JT-1500C High Precision Paper Core Cutting Machine

- Each cut just takes only 0.5s

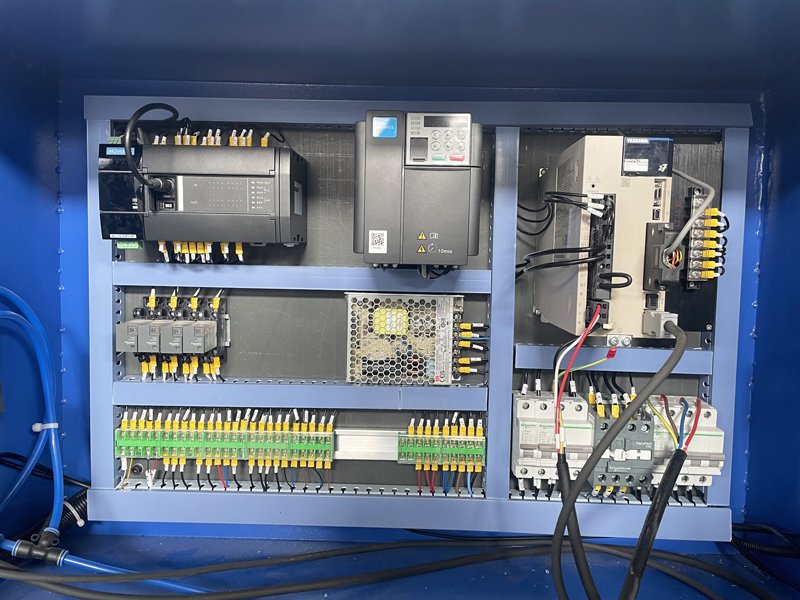

- PLC control and touch screen HMI

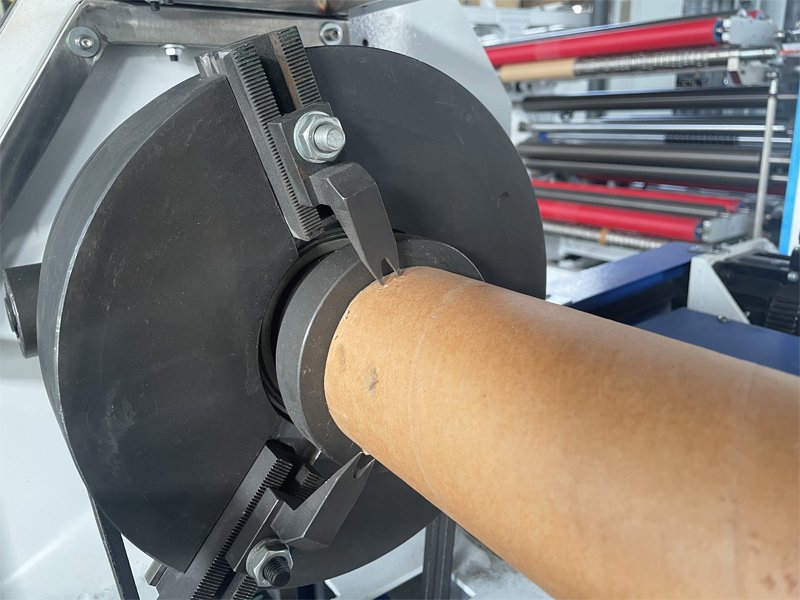

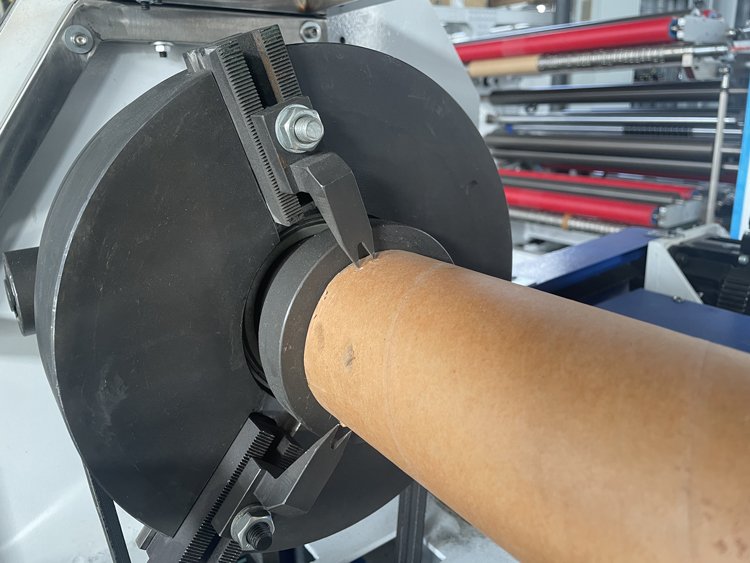

- Automatic tri-locker to clamp the paper core

- 121 years old US company Sonoco’s choice

- Specification

- Video

| Parameters | |

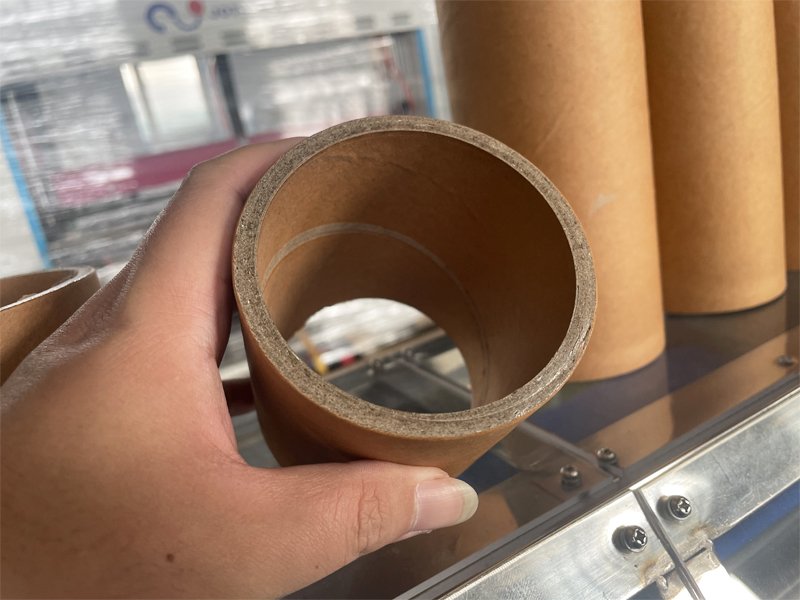

| Tube Diameter | 25mm-200mm |

| Tube Length | 10mm-1500mm |

| Tube Thickness | 5mm-18mm |

| Blade Moving Speed | 300mm/s |

| Cutting Precision | 0.1mm |

| Mandrel Rotating Speed | 150RPM-1000RPM |

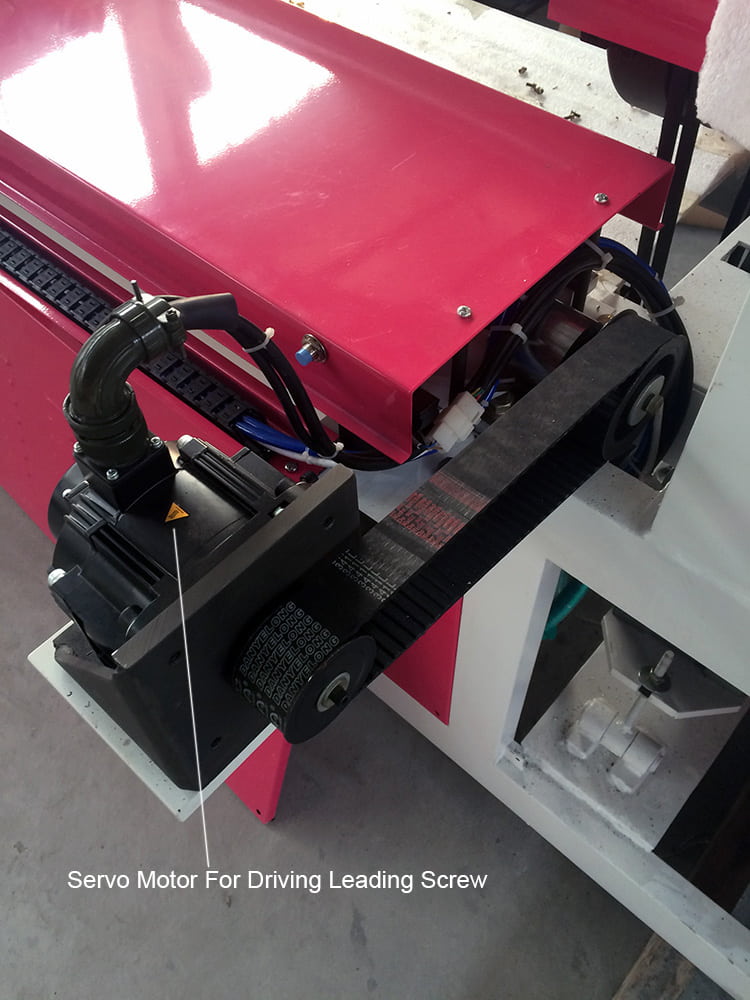

| Servo Motor | 0.75Kw |

| Working Pressure | 0.4Mpa-0.6Mpa |

| Rotating Motor Power | 4.0Kw |

| Voltage | 380V, 3 phase, 50Hz |

| Total Weight | 1000Kg |

| Overall Dimension | 3000mm x 1100mm x 1370mm |

| Specifications |

| 1. Each cut only takes 0.5s. |

| 2. PLC control system and touch screen HMI, all the parameters could be preset and displayed on the screen. |

| 3. Automatic stop function, after each cut, the machine will stop automatically. |

| 4. Automatic tri-locker to clamp the paper core. |

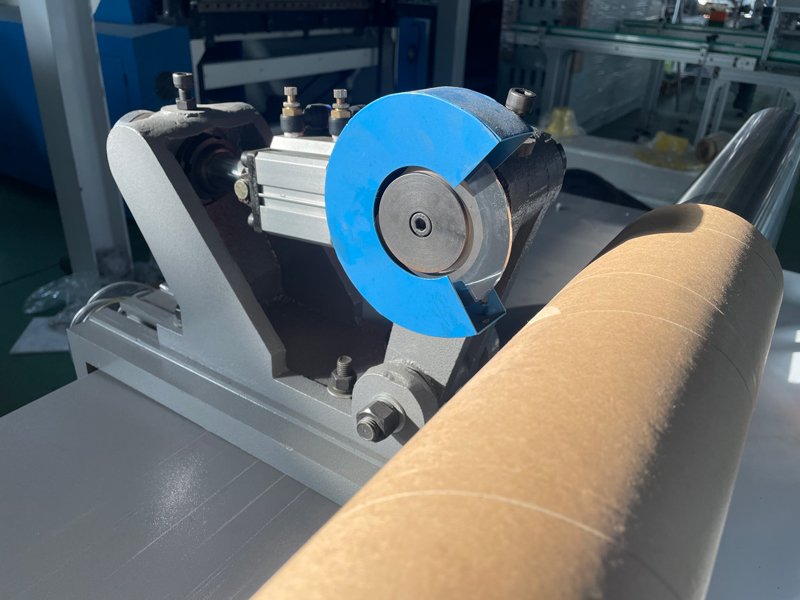

| 5. Servo motor drives round knife, Yaskawa AC drive controls servo motor, high precision. |

| 6. Auto-diagnosing function, all the errors could be displayed on the screen, easy for repairing. |

| 7. CNC processed high precision tungsten steel blades, cutting precision is around 0.1mm. |

JT-1500C High Precision Paper Tube Cutting Machine

Last Update Time:27/10/2023

With excellent performance and durable quality, the JT-1500C high precision paper core cutting machine is sold all over the world.

As a traditional packaging consumption field, paper tube plays an increasingly important role in our daily lives.

Many high-end packaging could be turned into a beautiful packaging box by means of converting paper tube curling, capping/sealing, and labeling

In addition, the paper tube has a very important use in many printing factories or material factories, that is, it is used as the core of paper or film.

As a supplier of professional slitter rewinder machines, we have found that almost every customer has a certain demand for paper tubes.

If the demand is relatively small, manual paper tube cutting machines can be used.

If the demand is relatively large, automatic paper tube cutting machines can be used.

No matter what it is, you need a paper tube cutter machine definitely to get your suitable paper tube length.

The paper tube core cutting machine I recommend is a PLC control medium-sized tube cutting machine.

Because of its simple operation and quick action, it has been recognized by customers all over the world, especially in Mexico and Saudi Arabia.

You only need to set the length of each cutting tube in advance on the touch screen, and the machine will automatically complete it.

It is not difficult to cut the paper tube, you can even use a saw to cut it directly by hand, but the section will be unsightly. A good paper tube cutting machine should have precision and speed, and be free of dust. The machine I recommend to you is very satisfying, and the price is acceptable.

Based on past experiences, our engineers have optimized the working model of the machine.

At present, the paper tube rotates. Both mandrel and core cutter are fixed methods, so the speed is 0.5 seconds/cut, and the accuracy is 0.5mm.

It can meet the cutting precision requirements of almost all customers.

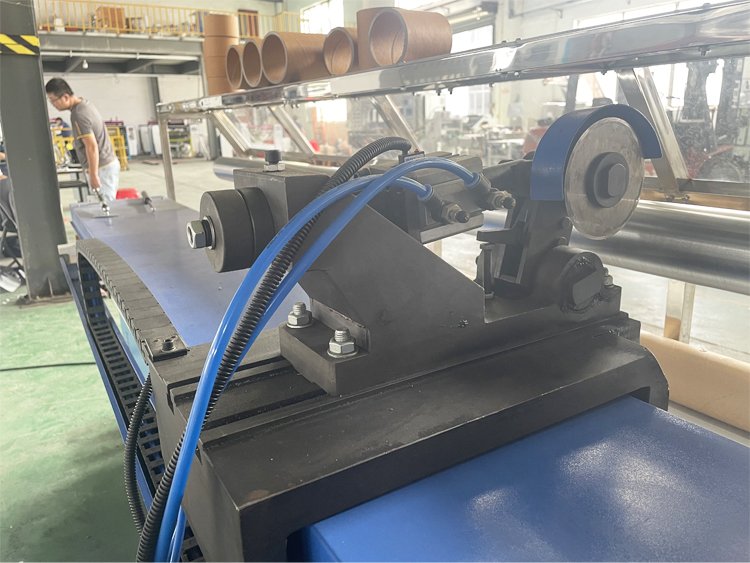

In addition, this paper tube recutting machine is equipped with a Yaskawa servo motor, which is used to control the accuracy of the knife displacement with the aid of the slider and the track, which is quiet but accurate.

Fortunately, the US giant client Sonoco also purchased this precision cardboard tube cutting tool, they requested us to customize 2500mm and 3700mm width cardboard tube cutting tools according to their requirements.

Sonoco was founded in 1899.

After 121 years of development, Sonoco has grown into the world’s largest manufacturer of composite cans, cores, tubes.

Now, Sonoco has over 19,900 staffs working in 33 different countries.

Sonoco’s Mexican Factory

Before Sonoco got cooperated with we Jota, they have searched for precision paper tube cutter supplier in China for a long time, and selected several suppliers as candidates.

We Jota is one of these candidates.

In order to compare the quality of each candidate supplier’s paper core cutter, Sonoco purchased sample paper tubes from each alternative supplier for testing.

After testing, Sonoco believes that Jota’s paper core cutter machine is very in line with their requirements, and some special selling points are especially attractive to them.

- Tube cutting accuracy.

Servo motor for cutting width control, high-hardness tungsten steel knife for rapid cutting, tube cutting tolerance is within 0.1mm.

High-hardness Tungsten Steel Knife

- 10 groups of different cutting widths could be preset.

And the tube cutting width could be changed during the working process.

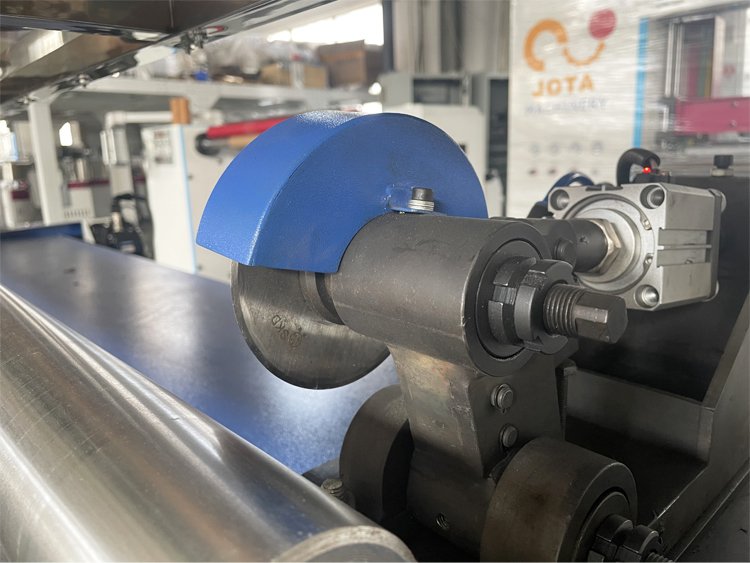

- For core cutting, only the paper tube rotates, the blade engages the rotating paper core, both blade and mandrel don’t rotate.

In this way, it could effectively protect the cutting blade and mandrel, prolonging these 2 components’ service life.

- Jota cardboard tube cutter machine comes with an automatic diagnosis function.

If the machine fails, errors will be displayed on the touch screen in real-time.

With such a function, Sonoco’s operator could determine the cause of failure, quickly find the problem and solve it, finally reduce the cardboard tube cutting tool downtime.

- Safety cover is optional for your choice.

Due to the above outstanding selling points and stable operation of the JT-1500C paper core cutter machine, we Jota won Sonoco’s initial trust.

Subsequently, our General Manager and Chief Engineer flew from China to Sonoco’s Mexican factory.

Jota not only just go there providing after-sales service, but also deeply understand Sonoco’s scenario.

This series of actions made Sonoco fully feel Jota’s extreme service and cooperation sincerity.

As the paper tube cut by Jota’s paper tube cutter is of good quality, looks beautiful, and has fewer burrs, Sonoco got the order of Fuji Seal, a major Japanese company.

Tube Cutting Samples

Fuji Seal purchased a large number of paper tubes from Sonoco for winding labels material, such as shrink sleeve labels, self-adhesive labels (pressure sensitive labels).

Joint Photo with Sonoco and Fuji Seal Workers

In order to meet Fuji Seal’s higher requirements for paper tubes.

Sonoco customized 2500mm and 3700mm width, 6-inch mandrel paper tube cutter from us, to further expand production capacity and enrich paper tube categories.

The customized 3700mm width precision paper tube cutter was just shipped to Mexico on May 25, 2020, when it reaches Sonoco’s factory.

Its paper core output will be increased by about 150% compared to the 1500mm width machine.

3700mm long Paper Tube Cutting Machine for SONOCO

Customized 3700mm Width High Precision Paper Tube Cutter

JT-1500C High Precision Paper Tube Cutting Machine FAQ Guide

Paper tube packaging continues to play an increasingly vital role in our lives today.

This packaging method is used in a boatload of industries, from cosmetic industries to food industries, among others.

Paper tubes also have a very important role in many print factories, where they are used as the core of paper or film.

There are reasons why paper tubes are swiftly phasing out the traditional packaging methods.

Paper tubes and cardboard boxes are lightweight, durable, and cost-effective.

Being both light and strong means plastic tubes are easier to transport and can ship more products with less packaging material needed.

Likewise, by using less packaging material, paper tubes result in significant reductions in energy use and waste.

They are also eco-friendly and can cut down greenhouse gas emissions, thus contributing to environmental conservation.

If you are looking to venture into the paper tube business or paperboard production, Jota Machinery is ready and willing to support you.

As the leading supplier of professional slitter rewinder machines, we know that customers have different demands for paper tubes.

In light of these ever-changing demands, Jota offers three different types of kraft paper tube-making machines to suit your needs.

These include a kraft paper slitter rewinder, a tiny paper tube manufacturing machine, and a paper tube recutting machine.

This exhaustive FAQ guide breaks down everything you need to know about the JT-1500C High Precision Paper Tube Cutting Machine. Read on to learn more about this revolutionary paper tube cutter from Jota Machinery.

What is a Paper Tube?

Before we talk about the JT-1500C high precision paper tube cutting machine from Jota, it would be great if you know what a paper tube actually is.

A paper tube is a packaging tube made of paper or paperboard sheet layers that are rolled with a metal mold and glued together to form a strong, hollow, and usually cylindrical shape.

Both paper and paperboard can be sourced from pulp, plant fibers, or cellulose.

In most cases, paper is less than 12 points (or 0.12 inches) thick, while paperboard is more than 12 points thick.

The most common type of paper used in manufacturing paper tubes is kraft paper.

This type of paper is stronger than the stationary or white type of paper. In fact, the word “kraft” loosely translates to strength in German and Swedish languages.

Usually, paper tube manufacturers laminate and bind the paper layers using adhesives. You’ll want to know that paper tube production requires high tack and very quick setting properties.

For that reason, dextrin adhesives are mainly used in the tube winding industry.

These adhesives have low viscosity. That means they improve the running speed of your winding equipment and increase your overall production efficiency.

After the tube is formed, the binding glue or adhesive must be left to dry fully before the tube can be cut.

If the paper tube is to be used for packaging, then it would need additional steps like slotting, die-cutting, sealing, capping, and end forming.

These additional steps help produce a shipping tube, composite can or paper canister. A closure feature is added onto a paper tube to make tubular composite packaging materials like a paper can or mailing tube.

What is JT-1500C Paper Tube Cutting Machine?

Now that you know what a paper tube is, let’s move on and discuss the JT-1500C cutting machine. So, what’s it?

Put simply, this is a machine designed for cutting long paper tubes into shorter pieces to match the desired application.

It’s in your best interest to know that paper tubes go by several names, all of which mean the same thing.

In some quotas, paper tubes may also be known as paperboard tubes, cardboard tubes, cardboard tubes, paper cores, paper cans, composite cans, fiber tubes, fiber drums, paper tubing, or wound tubes.

In pretty much every application, shorter pieces of the paper tube are needed to meet the intended use. They can be used to roll different materials, including paper, film, label, and more.

There is no doubt that cutting the paper tube is a piece of cake. In fact, you can use a saw to cut it directly by hand.

But there is a catch—cutting the paper tube by hand may make the section look unsightly.

To mitigate this problem, you will need a good paper cutting machine that is fast, precise, and free of dust.

The JT-1500C paper cutting machine meets these requirements, and the price is reasonable.

Pioneers in the industry, Jota’s paper tube cutting machine has a simplified design for ease of operation.

It also allows for blazing fast paper tube cutting, with each cut taking just 0.5 seconds to complete.

Jota engineers have optimized this machine for absolute precision.

The paper tube rotates, while the mandrel and core cutter are fixed. This provides an accuracy of around 0.5mm to meet the cutting precision requirements of most customers.

For added precision, this paper tube cutting machine runs on a 0.75Kw Yaskawa servo motor.

With the aid of the slider and the track, the servo motor controls the accuracy of the knife displacement, ensuring high precision.

What Specs Does JT-1500C Cutting Machine Have?

As mentioned previously, customers have different demands for paper tubes.

Several parameters play a crucial role when it comes to paper cutting, such as max tube length, max tube thickness, and max tube diameter.

It’s important that you’re clear about these parameters when selecting your paper cutting machine.

That being said, here are the parameters of the JT-1500C high precision paper cutting machine:

Max Tube Length: 10mm to 1500mm

Max Tube Thickness: 5mm to 18mm

Max Tube Diameter: 25mm to 200mm

In order to ensure the highest cutting precision, this paper tube cutter comes with CNC processed high precision tungsten carbide steel blades.

Tungsten carbide has been used in industrial cutting applications for almost a century.

Tungsten carbide leaves a better surface finish of the cutting edge.

Likewise, it leaves little or no dust on the cut surface, ensuring more accurate cuts due to minimal friction. In addition, tungsten carbide has better durability.

Alloying tungsten with carbon significantly improves its toughness.

In Moh’s hardness scale, tungsten carbide occupies a level of hardness of around 9. As a result, it has greater wear resistance than many other materials.

The JT-1500C paper cutting machine is designed for speed. Its mandrel rotates at a speed of 150-1000RPM, while its blade spins at 300mm/s. Set at optimum speed, each cut would only take 0.5s. That’s pretty quick!

The importance of speed in paper cutting production cannot be underestimated.

Having a fast-manufacturing process means you’re able to fulfill orders in a shorter period of time. Consequently, it’s possible to meet changing demand levels.

For automation purposes, the JT-1500C features a programmable logic controller (PLC) and a touchscreen human-machine interface (HMI).

This allows you to give directions and receive feedback in the manufacturing process.

In other words, all the parameters in this paper tube cutter could be reset at any time.

And the machine will display your chosen parameters on the screen in real time. This feature or component allows for effective operation and control of the machine from your end.

Why Use Jota JT-1500C High Precision Paper Tube Cutting Machine?

With excellent performance and unmatched durability, many clients all over the world prefer the JT-1500C over other run-of-the-mill paper cutting machines. This medium-sized tube cutting machine is engineered for simple operation and quick action.

To operate the machine, all you need to do is set the length of each cutting tube upfront on the touchscreen.

Then the machine will automatically do the rest. Customers from across the globe, especially those from Mexico and Saudi Arabia, have applauded the JT-1500C for the following reasons:

- Tube Cutting Accuracy

The accuracy of the final product will determine whether or not the paper tube will fit your desired application. An inaccuracy as small as a fraction of an inch could cost you wasted product, money, and time.

The JT-1500C paper tube cutting machine features the servo motor for cutting width control, an automatic tri-locker for clamping the paper core, and a high-hardness tungsten steel knife for rapid cutting.

This combination ensures the length and wall thickness of the final product are accurate.

- Customizable Cutting Widths

Being able to customize your paper tubes makes it possible to meet your customers’ specific needs.

This involves customizing the widths, diameters, and core sizes of your paper tubes. The JT-1500 presents up to 10 groups of different cutting widths.

It is also possible to change the tube cutting width during the cutting process.

Thanks to the PLC control system and touchscreen HMI, all the parameters can be changed and displayed on the screen. This enables you to create your product to your specifications.

- Components’ Service Life

The ideal paper tube cutter should offer much more that precision and ease of use.

It should also be durable. The JT-1500C is assembled from durable and sturdy materials for maximum outputs and lifespans.

For paper tube cutting, the paper tube rotates, whereas the mandrel and core cutter remain fixed.

As a result, the cutting blade and mandrel are effectively protected from the rotating paper core.

That way, the two components’ service life is prolonged.

Jota Machinery engineers put in hours of scientific research and development to produce machines that stand up to the test of time. Each machine is backed by a one-year warranty, a box of vulnerable parts, and whole life technical support.

- Automatic Diagnostic Function

The JT-1500C paper tube cutting machine goes over and above quality, efficiency and precision.

It integrates an automatic diagnosis function that’s responsible for monitoring errors for easy repairing.

If the machine fails, for example, the auto-diagnosing function displays all errors on the touchscreen in real-time.

Ideally, this diagnostic program determines the operational status of the machine and provides the user with guidance regarding any problems found during its operation.

With such a function, it’s easy to identify the cause of the fault and solve it based on the analysis of the symptom values.

In the end, it reduces the paper tube cutting machine downtime and improves productivity.

- Safety At Its Best

It is obvious that the JT-1500C high precision paper tube cutting machine is designed to improve production efficiency in paper production.

However, it has moving parts, sharp edges, and hot surfaces that can cause serious injuries, like crushed fingers or hands, amputations, or burns.

To mitigate the likelihood of these problems, the machine includes an optional safety cover.

The safety guard covers moving gears and blades to guarantee your safety during operation.

Furthermore, this paper cutting machine includes an automatic stop function.

The machine is designed to stop automatically after completing each cut. This eliminates the likelihood of crushed fingers or hands, ensuring safety from start to finish.

What’s more, the JT-1500C complies with the stringent requirements for Health and Safety and conforms to all the latest European CE standards.

Will JT-1500C Paper Tube Cutting Machine Meet My Needs?

As the leading supplier of professional slitter rewinder machines, we’ve come to learn that the demand for paper tubes varies from one customer to another.

In order to recommend the right paper tube cutting machine for you, you’ll need to tell us what specs of the paper tube you want to produce.

The actual specifications we would like to know to include the paper tube length, paper tube thickness, paper tube inner diameter, and so on.

The JT-1500C will be your ideal machine if you plan on producing paper tubes with a tube length of 10mm-1500mm, the thickness of 5mm-18mm, and inner diameter of 25mm-200mm.

Giant US company Sonoco’s choice, the machine is optimized to be fast, precise, and free of dust.

It can meet the cutting requirements of nearly every customer. Furthermore, you can request us to customize the machine to fit your paper production needs.

For example, when our giant client Sonoco bought this precision paper tube cutting machine from us, they asked us to customize 2500mm and 3700mm width, 6-inch mandrel paper cutter to match their requirements.

We did exactly as they had requested. And now, Sonoco has increased its production capacity by up to 150% compared to the standard 150mm width paper tube cutting machine.

The company has also enriched its paper tube categories to serve diverse customer demands.

That said, if your demand is relatively small, we recommend the JT-600 manual paper tube cutting machine.

This is an economical model that can produce paper tubes with a thickness of 0.5mm-15mm, the inner diameter of 35mm-152mm, and length of 30mm-600mm (customizable to 1000mm).

The JT-600 is suitable for cutting different sizes, including long-length paper core and high output narrower core.

It gives you very clean, accurate, and burr-free cuts.

This ensures your core cutting process is simple and cost-effective. What’s more, this manual paper core cutting machine is versatile.

That is, it not only cuts paper tubes or cardboard, but it could also cut plastic cores without compromising quality and accuracy.

Of course, there are much more features you need to know about Jota JT-600 manual paper core cutter. You might want to call us to learn more.

For those whose paper tube demand is relatively large, we recommend the JT-SL-2000C fully automatic paper core cutting machine.

It can produce paper tubes with a thickness of 4mm-15mm, inner diameter of 50mm-152mm, and length of up to 2000mm.

Being a fully automatic machine, it doesn’t require a dedicated operator.

Even delicate tasks like parent core feeding and kid core collecting are fully automated. Plus, all the parameters are down on the touchscreen in real-time and can be changed at any time.

Why Should We Choose Jota Machines?

At Jota, boast of more than 1200 trusted clients from across the world.

We take pride in a wonderful team of qualified and passionate engineers. Once allocated a task, our engineers go above and beyond to ensure the finished machine is excellent.

No matter what your needs are, we’re ready to take the challenge and assemble your machine in line with your unique requirements.

In order to understand your needs better, we request that you contact us so we can discuss this in detail.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply the following related machines, if you are also interested in high precision paper tube cutter machine, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine