CAD Plotter Paper Roll Slitter | Best Choice for Boosting Output

- The first slitting machine was born in 2013

- Working for 2-inch & 3-inch paper core rewinding

- Max unwinding width 2100mm

- Automatic loading paper tube

- Customized packaging line

- Label sealing or double sided tape

Jota Slitting Rewinding Machine

If you are looking for a suitable jumbo roll slitting rewinding machine whether you are in the field of printing, packaging, new energy, aerospace, or new carbon fiber technology materials.

Our professional team could meet your requirement to providing a suitable solution on slitting rewinding machine.

As a professional jumbo roll slitting rewinding machine manufacturer, we have not only 20 years of experience, but also a highly educated R&D team, advanced mechanical design team, and electrical software design team.

These can ensure that our slitting rewinding machine can meet customer needs and conform to the market requirement.

At the same time, our company is also completing its own upgrading and transformation.

From the most basic paper and film roll slitting rewinding machine to the latest new energy carbon fiber and the slitting of aerospace materials, this is also a testimony of our own strength.

Currently, we can provide slitting machines for various materials.

The width of parent mother rolls can reach from 50mm to 3500mm, and the slitting width can range from 3mm to 3500mm.

There are various winding methods such as reverse winding, disc winding, and rewinding. The maximum diameter can be up to 1800mm. There are also various slitting models for you to choose from.

Many people have a misunderstanding about the slitting rewinding machine.

You think that it is to find a simple machine to cut large rolls into small rolls or rewind them into small rolls.

In fact, different material characteristics, hardness, tension requirements, and subsequent processes are different.

The requirements vary greatly.

For each different material, the material threading flowing route on the machine, the angle between the roller and the diameter of the roller, and the selection of the slitting knife are all professional technical issues.

If you are looking for a professional jumbo roll slitting rewinding machine supplier, Jota Machinery should be your best choice.

Jota slitting rewinding machine could be applied for many different materials,

such as adhesive labels, kinds of paper, film, foil, non-woven fabric, CFRP, CFRTP, FRP prepreg, etc.

For a deep discussion about Jota slitting rewinding machine, please just send us an inquiry.

CFRP, CFRTP, FRP Prepreg UD Tape Slitting Rewinding Core Technology

Jota Machinery: Original Slitting Rewinding Machine Manufacturer in China

Jota is capable of manufacturing 30 sets of slitting rewinding machines in 1 month.

We also accept free material converting test, you just need to send some of your material to us.

we will use our Jota slitting rewinding machine test it, then show you the testing video.

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

CAD Plotter Paper Roll Slitter Machine : Production Solution Expert

CAD plotter paper roll, also known as large-format or engineering paper, is a specialized medium meticulously designed to meet the unique requirements of plotters and wide-format printers.

Widely utilized in sectors such as architecture, engineering, construction, and design, plotter paper plays a pivotal role in producing precise and detailed drawings, maps, blueprints, and other essential large-scale documents.

At its essence, plotter paper symbolizes a commitment to excellence in craftsmanship.

Crafted from high-grade bond or engineering paper, it undergoes a rigorous manufacturing process to ensure not only durability but also a smooth surface that enhances the clarity of printed output.

Some variations feature specialized coatings or treatments, such as water-resistant layers, providing an additional layer of resilience to its performance.

The genesis of plotter paper can be traced back to the mid-20th century, emerging alongside the growing need for large-scale technical drawings in engineering and architectural domains.

Initially, pen plotters were employed for rendering vector graphics on paper, offering a convenient means of reproducing intricate designs with unparalleled precision.

Technological advancements ushered in inkjet and electrostatic plotters over time, marking significant milestones in the evolution of plotter paper.

Early versions of plotter paper faced challenges such as ink absorption and line definition.

Innovations in coating technologies were introduced to address these concerns, paving the way for improved print quality.

What’s the use of CAD plotter paper rolls?

Key Specifications:

Versatile Thickness (45g – 120g):

The core strength of our plotter paper rolls lies in their versatility. Ranging from a sturdy 45g to a substantial 120g, these rolls adapt to the demands of your diverse printing needs.

Whether you’re drafting intricate designs or producing technical schematics, our plotter paper serves as the canvas for your vision.

Total Length Options (50m and 100m):

Acknowledging the importance of continuous printing, we offer plotter paper rolls in two lengths – 50 meters and 100 meters.

Whether you’re working on a concise project or an expansive masterpiece, our roles ensure uninterrupted creativity, roll after roll.

The Art of Precision:

Detail-Driven Printing:

Engineered for precision, our plotter paper rolls guarantee sharp, clear prints that capture the intricacies of your designs with unparalleled accuracy.

Color Brilliance:

Witness your colors come alive. The optimized surface of our plotter paper enhances color reproduction, making your graphics, charts, and illustrations vibrant and true to life. Your creations deserve nothing less.

Compatibility Across Platforms:

Versatility extends beyond thickness and length.

Plotter paper rolls seamlessly integrate with a wide array of printers, from inkjet to laser plotters.

Whatever your printing setup, rest assured that our roles will meet and exceed your expectations.

The Science of Durability:

Resilient Construction:

Designed for durability, our plotter paper resists wear and tear. This makes it the ideal choice for projects that demand longevity, ensuring that your prints stand the test of time.

Environmentally Conscious:

We take pride in our commitment to sustainability. Our plotter paper rolls are crafted with eco-friendly materials, making them a responsible choice for environmentally conscious printing.

Applications:

Architectural Marvels:

Bring your architectural visions to life with prints that reflect the precision of your designs.

Engineering Excellence:

From technical drawings to complex schematics, our plotter paper handles the intricacies of engineering with finesse.

Graphic Design Mastery:

Elevate your graphic design projects with prints that showcase the true brilliance of your creativity.

CAD Precision:

For CAD applications, our plotter paper rolls deliver the accuracy and detail demanded by the most sophisticated designs.

CAD plotter paper roll slitter machine

In the present year, our sales team engaged in substantive discussions with a Russian customer concerning the production plan for our CAD drawing plotter paper roll slitter machine & packaging line.

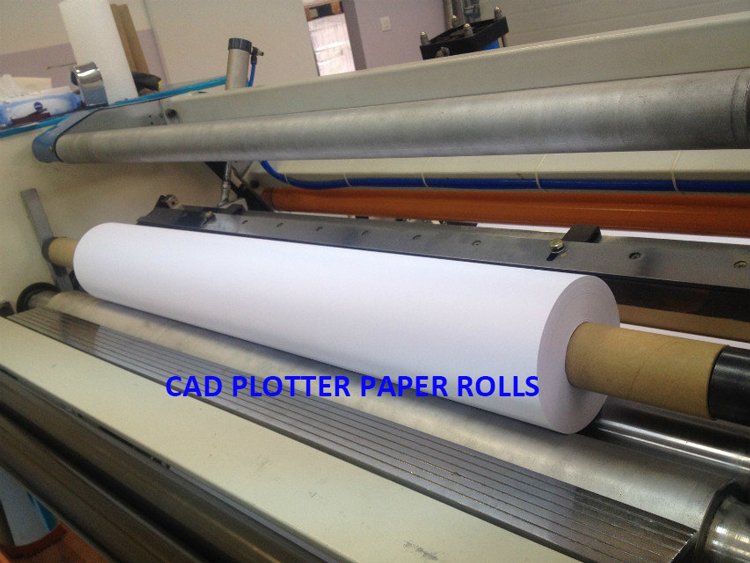

The CAD plotter paper roll slitter machine is a specialized converting equipment designed for the precision slitting and rewinding of office paper.

It is primarily used to accurately separate jumbo roll into 600-1200mm small width.

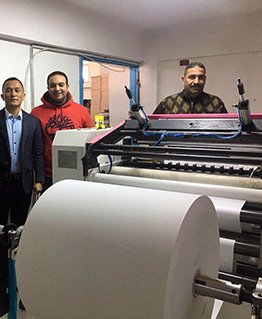

Our journey with plotter paper commenced in 2013 when our initial CAD drawing paper slitting machine found a home with a customer in Croatia.

At a milestone moment, this first-generation slitter rewinder machine boasted a maximum unwinding width of 1100mm.

Since then, our specialized slitting machines have evolved to the third generation, achieving a remarkable width of 2100mm.

Our engineers were on-site in Croatia on December 13th, diligently debugging the latest iteration of our slitting machine, as depicted in the accompanying image.

A notable distinction between our advanced slitter machine and its conventional counterpart lies in the maximum rewinding tube diameter.

Specifically, the CAD drawing paper rewinding tube attains a substantial 3 inches (76mm) in diameter, while the thermal paper rewinding diameter ranges between 13-17mm.

Meticulous adjustments to the tucker enable seamless handling of both 3-inch and 2-inch rewinding requirements.

Despite appearing as minor details, our engineers and clients collaboratively overcome challenges to meet exacting customer specifications.

Before venturing into plotter paper, water-based glue sealed the tails of small rolls.

However, due to the double-layered nature of CAD drawing paper, water-based glue proved impractical, leading to wastage.

Drawing upon our expertise in slitting this distinctive paper, we now utilize double-sided tape or labeling for tails sealing, ensuring precise control over production quality.

Yet, the crux of the challenge lies in the packaging phase.

With a minimum slitting width of 600mm, simultaneous production of two different widths results in a mismatch between the slitting and packaging units.

While the winding speed is commendable, packaging operators must continuously handle various specifications, reaching a maximum slitting width of 2000mm.

To address low output and extensive manual intervention arising from speed disparities between the two machines, a comprehensive solution was developed in December.

For a detailed understanding of how we efficiently package drawing paper of different specifications while enhancing production, please feel free to contact us.

Given the confidential nature of this solution, we refrain from providing extensive details here.

The Jota Machinery sales team engaged in a fruitful discussion on slitting and packaging solutions with our Russian counterparts in the morning.

Subsequently, our team led the customers on an insightful tour of our fully automatic thermal paper slitting machine in the afternoon.

By evening, we received a positive response from our esteemed customer, expressing recognition and satisfaction with our service.

Over the past decade, our unwavering commitment to communication with customers has driven continuous improvement in our slitter machine.

By delving into the core needs of our clientele, addressing root causes, and providing innovative solutions, we have cultivated the secret to our success.