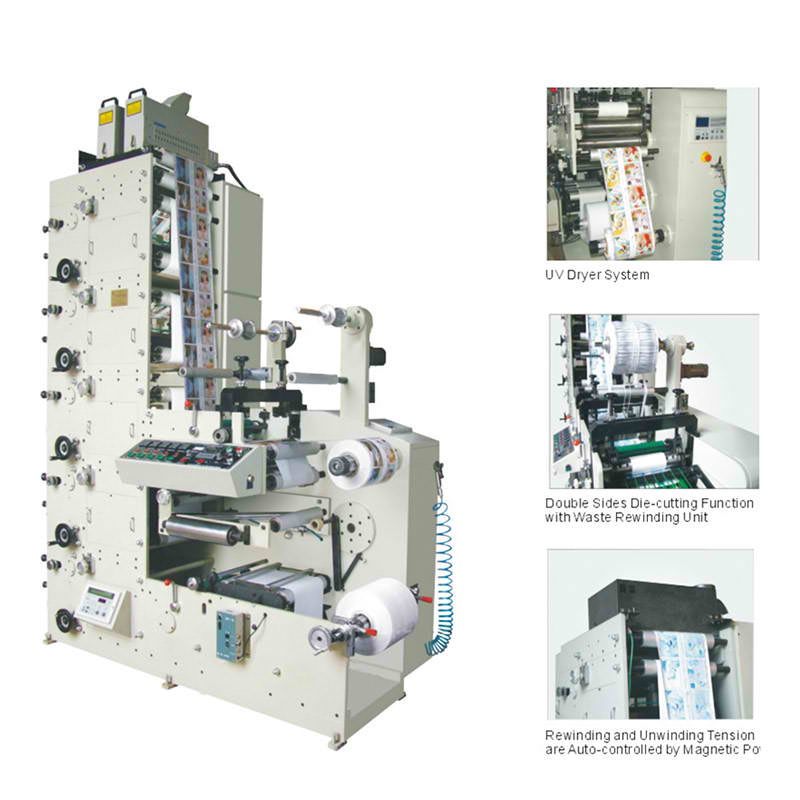

JT-JTH-4100 4 Colors Thermal Paper Flexo Printing Machine

- Printing Length 300mm-1100mm

- Max. Machine Speed 100m/min

- Max. Printing Speed 80m/min

- Color Register Precision ±0.30mm

- Specification

- Video

| Item | JTH-4100 4 colors thermal paper flexo printing machine |

| Colors | 4 |

| Web Width | 1000mm |

| Max. Printing Width | 960mm |

| Printing Length | 300-1000mm |

| Max. Machine Speed | 100m/min |

| Max. Printing Speed | 80m/min |

| Anilox Roller | 200LPI-1000LPI, ink loading capacity is 3.5bcm-10.5bcm |

| Precision | ±0.30mm (horizontal); ±0.30mm (longitudinal) |

| Max. Unwinding Diameter | 600mm |

| Max. Rewinding Diameter | 600mm |

| Tension Range | 3Kg-50Kg |

| Tension Precision | ±0.2Kg |

| Unwinding/Rewinding Shaft | 76mm (3″) air expanding shaft |

| Air Pressure | 0.6Mpa |

| Drying Power | 60kw |

| Air Blower Power | 3.2kw |

| Main Motor Power | 7.5kw |

| Total Power | 70kw |

| Overall Dimensions (L x W x H) | 5400mm x 3600mm x 3600mm |

JT-JTH-4100 4 Colors Thermal Paper Flexo Printing Machine

Last Update Time:24/11/2022

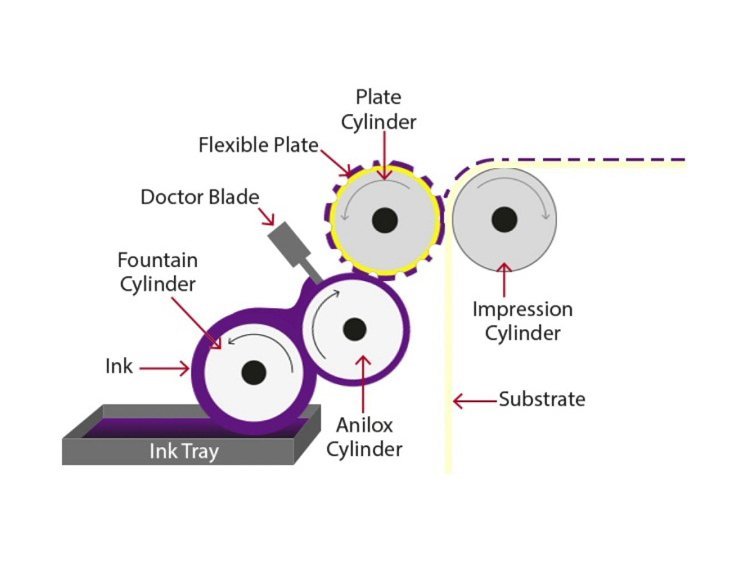

4 color is the one type among our flexo printing machine. You can mix various color basic on CMYK printing knowledge. JT-41000 thermal paper flexo printing machine has been exported to Saudi Arabia, Egypt, Mongolia, etc.

Egypt client’s joint photo with JT-JTH-4100

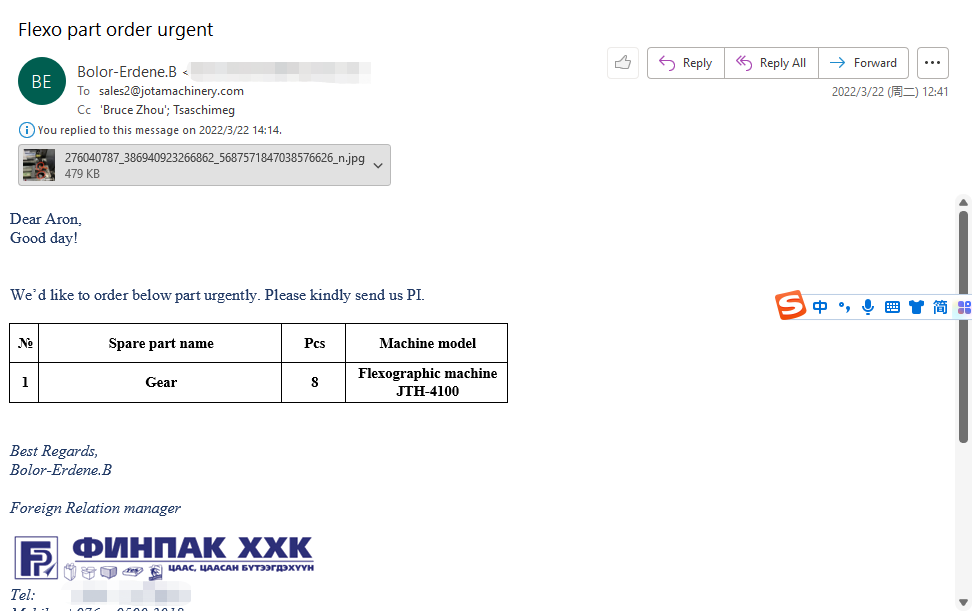

Mongolia client Finpack LLC also purchased JT-JTH-4100 4 colored thermal paper flexo printing machine from Jota.

The owner of Finpack LLC LLC is a Finn. He has been in Mongolia for more than 30 years setting up a factory. The current owner is the second generation, Mr. Joachim.

They used to have a second-hand paper slitter machine made in Finland, the 2nd hand machine has more than 30 years of history.

Mr. Joachim visited China for the first time in 2014. Similarly to other customers, he investigated numerous suppliers. He has extensive knowledge of the structure and transmission of the equipment.

He was not very satisfied with most suppliers’ machines.

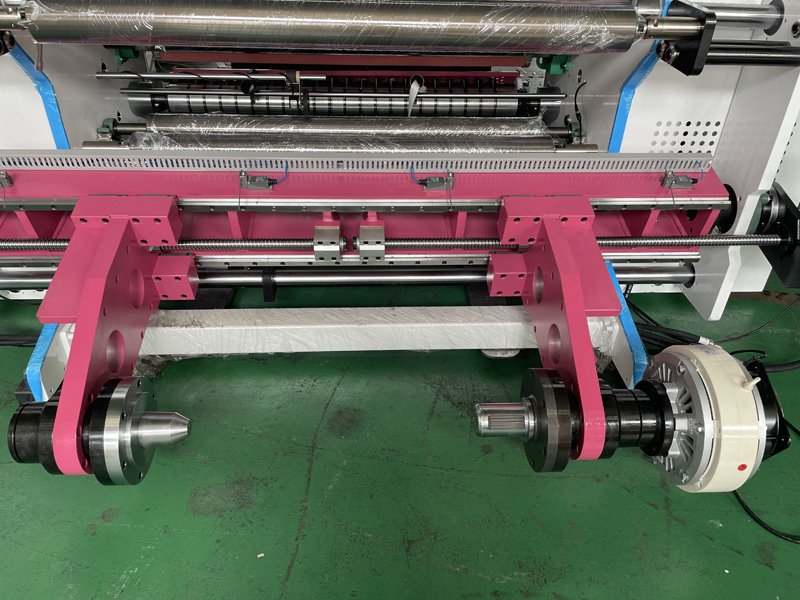

When Mr. Joachim came to our company and saw the transmission of our slitting machine, he was deeply moved and immediately decided to order our machine.

Even if other suppliers’ same type of machines is 30% cheaper, Mr. Joachim still chose Jota’s impressive machine.

The majority of small thermal paper rolls in Mongolia were previously imported from China.

As soon as Finpack LLC began mass production, it dominated the local market with a 30% market share and became Mongolia’s leading provider of paper small rolls.

As a result, Mr. Joachim bought a JT-SLT-900 paper roll slitting machine in 2017, a new JT-SLT-900A paper slitting rewinding machine, and a JTH-4100 four-color flexo printing machine in 2018.

New JT-SLT-900A Thermal Paper Slitting Rewinding Machine

Speaking of flexo printing machines, Finpack LLC was originally equipped with a second-hand European imported single color flexo printing machine.

As the market’s printing demands increase, single-color printing is no longer sufficient to meet these demands, as the printing needs of the majority of end customers are typically two or four colors.

Because of this, Mr. Joachim decided to purchase a high-quality 4-color printing press in 2018.

In view of Mongolia’s unique geographical location and the transportation that is not very convenient, we provide all kinds of commonly used consumables for Finpack LLC.

These consumables include water-based inks, anilox rollers, plate cylinders, printing plates, etc., consumables, and accessories that customers can think of, and we all helped him find them.

After the guests received the machine, they asked us to send engineers to Mongolia to assist them in installing and debugging the machine.

JT-JTH-4100 Flexo Printing Machine In Finpack Factory

We Jota have sent two groups of people to debug and successfully assist the customer to start the machine. The following video is the machine running video, it was recorded after the machine started to work smoothly.

Now we keep in close contact with Finpack LLC every year, and we will help them solve any accessories requirements.

Overseas debugging and parts replacement have always been concerns of customers. As a professional supplier, Jota pays special attention to the support of customers in these two aspects.

Considering the thermal paper’s particularity, we have made many optimizations and improvements for the JT-JTH-4100 flexo printing machine, such as an independent unwind stand, hydraulic loading, independent surface winding, etc.

The main selling point of JT-JT-4100 is also reflected in the following aspects.

For ceramic anilox roller, the general range of LPI for paper printing is 300-500, and the support range of ceramic anilox roller is 300-1000.

The size of the LPI will affect the resolution of the printing quality. The higher the LPI of the anilox roller, the clearer the resolution. However, the LPI suitable for cash register paper generally does not exceed 500.

Because if it exceeds 500, the ink carrying capacity of the anilox roller will be lower than 3.31BCM, as the anilox roller’s ink transfer volume is only about 30%, equal to 1BCM (1BCM = 1.55cm3/m2).

If such a small amount of ink is transferred to the plate cylinder, it will eventually affect the image printing quality.

Imported comma-shaped doctor blade cooperating with ceramic anilox roller, protects the surface of the anilox roller and improves the resolution. The comma-shaped doctor blade is consumable, it is recommended to buy a backup.

At the same time, the closed ink cartridge structure is also optional, which improves the machine running speed.

Optional Closed Chamber Ink Cartridge Structure

For large-weight parent rolls, we optimized and strengthened the entire body structure, equipped with an independent unwind stand and surface winding section, and provided optional pneumatic brakes and shaftless unwind stand for customers to choose.

Thermal paper has the possibility of blackening at high temperatures, and the printing machine is equipped with a heating and drying function.

Therefore, the entire thermal paper printer has very high requirements for temperature control, and it is necessary to ensure that the ink can be dried without blackening the surface of the thermal paper.

Jota machinery also has special experience in this section, and welcome you to send an inquiry on our company’s website for further communication.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Cardboard Tube Cutting Machine