Professional Slitting Rewinding Machine Manufacturer

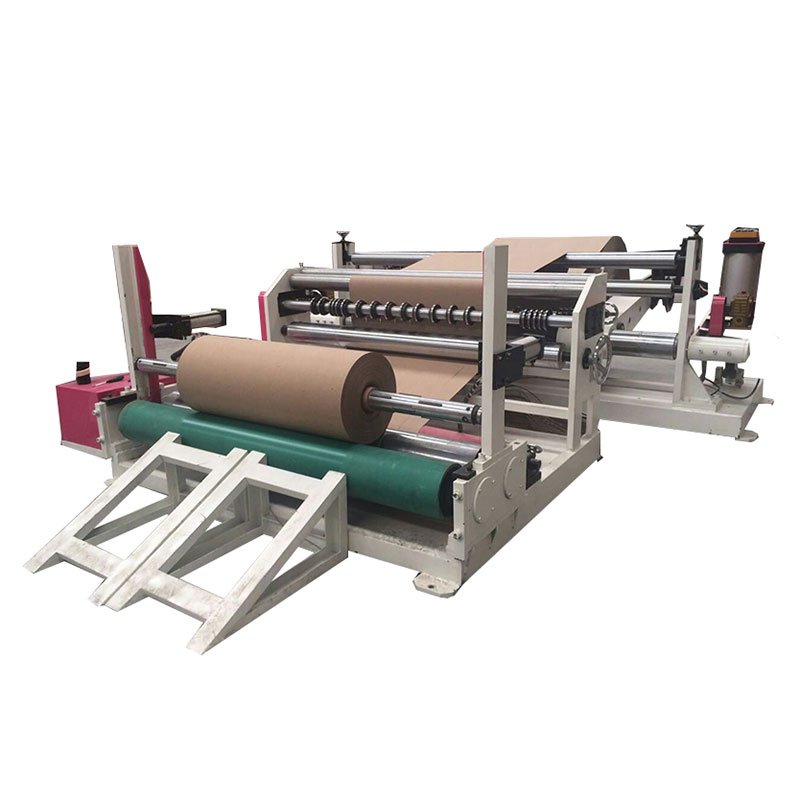

- Paper, foil, fabrics, film, prepreg UD Tape slitting rewinding Machine

- Unwinding width ranges from 320mm to 3800mm

- Slitting width ranges from 3mm to 3800mm

- Max unwinding diameter is up to 1800mm

- Razor cutting and rotary shear slitting switch

- Traverse spooling technology

Jota Slitting Rewinding Machine

If you are looking for a suitable jumbo roll slitting rewinding machine whether you are in the field of printing, packaging, new energy, aerospace, or new carbon fiber technology materials.

Our professional team could meet your requirement to providing a suitable solution on slitting rewinding machine.

As a professional jumbo roll slitting rewinding machine manufacturer, we have not only 20 years of experience, but also a highly educated R&D team, advanced mechanical design team, and electrical software design team.

These can ensure that our slitting rewinding machine can meet customer needs and conform to the market requirement.

At the same time, our company is also completing its own upgrading and transformation.

From the most basic paper and film roll slitting rewinding machine to the latest new energy carbon fiber and the slitting of aerospace materials, this is also a testimony of our own strength.

Currently, we can provide slitting machines for various materials.

The width of parent mother rolls can reach from 50mm to 3500mm, and the slitting width can range from 3mm to 3500mm.

There are various winding methods such as reverse winding, disc winding, and rewinding. The maximum diameter can be up to 1800mm. There are also various slitting models for you to choose from.

Many people have a misunderstanding about the slitting rewinding machine.

You think that it is to find a simple machine to cut large rolls into small rolls or rewind them into small rolls.

In fact, different material characteristics, hardness, tension requirements, and subsequent processes are different.

The requirements vary greatly.

For each different material, the material threading flowing route on the machine, the angle between the roller and the diameter of the roller, and the selection of the slitting knife are all professional technical issues.

If you are looking for a professional jumbo roll slitting rewinding machine supplier, Jota Machinery should be your best choice.

Jota slitting rewinding machine could be applied for many different materials,

such as adhesive labels, kinds of paper, film, foil, non-woven fabric, CFRP, CFRTP, FRP prepreg, etc.

For a deep discussion about Jota slitting rewinding machine, please just send us an inquiry.

CFRP, CFRTP, FRP Prepreg UD Tape Slitting Rewinding Core Technology

Jota Machinery: Original Slitting Rewinding Machine Manufacturer in China

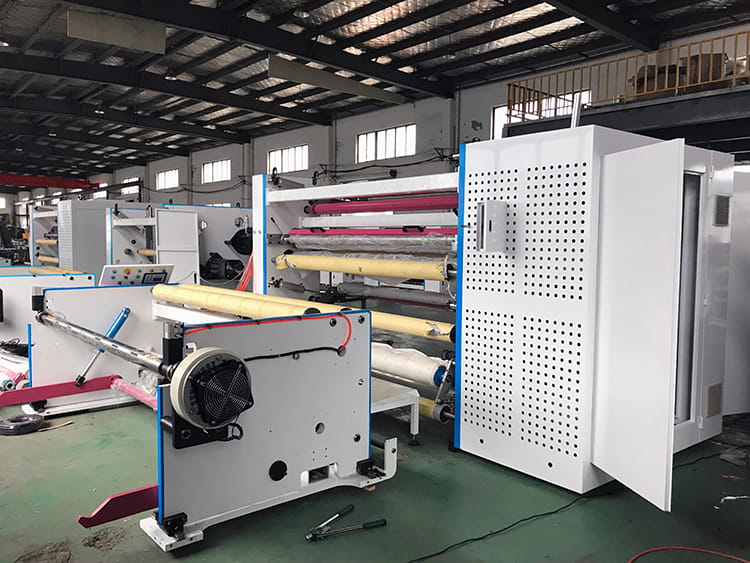

Jota is capable of manufacturing 30 sets of slitting rewinding machines in 1 month.

We also accept free material converting test, you just need to send some of your material to us.

we will use our Jota slitting rewinding machine test it, then show you the testing video.

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Why Choose Jota Slitting Rewinding Machine

Last Update Time:04/12/2023

As an original roll slitting rewinding machine manufacturer, Jota Machinery could supply you with different types of slitters.

The slitter rewinder machine is common machinery used in the material converting industry, it is used for converting many kinds of roll materials.

The roll materials could be processed by slitting machines mainly include:

- Paper

- Film

- Nonwoven fabric

- Wire mesh

- CFRP, CFRTP, FRP prepreg

- Aluminum foil

- Adhesive label

- Textile

With a slitting rewinding machine, you could get small finished rolls from a material jumbo roll, it is widely used in many industries.

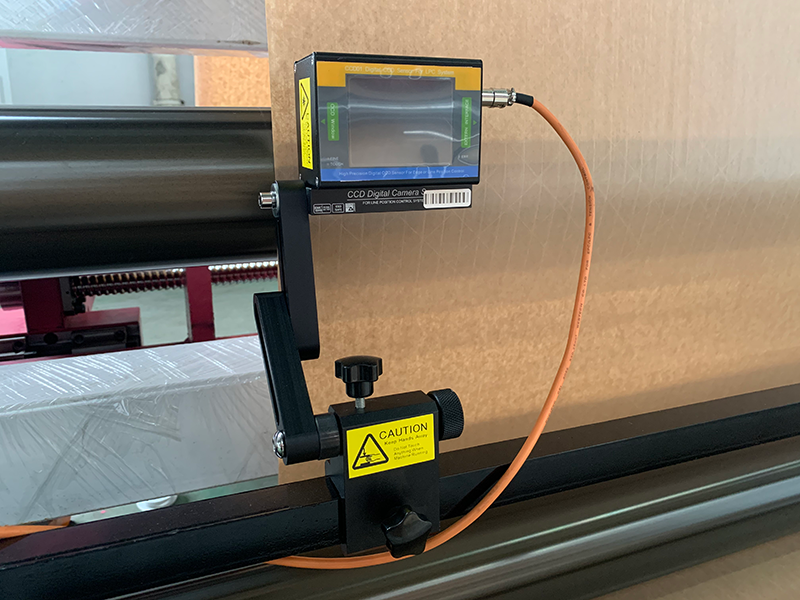

Our automatic knife positioning system can help you reduce your time, and all the slitting widths can be freely preset.

Automatic Knife Positioning System Working Video

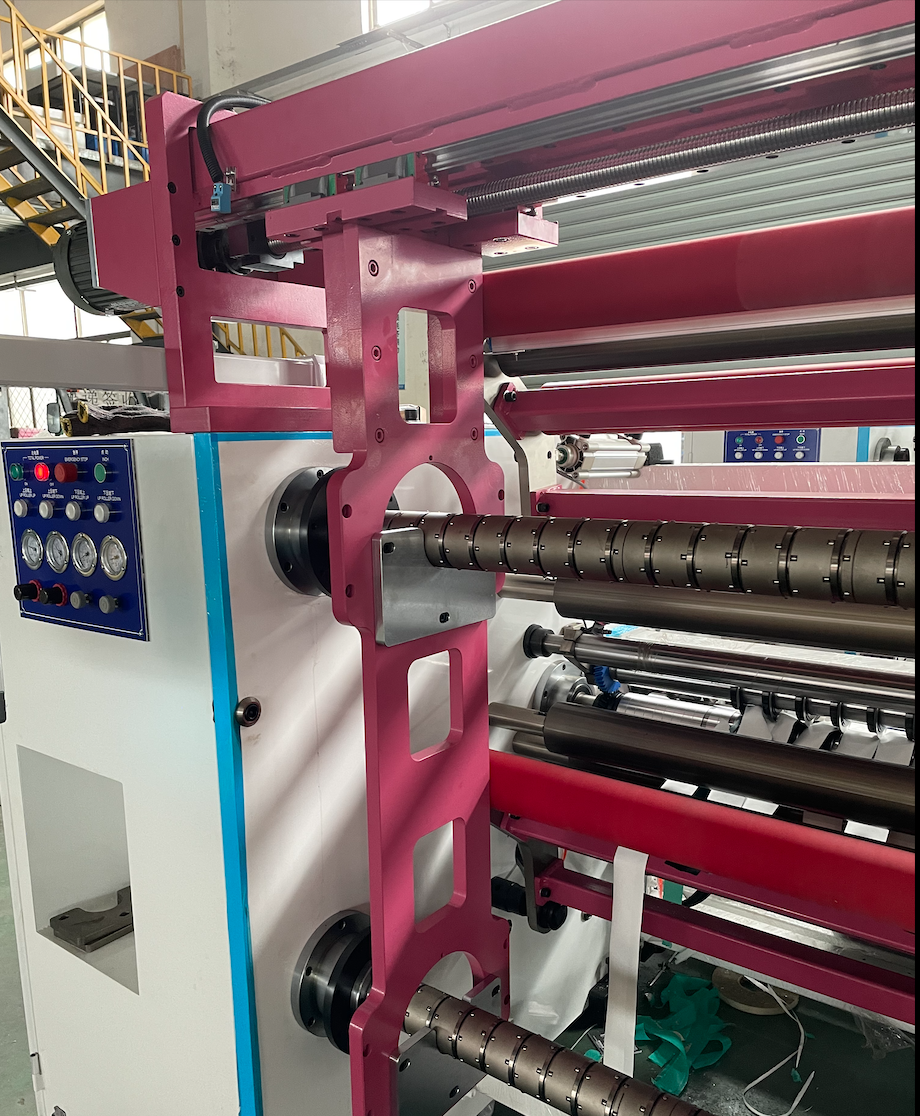

Generally, slitting machinery includes unwinding, web-feeding, slitting, rewinding, controlling, waste collecting sections.

It consists of PLC module, AC drive, several motors, digital camera sensor, and automatic tension controller, etc.

In order to meet your different requirements, our slitter rewinder machine could integrate automatic loading and unloading function, equip with the differential friction shaft, rotary encoder meter counter, realize automatic stop, and automatic waste edge trimming.

Normally, we use circular knives for paper cutting and slitting we call it paper rewinding machines, and we use razor blades for film slitting rewinding we call it plastic film rewinding machines.

Razor Blades

According to your jumbo roll width and material type, Jota Machinery will help you choose the right slitting and rewinding machine.

If your material is thermal paper, you can consider our Jota’s latest fully automatic thermal paper roll slitting packing machine JT-SLT-1400FA, from core feeding to finished roll packing, no need dedicated operator, optional online printing function can also be integrated.

If your material is film or regular paper, you could choose our JT-SLT-1300C slitting and rewinding machine;

For cigarette paper or aluminum foil, we would like to recommend you check JT-SUR-1600 surface rewinding slitting machine in detail;

If your jumbo roll width ≥ 2500mm, then JT-SLT-2500C slitting and rewinding machine may match your needs.

We also supply a heavy duty shaftless Unwinding stand for easy loading a heavy mother rolls:

A Saudi Arabian customer recently gave us feedback that his 17-year-old slitter rewinder is still in normal use and he is reluctant to throw it away.

Please watch the following video to understand this 17-year-old slitter rewinder’s working effect in 2021.

In order to choose a suitable roll to roll slitting machine, please send us an inquiry on this website to get assistance, we are reliable manufacturer worthy of your trust.

Slitting Rewinding Machine Ultimate FAQ Guide

- What is a slitting machine

- Roll slitting machine working principle

- What is a rewinding machine?

- What is the difference between roll to roll slitting machine and log slitting machine?

- Slitting and rewinding machine application in the adhesive label industry

- Slitter rewinder application in the film rewinding industry

- Roll slitting machine application in emerging industries and new energy fields

- Slitting machine customization

- Slitting machine blades

- Slitter machine tension control

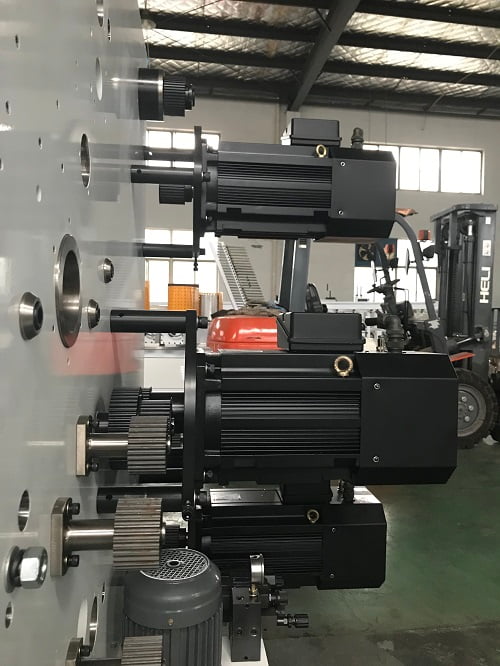

- Slitting machine motors

- How to choose a satisfying slitting machine

- Slitting rewinding machine

- Prepreg slitting machine

- Paper slitting rewinding machine

- Label slitting rewinding machine

- Fabric slitting rewinding machine

- Aluminium foil slitting rewinding machine

- Film slitter rewinder

- Surface slitter rewinder

- Center slitter rewinder

- Center surface slitter rewinder

- Duplex slitter rewinder

- Slitter rewinder machine manufacturer

- Slitting rewinding machine China

- Slitting rewinding machine price/cost

What is a slitting machine?

A slitting machine is a common machine in the machinery industry.

One type of slitting rewinding machine is used to slit hard materials such as steel and metal; another type of cutting and slitting rewinding machine is used to slit soft materials such as paper, film, aluminum foil, and fabric.

If you are in the printing business, you definitely need one or both of the above equipment.

The size of the tension is adjusted by the tightness of the friction rubber plate, which is very simple.

About 20 years ago, the unwinding stand was like this.

With the development of technology, modern unwinding stand are advanced, and they are generally equipped with an automatic loading device to load heavy mother roll to the unwinding stand, reducing manual work intensity and improving safety.

The ball screw and leading way in the deviation motor will wear out after a long time of work.

Or if the paper roll is too heavy to damage it.

Basically, after 2 years of continuous working, the ball screw may be replaced.

Now our web guide adopts an ultrasonic sensor, which cooperates with a servo motor for deviation, with high sensitivity and high precision. With it, you can have good performances.

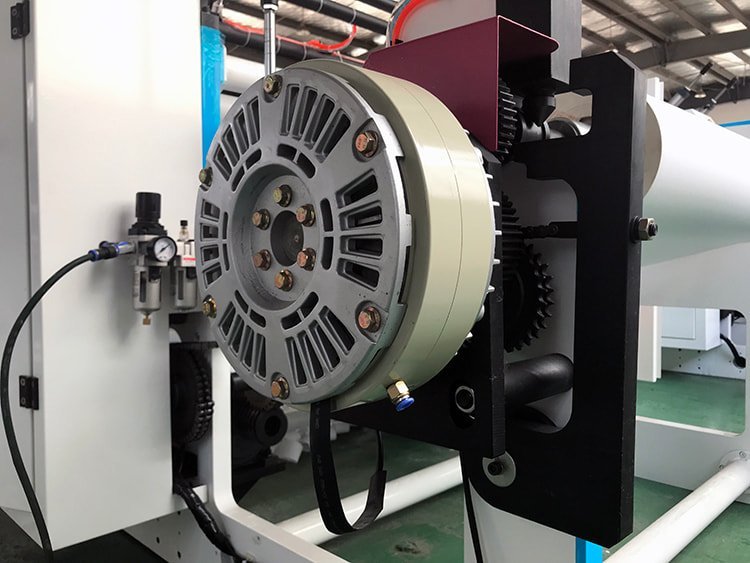

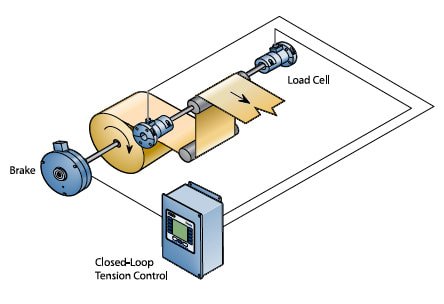

Another very important part of the slitting machine is tension control.

Each slitting machine will have a NIP roller.

This pair of NIP rollers is mainly used to control the speed of the running.

Generally speaking, the general slitting machine is equipped with 3 sets of auto tension control systems, one set of unwinding tension control systems, and two sets of rewinding tension control systems.

Generally speaking, in order to convert large rolls into small rolls, the cutting and slitting machine’s working process mainly includes:

- Unwinding

- Web-feeding

- Slitting

- Rewinding

- Waste collecting

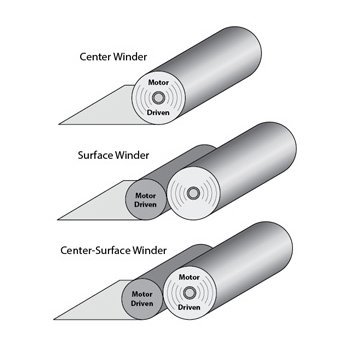

In addition to classification according to material type, slitter machines arel also be classified by the winding form, winding form is mainly divided into:

- Center winding

- Surface winding

- Center-surface winding

Roll slitting machine working principle

The slitter rewinder unwinds the jumbo roll material, cuts it through the blades, and then motor drives the winding shaft rotating to roll the material up.

If your mother rolls are not neat, the web guide will 100% resolve this problem.

There is a magnetic brake or motor will be installed on the unwinding stand. It is used for the tension control of the mother paper rolls.

It is sensitive and easy to control.

sometimes servo motor will be installed on the unwinding stand. if your material is sensitive. our engineers will install servo motors on the unwinding stand.

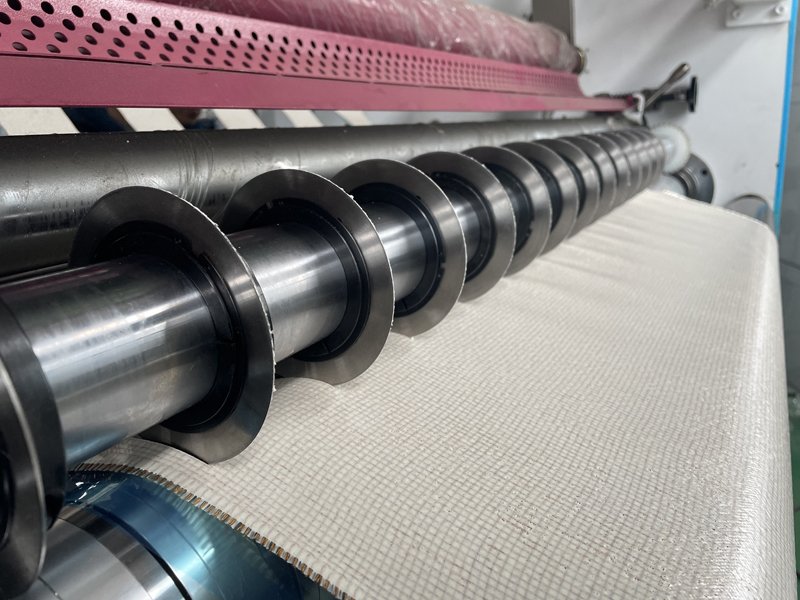

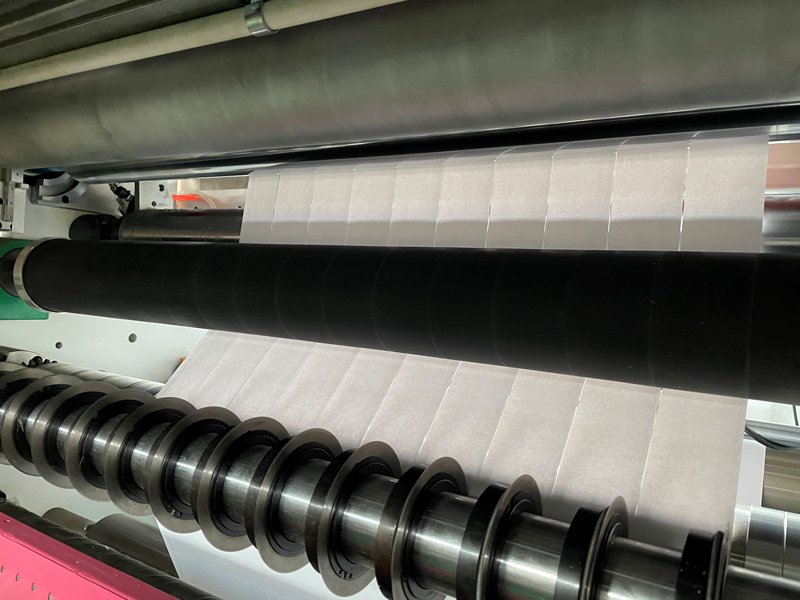

For different material rolls, we have different cutting methods for options. mainly the round disc cutters are installed for different materials like paper rolls, plastic sheet rolls, electric films, and some new energy films.

The round disc cutters are motorized, the lower cutter shaft is active for running.

And the upper knife shaft will be occlusal by the means of gear.

Many roll slitting machine suppliers just focus on the machine speed, they seldom focus on the disc cutting knives.

Actually different paper jumbo roll, which must have a suitable knife edge.

In order to keep the slitting width precision, our technician makes a high precision spacer for limiting your width.

It is a lower cutter shaft by assembling different widths of spacers like 5mm, 6mm, 7mm to make your different required width.

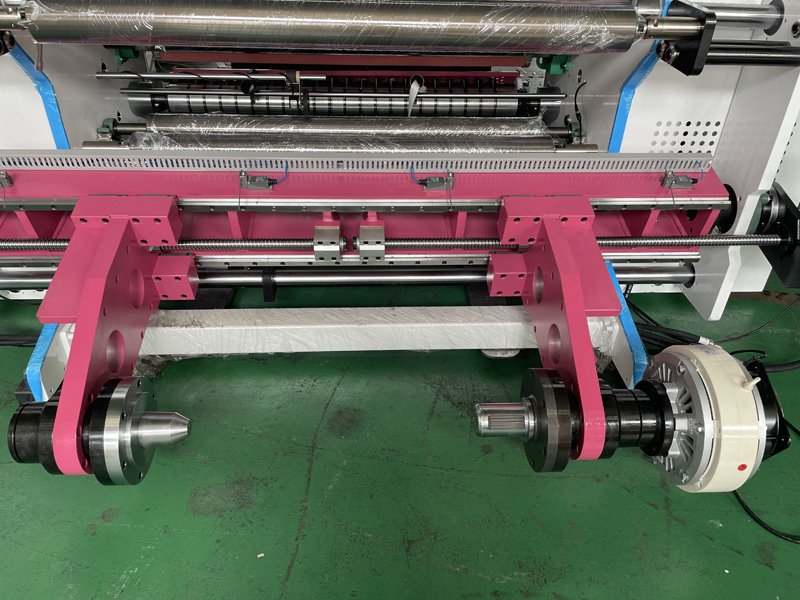

After the disc slitting cutters, the jumbo rolls will be rewinded by the rewinding shaft.

After the disc slitting cutters, the jumbo rolls will be rewinded by the rewinding shaft.

The recommended rewinding method is the central surface rewinding type.

The rewinding air shaft is motorized. But there is a swing type rubber roller to touch the rewinding jumbo rolls to ensure the rewinding edge neatly.

If you are interested in the roll slitting machines, it is better you understand which kind of cutting knife methods are preferable and how about your jumbo rolls tension control.

As a professional jumbo roll slitting machine supplier, we always have a machine in stock, you just send us the materials, after test running by our technician, our marketing team will set up a testing report and recommend proper working methods. It is easy.

What is a rewinding machine?

Speaking of rewinding machine, according to whether the rewinder machine has to slit part, the slitting process in flexible packaging can be divided into rewind machine and rewind slitting machine

The rewind machine’s actual function is to divide the large-diameter jumbo roll into multiple small-diameter finished rolls of a certain length, and the jumbo roll width equals to the finished roll width.

This rewinding machinery’s working principle is like this, the jumbo roll is unwound from unwind stand and driven by the motor to move forward, and finally, it is wound onto the rewinding shaft’s paper core.

This kind of winding equipment can be used to rewind many kinds of paper, aluminum foil, and stretch film.

Paper roll slitting rewinding machine has two functions, one is slitting functions which is used to slit the mother roll into narrow sizes.

The other one is rewinding function which is used to rewind the big mother rolls into small diameter paper rolls.

The rewinding machine has two types: One is the centre rewinding device.

There is a motorized air shaft to rewind the material from big roll into the preset length.

The other one is the surface rewinding type.

There are two bottom roller, either of them are motorized, there is a pressure lay up roller on the top.

Two drum rollers in the bottom, one pressure roller on the top. It create a close loop for the paper rewinding.

If your paper rolls are thick, it is easy to bear a big tension strength.

The friction rewinding method is adequate.

Three rollers could clamp the rewinding rolls tightly. so it gets a stable functions, and tension could be controlled well. So it can easily get a high speed rewinding. The Max. speed sometimes gets to 500m/min.

Sometimes, if you need some small size rewinding machine, the rewinding diameter only 0.5” or 1”. The surface type rewinding method is adequate.

The shaft is too small to connect with a motor, which can’t bear such big torque. So the surface frictions luckily protect the rewinding shaft, under the help of pressure, it can get a good friction for rewinding.

On the basis of the friction rewinding method, you also can expand its usage for some special material converting.

Like the wall paper rewinding, plotter paper rewinding.

The waste trim edge will be rewinded or air suctions to collect it.

Sometimes, you could meet some sensitive paper or films. During the transmission, the film is easy to be wrinkles. One piece of banana roller will be installed to avoid this problems.

The banana roller will spread the paper rolls or film rolls at a certain angle. There is no winkles occur.

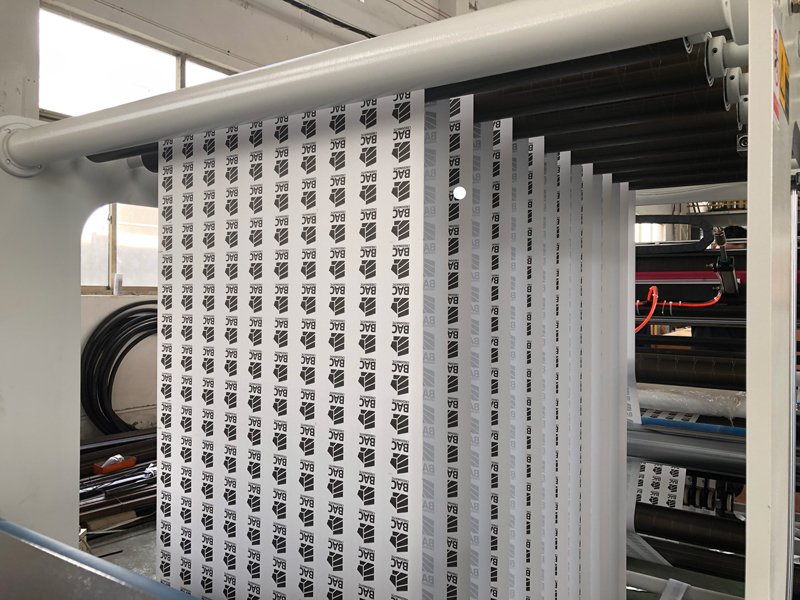

For the slitting rewinding machine, after unwinding the jumbo roll, the web must pass through the slitting unit first.

The slitting unit is equipped with multiple circular slitting knives, which will cut the jumbo roll into multiple strips, these narrow strips are then wound onto the paper cores of the rewinding shaft.

Based on different slit widths, the assembled slitting knives’ amount for the rewind slitting machine is also different.

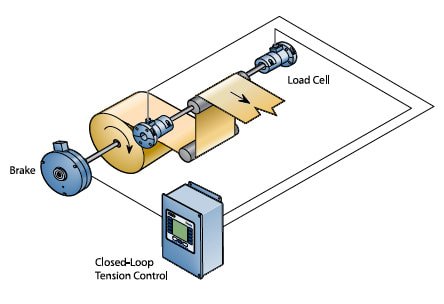

For rewind machines and rewind slitting machines, tension control is the most important factor, it ensures the machine’s smooth operation.

What is the difference between roll to roll slitting machines and a log slitting machines?

The roll to roll slitting machine has unwinding, slitting, and rewinding stations, and the log slitter has only a large cutter that directly cuts the material into bobbins.

It is generally used in the viscose product industry, such as BOPP tapes, electric tapes, mask tapes.

The log slitter cuts with a large knife at a time, which is not suitable for large rolls with a diameter of more than 350mm, and the cutting table’s large rolls cutting quality is difficult to meet the requirements.

The log slitter is suitable for cutting such big adhesive cylinders.

It is a high precision machines, all the parameters could be controlled by the PLC and HMI, at least 3 sets of servo motors could be installed on the machine for knife control and cut material rotaries.

If you can’t decide which way is suitable for you, please contact our professional sales team, we will give you a recommendations.

Slitting and rewinding machine application in adhesive label industry

The self-adhesive paper sticker industry has a strong demand for slitting cutter machine.

And then the pattern is printed with water-based ink by a flexo printing machine, passes through the die cutter or mini slitter rewinder machine being cut into narrow strips.

The self-adhesive industry needs 2 types of roll slitter, 1300mm or 1600mm roll to roll cutting and slitting machine, 320mm slitting and winding machine, and possibly an inspection rewinder.

The self adhesive sticky label has a wide range of applications, including food packaging, daily chemicals, electronics, daily necessities and medicine etc.

In addition to the most basic function of displaying information, the label function also has other functions, such as reposting and repeated use, anti-counterfeiting functions, etc.

Because of its smooth face stock material, and the overall thickness of 150-250gsm.

The production process of self-adhesive is inseparable from coating and lamination machine, self adhesive label slitting rewinding machine and self adhesive label flexo printing machine, die cutting machine.

But now we can supply the New Innovated High Speed slitting rewinding machine for self adhesive sticky papers.

The Shaftless Unwinding Stand uses two cams to clamp the self adhesive sticky paper mother rolls and uploading to the unwinding stand.

During the transportation, sometimes the core of the sticky paper mother roll was deformed.

The air shaft is hard to be inserted. And the mechanical expandable cam could clamp the heavy rolls.

Auto Knife Positioning Device: It is a new innovated technology product. You only need to preset the slitting width, the knife will be automatically positioned under the help of the servo motor.

Then the expandable shaft will lock up the knife position. Easy operations.

Laser Core Positioning Device: There is a laser launcher will launch a red line to facilitate the positioning of the paper tube. This is to ensure that all paper tube edges and slit material edges are on the same plane.

Differential Friction Shaft: During the coating process, due to the inconsistent thickness of the adhesive surface, the self adhesive sticky paper will be thick in some places and thin in some places.

The differential friction shaft adopts an independent slip ring to solve the problem of uneven thickness.

We recommend using this slip ring device on your sticker paper slitting rewinder. He is very helpful to improve the quality of products.

If you are interested in adhesive sticky paper slitter rewinder, please feel free to contact us.

Roll slitting machine application in emerging industries and new energy fields

In the new energy field, such as lithium battery separator film, optical film, or glass fiber industry, the roll rewinder slitter has also been more widely used.

Because of the new material characteristics, the optical film has higher requirements on the tension.

This requires us to upgrade the mechanical components, transmission system, and control system of the cutting and slitting machine.

In these fields, Jota Machinery has a certain experience, welcome to consult.

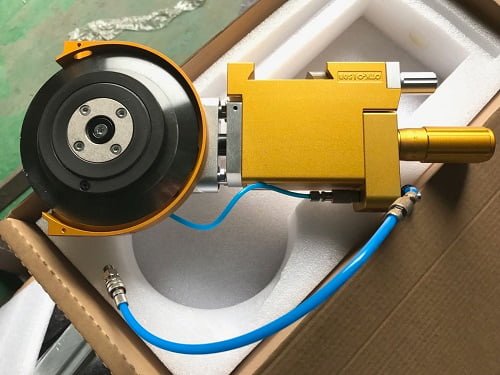

What’s more, for slitting and winding machines with higher requirements, we will use Taiwan-made pneumatic knife.

This kind of knife itself has high requirements, when machine speed is up to 500m/min, beating range is within 5mm.

Slitter machine tension control

Tension is an important factor in the slitter machine.

The more stable the tension of a slitter and the faster the speed, the better the effect of the slitter.

The traditional cutting and slitting machine contains 3 automatic tension units.

1 unit is used for unwinding and 2 units are used for rewinding, each unit contains 1 controller and 2 sensors (load cell).

With PLC and touch screen’s widespread use in slitter rewinding machines, taper tension control of the motor is introduced.

This intelligent design brings simpler operation, we can set the tension curve directly according to your material, so as to control the tension more simply.

Slitting machine motors

The initial slitting rewinder was equipped with a motor, working with a magnetic powder clutch or brake, speed is 100m/min.

These motors are imported variable frequency drive motors, and then coupled with Yaskawa AC drive to work together, the performance is very stable.

Now we also use 3 asynchronous servo motors.

Compared with traditional inverter motors, this new servo motor has a more refined appearance and greater torque, occupies a smaller installation space, and is increasingly welcomed by customers.

Slitting rewinding machine

What is a slitter?

A slitter is a pre-press and post-press equipment, it cuts paper, film, non-woven fabric, aluminum foil, and other thin materials big rolls into small rolls, or sheets of different widths.

It is commonly used in the packaging and printing industry.

When the situation is serious, the machine operation will be hindered, bring serious consequences to production, and seriously affect production efficiency.

Nowadays, the slitting rewinder machine is generally driven by double inverter motor.

When the winding diameter becomes larger, the inverter motor control is adopted to realize certain magnetic powder friction, with no high temperature.

How a rewinder works?

Usually, the jumbo roll from the paper making machine is placed on the unwind stand, and the braking device on the unwind stand keeps the paper web at a certain tension.

The paper web is cut into the required width by the circular slitting knives after passing through idler rollers and then rewound into small paper rolls according to the required width, tightness, and diameter.

A rewinder’s main parameters are web width, max. speed, max. unwinding diameter, winding diameter, cutting method, etc.

Slitting machine price

The slitting machinery price varies greatly depending on the material type, jumbo roll width, unwinding and winding diameter.

The 320mm width label slitting machine costs only a few thousand dollars; some slitting machines customized for glass fiber and carbon fiber prepreg cost more than 100,000 US dollars.

In order to better confirm your desired slitting machinery’s price, you can tell us your material type, your jumbo roll width, your jumbo roll diameter, required slit width, and winding diameter, we will recommend the right model to you.

Slitting machine HS code

In China, when we export the slitting machinery, the HS Code for customs declaration is 844110000.

For HS Code, the top 6 digits are internationally unified.

Slitting machine tension control

The slitter rewinding machine’s tension control is basically divided into:

- Manual tension control

- Automatic tension control

Manual tension control means that when the roll diameter changes to a certain stage during the winding or unwinding process, the operator needs to adjust tension manually.

Fully automatic tension control is to directly measure actual web tension by sensor, and then convert the tension data into a tension signal and feed it back to the tension controller.

By comparing this signal with the tension value preset, the control signal is calculated to automatically command the execution unit, and finally, the actual tension value is equal to the preset tension value, tension stabilizing is realized.

Tension control must remain effective at any running speed of different status, including acceleration, deceleration, and uniform speed.

Even when emergently shutdown, it should ensure that the material being cut is not scratched or damaged.

The tension control stability directly affects slitting quality.

If the tension is insufficient, the raw materials will loosen or drift, small finished rolls will wrinkle after slitting and rewinding;

If the tension is too large, the raw material is easily broken, which will increase material waste and downtime.

For this reason, the slitter rewinding machine is required to realize constant tension control, that is, during the winding process, the raw material web is subjected to the best tension.

As the selected tension detection element and torque adjustment element are different, various tension control solutions are optional.

Prepreg slitting machine

Prepreg manufacturing process

Take the carbon fiber prepreg manufacturing process as an example.

- Use plastic fiber bundles as raw materials.

- The plastic fiber passes through an oxidation furnace (for a few minutes, at a temperature of about 480F) to extract oxygen particles from the air.

This process rearranges the fiber atomic structure so that the fiber bundle obtains high-temperature resistance.

- When oxidized, the fiber bundle color will eventually become black.

- The next step is the carbonization process, the fiber bundle enters the anaerobic heating furnace.

During the heating process, most of the non-carbon elements are removed, and the remaining carbon atoms are transformed into tightly connected crystals, which are arranged in parallel with the fibers to enhance the fiber bundle strength.

- The fiber bundle passes through ionized water so that it can better absorb the resin.

- Apply a small amount of primary resin layer to the fiber bundle.

- The fiber bundle is wound into a roll following shaft rotating, and the buyer can either weave it into a carbon fiber product or add resin to make a prepreg.

Pre-impregnation is an important process for composite material molding.

It is a series of processes such as resin impregnation, drying, winding, cutting, etc., which are heat treatment or surface chemical treatment of fabrics.

It is mainly used for lamination, rolling, tape winding, and paste forming.

Carbon fiber dipping material is a composite of carbon fiber yarn and epoxy resin, the manufacturing process will be introduced below.

- Make impregnating resin.

- Pour the resin into the coating machine.

- The paper is coated with a thin wet resin film (the paper has been pre-treated with a release agent).

- Another machine makes 200-300 bundles of carbon fiber into unidirectional carbon fiber cloth.

- Put the two-axis resin-coated paper into the resin impregnating machine.

- When the carbon fiber unidirectional cloth is fed in, the heating element heats it to accelerate the resin absorption in the later stage.

- The carbon fiber unidirectional cloth passes between the two layers of resin paper, and the high-pressure hot roller makes the resin fully penetrate between the carbon fiber filaments.

- The cooling plate turns the liquid resin into a gel.

- After the resin becomes gelatinous, the paper pretreated with the release agent can be easily removed.

- Use polyester film to cover the prepreg surface (as a protective film).

- The prepreg is rolled into a roll and collected.

Because of the complex production and processing of carbon fiber, carbon fiber products shine in various fields.

What do you use prepreg carbon fiber for?

Prepreg carbon fiber has a wide range of uses.

Carbon fiber is light in weight and is a good ablation resistant material that can be used in high temperature and high heat fields;

It has a strong transmittance to X-rays and can be used in medical equipment;

Corrosion resistance, oxidation resistance, can be used in aerospace, such as aircraft fuselage, aircraft, aircraft seats;

Military field, such as radome, command cabin, body armor;

Water and land transportation, such as car shell, train shell;

Carbon Fiber Train Bodyshell

New energy sources, such as wind turbine blades, offshore oil production platforms, offshore drilling platforms, etc.;

Carbon Fiber Wind Turbine Blades

Construction projects, such as bridge structure reinforcement, carbon fiber tube frame, etc.;

Sports field, such as fitness equipment, clubs;

The medical field, such as CT board, traction table, athlete prosthesis, etc.;

Daily life areas, such as floors, bicycle racks, fishing rods, gift boxes, wallets, suitcases, briefcases, etc.;

Carbon Fiber Bicycle Rack

Fashion and entertainment fields, such as mobile phone cases, iPad protective covers, bathtubs, seats, etc.

Prepreg slitting slitter machine

The slitting width of prepreg slitter machine is usually very narrow, common slitting widths include 0.5 inches (12.7mm), 0.25 inches (6.35mm), and 0.125 inches (3.175mm).

Traditional narrow web slitter rewinder machines use rigid blades, rigid blades are not flexible enough.

Although the width tolerance of rigid blades is very high, when multiple blades are installed side by side, cumulative errors will occur.

When slitting many strips of prepreg tape, this error will increase exponentially.

For example, when more than 40 slitting blades are installed on the prepreg slitter machine, the width deviation of the blades in some positions may reach 0.25 mm after slitting.

This type of rigid slitting knife is usually overloaded to maintain efficiency, which in turn influences the slitting effect.

We at Jota are developing the use of spring-bound knives, spring-bound knives produce less cutting force, such cutting can effectively reduce blade wear and enhance the cutting effect.

Composite machinery

Speaking of composite machinery and equipment, the common ones are listed in the following table:

| Prepreg Making Machine |

| Prepreg Slitting Slitter Machine |

| Filament Winding (FW) Machine |

| Automatic Fiber and Tape Placement Machine (AFP/ATL) |

| Automatic Edge Welding Machine |

| Profile Moulding Machine |

| Drape Forming System |

Carbon fiber machinery

Carbon fiber machinery mainly includes:

| Carbon Fiber Prepreg Making Machine |

| Carbon Fiber Prepreg Slitter |

| Carbon Fiber Filament Winding (FW) Machine |

| Automatic Carbon Fiber and Tape Placement Machine (AFP/ATL) |

| Automatic Carbon Fiber Edge Welding Machine |

| Carbon Fiber Profile Moulding Machine |

| Carbon Fiber Weaving Machine |

Plotter paper slitting machine

Jota plotter paper slitting machine JT-SLT-900A has bagged the order from the well-known Portuguese company Navigator.

Navigator has used this machine for nearly 5 years and it is still running normally.

Winning the order from Navigator is enough to show that our Jota plotter paper slitter rewinding machine quality can stand the test of time, meet big client’s strict requirements.

If you also want to purchase a plotter paper slitter rewinding machine in the near future, please contact us.

Our professional sales team at Jota will provide you with one-on-one intimate service.

Parchment paper slitting machine

So far, no customer has asked our Jota to customize a parchment paper cutting and slitting machine.

If you need to customize the parchment paper slitting machine, we are very happy to communicate with you for your parchment paper cutting and slitting machine’s specific requirements.

We Jota have different models such as center slitting machine, surface slitting machine, center surface slitting machine, etc. for processing different types of materials.

If possible, please send us some of your jumbo roll parchment materials.

We will try to cut your materials with different slitting machines until you are satisfied with the cutting effect.

Sticker paper slitting machine

The demand for sticker paper slitting machine is relatively large, and many customers have purchased sticker paper slitter rewinder machines from our Jota.

The sticker paper slitter rewinder machine is relatively simple in structure.

As the sticker paper jumbo roll width is usually 320mm or 420mm, so the sticker paper slitter rewinder machine is generally a mini machine, small footprint, flexible.

Many customers will also request custom-made sticker paper slitter rewinder machines with die-cutting function.

Customized machines are what we Jota is good at, welcome to contact us to inquire about customized sticker paper slitter rewinder machines.

Paperboard/cardboard paper slitting machine

The cardboard paper slitting machine is a heavy-duty cardboard disc cutting machine.

It is a special machine especially suitable for cutting heavy-duty book cover paper, cardboard, hardcover bookcases, color box cases.

The machine is easy to operate, the cut is flat, and the accuracy and efficiency are high.

Thermal receipt paper slitting machine

The thermal paper slitting machine is our Jota’s best-selling product, well-known customers such as K.M.S Group in Egypt, Navigator in Portugal, Monospool in Bangladesh, and SS Labels in Sri Lanka have all purchased Jota’s thermal paper slitter rewinder machine.

If you are looking for a professional thermal paper slitter rewinder machine procurement guide.

We will contact you in time to solve your doubts.

Sublimation paper slitting machine

An Iranian customer has been talking to Jota about the sublimation paper slitting machine customization.

He originally planned to come to China to inspect our factory and check our Jota thermal transfer paper slitter rewinder machine on the spot.

However, because of the COVID-19 epidemic, he was delayed in coming to China.

If you also want to customize a sublimation paper slitting machine for your own factory, it is recommended that you send us a sublimation paper jumbo roll.

We are very happy to test out a suitable sublimation paper slitting machine that meets your requirements.

Label slitting rewinding machine

The self-adhesive label slitting rewinding machine is a relatively mini and simple machine.

The mainstream unwinding width is 320mm and 420mm, which is very small and easy to operate.

There are too many suppliers of this kind of machine, so the quality of each brand machine varies.

If you don’t want to spend money to buy a machine that often has problems, and no one responds every time you need after-sales, I suggest you just turn to a professional manufacturer like our Jota.

Fabric slitting rewinding machine

Non woven fabric slitting machine

Swedish client Mr. Johan ordered Jota PP spunbond non woven fabric slitting machine JT-SLT-2100D together with a precision paper core cutting machine JT-2400D in July 2020.

Mr. Johan purchased these 2 machines quickly because our Jota sales always answer his questions in a timely and professional manner, and customers are impressed by easy slitting knives replacement;

Besides, our Jota sales provided some other client’s feedback photos to Mr. Johan from time to time, these photos can clearly reflect our Jota non woven slitting machine’s excellent slitting and winding effect.

Mr. Johan customized a 2100mm width non woven fabric roll cutter slitting machine, if your non-woven fabric jumbo roll width is also close to 2100mm, you are welcome to discuss it with us.

We can customize a more suitable non woven fabric slitter machine based on Mr. Johan’s machine, the non woven fabric roll cutting machine you are dreaming of.

ol is the most important.

The tension control of the film slitting equipment includes unwinding tension control, winding tension control, and so on.

Unwinding tension control is mainly realized through the coordinated work of tension controller, tension sensor, magnetic powder brake, air brake, and other components;

The winding tension control function is integrated into the cutting and slitting machine’s PLC, the winding motor has a built-in encoder.

The PLC can appropriately increase or decrease the torque according to the change of the winding shaft speed and the winding diameter, so as to achieve reasonable control of the winding tension.

Surface slitter rewinder

Speaking of surface slitter rewinder, the rewinding shaft just rotates against one or more motor-driven drums, motor-driven drums are proactive, rewinding shaft rotation is driven by these drums.

Most of the time, the surface slitter rewinder can only wind the material in one direction and relies on the nip roller to achieve rewinding.

Surface slitter rewinder is mainly introduced to wind elastic or inelastic materials rolls of large diameter, but these materials should not be too sensitive to nipping or compressing, such as textiles, kind of paper, nonwoven fabrics.

Surface slitter rewinder is not suitable for winding sensitive materials afraid of being nipped.

Center slitter rewinder

Lay-on rollers are often introduced to control air volume between the nipping pressure roller and the rewinding shaft.

It is suitable for winding sensitive, soft, uneven thickness webs, such as a nipping-sensitive plastic film or composite webs, nonwoven fabrics and kinds of paper, and materials that are suitable for winding at low tension or materials that are sensitive of being compressed in the winding process.

Center surface slitter rewinder

The center surface slitter rewinder introduces all the 3 TNT principles for winding, tension, nipping, torque.

A motor-driven lay-on roller is used to control the web tension, good web tension control leads to slitting and web spreading optimization.

What’s more, lay-on roller loading can also play a role as a nip roller.

The center surface slitter rewinder’s advantage is that more precise winding tension control can be realized, better winding tension control means the better winding effect of finished roll.

Duplex slitter rewinder

Duplex slitter rewinder means that the slitting machine has two winding stations in total, and each winding station can be used to wind a certain number of small rolls.

After the parent roll is slit, the two neighboring strips can be wound with two different winding shafts respectively, which can effectively avoid the possible overlapping problem when one winding shaft is wound.

Turret slitter is also a kind of duplex slitter rewinder.

Such turret slitter usually only uses one winding shaft for winding, and two winding shafts take turns in charge of winding.

After one winding shaft completes its work, the other winding shaft automatically rotates to the winding position to take over the previous one to continue working, without the need for manual core loading and tape tail pasting.

Slitter rewinder machine manufacturer

Roll slitting machine

Roll slitting machine is a kind of machine suitable for cutting a jumbo roll material to several strips of a certain width, then these strips are wound to narrower finished rolls.

Paper, nonwoven fabric, adhesive label, plastic film, prepreg terminal rolls are both produced by roll slitting machines.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Paper Sheeter

- Paper Tube Making Machine

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine