parts that can be dusted. Use the recommended cleaning agents and avoid bleach.

- Clean out all the bright surfaces. Coat the surface with rustproof oil for durability. If the machine has not been in use for sometimes, use anti-rust oil.

- Oil all the moving parts. Use recommended oil and check its quality. Using substandard oil will lead to wear and tear of the moving parts.

- Check the wiring of all the electrical parts. Check that no cables are loose or out of their terminals. Replace any worn-out cables and note down the diagnostics. One in a while, you can use a blower to remove dust particles on the wiring. Never use a wet cloth on the electrical wirings of the paper-slitting machine.

- Check the round disc cutters. Check out for wear and tear and replace them accordingly. Be sure to wear protective gloves to avoid cuts from the round disc cutters. Some round disc cutters need sharpening regularly. Ensure you sharpen them following our provided maintenance manual.

- Follow the maintenance schedule. Do not carry out unauthorized maintenance on your paper-slitting machine.

- Any component that needs adjustments or replacement should be flagged off early. If you are not sure of how to go about the replacement, kindly contact us.

- Record all the major maintenance undertakings such as parts replacements, electrical parts issues. This will enable subsequent slitter machine maintenance protocols. It is also helpful in understanding the root cause of an issue.

- The personnel and operator should undertake regular training. This is important in keeping up with machine technology.

If you are not sure of how to undertake certain maintenance issues, kindly contact us for directions.

It is highly recommended not to dismantle your JT-SLT-1400FA fully automatic thermal paper roll slitting packaging machine

Only professional technicians are allowed to undertake such maintenance procedures.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine