JT-SL-2000C Fully Automatic Paper Core Cutting Machine

- All the parameters are displayed on the touch screen

- 2 sets Yaskawa servo motor (Japan)

- Fully automatic core feeding and gripping

- Automatic rotation blades

- Specification

- Video

Main Parameters

| Parent Core Length | 2000mm |

| Parent Core Inner Diameter | 50-152mm |

| Paper Core Thickness | 4-15mm |

| Cutting Length | 10-2000mm |

| Cutting Speed | 60 cuts/min |

| Turret Movement Speed | 1.8 m/min |

| Working Pressure | 0.6Mpa |

| Voltage | 380V, 3 Phase, 50Hz |

| Power | 7Kw |

| Cutting Mode | Paper tube rotates, blades and mandrel keep static |

| Blades | Automatic Rotation |

| Mould | 2 sets |

| Parent Core Preloading | Manual |

| Dimension | Main Body: 3900mm*1000mm*2100mm Core Feeder: 3600mm*900mm*1200mm |

| Weight | 1800Kg |

| Extremely simple and intuitive operation. |

| Automatic core length measurement. |

| Programmable speed setting to suit core outside and insider diameter. |

| Programmable edge core trimming. |

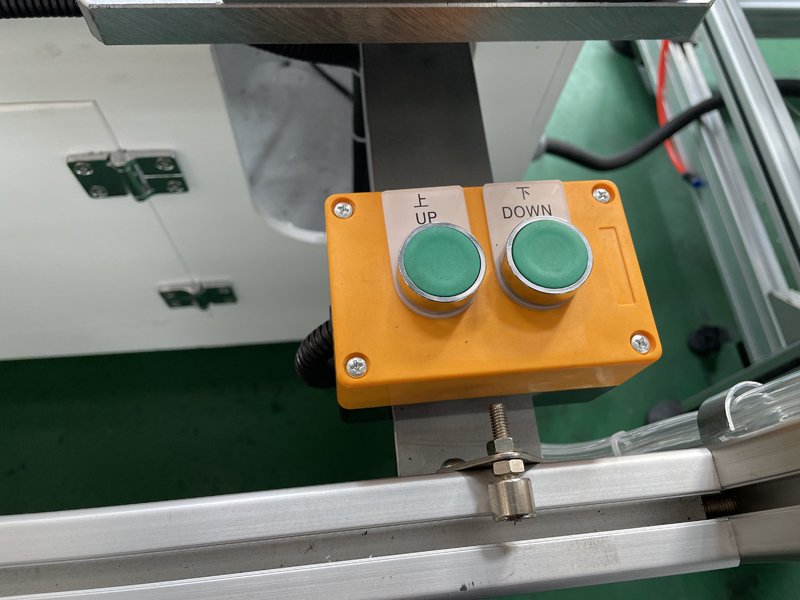

| The core support height is adjustable. |

| Automatic rotation blade to extend service life. |

| Automatic core feeding and gripping. |

| Clean edge cut (without burr). |

| Minimal dust generation. |

| 2 minutes of core size change. |

| High speed for large volume core production. |

| Minimize core wastage within the current program. |

| Single or multiple cut lengths within the same program. |

| High-resolution color touch screen. |

| Accurate cutting length with indexing accuracy of ±0.15mm. |

| Safety cover (optional). |

Why Jota JT-SL-2000C Fully Automatic Paper Core Cutting Machine

Last Update Time:16/11/2022

As of 2022, many customers have requested to customize our fully automatic paper core cutting machine. The longest among them is 3850mm.

The reason why these customers choose us is that we are a manufacturer and have our own processing workshop

Upgraded one VS old one

The left side is a newly upgraded type tube cutter and the right side is the old type version. The new paper core cutter is for a German client and the old version is for a Vietnam client

Besides appearance changes we also add some functions to this machine:

- Automatic measure paper tube length function

- Emergency stop induction function

- Safety net

- Measure air pressure

Above is only some special points I listed, for more information please contact our sales team.

Iconic Thailand customer Mondi Group also highly appreciates Jota JT-SL-2000C fully automatic paper tube cutting machine’s fantastic performance.

JT-SL-2000C could attract Mondi Group to place an order mainly because it has many flashpoints. It not only looks high-end from the outside but also has many attractive internal features.

This set fully automatic paper tube cutter has a compact structure, its body is made of 1045 steel, and its surface is baking paint treated.

There are many aspects of the performance, from feeding the parent core to collecting the kid core, that is deserving of praise.

The Jota JT-SL-2000C fully automatic paper core cutting machine is an automatic cardboard tube cutting machine with automatic core lifting switches in the core feeding section.

Automatic Core Lifting Switch

Upgraded Paper Tube Cutter

After the last paper tube is cut, the automatic core lifting switch lifts a new paper tube upward, and the new paper tube then rolls down to the feeding trough, waiting for the pneumatic pushing rod to push it into the mandrel and tube gripper.

You only need to manually preload the mother tube to the paper tube rack.

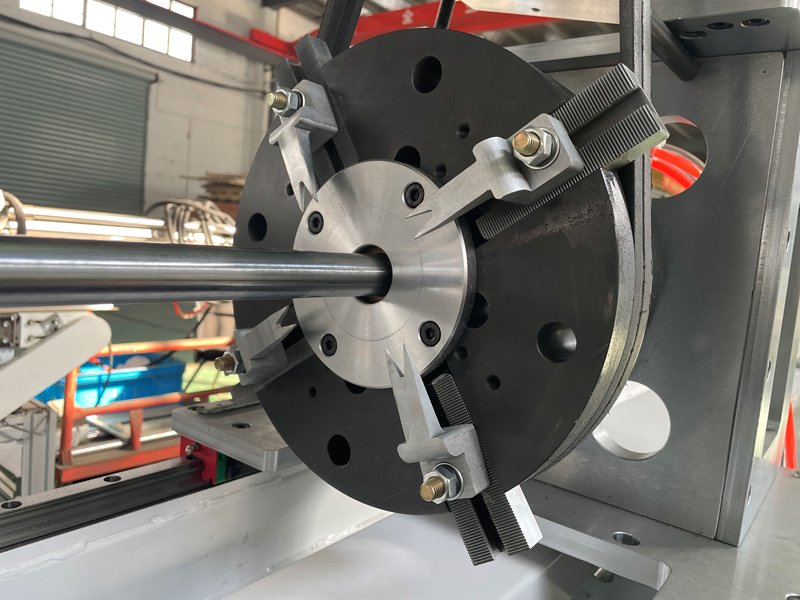

In terms of tube gripping, 4 pneumatically actuated mechanical grippers are applied, these grippers’ positions could be adjusted, and different diameter paper cores could be cut by our Jota JT-SL-2000C cardboard tube cutter.

4 Pneumatically Actuated Mechanical Grippers

In order to let you get a better understanding of the Jota JT-SL-2000C Automatic Paper Core Cutter, you could watch the following presentation video for reference first.

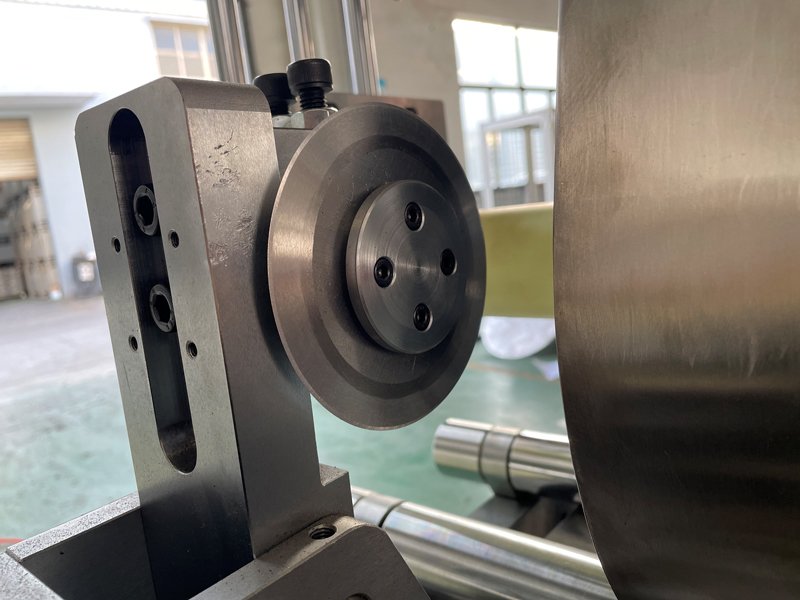

As you could see in the video after the mother core is gripped, it moves backward first, then moves forward. Such round trip is realized by the cooperation of lead screw and servo motor.

Lead Screw

Hiwin Linear Guideway

Of course, several other important components are also involved, such as cable carriers, linear guideway, and limit switches.

All these components ensure that each time’s paper tube round trip is accurate, avoids deviations of tube cutting length, and minimize the waste of your mother core material.

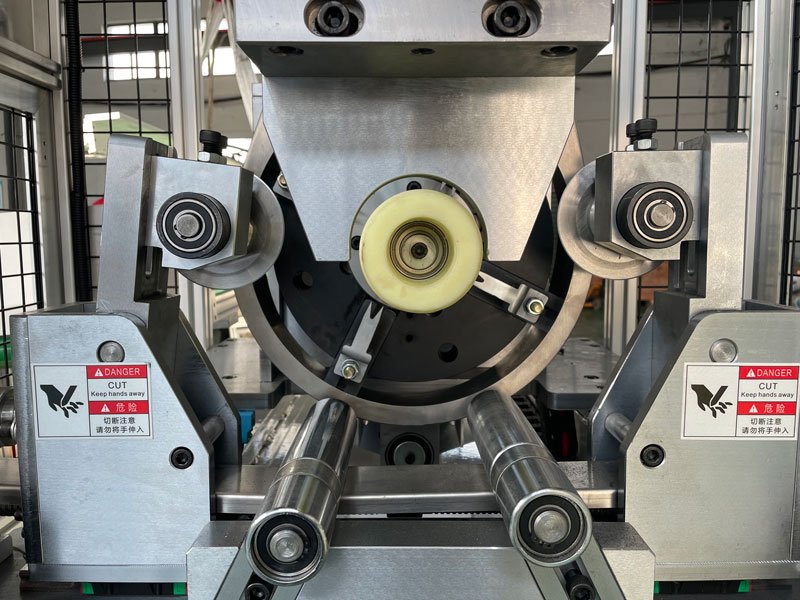

In terms of tube cutting, three main points must be emphasized to you.

Firstly, pneumatically control automatic rotation blades, effectively extends the blades’ service life;

Size:110*42.5*1.5

Secondly, core support height is adjustable to suit different ID cores;

Thirdly, as diameter mold is introduced to this section, it is not only useful for adapting to different diameter paper tubes but also helpful for extending blades and mandrel life.

White Color Diameter Mold

The waste pipes at the beginning and end of the core trimming and core collection process could be automatically unloaded, ensuring that only the appropriate paper tubes enter the core collecting trough and saving labor costs associated with manually sorting waste tubes.

In terms of control, the JT-SL-2000C cardboard tube cutter machine uses INOVANCE PLC (changed from DELTA to Inovance in 2022) and touch screen, and Yaskawa frequency inverter, both of them are high-quality well-known brands, JT-SL-2000C paper core cutter machine’s quality is visible at your first glance.

New type electric panel and PLC

In addition, we have designed alternative safety covers in response to customer requirements. If you have strict requirements on production safety, you could choose an optional safety cover for your workers.

If you want to customize your own desired cardboard tube cutting machine, please feel free to send us a request, and we will discuss and analyze with you like teammates, and assist you to figure out the best solution at a competitive price.

Feedback from the German client

JT-SL-2000C Fully Automatic Paper Core Cutting Machine FAQ Guide

What exactly is a device for cutting cardboard cores, first of all? What distinguishes it from a paper cutter?

These are two very different machines, to be sure.

One is used for business purposes, while the other is used to cut regular paper. Cutting paper tubes that can be used to roll up items like fabric, labels, film, etc. is what this is for.

So, a paper cutter and a paper tube cutter are used for completely different things. The latter can be used for many different things.

The best way to learn about paper tube cutting machines is to look at questions that people often ask.

So, here we go.

- 1. What is a paper core cutting machine?

- 2. Where is the paper core cutting machine used?

- 3. What kind of core or tube could be processed by a paper core cutting machine?

- 4. What are the advantages of the JT-SL-2000C fully automatic paper core cutting machine?

- 5. What Exactly Is Paper Core Cutting?

- 6. What Is a Cardboard Tube?

- 7. What Are the Uses of Paper Core Cutting Machines?

- 8. Where Can I Buy a Paper Core Cutting Machine?

- 9. What Are the Different Automaton Degrees for Paper Core Cutters?

- 10. How much Does a Paper Core Cutting Machine Cost?

- 11. Do You Offer Replacements for Cutter Blades? What’s the Breakage Rate?

- 12. I Am Confused, Which Paper Core Cutting Machine Should I Buy?

- 13. Do You Supply Other Related Machines?

- 14. Do You Have Video Demonstrations of the Paper Core Cutting Machines?

- 15. Do You Have Any Customer Reviews and Feedback?

- 16. What’s Your Delivery Time?

- 17. What’s The Precision Rate of Your Paper Cutting Machines?

- 18. Why Should We Choose Jota Machineries?

1. What is a paper core cutting machine?

The main purpose of paper core cutting machines is to split long tubes of paper or plastic into numerous smaller tubes. Short paper or plastic cores will be used to roll paper, fabric, fiberglass, and other materials, as well as to package tea and sugar.

2. Where is the paper core cutting machine used?

The paper core cutting machine could be widely used in many industries, such as paper mills, aluminum foil factories, plastic film workshops, tea packaging box factories, etc.

3. What kind of core or tube could be processed by a paper core cutting machine?

Currently, the Jota machine is specially designed for paper or plastic tube cutting.

4. What are the advantages of the JT-SL-2000C fully automatic paper core cutting machine?

As the JT-SL-2000C machine is a fully automatic machine, its biggest advantage is definitely the fully automatic feature. No dedicated worker is needed.

The other big advantage is auto-rotating cutter blades, after finishing 1 cut, the cutter blade rotates at a preset angle, effectively extending the cutter blade life cycle.

5. What Exactly Is Paper Core Cutting?

Cutting larger, longer cardboard paper tubes into smaller paper tubes is a common industrial practice.

Kraft paper tube cutters, either automatic, semi-automatic, or completely automatic, are used in the process.

Fabric, labels, film, and other things can be rolled up in the cut cardboard tubes.

As a result, Jota Machinery, as the industry’s top producer, assures high-quality machinery.

6. What Is a Cardboard Tube?

A cylindrical product called a cardboard tube is created by winding numerous plies of kraft paper together.

It is referred to as Kraft Paper Cardboard Tube as a result.

A large product category in the industry is cardboard tubes.

It is sold by numerous factories, including the printing house, plastic film factories, and other businesses that produce related industrial goods.

There are many uses for cardboard tubes, and many businesses need them.

Aluminum foil, thermal paper, non-woven fabric, toilet paper, kitchen towels, wire, and other items are rolled and shipped in cardboard tubes. It is used to make paper cans for storing a variety of items, including clothing, paintings, maps, cosmetics, meals, and other commodities.

Not only the paper cardboard tube winding factory needs a tube cutting machine, but also many small factories also need it. It could help you to cut the long kraft paper tube into small segments for your next working processing.

7. What Are the Uses of Paper Core Cutting Machines?

The automatic core cutter is used in cutting cardboard tubes, which are then applied in making cans for different purposes.

These include cardboard for making clothes, paintings, maps, cosmetics, foods, and other merchandise.

The machines are also applicable in rolling aluminum foil, thermal paper, non-woven fabric, toilet paper, kitchen towels, wire, etc. Basically, the applicability of paper core cutters is wide.

8. Where Can I Buy a Paper Core Cutting Machine?

There is a slew of paper-core cutting machine manufacturers, each of them with unique, patented features. However, some brands come top, especially when gauging their machines’ efficiency.

It’s always best to go with a brand that’s won the trust of reputable manufacturing clients.

You can never go wrong with a paper-core cutting brand whose reviews are nothing but positive.

That is, a great core-cutting machine ought to improve productivity whilst minimizing maintenance costs. Which is exactly what Jota Machinery is all about.

Thanks to its high-quality paper core cutter, the manufacturer has won the trust of Mondi Group, an iconic corporation in Thailand.

9. What Are the Different Automaton Degrees for Paper Core Cutters?

The machines are either automatic, semi-automatic, or manual. At Jota Machinery, we offer all these three types of machines. It usually depends on what you need, and what’s best for the material you’re using.

Nonetheless, all three automatic degrees are helpful in cost-saving, time-saving, labor-saving, and improving productivity. Let’s look at the machines.

a) The Manual

Jota manual paper tube cutting machine model is JT-600, which is a very simple machine, and the operator can use it in just 5-10 minutes.

b) Fully and Semi-Automatic

If your budget allows, you should consider Jota’s completely automatic paper tube cutting machine.

Because it has a fully autonomous feature, no dedicated operator is required, lowering labor expenses.

The operator of the automatic core cutting machine only needs to place the long paper tube on the rack before starting the machine, then start the machine, and the machine will do the rest of the work.

Furthermore, a fully automatic cardboard core cutting machine includes an automatic rotation blade to improve blade service life.

The blade rotates a specific angle after each cut, avoids cutting against the tube at a fixed position, extends blade service term, finally saves cost.

Besides, such a fully automatic cardboard core cutting machine’s working speed is much faster than manual or semi-automatic type cardboard cutting tools.

Therefore, as long as you own this automatic cardboard core cutting machine, the production efficiency of paper tubes will be greatly improved, and you can save a lot of labor costs.

10. How much Does a Paper Core Cutting Machine Cost?

The price for a paper cut core automatic machine ranges from $2,000 to $30,000 depending on the model.

The models are based on the paper tube. What’s the paper tube length? What’s the tube’s inner diameter? And what’s the paper tube thickness?

The model is also based on the automation degree. In other words, is the machine manual, semi-automatic, or fully automatic? As expected, the manual core cutting machines cost less than both semi-automatic and fully automatic.

The fully automatic cutters are the most expensive, but they are not prohibitively pricey! This is because completely automatic core cutting machines eliminate the need for manual work, saving you money in the long run.

Jota Machineries’ paper core cutters are a good investment from a financial standpoint. You’ll obtain a good return on investment whether you buy a manual paper core machine, a semi-automated machine, or a completely automated one.

11. Do You Offer Replacements for Cutter Blades? What’s the Breakage Rate?

Since paper core cutter blades are usually the biggest victims of replacements, we suggest you to purchase more vulnerable parts.

When it comes to the cutter blades’ breakage, you need to understand that the rate is understandably high. But not too high to be costly on your business.

The breakage rate depends on the machine’s rate of usage. The more it’s used, the more you’ll experience cutter blade breakages. However, this shouldn’t much of a problem with Jota Machineries.

We’ve made our core cutter blades rotate at an angle after each cut. Which keeps the blades from damaging thus extending their service life.

12. I Am Confused, Which Paper Core Cutting Machine Should I Buy?

In order to recommend a suitable paper core making machine for you, you need to know what specifications of the paper tube you want to produce, such as paper tube length, paper tube inner diameter, paper tube thickness, etc.

- If you want to produce paper tubes with a thickness of 0.6mm-5mm, an inner diameter of 10mm-120mm, and a length of 500mm-2000mm, you can consider our JT-50A paper core making machine;

- If you want to produce paper tubes with a thickness of 1mm-10mm, inner diameter of 20mm-156mm, and length of 500mm-4000mm, you can consider our JT-120A paper tube making machine;

- If you want to produce paper tubes with a thickness of 1mm-18mm, an inner diameter of 20mm-250mm, and a length of 500mm-5000mm, you can consider our JT-200A paper core winding machine.

13. Do You Supply Other Related Machines?

Of course, you can also buy multiple machines according to your own requirements for output, it can be a slitting machine or…

Generally speaking, paper tube manufacturers need to own 3 machines, a kraft paper slitting rewinding machine, a paper tube winding machine, and a cardboard tube cutting machine.

With these 3 machines, the most basic paper tube can be produced. You should know that Jota Machineries puts customers first. And we understand that different clients have different needs.

14. Do You Have Video Demonstrations of the Paper Core Cutting Machines?

Of course, we do. Who would we be if we didn’t have videos for demonstrations?

We’ve not only captured videos of how the automatic paper core machines work, but we also have videos of satisfied customers from all over the world.

Here are some video demonstrations:

- how cardboard tubes are cut

- how the cardboard tubes are cut

- how the manual paper core cutter work

- JT-3500D

15. Do You Have Any Customer Reviews and Feedbacks?

The best way to find automatic paper core cutting machine reviews is by contacting clients we’ve worked with, or who bought our machines.

If you give us your location, we’re more than happy to direct you to the nearest client(s) using machines bought from Jota Machineries.

We usually tell our clients to provide videos on how the machines work. I

n the process, they give us feedback on how to better improve the machines. We’re always open-minded and take our clients’ suggestions very seriously.

Here are videos on satisfied clients:

- Ivan from Georgia, US

- Ahmed from Egypt

- Mario from Mexico

16. What’s Your Delivery Time?

Around 30-45 days, mainly depending on the machine type. Note that the delivery time is dependent on your location, as well as on the type of machine you’re asking for.

Also, if it’s a machine for you that need specific customizations, we may take longer, but no more than 45 days as mentioned. We have a quick turnaround time.

17. What’s The Precision Rate of Your Paper Core Cutting Machines?

Different machines have different rates, the simple cheapest paper core cutting machine price is around USD3000.00

The fully automatic paper core production line is around USD30000 – 80000.00

Send an inquiry, left more detailed requirements, and we will send a formal quotation.

18. Why Should We Choose Jota Machineries?

We are proud to have more than 1200 dependable customers from all over the world in addition to our high-quality automatic paper core cutters.

Jota Machinery is a top manufacturer for the following reasons as well.

A) The Best R&D Department

Jota Machineries has a great team of qualified, passionate engineers. Once they’ve been given a task, the engineers see it as a challenge and so they’ll do everything to make sure the finished machine is perfect.

The team is led by an experienced slitter rewinder designer, whose design was highly praised by Portugal’s famous brand ‘Navigator’.

B) In-House CNC Center

With our own CNC center, the components for the slitter rewinder are precise enough. Through the assembly of our craftsmen, the various parts are organically combined into a machine, it has both internal and external attraction.

C) Top-Notch Suppliers of Raw Materials

Thanks to China’s strong supply chain system, we have cooperated with high-quality raw material suppliers for many years.

Our slitter rewinder marketing history is over 10 years, it has fully proved our product quality. German Industrial Park and Japanese Industrial Park indirectly promote Kunshan machinery manufacturing development too.

D) Best Pre-Sale Services

We are more than happy to assist you with your needs before we sell any of our machines.

In other words, we assist you in investigating the fundamental cutting devices before presenting you with solutions tailored to your needs.

The best part is that we have engineers available from around the globe who are willing to jump in and provide installation and maintenance advice.

In order to let you know more about we Jota company, please watch the following video for reference.

We not only provide fully automatic paper core cutting machines and also supply the related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine