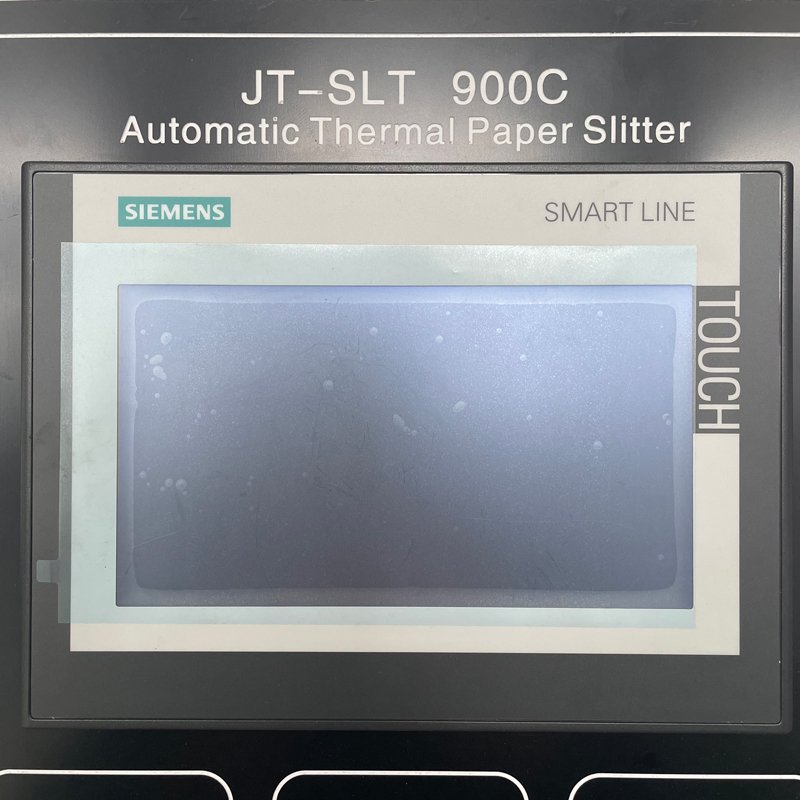

Thermal Cash Register Paper Roll Slitting Machine JT-SLT-900C

- 10000 rolls/8h, 300m/min

- CNC processed 37mm thickness frame

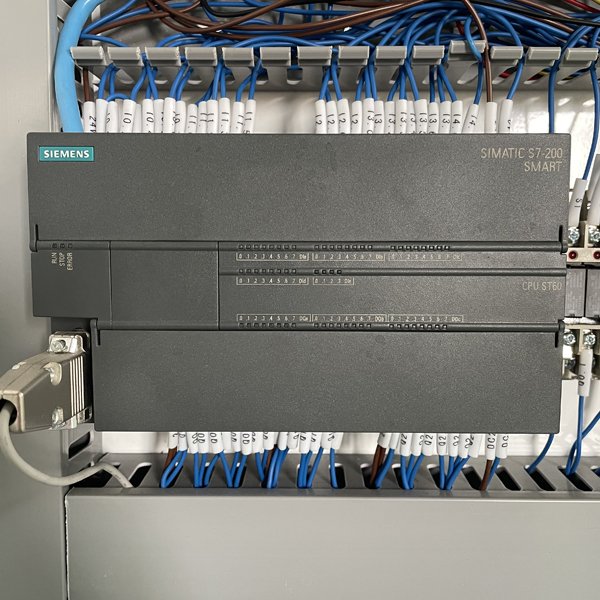

- Siemens PLC and Yaskawa AC drive

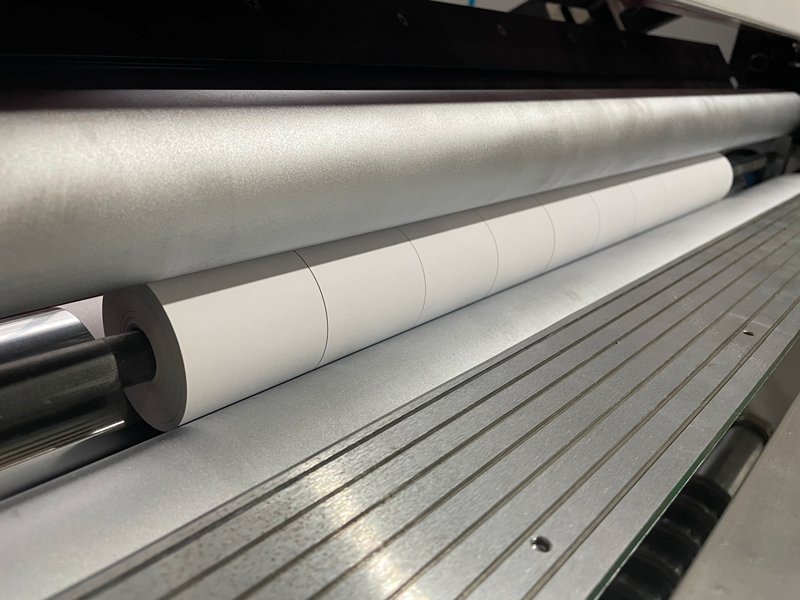

- Max. rewinding diameter 300mm

- High capacity, easy operation, simple maintenance

- Automatically POS Paper Roll Cutting Making Machine

- Operation Manual

- Slitting Machine in Iran

| Item | JT-SLT-900C thermal cash register paper roll slitting machine |

| Max. Unwinding Width | 900mm |

| Max. Unwinding Diameter | 1000mm |

| Max. Rewinding Diameter | 300mm |

| Min. Slit Width | 25mm |

| Max. Speed | 300m/min |

| Thermal Paper Thickness | 35gsm-120gsm |

| Weight | 2000Kg |

| Voltage/Power | 380V/50Hz, 7.5Kw (Voltage is customizable) |

| Dimension | 2000mm x 2000mm x 1500mm |

| SPECIFICATIONS | |

| JT-SLT-900C thermal cash register paper roll slitting machine is able to make fax roll, cash register roll, ATM roll, ECG roll, till roll, POS roll, etc. | |

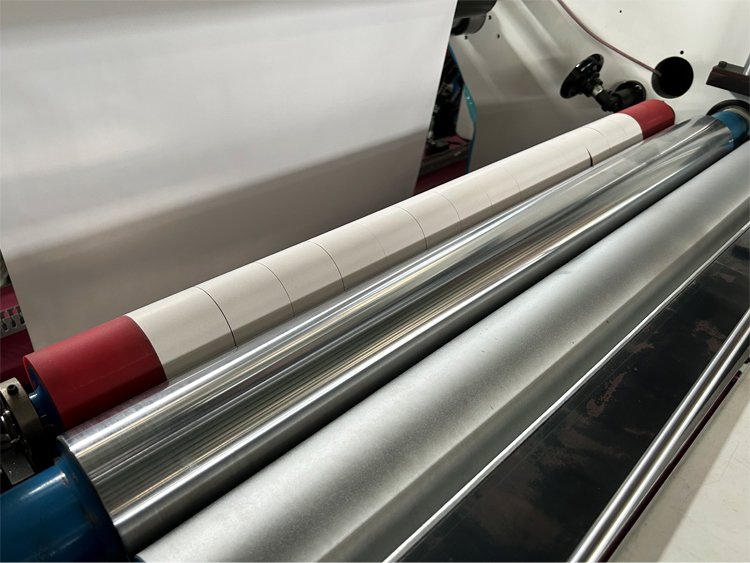

Unwinding Section | Shaftless hydraulic jumbo roll loading unit. |

| Fully automatic tension controller. | |

| 20kg/m2 electromagnetic brake from Taiwan. | |

| Web guiding photoelectric senor. | |

| Direction adjustable balancing roller, it ensures the roller itself always keep in tight touch with the web surface. | |

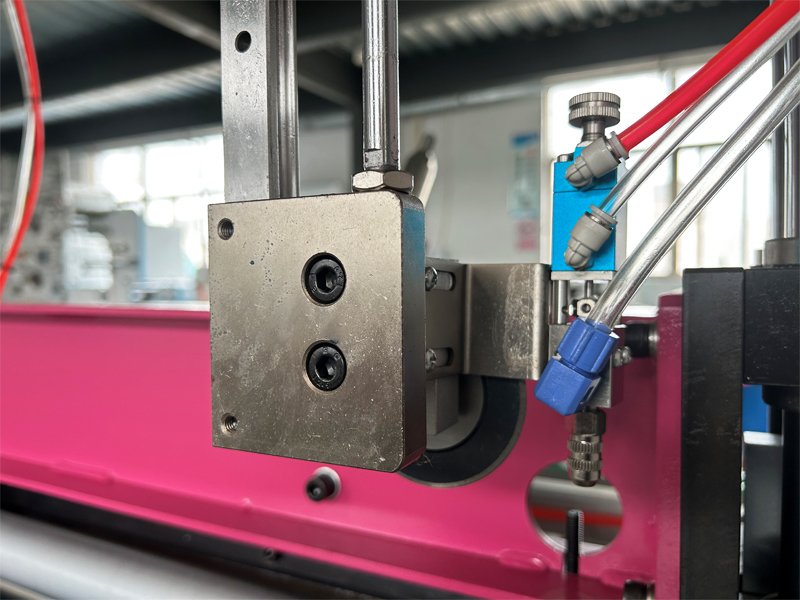

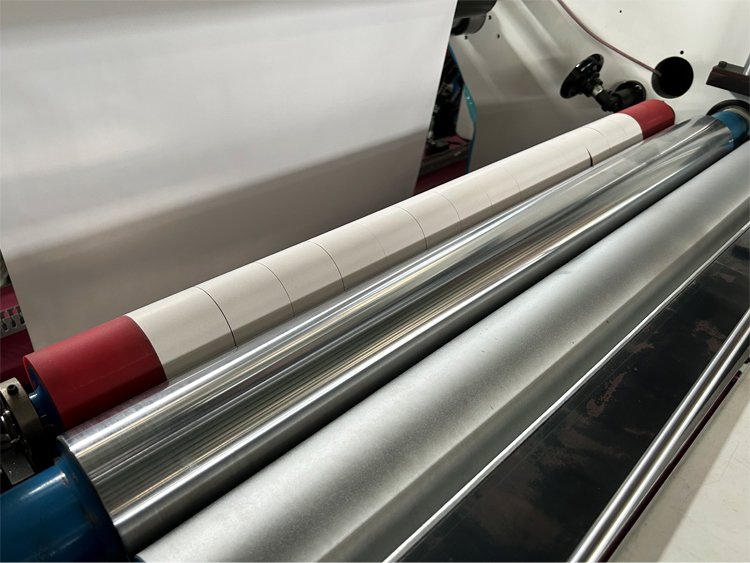

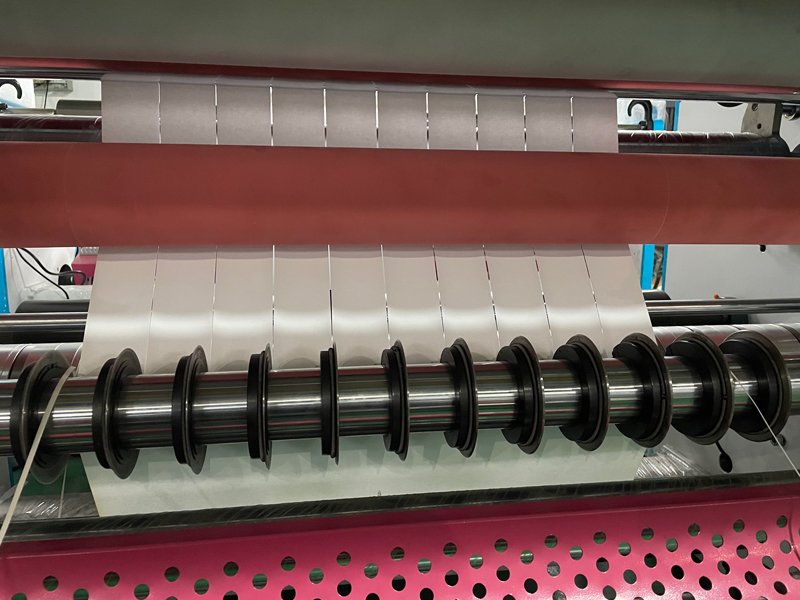

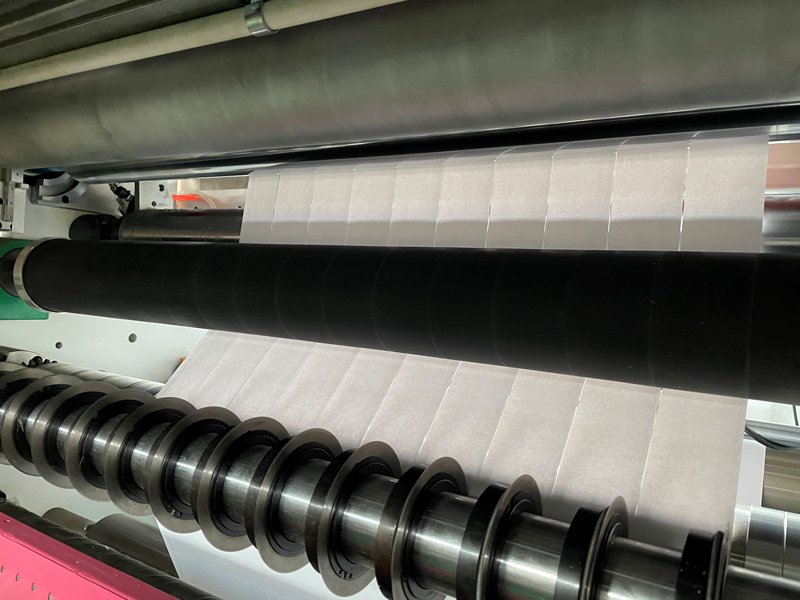

Slitting Section | The upper circular knives are fixed by screws, and the lower circular knives are fixed by the aluminum spacer, cutting precision can be guaranteed. |

| The rotary encoder automatically metering slit length. | |

Rewinding Section | Automatic tucker tucks the tail, convenient for quickly trigger rewinding. |

| 90° vertical lay-on roller, capable of moving up and down, ensures more balanced left and right pressure, wider rewinding diameter could be realized. | |

| The overlapping problem could be avoided with a banana roller. | |

Controlling Section | Siemens PLC module, touch control screen, and graphic user interface (HMI). |

| Yaskawa AC drives for Siemens master motor. | |

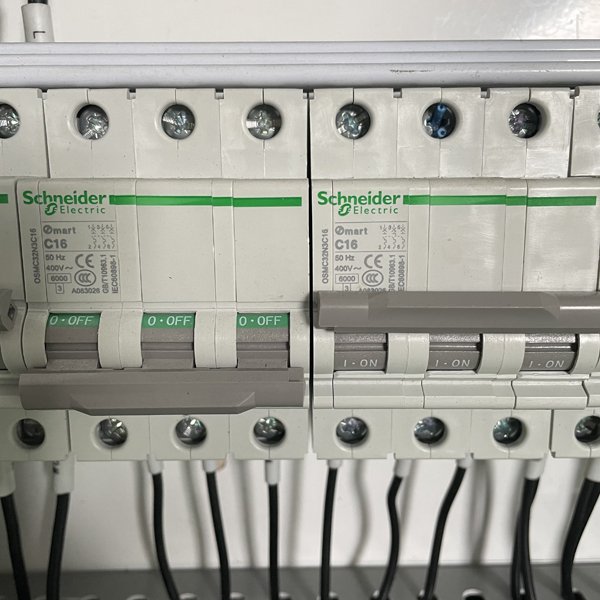

| Schneider low voltage electrical appliances. | |

Waste Removing | Edge waste blower through expulsion tube. |

Optional Parts | Safety guard. |

| 4 corners emergency switches. | |

| Automatic core loader. | |

| Blower and shredder. | |

| Automatic tail cutting and gluing unit. | |

900mm Width Thermal Cash Register Paper Roll Slitting Machine JT-SLT-900C

Last Update Time:23/08/2023

The thermal cash register paper roll slitting machine is Jota Machinery’s main push product,.

If you are searching for such a machine, let me tell you more details about it based on our knowledge and rich experience in this field.

The newest video from Jota Machinery for the JT-SLT-900C cash register paper roll slitting machine with 3-color flexo printing machine

A thermal cash register paper roll slitting machine is also called a thermal paper slitter rewinder.

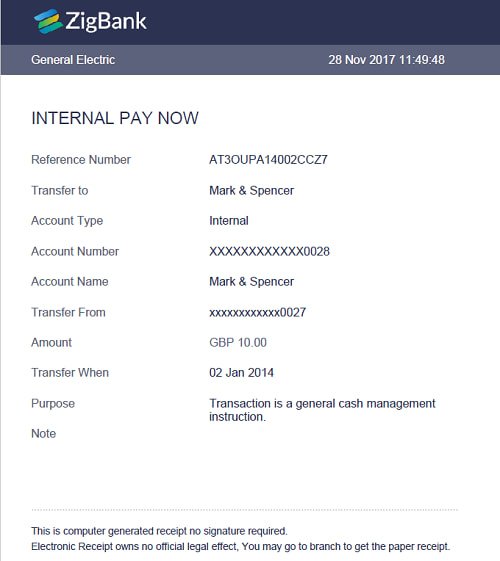

It is capable of cutting a jumbo roll of thermal receipt paper into several narrower till rolls, paper ATM rolls, roll POS, fax paper rolls, etc.

Some of the freshmen don’t know how to do or don’t know how to solve the issue when operating our slitting machine then we made a page for frequent troubleshooting and solution. Kindly check this page

The narrower till rolls could be furtherly installed in POS, automatic cash registers, ATMs, thermal printers, swipe machines, and adding machines for printing.

In order to introduce our thermal cash register roll-making machine more clearly to you, I would like to present it according to different sections.

This type of cash register roll-making machine, consists of the unwinding section, web-feeding section, slitting section, rewinding section, controlling section, waste removing section, etc.

The tension control is the most important part of Jota’s thermal cash register roll production.

With the existence of automatic tension control, the whole running process tension is constant, the winding effect can be guaranteed.

Generally, the tension control section consists of a load cell sensor, tension controller, and electromagnetic brake.

The tension sensor feeds back real-time tension to the tension controller, the tension controller calculates it, then feeds the result back to PLC, PLC sends the command to the electromagnetic brake.

Electromagnetic brake uses magnetic powder as a medium to form a magnetic powder chain, when the magnetic powder chain is stimulated by the excitation current, it will transmit torque, and the unwinding can be controlled by different torques.

As for the slitting section, Jota thermal cash register paper roll slitting machine usually equips with a dual knives system, proactive lower circular knives, and slave upper circular knives, accurate slit widths could be guaranteed with such shear cutting.

We also supply a fully automatic knife positioning system to simply your slitting size adjustment, if you are interested in it, please let us know.

After slitting, the thermal paper goes to the rewinding shaft and was wound to several pcs terminal roll.

Compared with 900mm width economical model JT-SLT-900 cash register roll making machine, this high-end JT-SLT-900C thermal paper roll slitting machine has many advanced features.

These advanced features are highly appreciated by many clients.

When Jota boss Bruce went to visit 2 Saudi Arabia clients’ sites, they all stood in front of our thermal cash register paper roll slitting machine, gave a thumbs up to our camera lens.

Maybe you are interested in these 2 Saudi Arabia clients’ success stories after reading here, learn more things and gain more experiences about the thermal paper roll business, please feel free to send us an inquiry on the website, we are willing to share more with you.

For customers sending an inquiry through Jota’s website, we Jota could offer more upper blades and lower blades for you as a backup once you order Jota’s thermal paper slitting machine.

As Jota Machinery is the leading thermal cash register paper roll slitting machine manufacturer in China, there are over 1200 installations over the world, our rich experience in this industry could assist you greatly save time and energy.

The roots create the fruits, quality is the cornerstone of Jota Machinery gaining trust from customers around the world.

Many clients suddenly contact us for small component replacement after 4-5 years of silence.

Each time we receive such mail, we could feel the client’s satisfaction overflowing from each word.

We also supply the inkjet printer for date coding on the side surface of the thermal paper rolls, please check the following video:

Thermal Cash Register Paper Roll Slitting Machine Purchasing Guide

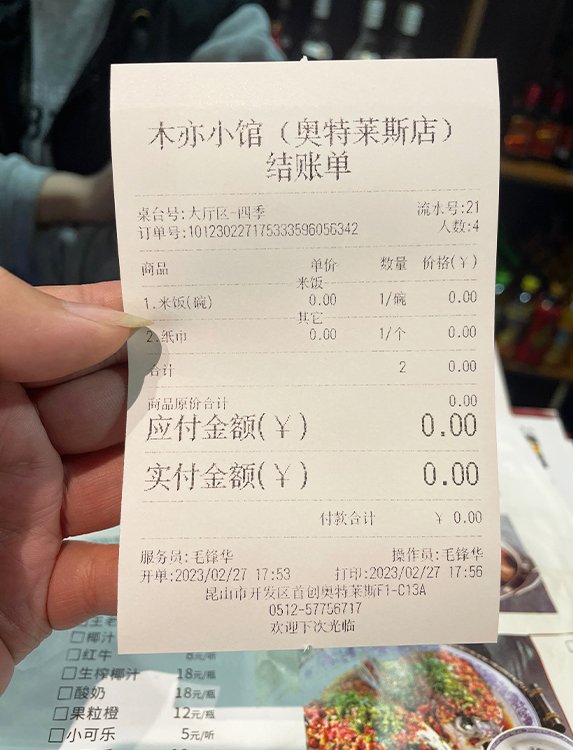

Thermal Paper Rolls

Thermal Paper Rolls

Thermal paper rolls are mainly applied in the:

- Point of sales (POS)

- Automated teller machine (ATM)

- Cash register

- Credit card machine

- Visa card machine

- Mobile printer

- Thermal printer

- Adding machine

- Swiping machine

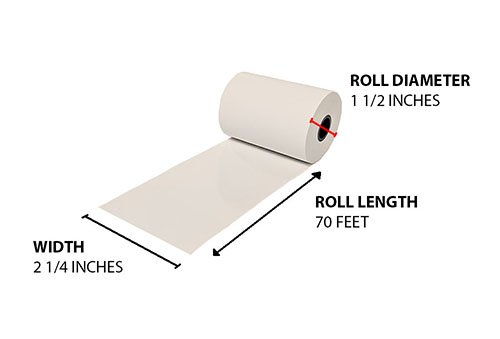

Thermal paper rolls’ mainstream width includes 3 1/8″ (80mm) and 2 1/4″ (57mm) widths.

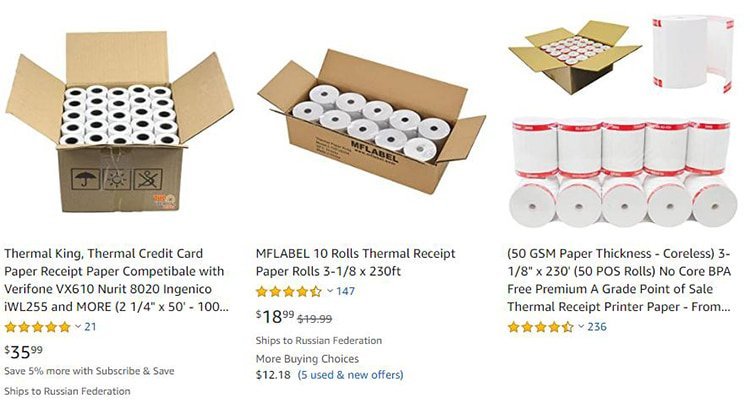

Thermal Paper Rolls Price

There are many ways to check the current thermal paper rolls price, such as Amazon, Aliexpress, etc.

Please check the following photo, it displays thermal paper rolls price for your reference.

Thermal Paper Rolls Price For Reference

Thermal Paper Rolls HS Code

Thermal paper rolls HS code is 4816901000.

Thermal Paper Rolls 80mm

Thermal paper rolls 80mm is widely used in automated teller machine (ATM)

The European and American countries usually use inches to indicate thermal paper rolls width, 80mm width thermal paper rolls are 3 1/8″ POS paper rolls in Europe and America.

Thermal Paper Rolls Wholesale

You could import thermal paper rolls from China, then wholesale them in your local market;

Or you could purchase a thermal paper roll slitting machine, make thermal paper rolls yourself, then wholesale it to your own country’s dealer.

If you own a thermal paper slitting machine yourself, you could control thermal paper rolls’ quality and delivery time, this is the biggest advantage.

Thermal Paper Rolls Manufacturers

There are many thermal paper roll manufacturers here in China.

If you are willing to spend much of your priceless time and energy to filter out the most suitable one, you could get a good result in the end.

As a professional thermal paper roll slitting machine manufacturer, we Jota certainly hope you could purchase our thermal paper roll slitting machine.

If you really insist on importing thermal paper rolls directly from China manufacturer, we could also recommend a suitable one for you.

1 more friend is 1 more way.

Thermal Paper Rolls For Credit Card Machine

The credit card machine is also called POS terminal, POS machine, credit card terminal.

Such terminal could be loaded with thermal paper rolls, print out the billing record of each credit card payment.

Thermal Paper Rolls 2 1/4

2 1/4 is Anglo-American length unit, 2 1/4 inches is about 57mm, thermal paper rolls 2 1/4 stands for 57mm width thermal POS till rolls.

3 Inch Thermal Paper Rolls

3 inch thermal paper rolls actually refer to 76mm width thermal paper rolls, its popular applications include Axiohm A756 Series, Ingenico Scribe 612, Star TSP200 Series (serial no. below 930), TSP200-120, TSP200-24 (width adjustable) thermal receipt printers.

Thermal Paper Rolls Sizes

| 1 7/16″ (37mm) x 18′ (5.5m) | Blood pressure monitor machines, stopwatch printers, tv and radio eas systems |

| 1 1/2″ (38mm) x 165′ (50m) | Epson TM-L90, Royal Alpha 9180SC |

| 1 3/4″ (44mm) x 220′ (67m) | ERA410, ERA450T |

| 2 1/4″ (57mm) x 50′ (15m) | VX520, Nurit 8000, FD400, ICT200, etc |

| 2 1/4″ (57mm) x 70′ (21m) | Verifone VX520, Blue Bamboo H50 |

| 2 1/4″ (57mm) x 85′ (26m) | Verifone Omni 470, EBW Auto Stik 950 |

| 2 1/4″ (57mm) x 165′ (50m) | Nurit 2080, Citizen CBM262 |

| 2 1/4″ (57mm) x 230′ (70m) | AZT P281-PD |

| 2 5/16″ (58mm) x 209′ (64m) | Gilbarco pay, Gilbarco crind pay at pump |

| 2 5/16″ (58mm) x 400′ (122m) | Dresser wayne pay at the pump |

| 2 5/16″ (58mm) x 170′ (52m) | Tokheim Premier Insight printer 729-0245 |

| 2 5/16″ (58mm) x 338′ (103m) | Tokheim Premier C |

| 2 7/16″ (62mm) x 285′ (87m) | Dymo 400 printer, QPay Dymo 400 printer |

| 3″ (76mm) x 225′ (69m) | Ingenico Scribe 612, Star TSP200 series |

| 3 1/8″ (80mm) x 90′ (27m) | ZT8090 |

| 3 1/8″ (80mm) x 119′ (36m) | First Data credit card machine |

| 3 1/8″ (80mm) x 220′ (67m) | AZT 381PD, Beiyang BTP-2002-NP |

| 3 1/8″ (80mm) x 230′ (70m) | Citizen CT-S300 |

| 3 1/8″ (80mm) x 273′ (83m) | IBM 4610T1 Suremark |

| 4″ (102mm) x 80′ (24m) | Zebra RW 420 |

| 4 9/32″ (108mm) x 119′ (36m) | Samsung SRP 300, SRP 350 |

| 4 3/8″ (112mm) x 80′ (24m) | Red Jacket RLM 10000, Star Micronics TSP800 |

| 4 3/8″ (112mm) x 328′ (100m) | Seiko DPU414, DPU5442, Star Micronics TSP800 |

Thermal Paper Roll Business Plan

Regarding the thermal paper roll business plan, you need to know thermal paper roll business outlook in 10 years first.

E-receipts are becoming more and more popular and widely introduced in many aspects, fields, industries.

E-receipt replacing paper receipt’s trend is obvious, you should try your best to figure out the shrinking market, find an entry point into the business.

You must be familiar with this industry enough, you are able to integrate all aspects of resources, and are good at the production, sales, and marketing of thermal paper rolls, so that you have a greater chance of achieving success.

Thermal Paper Roll Slitting Machine Manufacturer

When you integrate all the resources of thermal paper roll industry, you definitely want to establish contact with as many thermal paper jumbo rolls, thermal paper slitting machines, and paper core or plastic core manufacturers as possible.

On this planet, there are thermal paper roll slitting machine manufacturers in many countries.

They provide different technological products and different slitting methods.

It is precisely because of the difference that the art of thermal paper roll slitting is varied.

The manufacturer with the longest history is Spain’s Lemu group, which was founded in 1963.

They are pioneers in thermal paper slitter rewinder machines, occupying a large market share in Europe and the Middle East, and Lemu incorporated the Brazilian company Borche in 2015. to supply a better sale after serving to the South American market.

I once saw a piece of X hand Lemu thermal paper roll slitting machine in South America.

It has a life span of more than 30 years.

Although it does not have any advanced electric control technology, it still works stably.

I think a good equipment manufacturer is just that.

A good paper roll slitter rewinder supplier is a process of time accumulation and customer reputation. Lemu is a role model for us in this respect.

Speaking of a company with a long history, there is another American innovative company called Jennerjahn machine.

This innovative company was founded in 1979 and is famous for its high-speed, accurate, and fully automatic thermal cash register roll slitting machine production line.

Our Canadian customer has two of their paper roll slitting machines, and the customers are full of praise for the technology of the machines.

Americans have always been ahead of the world in technological innovation, and the jennerjahn machine is just a microcosm of the American spirit.

A good slitting equipment supplier, only by continuous technological innovation, can it better match to more customer requirements.

We learned too much from our American counterparts.

There are also some thermal paper roll slitting machine manufacturers in India and Iran.

Their machines are basically semi automatic thermal paper slitting machines. Although various slitting methods are different, the technology has been constantly improving.

I believe their new slitting products will get better and better.

As a thermal paper roll slitting machine manufacturer in China, Jota Machinery has been committed to the creation and development of new technologies.

Although we are only a 20-year-old company, our mission is to empower the thermal paper industry to develop better.

We have gone from the simplest manual thermal paper roll slitter rewinder machine to the fully automatic thermal paper roll slitting machine production line. We have also gone for almost 10 years.

Around 2005, we only had a manu thermal paper slitting machine in hand. At that time, the focus of the thermal paper industry was fax paper and plotter paper.

The width was about 210mm, so the overall technical requirements of the machine were not high, only one meter.

And speed control, other actions are realized by time relay. The machine structure is very simple, but the control system is relatively complicated.

A certain relay has a problem at all times, and it needs to be checked manually one by one.

Later, because of the use of frequency converters.

The use of PLC and touch screen makes the control of the paper roll machine easier at once. Goodbye to the time relay, this is always troublesome for us.

As the demand for thermal paper increases, more and more 56mm and 79mm slitting sizes appear, we will encounter a very headache problem is an overlapping problem.

The thermal paper roll is easy to wrinkle during operation and then overlap.

At first, our engineers thought it was a problem with the accuracy of the paper slitter machine but later discovered that it was a problem with the pressure system and a tension problem.

Therefore, we have carried out a long period of research and improvement on these two issues and finally solved them well.

Every time a new technology appears, it means surpassing one’s own past experience, and it is also a baptism of one’s own industry experience.

And Jota Machinery has been on this innovation road.

At the same time, we are also exploring new technologies, and slowly we have auto tails cross cutting device and gluing, an auto core hooper loading machine, coreless thermal paper slitting machine, and automatic cash register thermal roll packaging line.

Every small step of success is a stage of our progress. On this road, we never give up.

The accumulation of technology is a long process, especially the accumulation of experience.

Only if you have enough customers and they can give you enough market feedback, can you quickly improve the stability and stability of your cash register paper roll slitter operational convenience.

In this regard, we, like the thermal paper roll slitting machine manufacturers in the world, provide customers with better equipment as well as service.

If you have some understanding of the technology of thermal paper slitting machines or new ideas, please feel free to contact us.

Relying on our strong industrial supply chain in China, we will definitely give you a solution.

Through your communication with so many original manufacturers, you could get more useful information, more competitive prices, and more timely after-sale technical support.

We Jota is original thermal paper slitting machine manufacturer with a professional team, please watch the following video for reference.

Fully Automatic Thermal Paper Roll Slitting And Rewinding Machine Price

Recently, we Jota has just released fully automatic thermal paper roll slitting and rewinding machine JT-SLT-1400FA,

From core feeding to finished roll packing, no need dedicated operator, inline printing function can also be integrated.

Please send us an inquiry on this website to get more details.

To know this JT-SLT-1400FA’s price, please send us an inquiry on this website, we will reply you timely.

POS Paper Roll Making Machine Price

If you are a POS paper roll supplier, you may be interested in buying one POS paper roll cutting machine to expand your present business.

As you know, A boat sailing against the current must forge ahead or it will be driven back, Only in uncertainty, find the most stable way to profit from the continuous progressing business.

Many of our customers’ stories like at the beginning, they are only a POS paper roll supplier for POS paper, receipt paper, bond paper roll wholesaling.

After some time, they found the pos paper rolls quality can’t be controlled by them, and the price has also fluctuated. It is depressing!

They will think buy one POS paper roll machine automatically slitting the small pos paper rolls.

But they don’t know the pos paper roll making machine price, they would contact some POS roll cutting machine supplier for inquiring a price.

Although the price has fluctuated, most of them will choose the right thermal POS roll cutting machine supplier at an acceptable price.

The POS paper roll business is hotter and hotter, and it has a higher requirement on technology, the pos paper roll should be slitted by the roll cutting machine automatically.

Less labor involved in, and a higher capacity to make a higher profit.

As a professional manufacturer of thermal roll slitting machines, we definitely supply you with a qualified POS paper roll cutting machine, please contact us for more pieces of information.

Mr. Ashwin, our Kenya customer has contacted us since 2017 on the double layer NCR paper roll slitting machine.

The customer’s workshop has 6 machines from Taiwan’s Dove, and 1 machine from Spain’s KMEC.

Mr. Ashwin has seen the rapid development of China mainland and feels that the quality of the machines made by Chinese machines is good and the price is reasonable, so he intended to have a trying on Chinese NCR paper roll slitting machine.

In the beginning, Mr. Ashwin has contacted many suppliers in China and was very satisfied with our machine quality and configurations, but he felt that the price of our NCR paper roll slitting machine was much more expensive than other suppliers.

After high efficiency communication, our machining lathe, assembly workshop, and machine manufacturing process online have left an impression on him.

After analyzing the differences and highlights of the machine, the customer happily accepted our machine configurations and price. Placed order to us in a short time.

What’s more, when the NCR paper roll slitting machine was in production, he makes a good customer reference to help us sold a 900 coreless thermal paper slitter rewinder machine to Tanzania. Million thanks!

During the Covid-19, we couldn’t dispatch our professional technician to Kenya for machine commissioning.

But Mr. Ashwin was professional and experienced on machines, they finally operated the machine smoothly under our long-term video view support.

So this is a movie made by Mr. Ashwin, he was so satisfied with our machine performances and shared this video with us. Please share our happiness!

Thermal Paper Slitting Machine For Sale In Germany

Selling Jota thermal paper slitting machine to Germany is always Jota’s relentless pursuit.

If Jota’s thermal paper slitting machine finally enters the German market, that means Jota’s technology accumulation in cashier paper slitting machine rising to a new level.

Jota thermal paper slitting machine is always for sale in Germany, the whole Jota professional team is willing to challenge customizing requirements.

As we know, most of Germany’s local slitter manufacturers and suppliers just supply standard configuration machines, they don’t accept any customization requests.

Customization is available with Jota, contact us to customize your dreamy or desired thermal paper slitting machine.

Do You Supply Thermal Paper Coating Machine Too?

The thermal paper coating machine is not covered in Jota’s business scope, but we could recommend a suitable source supplier for you.

Because Jota boss Bruce has been involving in this industry for nearly 20 years, and know many friends in this industry.

Bruce’s friends could definitely recommend a suitable supplier of thermal paper coating machines.

Bruce’s Boss Friends

Roll Cutting Machine FAQ Guide

- What is a roll cutting machine?

- What are the considerations I should put in mind when buying a thermal cash register paper roll slitting machine?

- How does a thermal paper roll cutting machine work?

- Why use a thermal paper rolling machine?

- What are the specifications of your thermal cash register paper rolling machine?

- What determines the price of cash register paper roll slitting machine?

- What is the maintenance procedure for thermal paper roll cutting machine?

- Can thermal paper roll cutting machine produce both core rolls and coreless rolls?

What is a roll cutting machine?

A roll cutting machine is a machine used to cut huge jumbo paper rolls into smaller rolls.

The smaller rolls then can be used as final products in either printing, packaging, or any other use.

Roll cutting machines are available in different sizes depending on their use.

Paper cutting and rewinding machine is one of the simplest machines which cuts rolled paper in needed amount and re-winded form.

Our roll cutting machine is manufactured using optimum quality components and advanced technology.

In tune with different requirements of our copious clients, we customize the entire range in various specifications.

At Jota Machinery, we ensure our roll cutting machine is available in a wide variety of specifications. All the specification must meet your exact requirement.

Our roll cutting machine is manufactured as per industry standards.

We use the best quality components and sophisticated technology under the guidance of our expert team.

In addition to this, clients can avail this machine from us in customized options and at market leading prices.

Some of the major use of role cutting machines include:

- Used in cutting rolls into cash register paper rolls.

- Making of point-of-sale (POS) paper rolls.

- Cutting of tissue paper rolls.

- Cutting of kraft paper rolls into required sizes.

- Cutting of pure pulp paper

- Cutting of corrugated paper into size.

- Coated paper cutting

- Cutting of double adhesive paper into various shapes and sizes as required.

- Grey board paper cutting

- White board paper cutting

- ATM machine paper roll cutting.

Paper roll cutting machines are considered for cutting jumbo rolls because of their effectiveness.

A good example of a paper cutting machine is the cash register paper roll slitting machine.

A cash register paper roll slitting machine is used in cutting jumbo paper rolls into useable cash register paper rolls.

This can then be fed easily into the cash register.

Paper roll cutting machines can be easily configured to cut different sizes of paper rolls.

This is advantageous because you will not need different types of machines.

It is a cost effective and efficient machine. Automatic thermal paper roll cutting machine can cut different width paper rolls.

It can also provide on-site roll paper cutting processing services.

Thermal paper roll cutting machines are widely used in paper mill, packaging, and printing factory for cutting the paper rolls.

It looks the same as a normal sitter but does not need a rewinder. This saves production time and reduces cost.

The paper rolls can then be soaked, wormed, or cut into bigger or special specification.

It all depends on customer demands and specifications.

You can use thermal paper roll cutting machine in your factory for cutting different width paper rolls.

Our paper roll cutting machines are simple and easy to operate. They also come in manageable weights and sizes. This ensures that they save your workshop or factory space.

What are the considerations I should put in mind when buying a thermal cash register paper roll slitting machine?

Thermal cash register paper roll slitting machine are machines that are used in cutting of thermal paper into smaller sizes.

Thermal paper rolls are special coated paper that is used in printing.

The thermal paper is used mainly in ATM receipts and POS systems receipts.

This makes a thermal cash register paper roll slitting machine very important.

With the increase in cashless transactions, there has been an increased need in thermal paper sue.

This is because of the increased dispensing in receipts.

If you work in a paper mill, it is important that you acquire a thermal cash register paper roll slitting machine.

It is important to not miss in this growing business.

Thermal paper slitter rewinders are basically used to cut large jumbo paper rolls into smaller paper rolls.

This small paper rolls can be fitted in items such as tills, ATM, POS systems, and fax.

The great thing with thermal cash register paper roll slitting machines is that it can cut jumbo paper rolls into very small rolls. It is considered because of its precision.

Before you acquire a thermal cash register paper roll slitting machine, there are some things you should consider.

This is important in getting the most out of your cash register paper roll slitting machine.

Some of the considerations that you should put in mind include:

Unwinding section

The unwinding section of a thermal cash register paper roll slitting machine works easily.

It involves unwinding the jumbo paper roll. This readies it for the slitting section.

The most important factor to consider here is the tension of the jumbo paper roll.

Tension is how straight and firm the jumbo paper roll is.

Tension is important in ensuring that the jumbo paper roll does not break during slitting.

The tension control is the most important part of Jota’s thermal cash register roll production.

With the existence of the automatic tension control, the whole running process tension is constant, the winding effect can be guaranteed. Some of the important sections of the tension control section include:

- Load cell sensor

- Tension controller

- Electromagnetic brake.

Our thermal cash register paper roll slitting machines use the latest technology in tension control.

The tension control is monitored electronically.

Our paper roll cutting machines come equipped with a digital touch screen.

You can use it in controlling the tension. It also can be used in giving out diagnosis of the paper roll cutting machine.

With an electromagnetic brake, our roll cutting machines will ensure that you get the desired quality of thermal paper rolls.

It helps you control the torque of the machine.

This subsequently help avert breakage of the parent roll. Buy from us to ensure quality and value for your money.

Web feeding section

The web feeding section is where the jumbo paper roll enters the slitting section.

It consists of rollers that hold the web of paper and direct it to the slitter head.

The web is held at a constant angle and tension.

This is to ensure that the web does not break or deform.

Slitting section

The slitting section of the cash register paper roll slitting machine is where the jumbo paper roll is cut.

The cut is done to the required lengths and widths, here the round disc cutters are set according to the required lengths and widths. Jota thermal cash register paper roll slitting machine usually equips with a dual knives system.

The cutting method that our Jota thermal cash register paper roll slitting machine apply is shear cutting.

Here, a bottom placed round disc cutters work with an upper round disc cutter.

They work in tandem and produce a scissor like cut. It produces very clean cuts of very high quality.

It is important that you ensure that the round disc cutters are always well set and aligned. This is to avoid having uneven cuts. Blunt round disc cutters will also lead to uneven edges.

Rewinding section

After slitting, the thermal paper goes to the rewinding shaft and was wound to several pieces’ terminal rolls.

Each smaller roll is rolled according to its end use.

Some rolls that are not needed immediately can be stored for further slitting when need be.

Ensure that you clear the rewinder section of any final product to prevent your roller cutting machine from clogging.

Our cash register paper roll slitting machine come with an automatic ejector.

Controlling section

The controlling section of our cash register paper roll slitting machine can be either manual or automatic.

The manual paper roll machine comes equipped with control buttons.

The different buttons control different components of the paper roll cutting machine.

On the other hand, automatic cash register paper roll slitting machine come equipped with a digital screen monitor.

Here all the process are controlled centrally.

By a click of a button, you can switch your roll cutting machine on and off.

The digital screen also gives you the ability to monitor your paper roll cutting machine.

Any mechanical issue with the thermal paper roll cutting machine will be shown on the screen.

Most our client prefer our machines because they incorporate the latest technology.

You can order our cash register roll slitting machine in any mode you like.

What we can guarantee you is that any module works perfectly.

The only difference is in the control. If you are a hands-on kind of individual, you can choose a manual module.

If you like integrating technology in your work, you can choose an automatic module.

Waste removing section.

The waste removing section is at the rewinder section where all the unwanted pieces can be removed.

The slitter section also has a waste removal outlet.

This allows wastepaper that is not needed to be removed. It is essential in ensuring that the paper roll machine does not clog.

Clogging of the cash register roll slitting machine can lead to poor quality final small size rolls.

It can also affect the tension and angle alignment of the web.

The round disc cutters can also get distorted from clogging.

Ensure that you collect all the wastepaper around the cash register roll slitting machine.

This is essential in avoiding injuries related to slips, trips, and falls. Remember, a clean work environment is a safe environment.

It is important that you follow our safety manual in operating the cash register roll slitting machine.

This will come with all the machines that you purchase from us.

How does a thermal paper roll cutting machine work?

Thermal paper roll cutting machines are used in producing thermal paper that can be used in different aspects.

A thermal paper roll cutting machine is used to cut jumbo paper rolls into smaller rolls. The smaller rolls are used to make thermal paper rolls used in thermal printers.

They are also used in devices such as credit card terminals, cash registers, tickets, POS, invoice, and rewinders.

Thermal paper rolls are also widely used in credit card terminals within the retail, catering, gaming, financial, government, hospitality sectors.

Production of thermal rolls has long been seen as a small manufacturing business.

But the business is growing with the increased demand for thermal paper rolls.

You will never go wrong with our state-of-the-art paper roll cutting machines.

With our thermal paper roll cutting machine, we guarantee you a return of your investment.

Our thermal paper roll cutting machine is precisely designed and constructed.

This is to ensure that it meets the standards that effectively meet the requirements of Fax Roll.

To produce thermal paper rolls, it takes 3 simple steps to produce thermal paper rolls.

Lifting the Jumbo Roll and setting it into position

The principle of the thermal paper roll cutting machine is simple.

The paper roll cutting machine uses the slitting and rewinding machine to cut the jumbo paper roll into small sizes.

The small thermal roll sizes are cut into the shape and size you want.

The first step involves lifting the jumbo paper roll into place.

Jumbo paper rolls are usually heavy. For larger productions, you can use a forklift in lifting the jumbo roll.

After lifting ensure that the jumbo paper roll fits perfectly into the holding roller.

Some of the common jumbo roll sizes include:

- 636mm x 6000m

- 795mm x 5800m

- 405mm x 6000m

- 565mm x 6000m

- 558mm x 5500m

- 790mm x 6000m

You should ensure that the jumbo roll you choose fits the requirements of the small roll sizes you want.

Different paper materials will require different jumbo paper sizes.

To avoid wastage, it is critical to ensure that the jumbo roll is divided correctly. If not careful, you might risk a lot of wastage.

A good example of utilizing your jumbo paper roll is if you want to produce an 80mm width thermal roll.

You can use the 405mm, 558mm, or 636mm width jumbo roll.

If you want to produce a 57mm width thermal roll size, you need to use a 565mm jumbo roll.

Make sure the jumbo roll size and small roll size are divided exactly.

You should also ensure that the paper roll is aligned perfectly. Another major thing to regard is the jumbo paper roll tension.

All this serve to enhance quality of your small thermal paper rolls.

The jumbo paper roll should be cut in sizes that can fit in the cash register, point of sale machine, or the ATM receipt dispenser.

Adjusting the round disc cutter

This is a crucial step when it comes to thermal paper roll cutting.

The round disk cutter must be adjusted to the correct position and size.

You should also ensure that the round disc cutter corresponds to the type of paper set for cutting.

When setting your round disc cutter, ensure that you adjust them to the specifications of the machine they will be used on.

For example, if you have an Epson printer that uses 80mm rolls you should ensure that you leave a bit of space.

Your actual roll width will be 79mm to make sure the rolls run smoothly through the mechanism.

If you cut to the exact printer width, the paper roll might get stuck on your printer.

It is worth noting that certain factors may guide you when choosing the round disc cutter to use.

Some types of round disc cutters are used for tough paper rolls while others are used to cut jumbo rolls that need fine edge details.

Some of the factors you should consider include:

- The tension of the jumbo paper roll.

- The type of paper or material being slitted with the paper slitter machine.

- The size of the parent paper roll (jumbo paper roll).

- The texture of the rolling paper being slitted.

- The size of the final rolling paper you require.

- The speed of the paper slitting machine

- The designs of the final rolls the customer required.

Ensure that you use a well sharpened disc cutter when cutting the paper roll.

Thermal paper cutting machines also come equipped with multiple disc cutters.

The disc cutters can be adjusted either manually or automatically.

Our thermal paper roll cutting machines round disc cutter also can be configured to be either automatic or manual.

Automatic disc cutters are controlled automatically through a central control unit.

Manual round disc cutters are usually adjusted by the operator.

The operator must adjust the disc cutters by hand whenever they require a certain size of slitted paper roll.

The settings and configuration depend on your requirements.

At Jota Machinery, we ensure the highest quality of machinery.

We will provide you with the highest quality of round disc cutters that give smooth clean cuts.

Quality description of our round disc cutters for thermal paper roll cutting machine include:

- Our round disc cutters are made from ultra-fine raw powder with suitable grade formula selected by professional material engineers.

- Our paper cutters have different usage grade to meet your different demands.

- The round disc cutters are made using quality equipment and unique pressing and sintering techniques.

- We ensure that the cutters have the required hardness.

- All our round disc cutters and pneumatic cutters meet the required standards and regulations.

- All our round disc cutters have a high bending strength. This ensures that you get clean and precise paper roll cuts.

- High excellent impact toughness

- Our round disc cutter edge is scientifically mirror polished and ground three times making it sharp and smooth.

- We have high anti corrosion chemical inertness thermal paper roll cutters.

- No blade breakage or blade rolling which is guaranteed.

- High abrasion resistance.

- The cutting resistance is small, so it is wear-resisting.

- The disc cutter is free from burrs and curls, which can significantly improve the class and appearance of processed products.

Our guarantee on long lasting round disc cutters mean that you will great reduce the frequency of breakdowns.

It also reduces the frequency of shutdown and tool change.

Quality round disc cutters greatly improve your production efficiency and reducing your production cost.

Besides paper, you can use our high-end round disc cutters in products such as:

- Adhesive tape

- Plastic film

- Electric wire

- Rubber

- Chemical fiber

- Aluminum foil.

- Multi-layer packing material

- Leather cloth

- Printing cigarettes

- Food packaging

For more information about round disc cutters, feel free to contact us. You can also share with us your specifications and we will gladly assist you.

Cutting the jumbo paper roll into smaller roll sizes

After lifting the jumbo paper roll and setting into place then adjusting the cutters, you can then start the cutting process.

Before powering the thermal paper roll machine, ensure that the jumbo roll is stable in the shaft.

After setting up the jumbo paper roll in the shaft, you can then power on your thermal roll cutting machine.

The thermal paper roll cutting machine will then cut your jumbo paper roll according to the specified configurations.

If your thermal paper roll cutting machine is automatic with a digital control interface.

Keep an eye on the digital counter to monitor the lengths of the rolls.

The monitor will also show the tension of the paper roll.

Ensure that the tension and stability is controlled for clean cuts.

Adjust the knives and monitor for any deviation or bluntness.

If the round disc cutters do not give a clean cut, you should either sharpen or change them.

Ensure you adhere to the manufacturer’s instructions and manual.

Ensure only qualified personnel operate the thermal paper roll machine.

Also, the cutting of the jumbo roll to small paper rolls should be closely monitored.

Never assume that an automatic thermal paper roll cutting machine does not need standby personnel.

A small mistake that is not identified early can lead to great losses.

Why use a thermal paper rolling machine?

A thermal paper rolling machine can assist you in all your thermal paper roll products.

Thermal paper is a special paper type that has a chemical coating on its surface.

Thermal papers are highly effective when it comes to first printing capabilities.

They are also efficient in being used with dispensing machines such as ATMs and POS systems.

They are flexible and can be cut in any paper roll sizes.

The working of thermal paper rolls is also simple.

When the paper goes through a thermal printer, heat from the print head causes the chemical coating to activate.

This forms an image of high definition. Unlike regular paper, this process uses heat to start a chemical reaction within the paper itself.

So, it does not require a ribbon or toner, making it more manageable than other options.

Thermal paper roll products can be used in thermal printers, cash registers, and POS systems.

They are also used in credit card terminals within the retail, catering, gaming, financial, government, hospitality sectors.

At Jota Machinery, we ensure that we provide the best quality of thermal roll cutting machine.

Our thermal paper roll cutting machine can cut different sizes of thermal roll widths.

There are numerous benefits you can get from using our thermal paper rolling machines. Some of these benefits include:

Clean cut

Our thermal paper machines are equipped with quality round disc cutters.

This ensure that your jumbo paper roll gets a clean, clear cut.

The thermal paper roll machine come equipped with double for cutting head.

One for approaching the roll (fast) and another for cutting (which has been scheduled).

The cutting head initiates its lateral movement immediately after the blade has released the roll.

This process of cutting ensures that lead times are achieved. This is due to the decreased production time.

The roll round disc cutter is specially fitted with a built-in cutting head for easy sharpening whenever it is required.

Similarly, it integrates a blade lubrication system that allows the cutting of fuses or fusible materials.

Cost effective.

At Jota Machinery, we always ensure that you get the best machines at affordable prices.

You are guaranteed value for money when you place your order with us.

The best thing is that you do not even need to come to our China offices.

Just place your order through our online platform. Our work will be to ensure that your thermal paper roll reaches you.

We ship internationally following strict international shipping guidelines.

At Jota Machinery, we will also assist you in getting the best shipping agents in the market.

This will save you valuable time and money.

We will also assist you in the payment of the required duties and licenses.

It is important to also be proactive in your shipping processes to avoid certain charges.

These charges may include warehousing fees and extra taxes associated with storage.

We ensure that we help you avoid extra charges on your thermal paper roll machine.

Quality thermal paper roll cutting machine.

As earlier stated, we at Jota Machinery ensure that quality is adhered to.

Our paper roll cutting machines are the best in the market.

The quality processes at Jota Machinery are continuous.

We ensure that quality is adhered to from the material acquisition stage to the final product.

We also ensure that our paper roll cutting machine meets the industry’s standards.

We are open to quality audits and ensure we adhere to the rules and regulations.

We ensure that every automatic thermal paper roll cutting machine meets the client’s country standards.

Some of the standards that we adhere to for our paper roll cutting machine include:

- CE Approvals for Slitting Machine

- ROHS certificate for Europe Union market

- GB/T 13328-2005

- China’s Compulsory Certification (CCC)

- American National Standards Institute (ANSI)

- Robotics Industry of America (RIA)

- Instrument Society of America (ISA)

- National Fire Prevention Association (NFPA)

- Underwriters Laboratories, Inc. (UL)

By adhering to the set standards, we ensure that you get the best machines in the market.

Feel free to call and inquire on the certification requirements.

It is worth noting that different roll cutting machines will require different certifications. This ranges depending on their use, size, and design configurations.

Integration of the latest technology

At Jota Machinery, we ensure that we integrate the latest technology in manufacturing of paper roll cutting machines.

All the components of the cash register paper roll slitting machine are the latest in the market.

Our paper roll cutting machines are available both in automatic and manual modules. This gives you a great flexibility when it comes to choosing the correct paper roll cutting machine.

You can easily adjust the round disc cutters from the digital monitor.

This can also be used to check the rollers.

You can also use the monitor in adjusting the tension of the paper web. The tension control is the most important part of Jota’s thermal cash register roll production.

With the existence of the automatic tension control, the whole running process tension is constant, the winding effect can be guaranteed.

All these are integrated with your paper roll cutting machine. The control is centrally placed to motor the working of your paper roll cutting machine.

You can also carry out machine diagnostics using the central monitoring system.

Our thermal paper roll cutting machine is incorporated wit the latest technology. In case of a breakdown, the digital screen will indicate the course of the issue.

Various uses

Our thermal cash register paper roll machines can be used in different ways.

Not only will you be able to cut clean cut cash register receipts. You will also customize the thermal cash register machine to make products such as ATM receipts and POS receipts.

At Jota Machinery, we are flexible in our design processes. We will design the cash register paper roll machine according to your specifications.

This will give your business more room to diversify your products. It also means that you can cut the jumbo paper roll into sizes you want.

Having the ability to put your paper rolling machines into various uses means you customer base will grow.

This is by having a wider variety of customers.

What are the specifications of your thermal cash register paper rolling machine?

At Jota machinery, we ensure that every product that we make meets the required standards and specifications.

We also give room for you to make your specifications.

Our designers and engineers are always ready to engage with you.

We can customize the cash register paper rolling machine to fit your exact specification.

All our thermal cash register paper rolling machines have specific specifications.

These specifications are standardized.

This is to give you an idea of how your paper roll cutting machine would look like.

The specifications are categorized according to the different sections of the cash register paper roll slitting machine.

Some of the specifications of our thermal cash register paper rolling machine include:

Unwinding section

The unwinding sections specifications include:

- A shaftless jumbo roll loading unit. This allows the jumbo paper roll to be loaded and readied for slitting.

- Equipped with a fully automatic tension controller.

- Our paper roll cutting machines also come with 20kg/m2 electromagnetic brake from Taiwan.

- The cash register paper rolling machine also has web guiding photoelectric sensor.

- Direction adjustable balancing roller. This ensures the roller itself always keep in tight touch with the web surface.

Slitting section

This is the section where the jumbo paper roll is cut into smaller paper rolls. Some of the specifications of this section include:

- The upper round disc cutters are fixed by screws. On the other hand, the lower disc cutters are fixed by aluminum spacer. This serves to enhance the cutting precision.

- The rotary encoder automatically metering slit length.

Rewinding section

The rewinder section is where the different slitted small paper rolls are rewinder back into smaller rolls. The specifications for this section include:

- Automatic tucker tucks the tail, convenient for quickly trigger rewinding.

- 90° vertical lay-on roller. This moves up and down enabling a more balanced left and right pressure.

- A banana roller to avoid the problem of slitted paper overlapping.

Controlling section

This is a centralized control that serves to control the cash register paper rolling machine. The specifications for this section include:

- Siemens PLC module, touch control screen, and graphic user interface (HMI).

- Yaskawa AC drives for Siemen’s master motor.

- Schneider low voltage electrical appliances.

Waste removing section.

This is the part that removes the wastepaper from the cash register roll slitting machine.

It ensures that the machine is clean from debris to avoid it from clogging. A major specification of the waste removing section includes:

- Edge waste blower through expulsion tube.

Optional parts

Some of the optional parts that can be installed in your cash register roll slitting machine include:

- 4 corners emergency switches.

- Safety guard

- Blower and shredder

- Automatic tail cutting and gluing unit.

What determines the price of cash register paper roll slitting machine?

There are different factors that determine the price of your cash register paper roll slitting machine. Some of these determinates include:

Taxes and custom duties paid.

The taxes and custom duties paid will determine the price of your cash register paper roll slitting machine.

It is important that you factor this in your paper roll cutting machine budget.

At Jota machinery, we will endeavor to connect you with the best shipping agents.

Exercise duties payable are mainly incorporated in the final price of our paper roll slitting machines.

We work hard to ensure that there are no hidden charges for your purchases.

We encourage you to pic your machine immediately after manufacturing. This will avoid you incurring extra charges.

These charges include cost of storage and warehousing.

We will also advice you on the best way to go about your shipping and taxes.

Sometimes problems might occur from the taxes you need to pay here in China and those you need to pay in your home country.

As much as we will offer guidance, it is important to seek clarification on the same from local authorities.

Our customer care line and agents are always available if you need clarification on the same. Feel free to call us.

Shipping costs

We understand that shipping cash register paper roll slitting machines can be hectic.

This is because the machines are usually a bit huge.

They also attract a slightly higher tax and shipping charges. To minimize your costs, we ensure that we connect you with the best shipping agents.

You can also do more research from your end on the best shipping agents between your country and China.

Also ensure that you insure your cargo against unforeseen circumstances.

This might include storms, shipwrecks, typhoons, earthquakes, or fires. Insuring your cash register paper roll slitter machine is important. You will get compensated in case of the events.

At Jota Machinery, we offer tracking of your machine, and we will give you periodic updates on the whereabouts of your paper roll slitting machine.

Any damages that are factory related we will take the responsibility.

You can either ship the machine back to us or request for our technician to come to your shop. Call us for any clarifications on replacements and returns.

Customization

The level of customization of your cash register paper roll slitting machine will also affect its final price.

Customized paper roll cutting machines are slightly expensive.

This is because we must install them with more features and halt our product line.

Manufacturing of customized paper roll cutting machines means reconfiguring our production line.

Our customization services are pocket friendly. Feel free to contact us for clarifications on customizations. Also contact us for customization requests.

Usage

Different paper cutting machines have different prices.

The usage of the paper roll cutting machine determines its specification and configuration.

The more the higher the parameters and specifications, the more expensive the paper roll cutting machine.

Technology and machine model

At Jota Machinery, we ensure that we utilize the latest technology.

Our latest cash register paper roll slitting machines are equipped with the latest technology.

This includes a Siemens PLC module, touch control screen, and graphic user interface.

The technological upgrade means that the cash registrar paper roll slitting machine price will be slightly higher.

The older models are slightly cheaper compared to the new ones.

We can also upgrade your cash register slitter machine to the latest configurations. At Jota Machinery, we also deal with spare parts for your paper roll slitting machine.

The drives and electrical appliances and wiring is done through utilization of the latest manufacturing technology.

Our cash register paper roll slitting machines are also fully automated. We guarantee you value for your money.

Size

The size of your cash register paper roll slitting machine also affects its price.

The bigger the machine, the more expensive it will be. This is because bigger paper roll cutting machines allow for bigger jumbo paper rolls.

Bigger jumbo paper rolls mean more small size paper rolls for the cash register.

Bigger paper roll cutting machines also are efficient compared top the smaller ones.

If you have large consistent paper roll orders, it tis important that you chose the bigger size roll cutting machines.

With bigger cash register paper roll cutting machine, you will need not order another one. Those are some of the considerations that you should put in mind to save costs.

Number of cash register paper roll slitting machines bought.

At Jota Machinery, we give discounts on high number of orders.

Place your cash register paper roll machine order with us. we encourage you to place more orders with us to save on the overall purchase price.

The more your orders the lower the price you pay per item.

We have a variety of machines that you can buy from us besides the cash register paper roll slitting machine. Some of our other products include:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine

Feel free to call us and place your order of any paper cutting and slitting rewinder machines.

What is the maintenance procedure for thermal paper roll cutting machine?

For your cash register paper roll slitting machine to last longer, you should do regular maintenance. All our paper roll cutting machine come with a repair and maintenance manual.

Before you embark on maintenance, you should put the following in mind:

- Ensure that you are qualified or qualified personnel undertakes the maintenance procedure.

- Ensure that the area you want to undertake the maintenance is clean ad free from debris.

- Check that all the electrical components are in their terminals.

- Switch of the power and put a safety lock before maintenance.

- Use appropriate safety signs when doing maintenance.

- Ensure that you wear the right personal protective equipment (PPE) while carrying out maintenance.

- For larger cash register paper roll cutting machines, ensure that you have someone to assist you in the maintenance.

After following the safety procedures, you can begin the maintenance protocols of your paper roll machine.

Different paper roll cutting machines require different maintenance procedures.

Some of the common steps of carrying out maintenance include:

- Ensure that all the electrical terminals are switched off before you start your maintenance procedure.

- The first thing is to make a 360-degree check on your cash register roll cutting machine. Ensure that you check all the parts.

- Note down any missing components all parts. Also note any loose wires or broken electrical terminals.

- Ensure all the oiled parts are oiled and greased accordingly. Use the recommended lubricants for your cash register roll slitting machine to last long.

- All the replacement parts for your paper roll cutting machine should be manufacturer recommended. Using parts that are not recommended will lead to your machine breakdown.

- For critical maintenance, contact us on the right procedures to go abut it.

- Do not use strong bleach and aerosols in in cleaning your cash register paper roll slitting machine.

Can thermal paper roll cutting machine produce both core rolls and coreless rolls?

Yes, our roll cutting machines can produce both core and coreless rolls.

This all depends on your machine settings and specifications.

When you order from us, just specify your paper roll cutting machine specifications.

You can order a combined roll cutting machine that can produce both the core rolls and the coreless rolls.

At Jota Machinery, we have integrated the latest technology in all our manufacturing process.

Expect high quality machinery from us that meet all your specifications.

Our designers and engineers are available and flexible.

Feel free to share with us your design ideas and we will incorporate them in your specified paper roll cutting machine.

We Jota could also manufacture the following related machines, if you are also interested in any type, please feel free to send us an inquiry.

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine