JT-200A Paper Core Winding Machine

- Paper Layer 3-24

- Paper Core Thickness 1mm-18mm

- Paper Core Diameter 20mm-254mm

- Paper Core Length 500mm-5000mm

- Specification

- Video

| Parameters | |

| Item | JT-200A paper core winding machine |

| Paper Layers | 3-24 |

| Paper Core Thickness | 1mm-18mm |

| Paper Core Diameter | 20mm-254mm |

| Paper Core Length | 500mm-5000mm |

| Max. Machine Speed | 0-20m/min |

| Raw Material |

| Kraft Paper |

| Features |

| Delta PLC control and automatic meter counter, all the parameters can be set up on the control panel. |

| HIGHTECH touch screen from Taiwan, all the parameters can be displayed on the HMI interface, easy operation. |

| Imported frequency inverter drives the AC motor, the machine working is more stable. |

| Independent electrical control box equips with input plug, the after-sale troubleshooting and repairing will be much easier. |

| Dialogue monitor, automatic operation memory and store, automatic fault display. |

| Multi cutter for cutting the paper core, high precision, and more bearable. |

| Extreme quiet design transmission parts after special treatment, with high efficiency and low maintenance. |

| Double side glue coating devices, the paper core is more sticky and stronger. |

| 2 photocells for the paper core length tracking, after reaching the preset length, the paper core will be cut off. |

| Circuit system with remote control function, if circuit or machine fail, the engineer can assist you in solving problems via machine communications tools and software. |

JT-200A Paper Core Winding Machine

Last Update Time:23/03/2022

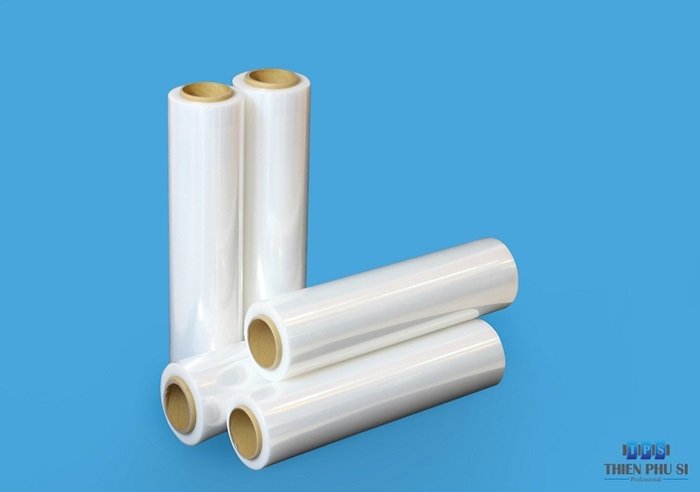

The JT-200A paper core winding machine was once exported to Vietnam, Thien Phu Si Co., Ltd of Vietnam purchased this machine. After so many years of cooperation, the boss of Thien Phu Si Co., Ltd is now our old friend.

Thien Phu Si focuses on providing high-quality stretch film, cling film and PP strip band products, which are exported to Japan and the United States.

The director board management headed by Ms. Xuan Ha has been working hard for many years, enabling Thien Phu Si to grow into a large-scale and diversified group company.

In 2007, when Ms. Xuan Ha first started working in the industry, she bought machinery and equipment such as stretch film extruder and PP band extruder from China.

Because of their serious research and production, product quality is guaranteed, and the price is very competitive, it quickly attracted the attention of Japanese customers.

The paper tubes for rolling stretch film and PP strip band are also in great demand.

So they contacted our company and purchased a complete set of paper tube production line equipment, including kraft paper slitting machine, JT-200A paper core winding machine, and cardboard tube cutting machine.

As the core of PP strip band is generally about 10″ and the thickness is about 15mm, only our JT-200A paper tube winding machine can meet Thien Phu Si Co., Ltd’s needs.

The number of kraft paper layers is 28 or 32. The diameter of the paper tube is determined by the size of the winding mandrel and can be customized according to your requirements. The common diameter is generally 76mm to 200mm.

Kraft Paper Unwind Stand

Since the products are exported to Japan, the quality requirements are very high. The paper tube they made at the beginning was always not hard enough, and the paper tube would be deformed under the pressure of the stretch film.

Later, we suggested that they consider a new process and use a drying room to dry the paper tube, which generally uses electric heating.

After 12 hours of circulating air drying, the paper tube produced in this way is hard and brittle, with good quality, and the hardness will be 30%-50% higher than that of the paper tube without drying.

If you also have requirements for paper tube hardness, you can contact us, we can provide the entire paper tube production process and technology.

Later, Thien Phu Si purchased BOPP tapes coating machines and auxiliary tools.

According to Chairman Ms. Xuan Ha, they have submitted an IPO application to the Vietnam Securities Regulatory Commission this year, and it is expected that Thien Phu Si will be listed in the stock market soon.

If you have requirements for stretch film, cling film, and PP strip band, please contact us and we will tell you the business contact information of Thien Phu Si.

Because Thien Phu Si is a large-scale production and operation company, plus Vietnam’s low labor cost, its stretch film, cling film, and PP strip band’s price will definitely be very attractive.

Thien Phu Si and Jota Machinery have witnessed each other’s growth and maintained focus and high growth in their respective fields together. We are very pleased to see that we achieve a win-win situation hand-in-hand.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine