Pioneer CFRP CFRTP FRP Prepreg UD Tape Prepreging Machine Line

- Pioneer Prepreg Composite UD Tape Machinery Supplier in China

- Amature Hot Melt Pre-impregnation Process

- Applications: Carbon Fiber / Glass Fiber + PP, PE, PPS and PA

- Applied by more than 10 customers all over the world

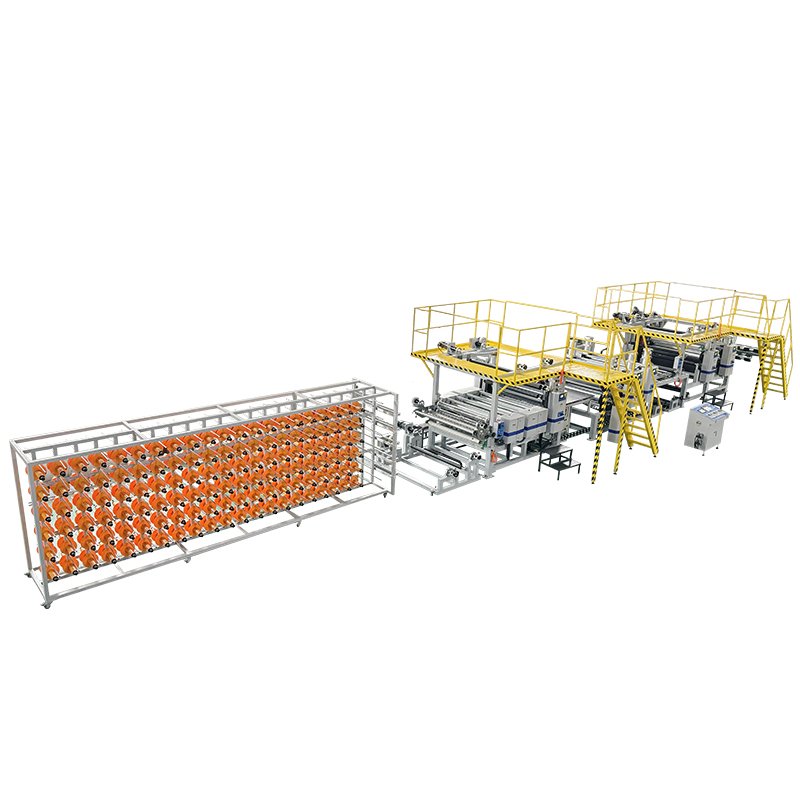

CFRP CFRTP UD Tape Pre-Impregnation Processing Machine

CFRTP UD tapes refer to Continuous Fiber Reinforced Thermoplastic Uni-Directional Tape. which has wide applications to the world.

As basic pre-impregnation equipment for the Uni-directional Tape, we have accumulated rich experiences on hot melt pre-impregnation processings.

The Max. UD Tape Width: 1500mm

Applications: PP, PE, PA, PPS

Jota Machinery: Your Reliable CFRP CFRTP FRP Prepreg UD Tape Slitter Manufacturer in China

CFRTP stands for Continuous Fiber-Reinforced Thermoplastics.

While prepreg stands for “pre-impregnated” to refer to composite materials made from fibers that have undergone the process of pre-impregnation.

Basically, prepregs materials are fibers (either carbon or glass) pre-impregnated using cured polymers matrix such as resin or epoxy.

The end result is a composite material whose characteristics provide the best performance and design flexibility.

Instead of having plastic, carbon fibers, or even steel as the primary component material, prepregs make up great (and highly effective) composite materials.

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

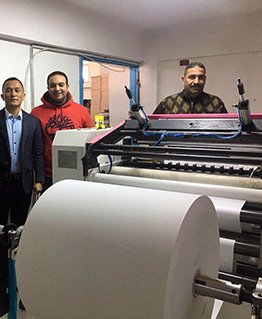

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

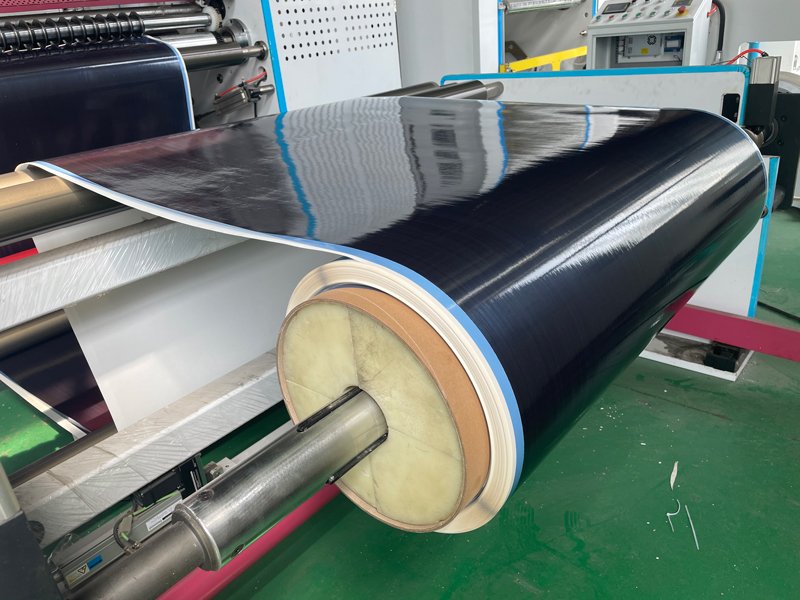

CFRP CFRTP Unidirectional Tape Prepreging Line

Last Update Time:24/01/2023

Around the end of the year, one of our customers placed an order for a CFRP/CFRTP unidirectional tape prepreg line remembered unit, which is still in production as of now.

Around the 1990s, CFRTP UD tape namely Continuous Fiber Reinforced Thermoplastic Uni-directional Tape has introduced to China from North America( especially Canada).

This innovative, lightweight material with strong tensile strength attracted market favor as soon as it entered China.

Only a small number of people were trapped by the technology and processing equipment at the time.

Research institutes have some related studies through import UD tape, but they don’t have a thorough understanding of product characteristics and application

CFRTP- UD Tape

We came into contact with CFRTP UD Tape in 2012 when there was a company in Shanghai called Genius Composites, and they tried to start their own production of CFRTP UD Prepreg process in China while need a slitting machine to cut unidirectional tape.

At that time, we only focused on the paper slitting and rewinding machine.

When we got this plastic-like sheet, which was thick and hard, our engineers just gave a few suggestions based on our own experience, and these contributed to our formation of the CFRTP- UD Tape Slitter rewinder machine.

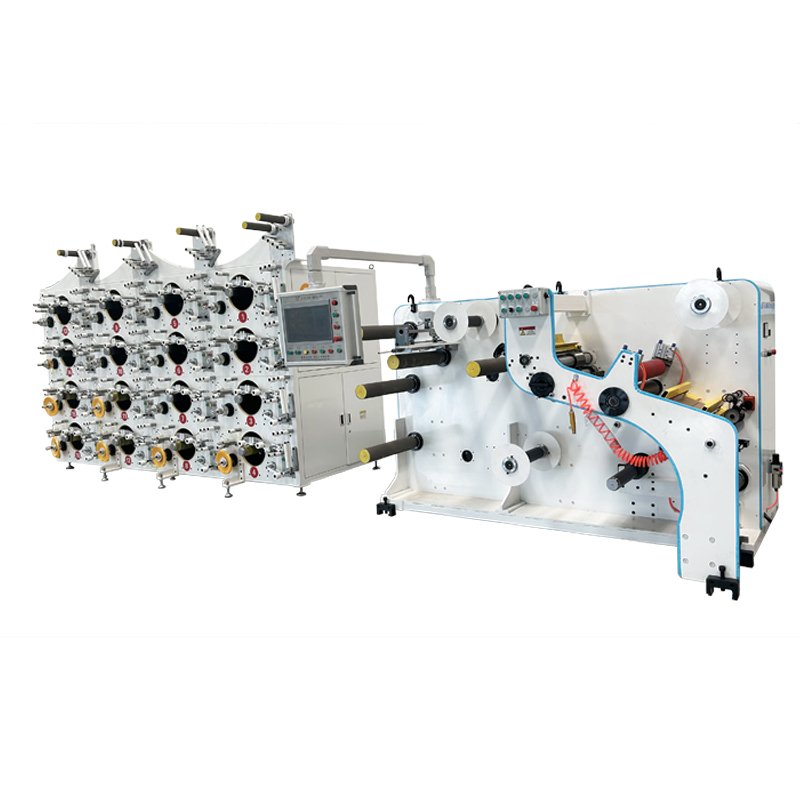

Continuous Fiber Reinforced Thermoplastic Uni-Directional Tape Slitter Rewinder

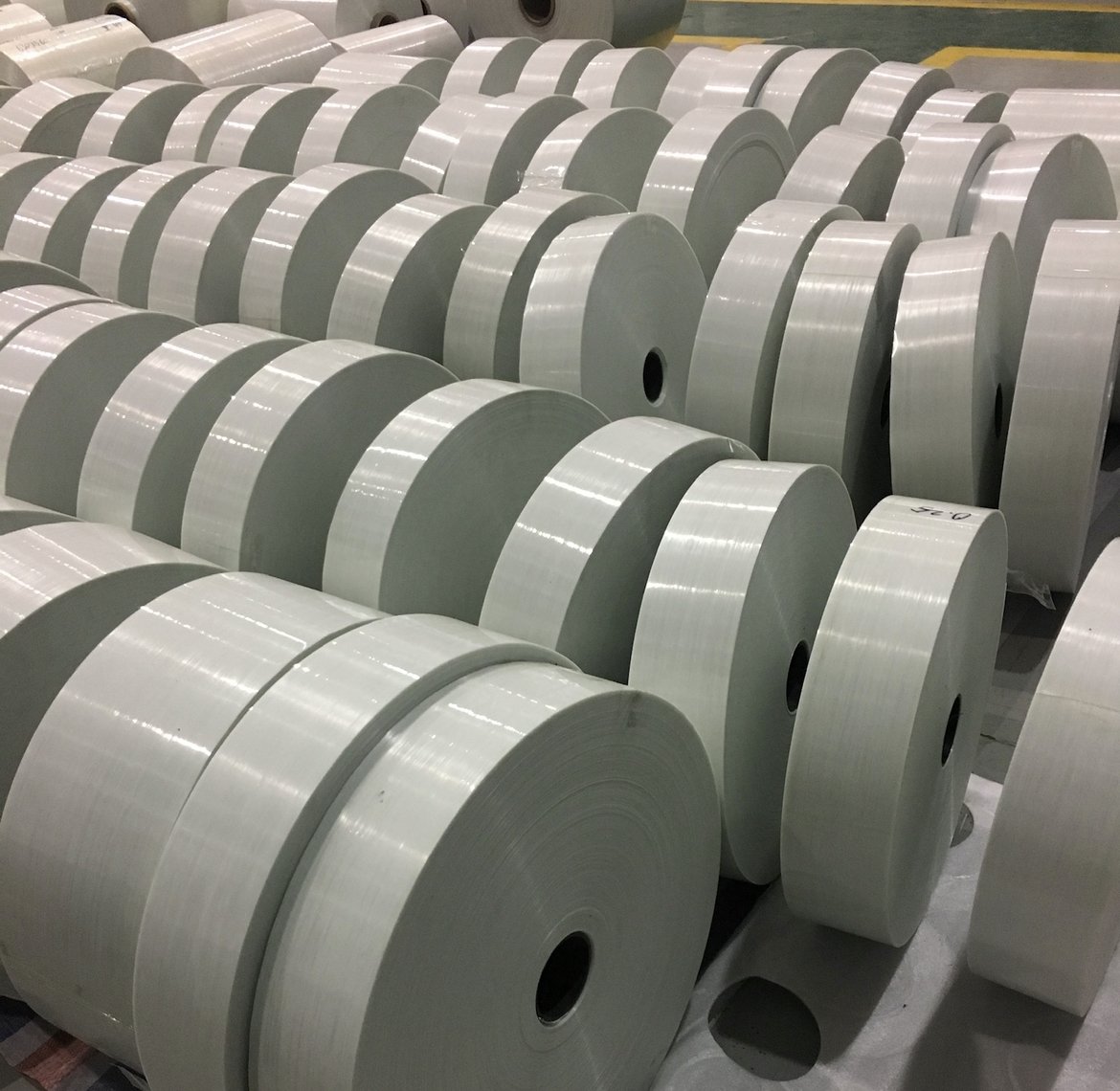

Later, with the further improvement of the Carbon Fiber CFRT UD tape market, we successively sold many UD Tape slitting machines to Chinese customers and gradually learned about the performance and characteristics of this material.

Jota Machinery have a deeper understanding of the application already.

In 2018, after owning 95% of the CFRTP UD Tape Slitter Rewinder market, in order to better serve our customers, our engineers began to develop the CFRT UD Tape impregnation process.

We adopted the more mature hot melt impregnation processing method on the market.

CFRTP- Uni-Directional Tape

The working principle of UD tape is easy to control, low in cost, and high in yield:

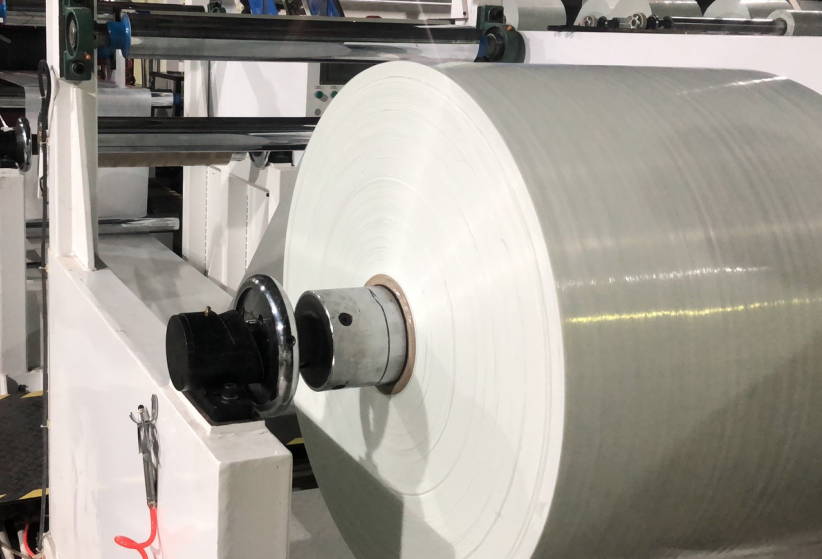

Fiber unwinding – the carbon fiber/glass fiber spreading,- preparing: (it enters the heating resin mold, the carbon fibers were immersed under the action of high temperature), – cooling ( cools and calendaring to form the shape), – finally rewinds it.

At present, all suppliers of thermoplastic glass fiber products in China use this process.

Of course, depending on the formula, although each product has a slight difference, the performance of all unidirectional belts can exceed 800MPa.

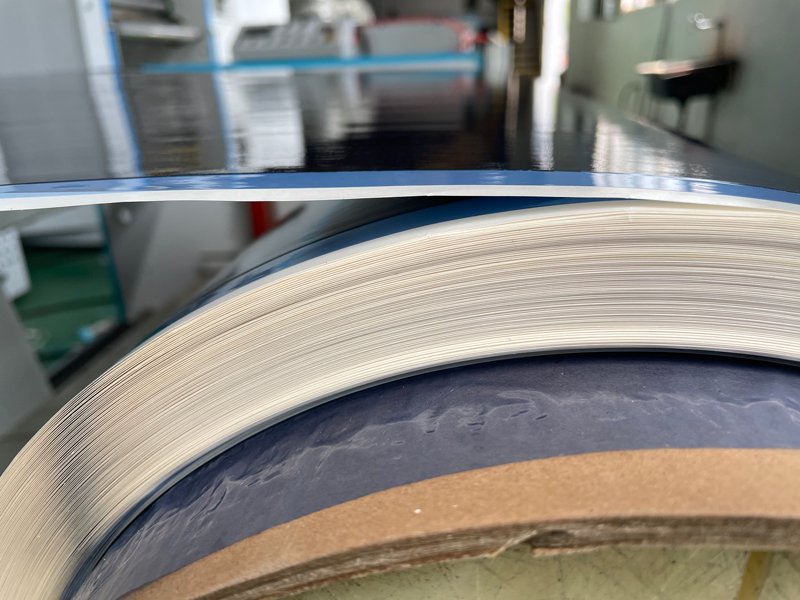

We currently provide unidirectional tapes with a width of 650mm (1500mm as optional), a thickness of about 0.25-0.35mm (0.6mm available), a glass fiber content of 50-70% (mass ratio), and a tensile strength greater than 800Mpa.

The resin is PP, PE, PA, and PPS if you are interested, please feel free to contact us.

Next, I will give an introduction to the whole process of CFRT UD Tape Prepreging Production Line

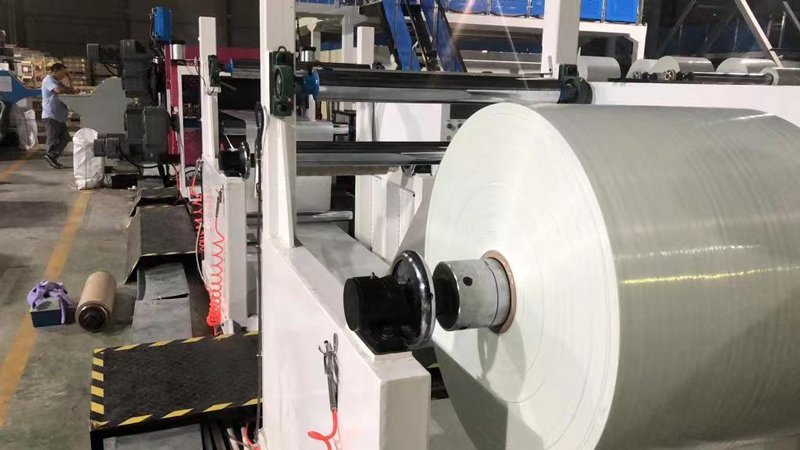

Unwinding Creel: We use a heavy-duty double-row creel frame.

The length of a roll of glass fiber is 12000m and the weight is up to 20kg.

The heavy-duty creel is equipped with automatic tension control, the tension is between 300-1200g, and the inner diameter of the bobbin paper tube is D152mm.

Fiber Glass Creel Frame

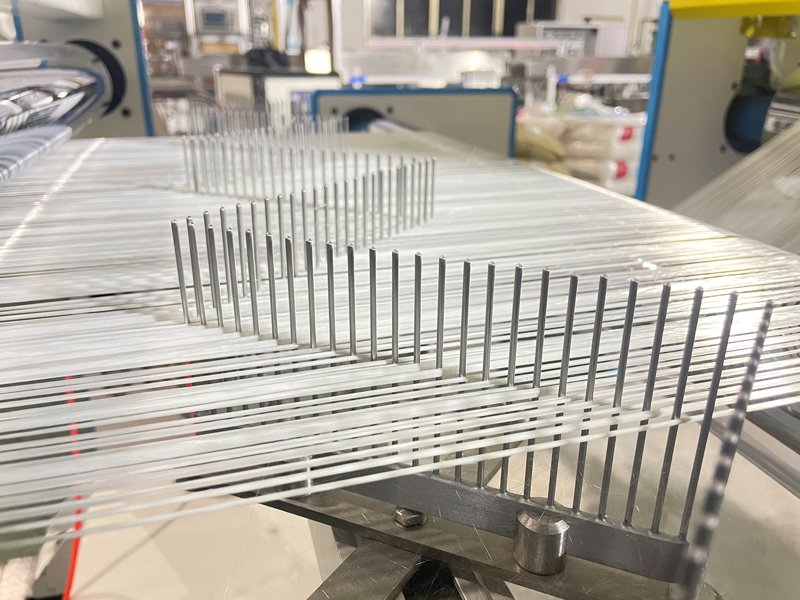

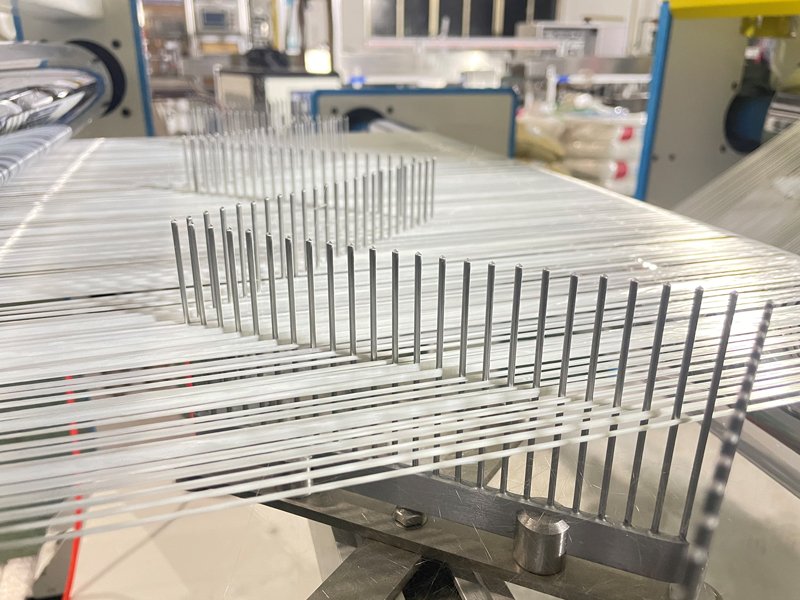

Spreading Frame: Spreading frame is a very important part of the processing, mainly used to spread the fiber yarn evenly without damaging it.

The upper and lower traction rollers are active NIP rollers, and all the Combs are stainless steel W-shaped adjustable fences.

The density of the entire fence can be adjusted from left to right, which is easy to operate.

Extruder: The main extruder is a single-screw extruder.

The main drive motor is 45Kw, equipped with Yaskawa frequency converter for speed regulation.

CFRTP UD Tape Extruder

The material of the screw is 38CrM, the heating method of the barrel is adopted, the automatic temperature control system, PLC integrated control

The output of the extruder is generally 20-80Kg/hr.

With the vacuum suction drying device, the operation is very convenient.

The metering pump is a precision control unit for materials, equipped with front and rear pressure sensors, and integrated control by PLC.

Mold: The mold is divided into two sets of T-type mold and Prepreg mold, which are the core components of this equipment.

The material of the mold is P20 mold steel, and the surface is chrome-plated.

If you need more information, please contact us.

Cooling and Calendering Roller: After preparing from the mold, it is the unidirectional Tape you need.

We need to pass through the cooling setting roller to calendar the thickness and Unidirectional Tape.

The shaping roller is driven by an independent frequency inverter motor with a reducer, and each roller has a well-designed cooling water circulation system.

Cooperate with a mold temperature controller to realize precise temperature control.

Waste edge collection device: The machine is equipped with an active waste slitting device and waste trim edge rewinding device.

During the prepreg process, each edge part needs to be cut off because of insufficient prepreging.

It uses a motor-driven round disc cutter and then cooperates with a simple transverse rewinding device for rewinding.

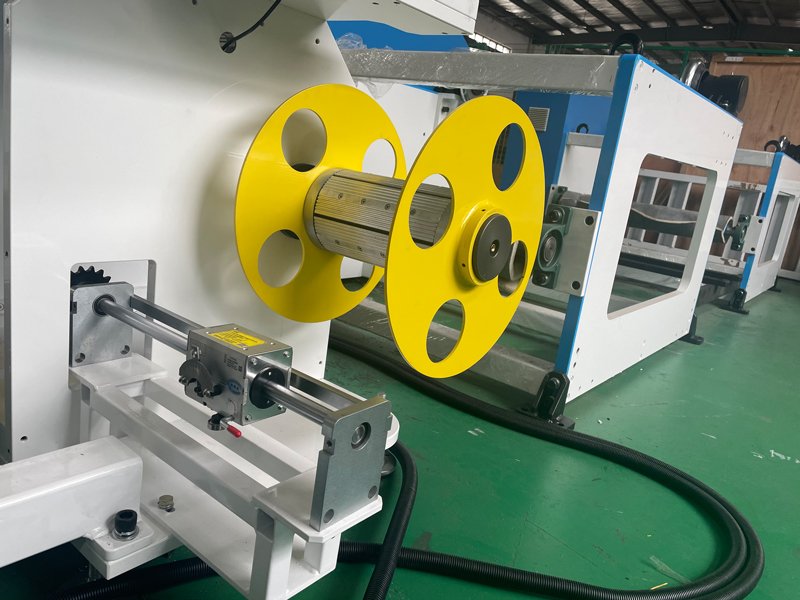

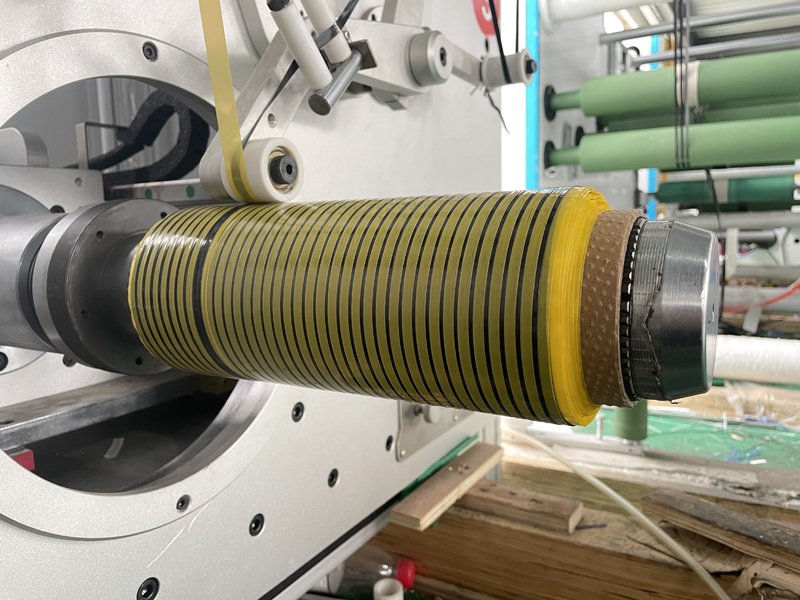

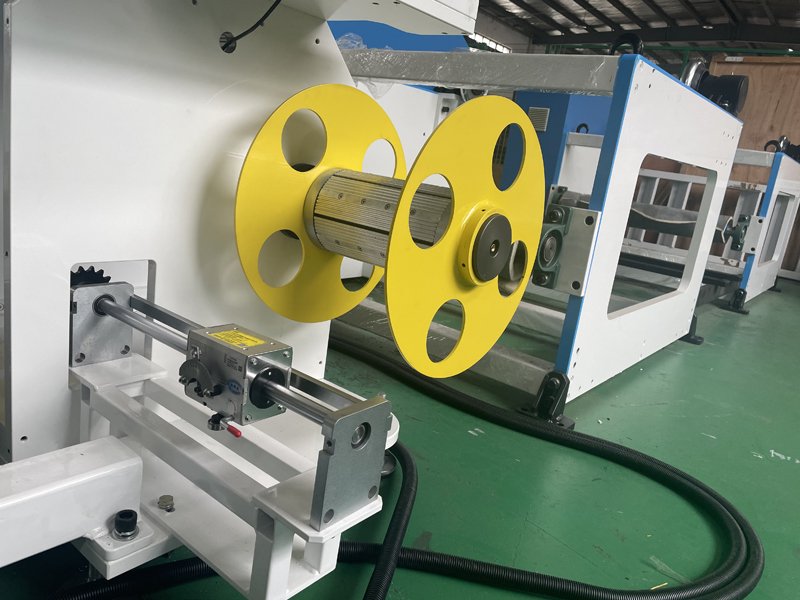

Rewinding device: This machine adopts a double-station rewinding frame, the rewinding adopts an automatic tension control system, and the rewinding shaft is 6″.

Under the drive of an asynchronous servo motor, the rewinding tension can be automatically adjusted.

And cooperate the tension control curve was developed by ourselves, and the rewinding is smooth and tight.

Central control system: This machine adopts a centralized control system of Siemens PLC and a touch screen.

All mechanical parts, electrical control, hydraulic control, and temperature control are centralized on the PLC.

All parameters only need to be preset, and the PLC automatic control is very intelligent.

Our prepreg line has been applied in China and the Russian market.

In the 9 years of contact with CFRTP UD tape, as witnesses, we have witnessed the growth of CFRTP UD tape throughout China, and we have also seen the current successful cases of the application of CFRTP-UD tape.

CFRTP Refrigerator Container

Refrigerator: The reefer box is currently the most important product in the Chinese market.

With the increasing requirements for automobile lightweight, CFRTP honeycomb panels are in great demand, coming from China and the world.

This is also the most mature application field of CFRT at present.

UD tape has undergone secondary compounding with honeycomb board to form a high-strength, low-weight honeycomb panel to replace traditional car box panels.

There have been very successful cases.

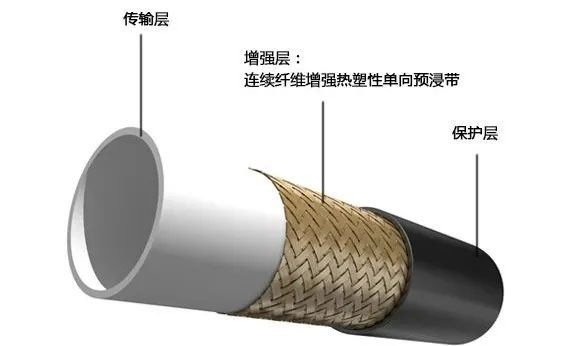

RTP pipeline: In the field of petroleum and subsea exploration, new RTP pipelines will be used to replace traditional transmission pipelines, which are lighter in quality and have greater pressure resistance.

RTP composite pipelines also have very successful cases.

The RTP pipeline technology is upgraded to the traditional composite pipeline.

In the middle layer of the pipeline, the strength of the entire pipeline is strengthened by winding several layers of UD tape and laser welding.

RTP pipelines are not only in the field of oil extraction but also in municipal domestic water and urban water pipeline networks.

From a supplier of paper-converting equipment, Jota Machinery has successfully transformed into an integrated supplier of new materials and equipment after 10 years.

We not only provide you with the most advanced equipment, but we can also provide a complete set of technical solutions for CFRT-UD tape, including market analysis, business plans, equipment, raw materials, process recipes, plant design, personnel training, technical support, and follow-up services.

If you are interested, you can contact us for in-depth communication.

Carbon Fiber Prepreg

Fiberglass Prepreg Line FAQ Guide

Prepreg composite materials have increasingly become popular in high-performance applications due to their consistent properties, ease of use, and high-quality surface finish.

They’re widely used in areas where the weight and mechanical properties of structures take precedence over cost.

Carbon-fiber-reinforced polymers (CFRP) and carbon-fiber-reinforced thermoplastics (CFRTP) are critical raw materials for manufacturing high-performance carbon fiber and glass fiber composite materials.

For more than two decades, Jota Machinery has been at the forefront of the Continuous Fiberglass Reinforced Thermoplastic Pregnation Uni-directional Tape (CFRTP-UD Tape) production line.

In order to help you understand thermoset and thermoplastic prepreg manufacturing more deeply, we’ve curated the following fiberglass prepreg machine FAQs guide for your reference:

What Are Prepregs?

The term “prepreg” is the short form of the phrase pre-impregnated.

It refers to composite materials that come from the factory already impregnated with a resin matrix in a specified ratio and plies thickness.

Usually, a thermoplastic or thermoset resin may be used.

The resin matrix in prepregs typically includes the proper curing agent for ease of handling.

For that reason, prepregs can be laid into the mold without adding any more resin. Prepregs are stored in a cool place to avoid complete polymerization.

In order for the composite materials to achieve complete polymerization, it is necessary to heat them in an autoclave or oven during the manufacturing process.

This is to apply high pressure and heat for the materials to cure.

The reinforcement in prepregs can be unidirectional fibers (UD prepregs) or fabric.

Prepregs have unique properties that make them befitting for highly technical applications.

They’re used for aerospace, race cars, and high-performance, lightweight parts, where the consistency of the resin matrix must be of the highest order.

The fiberglass prepregs offer several specific advantages, including:

- Near-perfect resin content for maximum strength properties for the reinforcement.

- High-quality finished piece engineered for consistency and minimal porosity.

- After curing and cooling, it is possible to add more layers without scuffing or additional preparation.

Are Thermoset and Thermoplastic Prepregs Similar?

Technically, thermoset and thermoplastic prepregs are both composite prepregs.

However, they’re dramatically different from each other.

Thermoset prepregs are more frequently used in prepreg composite manufacturing.

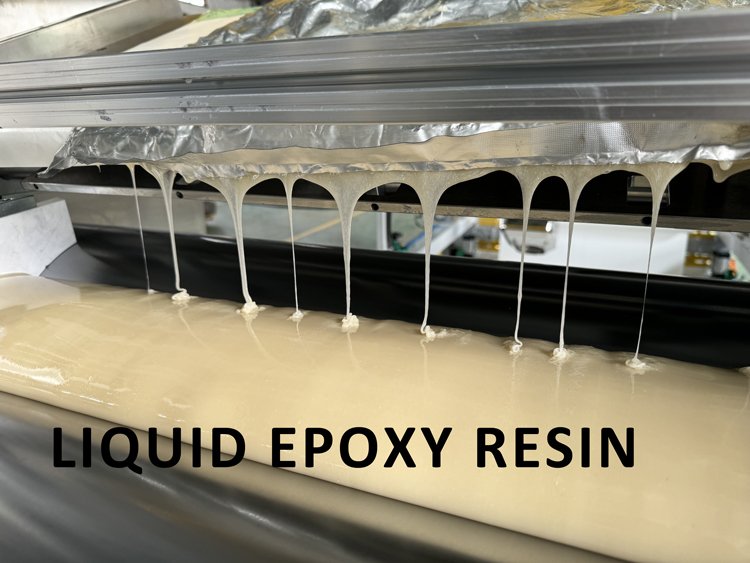

With a thermoset prepreg, the main resin matrix used is epoxy.

Additional thermoset resins like BMI and phenolic resins can also be made into prepregs.

The thermosetting resin begins as a liquid, which polymerizes to completely impregnate the fiber reinforcement.

Once impregnated, the excess resin is scraped off the fiber reinforcement.

The epoxy resin then goes through a partial curing stage, where the resin changes from liquid to solid.

This partial curing stage is popularly known as the “B-stage.”

The B-stage involves partially curing the resin so that it becomes tacky to the touch.

When the resin undergoes a higher temperature, it returns temporarily to a liquid state before it hardens completely.

After the curing process is complete, the thermoset resin gets fully cross-linked and ready to cut into different shapes.

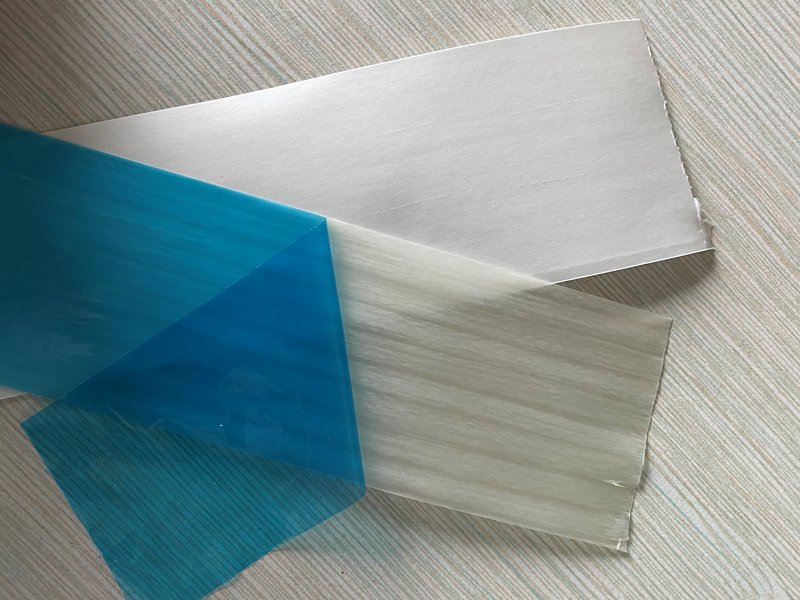

Unlike thermoset prepregs, thermoplastic prepregs are formed by pre-impregnating composite reinforcements (such as fiberglass, aramid, carbon fiber, etc.) with a thermoplastic resin.

This type of prepreg is produced by heat and changes into a solid state when cooled to room temperature.

Standard resins for making thermoplastic prepregs are PP, PE, PET, and PEEK.

Thermoplastic prepregs are usually offered in multiple forms, including unidirectional tape, veil mat, stitched or woven fabrics, and biaxial and triaxial cloth, among others.

As a result, the main difference between thermoset and thermoplastic prepregs is that the latter is stable at room temperatures.

This means they can be stored at room temperature without affecting the reinforcement material.

Also, with thermoplastic prepregs, it’s possible to reshape the material multiple times as necessary.

This is achieved by heating a specific thermoplastic resin matrix above its melting point.

What Are Fiberglass Prepregs?

Fiberglass prepregs (also known as glass fiber prepregs) are fabrics that are pre-impregnated with epoxy resin or phenolic resin as the primary matric.

This is to allow for ease of handling and processing.

The matrix already includes the proper curing agent and reinforced glass fiber filaments.

As a result, you don’t need to add any more resin before laying it into a mold.

Typically, fiberglass prepregs are shipped frozen. This means that customers must keep them frozen until ready to use.

These glass fabrics are heat cured at temperatures between 180 and 250F to achieve the completed laminate part.

Fiberglass prepregs are the cheapest composite fabrics used in industrial fields.

They’re most widely used in aircraft interiors, secondary aircraft structures, radomes, and sandwich panels.

Glass fiber prepregs are relatively lightweight with moderate tensile and compressive strength.

Used in industrial applications, they can effectively enhance strength and hardness and corrosion and wear resistance.

They can also improve impact resistance and prolong the service life

As previously mentioned, fiberglass prepreg products can be divided into two: epoxy resin system prepreg and phenolic resin system prepreg.

In 2018, the epoxy resin prepreg system accounted for at least 58.31% of the total glass fiber prepreg products in the Chinese market alone.

In 2019, about 29.69 million square meters of epoxy resin prepreg systems were consumed worldwide.

This represented a 4.12% increase in product consumption compared to 24.26 million square meters used in 2014.

Glass fiber prepregs are relatively environmentally friendly.

Even so, there is a need to exercise caution while using the product.

You’re recommended to avoid direct skin contact with the product at all costs.

This is because the glass fiber surface has a layer of the wetting agent.

The main ingredients in this layer include some coupling agents, water repellant, and epichlorohydrin, among others.

When these chemicals come in contact with the human skin, they can cause allergies, pimples, and dermatitis.

Furthermore, the curing agent of the glass fiber epoxy prepreg is mostly acid anhydride or amine.

This acid can irritate the skin and mucous membranes.

Why Choose Fiberglass Prepregs?

There are many benefits to using fiberglass prepregs rather than traditional wet layup options.

As mentioned earlier, the entire premise of the fiberglass prepreg concept is to provide the necessary quality and consistency.

In traditional wet layups, it is nearly impossible to achieve less than 50% resin content.

This is because the finished laminate weight will likely contain 50% fabric and 50% resin.

Hence, even when vacuum bagged, typical hand laminates could still end up with a considerable amount of excess resin.

You’ll want to know that excess resin causes brittleness, consequently reducing the quality of the finished piece.

On the other hand, most fiberglass prepregs contain 35% or less resin content.

Also, the resin tends to spread consistently across the material.

As such, the cured piece achieves maximum strength properties compared to standard hand lamination.

Furthermore, customers choose fiberglass prepregs due to their part uniformity and repeatability.

Human lamination techniques are prone to errors.

These pitfalls result in some resin-rich spots and dry areas that are difficult to work with.

In fiberglass prepregs, the material thickness is uniform.

Whereas vacuum bagging techniques may still create a margin of error, prepregs decrease these issues significantly.

This means the finished piece has a great chance of being identical.

Better still, prepregs create very little mess and waste compared to wet layups.

This could prove handy for a prototyping project in which you can’t afford to fight the clock trying to clean up after yourself.

Plus, you can handle fiberglass prepregs at room temperature.

That means there is no need to waste time waiting for your resin to set up before you’re ready.

Fiberglass prepregs are ready for service as soon as the heat curing cycle is complete.

Is Fiberglass Bulletproof?

When at the appropriate thickness, glass fiber can offer unique bulletproof characteristics.

This is why a layered, reinforced structural polyester laminate is sometimes known as Opaque Armor.

Bullet-resistant fiberglass can deflect a bullet as it penetrates by absorbing the energy through its layers.

When molded between steel plates at high temperature and pressure, this ultra-light material can progressively distort rounds and delaminate to stop them within the high-strength glass fibers.

You’ll want to know that composite materials have been used in armor applications since World War II.

For example, they were used to create bulletproof vests for soldiers, armored plates for military vehicles, and even explosion-proof systems for infrastructure.

Various reinforcing fibers were used to make these bulletproof- and explosion-proof structures.

Some used aramid fibers, others used ultra-high molecular weight polyethylene fibers like Spectra and Dyneema, while the rest were made of M5 fibers.

The glass fiber (S and E glass categories) also showed impeccable bulletproofing performance.

While glass fiber is the heaviest of all bulletproof materials, it is one of the most inexpensive. It also has a wider supply than most bulletproof materials in the composite armor market.

Currently, American ACY is the only company in the world that manufactures S-2 high-strength glass fiber. The company started manufacturing bulletproof armor way back in the 1980s.

S-2 fiber has high tensile strength, rigidity, compression resistance, and fatigue resistance. With these comprehensive properties, S-2 fiber can be used for bulletproofing and construction in composite products.

In order to make the HJI hard armor plate, ACY reinforces phenolic resin using S-2 glass non-twisted roving material.

Phenolic resin never burns when exposed to fire, while S-2 glass non-twisted rental gauze boasts a high energy absorption capacity.

Therefore, the armor system not only blocks missiles but is also resistant to fire, smoke, and poison.

What Are Prepreg Thermoplastic UD Tapes?

Unidirectional continuous fiber-reinforced thermoplastic prepreg tape (UD tape) is a sheet-shaped tape in which fibers are impregnated with a molten thermoplastic matrix.

In this prepreg UD tape, continuous fibers run parallel to each other after impregnation.

Ideally, completely new possibilities arise in the melt impregnation process.

Fibers impregnated with a thermoplastic resin matrix can have various weights and thicknesses in line with customer requirements.

Sheet density can range from 250gsm-620gsm, while sheet density can range anywhere from 0.15mm-0.40mm.

Different fiber types can be used to produce the prepreg UD tape, such as carbon fiber, glass fiber, and aramid fiber.

Similarly, different resin types can also be used, including polypropylene (PP), polyethylene (PE), and nylon (PA).

With unidirectional prepreg tapes, colors can be tailored to meet different customer requirements.

Better still, you can choose to go with either normal natural color or black color. It all boils down to your unique requirements.

The prepreg UD tape boasts high specific strength and stiffness, good impact resistance, and acid and alkali resistance.

As a result, it can be used for a variety of applications, including thermal welding, thermal compounding, molding, cutting, an adhesive connection, and other manufacturing processes.

Can You Cut Fiberglass Prepreg with Manual Tools?

In the process of applying fiberglass prepreg in various industries, cropping must be done. You can cut composites with manual tools like razor knives, scissors, and dremel tools.

However, manual cutting is only possible if you need simple graphics such as circles and quadrilaterals.

If it involves cutting some irregular patterns, standard cutting tools may not meet the processing requirements.

Furthermore, manual cutting can come with some inherent disadvantages. First, reinforcement fibers like fiberglass, carbon fiber, and Kevlar tend to be abrasive.

As a result, tools with traditional cutting edges can wear out quickly, thus shortening tool life.

Worse still, if you cut composites with dull tools, you could end up damaging the material due to severe overheating.

Typically, composite materials are poor conductors of heat.

Unlike metal chips, resin and cut fibers conduct relatively little heat.

This causes overheating, which could melt the resin in the process.

A melted resin can clog your cutting tool, or worse, damage the structural integrity of your piece.

Lastly, there is the likelihood of composites delaminating when cut with standard tools.

Delamination can show in the form of minor edge chipping or major stress fractures. But no matter how small it is, it could still end up damaging your finished part.

How Can You Cut Fiberglass Prepreg?

There are several methods for cutting fiberglass prepreg without affecting the structural integrity of the piece.

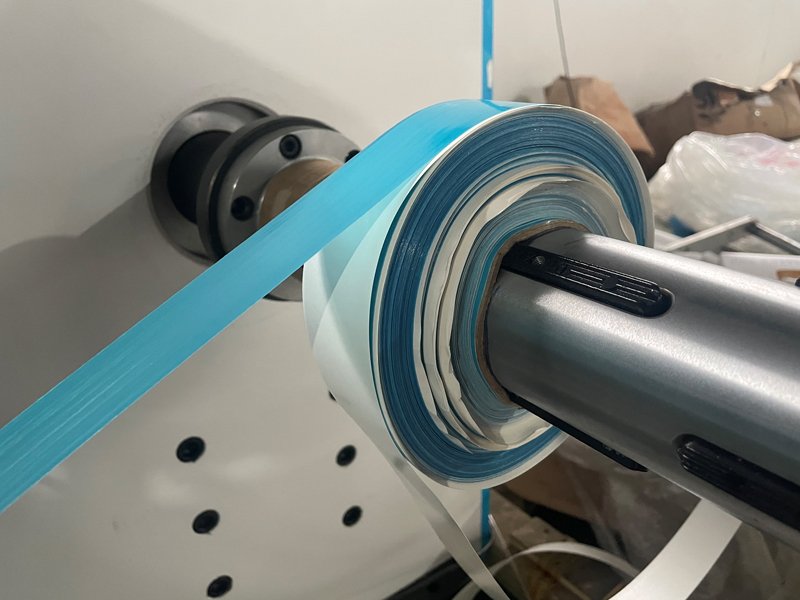

We recommend Jota Machinery’s prepreg slitting machine if you’re looking for cutting precision and speed.

Our prepreg slitting machine is engineered to cut the prepreg mother roll into narrow tapes to meet your application requirements. It can cut from a width of 600-1500mm down to 10mm.

Jota prepreg cutting machines are divided into parts, including web-feeding, unwinding, rewinding, control, and waste discharging.

We’ve been manufacturing these slitting machines for over 20 years. And we’ve shipped to several large prepreg manufacturers across the world.

Our carbon fiber prepreg cutting machine can cut fiberglass, carbon fiber, graphite gasket, asbestos, and so much more.

Our carbon fiber prepreg cutting machine has the following parameters:

Type: Vibrating knife cutting machine

Current: AC

Voltage: 380V±10%/220V±10% optional

Rated Power: 11kw

Control Method: CNC

Maximum Engraving Depth: <50mm

Positioning Accuracy: ≤0.02mm

Repeat Cutting Accuracy: ±0.05mm

Maximum Cutting Speed: 2000mm/s

Fast Forward Speed: 200-2000mm/s

Scope of work: Customized

Machine Size: Customized

Our carbon fiber prepreg cutting machine is designed to be a complete replacement for manual cutting.

It uses a computerized intelligent automatic discharge for improved discharge effectiveness and material utilization.

Additionally, the whole machine is welded.

This helps enhance the cutting accuracy, allowing for just ±0.02mm cutting error. It can reach a top speed of up to 2000mm/s, meaning that the efficiency is significantly improved.

With an automated feeding module, you’ll be able to achieve automatic continuous cutting.

Also available is the vacuum adsorption table. Vacuum adsorption fixes the material during cutting to ensure maximum cutting accuracy.

Generally speaking, Jota Machinery’s carbon fiber prepreg cutting machine saves you a lot of manpower and material costs.

With it, you have what it takes to meet the needs of various customers – whether in small batches, multiple styles, or short delivery times.

If you’re facing the issue of higher labor costs due to recruitment, this fiberglass prepreg cutting machine will solve this problem. It replaces human labor so that your factory can develop.

If you’re interested in this type of machine, feel free to send us an inquiry.

In order to let you know more about we Jota company, a professional CFRP CFRTP prepreg slitter manufacturer, please watch the following video for reference.

We Jota could also supply the following related machines, if you are also interested in CFRP CFRTP Unidirectional Tape Prepreging Line, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine