Leading Label Die Cutting Machine Manufacturer

- Die-cutting, rewinding, and waste stripping in 1 pass

- PLC control, graphic touch screen HMI

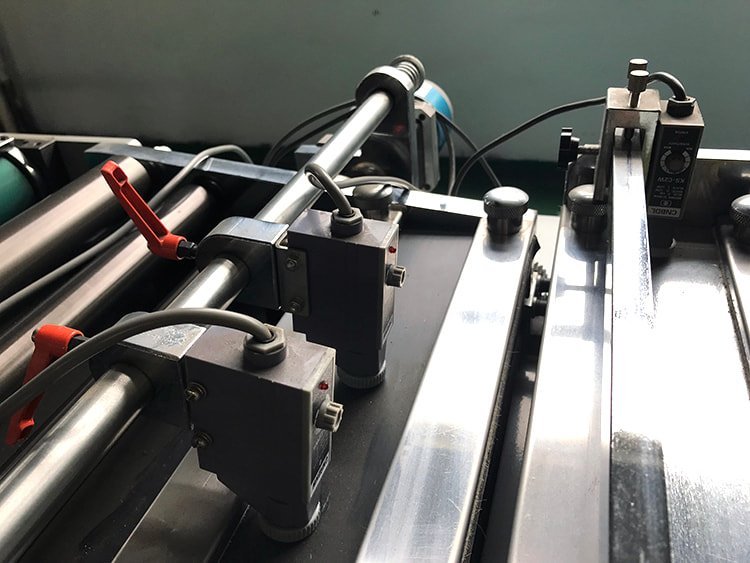

- 2 sensors web guiding, 1 sensor register tracking

- Optional punching, laminating or hot stamping unit

Label Die Cutting Machine

Jota label die cutting machine could produce plain labels, stickers for small to medium run.

Many optional parts are available, such as punching unit, laminating unit, hot stamping unit.

Please submit your inquiry on this website, we will reply to you based on our expertise and experience.

Flatbed Label Die Cutting Machine

Jota Machinery: Flatbed Label Die Cutting Machine Factory in China

As Jota is the original label die cutting machine manufacturer,

you are always welcome to make a video call with us via WhatsApp,

we will show you around our factory and CNC center through the camera lens.

Jota Factory

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Why Jota Label Die Cutting Machine

Last Update Time:26/12/2023

Label die cutting machine is applied for mass production of sheet labels, logos, stickers, etc.

Generally speaking, this machine’s working process is from web unwinding, feeding to die cutting, and finally waste stripping and collecting.

Jota Label Die-cutting Machine

Of course, if you have deeper requirements for die cut sticker machine, it could be customized or added as your request, such as slitting and rewinding, laminating, hot stamping, etc.

2 main types of die cut sticker machines are optional for your choice, one type is flat bed die cut sticker machine, the other is rotary sticker die cutting machine.

These 2 types of die cut label machine have their own features, and they can meet different client’s requirements.

Their main difference is that they equip with different dies, of course, each type has its own pros and cons.

Cutting Die

Rotary die cutting machine pros

- Fast speed, high efficiency, and labor-saving;

- Automatic waste removal when engaged in complex processes;

- Large output;

- Small footprint, save space.

Rotary die cutting machine cons

- Price is higher than flatbed die cutting machine, the investment is higher;

- The cutting die cost is higher;

- It is incompetent when die cutting tolerance requirement is high.

Flatbed die cutting machine pros

- Relatively lower price than rotary type;

- The cutting die price is relatively lower;

- Die-cutting accuracy is higher than the rotary type.

Flatbed die cutting machine cons

- In the production of complex processes, waste removal is manual, with higher labor costs.

Now, you basically understand die cut sticker machines, and it is helpful for you to decide which type of die cut label machine you need.

Please feel free to contact us for a deep discussion, we will assist you in customizing your dreamy label flatbed die cutter, as our expertise has been fueled by rich experience.

Jota Factory

Jota CNC Center

Jota QC

Label Die Cutting Machine Ultimate FAQ Guide

Adhesive Label

- Adhesive label meaning

- What is adhesive sticker?

- Self adhesive label

- Adhesive label HS code

- Adhesive label specifications

- Adhesive label company

- Types of self adhesive labels

- What type of paper is used for labels?

- What are the different types of labels?

- What is the difference between a label and sticker?

- Adhesive label printing machine

- Adhesive label printing company

Adhesive label meaning

The adhesive label is also called sticky label, it can be stuck on the object surface for info marking.

It consists of face paper, adhesives, and release liner, and it is produced by label die cutter machine through printing, die-cutting, etc.

Different from traditional labels, in the process of using self-adhesive labels, no need to brush glue, no need to paste, no need to dip it in water, which can save the labeling time;

And the adhesive label does not pollute the environment, it is an environmentally friendly product;

In addition, the self-adhesive label application range is very wide, it is an important medium for various types of product promotion.

What is adhesive sticker?

Adhesive sticker is actually a type of label, and its front and back sides are made of different materials.

The front material types include plastics, paper, etc.; the backside is coated with pressure-sensitive adhesive.

Adhesive stickers are often used by people to decorate walls or other places that need beautification.

The sticker color, shape, and design can be customized to meet your different decoration needs.

Self adhesive label

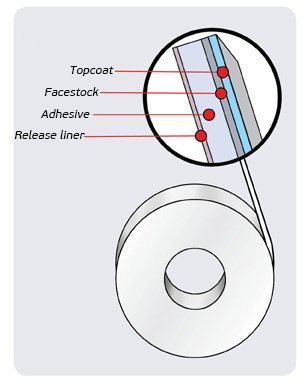

Self adhesive label is mainly composed of 3 parts:

- Face material

- Adhesive

- Release liner

The face materials mainly include Polypropylene, Polyester, Vinyl, paper, PVC, Polyethylene, etc.;

There are many types of adhesive used in making self adhesive label, such as hot melt, rubber adhesives, acrylic, water-based, etc.;

Release liner: coated paper, plastics.

Some labels also include topcoat or laminate.

Adhesive label HS code

Adhesive label HS code is 482110 or 482190.

If you want to engage in adhesive label import or export business, you can contact your local customs for confirmation.

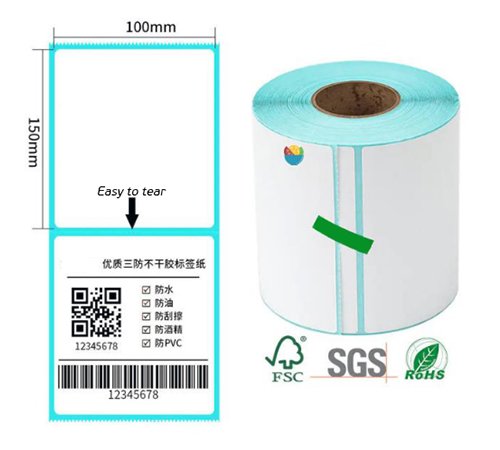

Adhesive label specifications

Self adhesive labels’ sizes are determined by the merchant’s merchandise, it is actually equivalent to a brand LOGO, when each product is affixed with an exclusive adhesive label, it is potential advertising.

Many businesses want to customize self adhesive labels, such businesses have many concerns, such as the self adhesive label’s material, the size of self adhesive label, the self adhesive label’s practical application, and so on.

The common adhesive label specifications on the market are 57mm x 30mm, 57mm x 40mm, 80mm x 60mm, 80mm x 80mm, 150mm x 100mm, which are relatively the most demanded by customers.

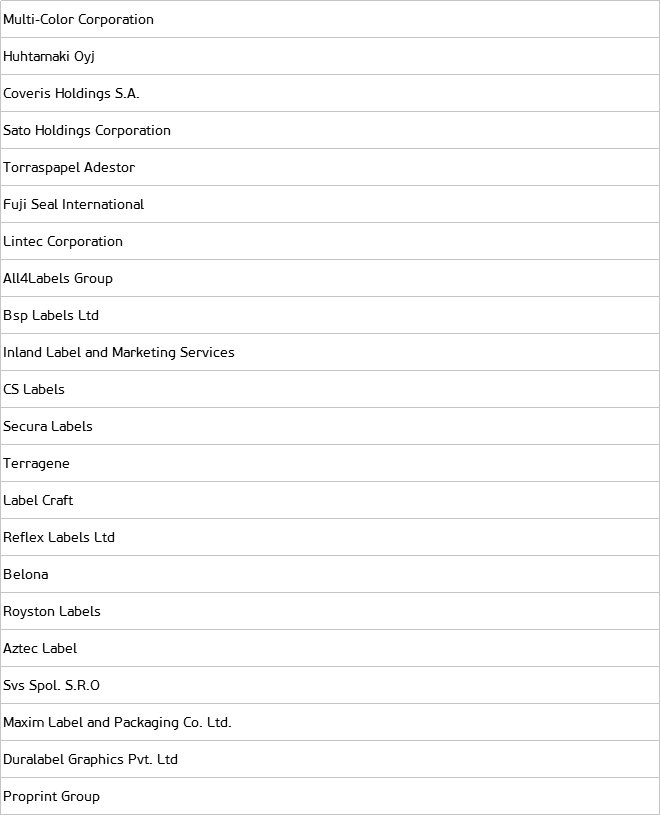

Adhesive label company

Because adhesive labels are used in various industries, there are a lot of self-adhesive label companies in the world.

And some companies are also very large, such as CCL Industries Inc., Avery Dennison Corporation, leading European adhesive label manufacturer Herma, and so on.

I also list some other important players in the adhesive label market, please check it for your reference.

Types of self adhesive labels

People always pursue a more convenient life, take self adhesive labels as an example.

With the use of self-adhesive labels, people’s lives have become more convenient, consumers demand more and more beautiful packaging, and the adhesive label design is getting more and more attractive.

This is a challenge for label printing companies because it means label printing becomes more and more difficult.

Depending on the material, there are many types of self adhesive labels.

- (Polyethylene) self-adhesive label.

- (Polypropylene) self-adhesive label.

- Thermal transfer label.

- Sticker label.

- Shrink adhesive labels, special label for battery trademark.

- Synthetic paper label, for water-resistant, petroleum and chemical products, high-end products, and environmentally friendly products.

- Copper label, which is medicine, food, edible oil, wine, beverage, electricity, tableware, and cultural articles’ information label.

- Mirror coat sticker.

- Aluminum foil sticker label.

- Laser sticker.

- Fragile sticker, for anti-counterfeiting sealing of electrical appliances, mobile phones, medicines, food, etc, after peeling off the self-adhesive seal, the label paper will be broken immediately and cannot be reused.

- Thermal paper labels, price tags, and other information tags for retail purposes.

- Heat transfer label.

- Removable labels, the fabrics are coated paper, mirror-coated paper, PE (polyethylene), PP (polypropylene), PET (polypropylene), and other materials.

- Washable labels, for information labels such as beer, tableware, fruits, etc., will not leave any dry glue traces after washing with water.

What type of paper is used for labels?

In fact, 2 types of material are used for labels, one is paper, the other is film.

- Paper substrate

Paper substrates are divided into offset paper, coated paper, glass cardboard, laser paper, kraft paper, fluorescent paper, gold-plated paper, aluminum foil paper, fragile (anti-counterfeiting) paper, silver-plated paper, textured paper, cloth label (TYVEK/nylon) paper.

- Film substrate

Film substrates are divided into transparent polyvinyl chloride (PVC), polyester (PET), polypropylene (PP), polycarbonate (PC), synthetic paper, PS, PE, shape-memory anti-counterfeiting material (SMP), etc.

What are the different types of labels?

The label is mainly used to indicate the name, weight, volume, usage, and other information of an article.

Scope of application

- Packaging

Mark label, postal package, letter packaging, shipping goods label, envelope address label.

- Electrical appliances

Internal labels for mobile phones, various electrical appliances labels, laptop labels, electromechanical product labels.

- Commodities

Price tags, product description tags, shelf tags, barcode tags, drug tags.

- Management

Book tags, vehicle inspection tags, security inspection tags, property tags.

- Office

Document labels, archive labels, various items, and stationery labels.

- Production

Raw material label, processed product label, finished product label, inventory management label.

- Chemical industry

Paint material labeling, gasoline engine oil product package labeling, and various special solvent product labels.

- Jewelry

Jewelry tags, tags that are not easy to stick to the product.

- Clothing

Clothing tags, wash tags.

- Airport

Boarding pass, luggage tag.

- Tickets

Train tickets, long-distance bus tickets.

- Food

Wine labels, food labels.

- Others

Anti-counterfeiting labels, encryption labels, anti-theft labels, parking lot tickets, highway toll tickets.

What is the difference between a label and sticker?

Stickers and labels have many similarities, such as their shape and size are not fixed, they both have adhesives, and so on.

Of course, they also have differences.

Stickers are relatively more used for decoration and focus on design; while labels are designed for commerce and are often used for specific products and places.

Adhesive label printing machine

In terms of adhesive label printing, letterpress printing is the mainstay, flexo printing is getting more and more popular.

1. Letterpress adhesive label printing machine

The main transmission mechanism changes from traditional mechanical transmission to electromechanical integrated shaftless transmission.

The web feeding length can be preset by the micro-computer, and the roller can automatically pull the material and convey the web, which completely eliminates mechanical errors.

Another significant change is the installation of UV drying devices and the use of UV inks, which expands the label printing range, increases the printing speed, and eliminates the laminating process.

2. Flexographic label printing machine

This type of equipment is all narrow web types, it has 2 obvious characteristics:

- Use UV ink instead of water-based ink.

UV ink has good stability and avoids frequent cleaning of the printing plate and inking system.

More importantly, the color density of UV ink is greater than that of water-based ink, which can improve the label printing quality.

- The direct laser plate-making technology without film is widely used.

It avoids the loss of small dots and the parallelization of large dots, improves the image level, and greatly improves the clarity of graphics and printing.

Flexographic printing self-adhesive labels are the future development direction.

At present, domestic companies adopt domestic components and foreign technology to produce flexographic printing equipment.

3. Die cutting equipment

There are 2 printing and processing methods for self-adhesive labels.

- One-step

That is, printing and die-cutting are completed in 1 pass.

One end of the machine inputs the raw materials and the other end comes out the finished label, which is suitable for simple label production;

- Step-by-step

That is, label printing and die-cutting are performed on 2 equipment, which is suitable for label production with complex graphics and text, multiple procedures, and batches.

Step-by-step processing can reduce costs, reduce waste, and improve efficiency.

Adhesive label printing company

There are many adhesive label printing companies, such as:

- Nova Label Company

- Focus Label

- Uprinting

- CCL Label

Of course, many other label printing companies are not listed here, you can search for them on Google, Bing, or other search engines.

Label Die Cutting Machine

- Label die cutter

- Rotary label die cutter machine

- Digital label die cut machine

- Label printing and cutting machine

- Die cut label machine price

- Which brand of label die cut machine is good?

- Label die cutter machine operation guide

- Die cut label machine’s knife adjustment

- Label die cut machine inaccurate positioning

- Label die cutter error

Label die cutter

Compared with the previous rod die cutting machine and the most primitive punching machine, the modern label die cutter has many advantages:

- Faster speed

- Full touch screen control

- More convenient operation

- Higher precision

- Higher production efficiency

The flatbed die cutter adopts punching up and down, using a cutting die to punch the label into a certain shape.

The label die cutter’s main parameters are:

- Maximum unwinding width

- Maximum unwinding diameter

- Maximum die-cutting width

- Maximum die-cutting length

- Die-cutting speed

- Die-cutting accuracy

- Total power

- Overall dimensions

- Weight

High-precision die-cutting, driving, and sheeting are controlled by a micro-computer.

Both sides and longitudinal printing marks are accurately tracked and positioned by 3 photoelectric sensors.

Die-cutting, laminating, sheeting, and waste striping are automatically completed in one pass.

It is very suitable for die-cutting paper sticker trademarks, polyester film trademarks, and laser anti-counterfeiting trademarks.

Die cut label machine is the best-supporting equipment for flexo printing machine, screen printing machine, and rotogravure printing machine.

Rotary label die cutter machine

The rotary die cutter machine is a cutting machine, which is often suitable for mass cartons or labels production.

The rotary die cutter machine’s magnetic cylinder continuously rotates when it is working, and its productivity is also the highest among all types of die cutting machines.

Digital label die cut machine

The modern printing industry usually includes 3 processes:

- Pre-press

- Printing

- Post-press

The die cut machine is modern post-press processing equipment.

It is widely applied for die-cutting, creasing, and cold embossing of trademarks, cartons, greeting cards, etc. in the paper packaging and decoration industry.

The traditional die-cutting plate’s making process is complicated, time-consuming, energy-consuming, and poor in operational flexibility.

Digital die-cutting (or plateless die-cutting) has changed the die-cutting dependence on the plate, reducing energy consumption and pollution.

Label printing and cutting machine

Label printing and die-cutting can be done on one machine simultaneously, you can use a flexographic printing machine with die-cutting station, or use a printing die-cutting integrated machine.

You can search for label printing and cutting machines on Youtube, then you can view such a machine’s demo video.

Through the demo video, you can get an overview of the label printing and cutting machine’s general working process.

Die cut label machine price

In the Chinese market, the die cut label machine’s price varies from supplier to supplier.

Low-end models cost as low as $2,800, and high-end models cost $35,000.

Which brand of label die cut machine is good?

Speaking of label die cut machines, there are several well-known manufacturers in the world that produce such machines, such as:

- GRAFOTRONIC AB from Sweden

- Daco Solutions Limited from the UK

- Preco Inc. from US

Relatively speaking, above European and American brand label die cut machines’ quality is very good.

Label die cutter machine operation guide

1. Operation regulations before starting up

- Check the handover records to understand the machine operation status.

- Check records, die usage, and stock.

2. Operating regulations in working

- Select the die, and fix the die and bottom plate on the die cutter machine.

- Adjust the die cutting pressure.

When adjusting, the pressure should be gradually increased from light to heavy to 80%, otherwise, it will cause equipment damage.

- After adjusting the die cutter machine, perform punching in accordance with the requirements.

And then send the first piece to quality assurance inspection, and normal punching can be performed after confirming the qualification.

- During the production process, sampling inspection should be performed every 30-60 minutes.

Quality problems should be reported in time, and production can be continued after resolution.

3. Operation regulations after finishing

- (1)The captain should fill in the die usage records and die cutter machine inspection form every day.

- (2)Separate the die-cut products into qualified and defective types, and clearly identify them.

- (3)Maintain the equipment according to the daily maintenance requirements.

- (4)Turn off the power and clean the machine.

Precautions

- Check the die and die usage records, if find any die is abnormal or any die is used beyond the service life, put them forward in time.

Check the inventory, if the inventory has material preparation, first consider using the inventory balance.

- Check whether the part number on the drawing is consistent with the number on the die box, and check whether the die part number on the die box is consistent with the number on the die.

After checking, machine running is allowed.

- Before adjusting the die, the pressure should be reduced first, avoiding damage to the equipment due to excessive pressure.

- Do the first piece inspection (the captain’s self-inspection, quality assurance inspection), and perform random inspections at work (the captain does random inspections and quality assurance inspections regularly).

- When the captain is using the die cutter machine, be careful not to put his hands in the place with the “yellow label (beware of hurting hands)” to avoid accidents.

- When the die cutter machine is working, do not let objects block the sensor.

Die cut label machine’s die adjustment

In the actual die cutting, the die adjustment is particularly important.

The correct position of the die directly affects the production efficiency and product quality, and may even cause safety accidents.

In actual production, the die adjustment mainly has the following functions:

- Ensure safe production without affecting the finished label quality;

- Adjusting the die is essential to ensure normal start-up operations, if the die is not adjusted properly, all die-cutting operations will not be carried out;

- Adjust the die to avoid producing defective products and wasting materials;

- The die adjustment helps to improve production efficiency;

- Good die adjustment habits are beneficial to protect the equipment die base from loss, improve equipment utilization, and extend equipment service life.

Several basic steps of die cut label machine’s die adjustment

- Die claim

- Fix die

- Angle adjustment of the fixed die

- Fix the backing plate

- Die cutting pressure adjustment

- Fine adjustment of die flatness

- Die angle adjustment

Label die cut machine inaccurate positioning

Die cutting distance refers to the distance between 2 labels after the die cutting waste is discharged.

Under normal circumstances, the die-cutting distance of the self-adhesive label is between 2-3mm.

In daily production, we often encounter the phenomenon of inaccurate die-cutting spacing, which is mainly reflected by the fluctuation of the spacing.

Such label products also do not meet quality standards. So, what is the cause of this phenomenon?

- The printing cursor spacing is not accurate

If you encounter this kind of problem, the die-cutting process cannot be solved, you may have to find the cause of the error during printing and start to solve it.

- Die-cutting machinery problems

In this case, you can try to adjust the photoelectric sensor again according to the operating procedure or restart the photoelectric sensor after turning off the machine.

If the problem is not resolved, you need to consider replacing the photoelectric sensor of the die cut machine.

- Material deformation

When encountering such problems, you can first measure whether the actual spacing of the printed cursors is smaller than the designed spacing.

If it is judged that the spacing is incorrect due to this problem, it must be controlled during the printing process.

We can reduce the chance of material thermal deformation by reducing the UV lamp power or increasing the printing speed.

Label die cutter error

- The influence of die cutter on punching accuracy

If the material feeding controlled by the motor isn’t accurate according to the specified step, the position of the die cutting will be uneven.

- The influence of dies on punching accuracy

In the actual die-cutting process, the shape of the die directly determines the shape forming of the die-cut part.

- The influence of material on punching accuracy

In actual production, the difference in material thickness and characteristics will affect the punching accuracy.

- The influence of die-cutting process on punching accuracy

There are too many uncertain factors that affect the accuracy in the die-cutting process because the different punching methods involve different equipment, material combinations, which directly affect the punching accuracy.

At present, in order to avoid this problem, the industry generally adopts the method of small hole-nesting, and at the same time, it is convenient to carry out the nesting operation and production.

Rotary Die Cutter

- What is a rotary die cutter?

- Small rotary die cutting machine

- Rotary die cutter for corrugated

- Rotary die cutting machine manufacturers

- Rotary die manufacturers

- Rotary die cutting services

- Advantages and disadvantages of rotary die cutter

- How much is a rotary die cutter

- How to adjust the rotary die cutter’s knife

- How many cuts/h of rotary die cutter

- Rotary die cutter operation guide

What is a rotary die cutter?

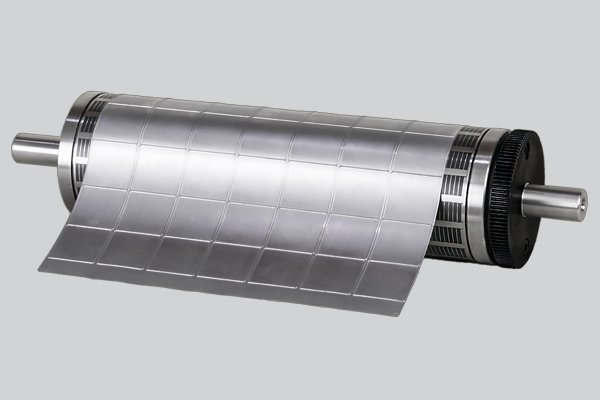

The rotary die cutter includes magnetic cylinder and anvil cylinder.

In the working process, the NIP roller sends the label between the magnetic roller and the anvil roller, and the label is clamped by the two, die-cut by the magnetic roller.

The magnetic cylinder rotates 1 circle, complete a work cycle.

Because of this, rotary die cutter’s production efficiency is the highest among all kinds of die cutting equipment.

Therefore, the rotary die cutter is particularly suitable for mass production.

At present, most advanced die cutting equipment is developing towards the fully automatic combination of printing and die-cutting, that is, organically combining die cutting machinery and printing machinery.

This type of production line usually includes a feeding unit (or called a feeding part), printing unit (or called the printing part), the die cutting unit (or called the die cutting part), and the collecting unit (or called the collecting part), realizes high-speed continuous production.

However, the above-mentioned rotary die cutter’s functions are not perfect and have considerable limitations, which need to be further improved.

Small rotary die cutting machine

For the rotary die cutting machine, according to the different die cutting objects, it can be divided into cardboard rotary die cutting machine, label rotary die cutting machine, etc.

The small rotary die cutting machine generally refers to the rotary die-cutting machine for self-adhesive labels, because this type of machine is usually small in size, and the unwinding width is generally only 320mm or 420mm, which is very small.

Rotary die cutter for corrugated

Rotary die cutter for corrugated is composed of 3 parts, namely die-cutting part, material feeding part, and electrical control part.

As for the die-cutting part, soft cutting is currently used. Soft cutting means putting a layer of high-strength polyurethane rubber sleeve on the roller, which is mainly beneficial to protect the die’s service life.

The advantages and characteristics of the rotary die cutting machine are that the die cutting speed is fast, the speed can reach 140 pieces per minute, and the die cutting accuracy is high, which can be controlled within +/-1mm.

At the same time, the rotary die cutting machine has the advantages of simple operation, moderate price, and long service time.

Rotary die cutting machine manufacturers

Rotary die cutting machine manufacturers include GRAFOTRONIC AB from Sweden, Daco Solutions Limited from the UK, Preco, Inc. and Duplo International from the US, ASHE from the UK, JURMET from Poland.

Rotary die manufacturers

On the thomasnet website, enter rotary die, and there will be many rotary die suppliers, including the following ones:

- Custom Fabricating & Supplies;

- Sun Process Converting, Inc.;

- CS Hyde Company;

- Converters, Inc.;

- Bernal, LLC;

- MODERNISTIC, Inc.

Rotary die cutting services

Many companies offer rotary die cutting services, such as:

- Pro Tapes & Specialties, Inc.;

- Pepin Manufacturing, Inc.;

- AMERICAN MICRO INDUSTRIES;

- Can-Do National Tape.

Advantages and disadvantages of rotary die cutter

Compared to flatbed die cutter, the advantages and disadvantages of rotary die cutter are summarized as follows.

1. Advantages

- Speed is faster, efficiency is high, labor consumption is lower;

- Output is higher;

- Waste removal is automatic.

2. Disadvantages

- Price is higher;

- Cutting die costs more;

- Die cutting accuracy is lower.

How much is a rotary die cutter

The price of rotary die cutter machines from Chinese suppliers has a wide range, ranging from US$5,000 to US$100,000.

It will take much of your time and energy to filter out the most suitable supplier, if you have a plan to purchase a label rotary die cutter, turn to us for saving your priceless time and energy.

How to adjust the rotary die cutter’s knife

- Preheat and keep warm

Before the official start-up, preheat the rotary die cutter’s die; when it is not in use, it will be kept warm.

- Pressure relief and pressurization

In the initial use of the rotary die-cutting die, according to the die manufacturer’s recommendations, when the die is not used for a short time, the pressure should be released;

When it is used again, it needs to be re-pressurized and adjusted to the appropriate pressure.

- Spacing adjustment

Maintaining the correct die spacing is the key to ensuring the die cutting quality and die-life maintenance.

Under the condition that other parts are in normal use, the author adjusts the spacing of the rotary die cutter’s die as follows.

(1) Use imported carbon paper to adjust the gap between the upper cutting line of the die and the anvil cylinder.

If it is completely cut through, the die cutter blade of the upper roll may hit the anvil cylinder.

(2) The gap between the die cutting line and the anvil cyliner must all meet the above requirements.

If the gap is too large, a thin steel sheet with a thickness of 0.003mm must be used to adjust one by one;

if the gap is too small, professional tools can be used to properly grind the die cutter.

- Adjustment and maintenance

When the rotary die cutter’s die runs about 1 million revolutions, the machine stops, the die is unloaded, and the die is inspected, adjusted, and maintained.

Tests have proved that this solution not only guarantees the die-cutting quality of the label but also guarantees the service life of the rotary die-cutting die.

During the adjustment and maintenance of the rotary die cutting die, the spare die can be put into use.

According to the actual production experience, the rotary die cutting die will be reground as a whole every time it runs about 12 million revolutions, and the maintenance effect achieved is better.

How many cuts/h of rotary die cutter

For the rotary die cutter, the speed is not measured in cuts per minute, but in meters per minute.

The fast rotary die cutting machine can reach a speed of 300 meters per minute.

Rotary die cutter operation guide

Rotary die cutter’s operation is similar to flatbed die cutting machine, the only difference is the cutting die registration and replacement.

Rotary die cutter’s die needs to be installed on a magnetic cylinder, while flatbed die cutting machine’s die needs to be fixed on a plate.

Once you ordered a rotary die cutter from us, we will share a rotary die cutter operation guidance video with you for reference.

Flat Bed Die Cutting Machine

- Flat bed die cutter

- Flat bed die punching machine

- Semi-automatic flat bed die cutting machine

- Fully automatic flat bed die cutting machine

- Flat die cutting machine manufacturers

- Brand list of flat bed die cutting machine

- Flat bed die cutting machine price

- Flat bed die cutting machine India

- Flatbed die cutting machine operation tutorial

Flat bed die cutter

The flat bed die cutter’s plate table and press-cutting mechanism shape is flat.

When the die-cutting machine is working, the label or cardboard is driven to the plate table and punched by cutting die to produce indentations, and then die cutting is realized.

The whole machine is composed of a material feeding section, die cutting section, finished product collecting section, electrical control, mechanical transmission, and other parts, and some also have an automatic cleaning device.

Flat bed die punching machine

Flat bed die punching machine is actually another common name for flat bed die cutter, which is often heard in the US and Indian markets.

There are also many types of flat bed die punching machines, which are mainly divided into cardboard punching and label punching according to the different materials.

Semi-automatic flat bed die cutting machine

The semi-automatic flat bed die cutting machine is generally used to die-cut cardboard, and the motherboard needs to be manually stacked to the feed port of the semi-automatic flat die-cutting machine.

Fully automatic flat bed die cutting machine

There are several kinds of automatic flat bed die cutting machines.

According to the different die-cutting materials, there are special die-cutting paper cups, special die-cutting cardboard, and special die-cutting sticker labels.

We, Jota, are a professional manufacturer of automatic flat-bed die-cutting machines for self-adhesive labels.

If you have any needs in this regard, you are welcome to call or mail us for consultation.

Flat die cutting machine manufacturers

GRAFOTRONIC AB from Sweden, Daco Solutions Limited from the UK, Preco, Inc. from the US, ASHE from the UK, Duplo International from the US.

Brand list of flat bed die cutting machine

Because there are many types of flat bed die cutting machines for different materials, the brand list of flat bed die cutting machines for different materials is different.

For self-adhesive label flat die cutting machine, the main brands include:

GRAFOTRONIC AB from Sweden, Daco Solutions Limited from UK, Preco, Inc. from US, ASHE from UK, Duplo International from US.

Flat bed die cutting machine price

There are many flat bed die cutting machine suppliers in China, and the prices of flat bed die-cutting machines from various suppliers vary greatly.

The cheap flat die-cutting machine is priced at $5,000, and the high-end flat die-cutting machine is priced at $50,000.

In the process of purchasing a flat bed die cutting machine, it is best to confirm whether the supplier is the real die cutting machine source factory.

Flat bed die cutting machine India

India also has many suppliers of flat bed die cutting machines, such as Rekha Enterprises, R.K. LABEL PRINTING MACHINERY (P) LTD, Reborn International.

If you are in India, you can contact these suppliers to discuss issues related to flat bed die cutting machines.

Flatbed die cutting machine operation tutorial

Flatbed die cutting machine operation tutorial is summarized as follows.

- 1. Before starting each shift, you must do a careful check.

Check whether the brake button, stop button, and safety device is sensitive and reliable, whether the various protective devices of the machine are sensitive and fastened and whether there is jamming;

Check whether there are sundries on the running parts of the machine to avoid influence.

It is strictly forbidden to remove or modify the safety devices and protective poles without permission to avoid potential safety accidents.

- 2. After starting up, observe the machine’s running status.

Check whether the sound of the machine is normal, whether the braking system is sensitive, and whether the safety protection device is flexible and reliable.

The control switch on the machine should act flexibly and stop quickly; the action of the transmission mechanism should be accurate, coordinated, and error-free; the equipment should be lubricated regularly every shift;

- 3. Calibrate and install the die.

Lock and fix it, then debugging can be started;

- 4. When debugging the pressure, the pressure of the die-cutting machine should be adjusted gradually from light to heavy.

So as to avoid excessive pressure and damage to the machine;

- 5. In the process of die cutting, the bottom plate screws must be tightened.

To make the iron plate stable before starting the die cutting;

- 6. In the process of die-cutting, if the printed sheet is not put or taken out in time, stop quickly or pull down the air pressure handle to avoid waste.

During operation, to ensure personal safety, grabbing and releasing are prohibited.

- 7. When loading, correcting, adjusting the gauge and pressure, turn off the working power supply and wait for the flywheel to stop rotating before proceeding.

It is strictly forbidden to turn on the working power supply and load the die when the flywheel is running, avoids safety accidents.

- 8. During operation, the operator should stand directly in front of the movable plate.

It is strictly forbidden for the operator to stand on both sides to pick up or put paper, and it is strictly forbidden to chat with others during operation.

- 9. During operation, you should always pay attention to the operation of the machine.

If you find an abnormal or emergency situation, you should stop it in time, turn off the power and notify the supervisor, and the standby maintenance personnel can start production after confirming that there is no problem;

- 10. Always pay attention to and keep the machine clean, and conduct regular maintenance.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine