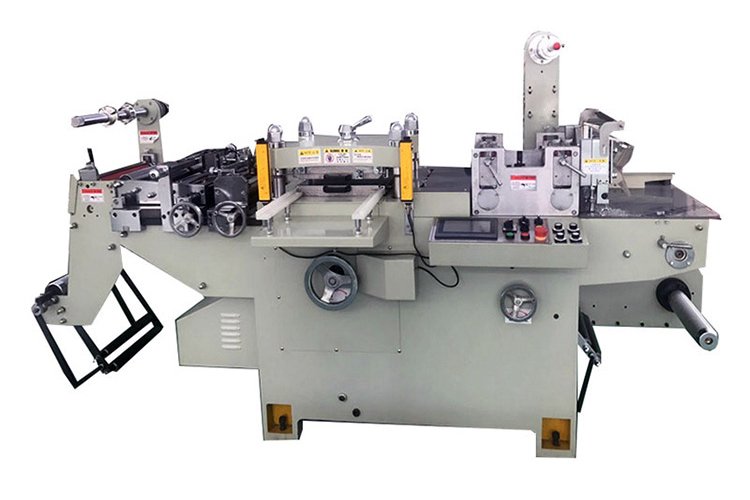

JT-ADC-320 Die Cut Sticker Machine

- Cutting Speed 20-170 pcs/min

- Max. Unwinding Diameter 500mm

- Max. Web Width 320mm

- Max. Die Cutting Width 300mm

- Specification

- Video

| Parameters | |

| Item | JT-ADC-320 die cut sticker machine |

| Cutting Speed | 20-170 pcs/min |

| Max. Unwinding Diameter | 500mm |

| Max. Web Width | 320mm |

| Max. Die Cutting Width | 300mm |

| Max. Die Cutting Length | 300mm |

| Die Cutting Precision Tolerance | ±0.1mm |

| Total Power | 4.5Kw |

| Power Voltage | 220V/380V |

| Weight | About 2000Kg |

| Overall Dimensions (L*W*H) | 2.9m x 1.4m x 1.4m |

| Specification |

| JT-ADC-320 die cut sticker machine adopts an accurate flatten die-cutting system, computerized material feeding, two lateral registration sensors, and one longitudinal registration sensor, which ensures high die-cutting accuracy. It is suitable for the die-cutting of the adhesive label, sticky label and laser hologram mark. |

| Die-cutting, waste rewinding and finished-material rewinding are finished in one process. |

| Mitsubishi PLC and touch screen control, all the parameters can be preset on the touch screen, such as die-cutting speed, die-cutting length, servo motor speed, etc. Once preset, the record stored. |

| This is the ideal auxiliary equipment for flexo printing machine, silk screen printing machine, rotogravure printing machine, and hologram mark printing machine. |

| The machine uses automatically cycling the oil-supply system to ensure the stable pressure and service life of the machine. |

| High precision, web path controlled by servo motor. |

| Punching, laminating, or hot stamping unit can be customized as optional part. |

JT-ADC-320 Die Cut Sticker Machine

Last Update Time:24/11/2022

One of our Zimbabwean customers by the name of Nico choose our die cut sticker machine to expand his business. We admired his confidence in Jota Machinery.

Mr. Nico Dlamini Stands By JT-ADC-320 Die Cut Sticker Machine

Mr. Nico Dlamini is from Bulawayo, Zimbabwe. He has a small printing plant of his own, and a second-hand Heidelberg 2 colors offset press, which is used for printing some common advertisements.

He has been in this field for more than 20 years and has very deep experience in printing.

In 2008, Mr. Nico predicted that the self-adhesive label would have a big market in Africa.

Self-adhesive Labels

So, he decisively separated a piece of space from the original printing plant, pooled a sum of money, and started label printing.

After communicating with us by email back and forth for nearly 2 months, he was very impressed by our professionalism and enthusiasm.

Jota Factory

Subsequently, we started the first order of our cooperation, a 4+1 flexo printing machine, 2 sets die cut sticker machines, and 2 sets of 320mm width mini slitting rewinding machines.

We assembled all the machines with some raw materials, put them in a large container, and sent them to Mr. Nico’s city together.

In shipping, we also have our own professional suppliers. Goods sent to Bulawayo are sent to Durban, South Africa first, then are transferred to Bulawayo by rail.

After 90 anxiously waiting, Mr. Nico received his first batch of machines from China.

With these machines, as if a soldier had a weapon, Mr. Nico quickly started his label printing business in full swing.

Die Cut Sticker Machine

Big Slitting Rewinding Machine

320mm Width Mini Slitting Rewinding Machine

Subsequently, Mr. Nico’s wonderful life and the prosperous business officially began.

Because Africa is very poor and lacks a lot of light industry equipment, Mr. Nico has purchased more than 30 sets of various equipment from our company.

Those machines include slitting machines, cut-size sheeter machines, paper cutters (guillotine), shrink film packaging machines, book cutting machines, bookbinding machines, thermal roll slitting machines, etc.

Anyway, if any equipment is required, Mr. Nico will contact Jota, listen to our suggestions, and let us help him purchase it.

With professional equipment, Mr. Nico quickly developed into Zimbabwe’s premier printing house.

At the same time, Mr. Nico shared with us that doing business in the local area is very profitable. He has also invited us to Zimbabwe to travel and start a business many times.

Now Mr. Nico travels to China every year, and our relationship with him is like our own relatives. We often visit the great rivers and mountains of China together.

Mr. Nico and his wife came to visit charming China

We hope that the relationship with all customers can be based on business, and eventually surpass business partnerships and become an intimate relationship. We share each other’s stories and witness each other’s growth.

Jota Machinery has been waiting for you in China, maybe you give us a phone call or send us an email, you can have a real good friend in faraway China.

Die Cut Sticker Machine FAQ Guide

Die-cutting saves time and ensures a consistent, high-quality cut, making wedding invitations and other important crafts easy and fun to do at home.

We’ve seen a lot of change in the last twenty years because sticker making, scrapbooking, and crafting have become more popular.

Die cutting machines are less expensive and smaller now than they were in the past because of new technology.

Models that could only cut paper before have been changed so that they can cut vinyl, felt, and even metal with ease. They used to be big and cumbersome, but now they are light and sleek, like a desktop printer.

Check out our guide to the best die cutting machines if you’re willing to buy one.

- What Is a Die Cut Sticker Machine?

- Working Process for Printed Sticker Sheets

- Working Process for Printed Sticker Rolls

- Can I Print with the Die Cut Sticker Machine?

- Benefits of Flexo Printing

- Raw Material

- Are Die Cut Stickers Recyclable?

- Digital V.S. Manual Die Cutting

- Is Die Cut Sticker Machine Eco-Friendly?

- Die Cut Sticker Machine Price

- Ideal Die-Cut Sticker Machine Manufacturer

- Qualities You Should Look While Buying the Die Cut Sticker Machine

- Manufacturing Process of Die Cut Sticker Making Machine

- Advantages of Using Die Cut Stickers

- Customized Die Cut Sticker Machine

- Is Jota Die Cut Sticker Machine CE Certified?

- Is It Profitable to Use Die Cut Sticker Machine?

- Does Die Cut Sticker Making Machine Waste Paper?

- Do I Get OEM Services?

- After-Sale Services

- Applications of Die Cut Stickers

- Various Types of Die Cut Stickers

- Difference between Decal and Stickers

- Are Stickers Waterproof?

- What Are Die Cut Labels?

What Is a Die Cut Sticker Machine?

Die cutting is a method of mass-producing cut-out shapes with a machine.

There are three types of die cutting machines:

- Manual

- Digital

- Industrial

Die cutters for industrial use are made for large production. The entire material cutting process is automated, that allows the production of more shapes at a faster rate.

These machines are equipped with one of the following:

- The shapes are created by pressure supplied to a rounded anvil that presses down on the die in a rotary cutter.

- As the material passes through a hydraulic press, the shapes are created in the flatbed cutter.

What exactly is a die cutting machine?

To begin, I’ll give you a bird’s eye view before diving into their specialized uses.

Any procedure in which a machine is used to mass create a single cut-out shape is known as die cutting. This eliminates the need for a stencil or scissors to cut out the same design repeatedly.

Die cutting machines were used to be bulky, inefficient, and difficult to operate industrial machines. Now, Jota has made it convenient for you to operate a die cut sticker machine.

A die cutting machine uses a range of materials to create designs, including paper, cloth, sticky sheets, and magnets.

It cuts the stickers into custom shapes and sizes.

They’re usually the size of a printer and work in a similar way. The die cutting machine slices through the material where the printer inserts ink.

The primary distinction between machines is whether they are manually or digitally operated. Here you will find the similarities and differences, as well as how die cutting works for each.

Working Process for Printed Sticker Sheets

- Die cutting means the stickers that are cut in a specific shape.

- A special tool is made from a block of wood and steel rule which is called a die tool. The die tool is set up with the same layout as the printed sheet of stickers.

- The die tool requires great care to make sure that stickers are aligned properly within the die.

- Rubber is added to the die cuts so that the stickers do not get caught in the tool while cutting.

- Glue is applied to the inside surface of the tool and a thick rubber sheet is pressed into the die.

- A final check is done to ensure that the printed sheets of stickers and the final die align properly on the die cutting press.

- The die is now mounted on the die cutting press.

- After inserting the die into the die-cut machine, great care is required to make sure that the printed sticker sheet and the die are aligned perfectly.

- A single test sheet is used to check the final set-up so that any last-minute adjustments can be made.

- All the printed sheets of stickers are now loaded into the die cut sticker machine’s feeder automatically.

- A series of suction tubes and steel grippers grab one sheet at a time and place it on the cutting surface.

- Each sheet is cut individually in place to the side.

- The die cutting is now finished and a single cut by this cutting machine frees the stickers for the next step.

- The die cut stickers are now punched out by hand. A simple rubber band keeps the sacks of stickers in order.

After knowing about the cutting process of printed sticker sheets, let us see how sticker rolls are cut.

Working Process for Printed Sticker Rolls

- In case of the printed sticker rolls, the die cut machine uses large printed sticker rolls instead of smaller sheets.

- Jota’s die-cut machine is fully automatic and uses printed sticker rolls for making die cut stickers.

- The whole process is automatic and reduces the manual aid. While in the case of the printed sheets, you may need to work manually alongside the working of the machine.

- The large printed rolls of stickers are loaded into the feeder of the die cut sticker machine.

- The machine has a 500mm unwinding diameter where it unwinds the sticker roll.

- It cuts the sticker rolls with a speed of 20 to 170pcs per minute which is quite favorable for high production.

- The rolls slide into different cylinders and the cutter cut it into desired shapes of the stickers.

Can I Print with the Die Cut Sticker Machine?

The JT-ADC-320 from Jota is a flatbed down-cutting machine that can’t be used with an inline printer.

But if you want to print your die cut stickers, Jota has another state-of-the-art machine for that called the JT-ADC-320G die cut sticker making machine.

It is made with a printing unit that goes along the line. It is a roll-to-roll printer that can print a lot of pieces at once.

Jota puts inline flexo printers on this machine so that printing is easy and can be done in many colors.

To do this, you put rolls of raw paper into the machines and tell the machines how to make the stickers you want.

When the stickers are printed on the paper, the rolls are moved to the cutters, where the stickers are actually cut out.

Benefits of Flexo Printing

- The most common inks used in flexo printing are water-based, making them easier to work with and drying faster.

- The technique for creating flexo printing plates is simple, and it can be quickly adapted to a variety of substrates.

- In areas like fiber-board packaging manufacture, new developments in in-line flexo printing presses have allowed flexographic presses to compete against gravure and lithographic equipment.

- A flexo press employs water-based ink or UV/UV ink and takes less time to set up than a gravure press, resulting in less waste.

- LED inks are considerably less harmful to the environment than gravure inks.

- Flexo presses are ideal for medium- to long-run printing jobs.

Raw Material

As the outcome is heavily dependent on the input, raw material is an important step to consider after purchasing the sticker die cutting machine.

A high-end manufacturer, such as Jota Machinery, develops your equipment with high-quality raw materials and components from well-known manufacturers.

For this reason, your machines are capable of delivering excellent results and a quick (ROI) Return on Investment.

The die-cut stickers are made by Jota machinery using high-quality vinyl paper, glue, and ancillary equipment.

The raw material used for making die cut stickers is mainly vinyl paper.

A little detail about the type of raw materials used in the manufacturing of the die cut stickers is as below.

Vinyl

Vinyl has a tiny flex or stretch to it, which allows it to be applied to both flat and curved surfaces more easily. It is also long-lasting and silky to the touch.

Removable White Glossy Vinyl

This material includes a strong adhesive that will stay on your chosen surface, as well as bubble-free air egress technology that makes application a breeze.

This material is also waterproof and weather-resistant. Also, it can be removed quickly without leaving any sticky residue or glue behind.

Removable White Matte Vinyl

Matte vinyl is a terrific way to give your stickers a nice matte feel. Matte stickers have a more subtle, natural look; thus, the cosmetic difference is basically the only distinction.

This material is identical to White Glossy Removable vinyl in all other dimensions, and it is likewise waterproof, outdoor durable, and bubble free.

Permanent White Glossy Vinyl

Permanent adhesive has the strongest “stick” of any type of glue. As a result, they’re ideal for more industrial uses like property identification and warning or safety labels.

This material is also weatherproof and robust outdoors. Although permanent vinyl is simple to apply, it does not come bubble-free. Because of the powerful adhesive, you can rest assured that they will not be removed carelessly, making them ideal for use outside.

White Permanent Glossy BOPP (Biaxially Oriented Polypropylene)

It is a plastic-based label material that is perfect for labeling objects that require resilience and longevity.

White Permanent Glossy BOPP resists practically everything (fading, oil, heat, and abrasion), making it ideal for applications that will see a lot of use.

This material is available in rolls with a minimum order quantity of 250 units. BOPP stickers are often less expensive per sticker on a roll than white vinyl, especially if you order bigger quantities.

White Permanent Matte BOPP

As it can be written on with pens, pencils, or markers, matte BOPP is ideal for product labels that carry unique information.

You can write multiple flavors, expiration dates, and fragrances on this.

They’re also waterproof and long-lasting (just not quite as protected as our durable BOPP, as there is no lamination on them).

BOPP stickers are often less expensive per sticker on a roll than white vinyl, especially if you order bigger quantities.

Clear BOPP

BOPP clearly has all of the advantages of BOPP white, but with a transparent background.

This material is ideal if you want to see the package through the sticker or if you want to see through clear sections.

Holographic

These stickers are manufactured from an innovative 3mil thick metalized vinyl and combined with a permanent acrylic adhesive.

They are digitally printed with white ink and made from an innovative 3mil thick metalized vinyl.

They’re designed with a highly reflective metallization layer that creates stunning visuals even in low-light conditions, such as on a car’s dashboard at night.

Glitter

Glitter is back in style in pop culture. Glitter stickers are the perfect way to bring your rainbow vision to life if you’re seeking to add some flair to your artwork.

This metalized vinyl is made from a full-spectrum, holographic flake substance that is very high quality and long lasting.

Electric Films for 3C Products

By 3C we mean, Computer, Communications, and Consumer electronics. We can also call it Information Appliances.

Metallic shiny stickers on these appliances are made with electric foils. You can give a glossy shine to your 3C products with these stickers.

Custom-made 3C product stickers with printed product descriptions and custom designs are a need of time.

Are Die Cut Stickers Recyclable?

No matter how advanced technology is used, but not all stickers are recyclable.

One reason for variation is that recycling facilities vary in their capabilities, and particular stickers and materials may necessitate more specialized equipment and sorting processes than others.

Always check with your local facility to see what services they offer.

Furthermore, certain materials have qualities that make them only useful once, or the combination of components makes recycling impractical.

When a paper sticker adheres to cardboard or corrugated packaging the paper is usually considered recyclable.

Ink and adhesive, as well as other elements from the package are sometimes considered contaminants and get removed from the process.

Digital V.S. Manual Die Cutting

Digital Die Cutting

Digital die cutters are electric and require electricity to operate. They contain a small microprocessor that, similar to how a printer controls an ink nozzle, controls a cutting blade.

They don’t need a manual die since they can regulate where the cutting blade slices the material.

They not only perform the same functions as a printer, but they also have a similar appearance and footprint.

Designs for digital die cut machines can be downloaded online, or memory cartridges can be purchased and inserted into the machine.

Digital die cutters can be connected to your computer by USB or Bluetooth wirelessly.

Manual Die Cutting

Manual die cutting machines are less expensive and more powerful than digital die cutting machines. Moreover, they can cut through a wider range of materials.

They’re also wonderful for embossing, which is something that most computerized machines can’t do.

Hand-held machines are typically larger and heavier. The major disadvantage is that any design we want to cut, requires an actual die.

Consider a desktop printer that could only print materials with a metal impression. Manual dies and forms are less expensive to buy at first, but they add up over time.

Is Die Cut Sticker Machine Eco-Friendly?

Yes, your die cut sticker making machine is eco-friendly.

It uses biodegradable material in the manufacturing of the stickers so that it does not pollute the environment.

Moreover, it does not produce much waste material which reduces your cost as well.

Die Cut Sticker Machine Price

The features of the machine highly determine the price of your machine. If you want to add more features in your die cut machine, its price will increase.

For example, adding a flexo printer in your die cut sticker making machine can increase the price of the machine up to a certain level.

However, the average die cut sticker machine price oscillates between $10,000 – $50,000.

Ideal Die-Cut Sticker Machine Manufacturer

You can easily find the die cut sticker making machine manufacturer. You just need to conduct research about different manufacturers for the credibility of their work.

In China, Jota machinery is the best manufacturer of the die cut sticker making machine. It has earned international repute and customer trust.

For choosing any credible manufacturer you must check their official website and ask people about their experience with the particular firm. Moreover, you can also contact Jota for its services for you.

Qualities You Should Look at While Buying the Die Cut Sticker Machine

When buying a die cut sticker machine, look for the following characteristics. It may assist you in determining whether or not the machine is of good quality.

- You can judge its qualities by its production speed. Jota’s die cut sticker making machine facilitates you with high-speed production.

It can make up to 20 – 170 pcs/min.

- The use of high-quality components in the production process leads to efficient operation and reduced maintenance costs.

You can also use the maintenance (on demand) and spare parts services.

- Check if the machine I automated or not because that greatly adds to the high-speed manufacturing.

- An ideal die cut sticker making machine is also cost-effective.

- An ideal die cut sticker making machine is simple to use. To run your machine, there are no complicated steps to take.

Put the necessary information into the PLC HMI control panel and watch your die cut sticker making machine work automatically.

- A machine with a compact design is ideal. It may be easily installed in your workspace.

It is also simple to put together, and you may obtain help from the manufacturer (on demand).

- Another key feature that you cannot overlook is the mechanism’s current state. Your die cut sticker production machines are made in accordance with market trends and developments.

You can get the greatest results from your high-quality automated sticker making machine by utilizing cutting-edge technology.

Manufacturing Process of Die Cut Sticker Making Machine

To make your die cut sticker making machine, Jota machinery uses a precise production method. The meticulous method aids in the development of cutting-edge machinery. The steps in the production process are as follows:

Designing and Building

The design of your machine is the initial stage. Jota Machinery creates the machine based on your specifications.

Disclose the design of your ideal die cut sticker making machine to our engineering staff. You can also download a CAD or PDF version of your machine design.

Whether it’s a conventional or custom design, Jota’s engineers and R&D team will provide you with unique and new features.

Assurance of Quality

The raw materials and components are sourced from reliable sources. Before the process begins, the quality control team rigorously inspects each component.

The production procedure begins after the approval.

Collection of Components

The machine components are assembled by a skilled technician. Each component is properly assembled using the engineering diagrams given.

Connections to the Electricity

The electrical engineering team installs the electrical components in addition to mechanical engineering.

Sensors, an EPC system, and an automatic tension control system are installed for accurate automatic operation.

Final Inspection

Engineers take over your machine after it has been assembled and thoroughly inspect it.

Advantages of Using Die Cut Stickers

- Stickers are a fantastic promotional medium for bands, fashion, art, media, and retail, since they allow you to carry your brand anywhere and put it on products and packaging, as well as pass them away as promotional items. The die cut stickers, in short, help you to promote your brand.

- Stickers can be customized with messages, sports team images, and other creative designs to sell as unique items or to effectively spread the news about your non-profit organization or personal cause. It increases customer attraction.

- It is a more suitable way of marketing.

- It is less time-consuming.

- It is less costly.

- You can earn a great profit by using die cut sticker machine.

- When you offer out die cut stickers, consumers think of them as a gift rather than as a marketing tool. This decreases the chance that the stickers will be thrown away and your brand will be forgotten.

- Die cut stickers stand out more because they are already cut into the shape of your design, successfully attracting your audience’s attention.

- Most people nowadays would only display stickers that seem attractive and resonate with them, therefore die cut stickers might help you gain more visibility.

- While it is not ideal to have a complex design while die-cutting, die cut stickers allow for more flexibility, allowing you to highlight your brand’s message and appeal to your customers.

- Die-cut stickers are more appealing than plain stickers, giving you a competitive edge.

Customized Die Cut Sticker Machine

If you feel the need to personalize your straw paper packaging machine to your liking, you may certainly do so.

JOTA completely supports on-demand customizations and provides the most reliable, fully automatic, customized die cut sticker machine on the market.

Whether it’s a machine component, size, or production capacity that needs to be customized, Jota’s highly skilled experts can make your dream machine a reality.

You can also contact Jota services to get your desired die cut sticker machine.

Separate CNC Center for Manufacturing

For machine manufacture, Jota, like most professional industries, has its own CNC center.

Jota allows you to visit their CNC facility to ensure that you are satisfied with the fabrication of your machines.

You can observe the production process, choose your own equipment, and learn how to install and operate it on-site.

Throughout the manufacturing and installation process, Jota works closely with you.

Jota Machinery provides quality control services to ensure that output increases. It can be done directly by the Jota Machinery team or by allowing access to our suppliers’ extensive knowledge and expertise.

Is Jota Die Cut Sticker Machine CE Certified?

You can rely on Jota machinery to deliver machines that meet international safety standards.

The machines from Jota are CE certified. It denotes that your machines are risk-free to operate.

Your Jota die cut sticker machine also has the following certificates:

- CE certificate

- ISO 9001:2015

- SGS

Is It Profitable to Use Die Cut Sticker Machine?

Many foreign customers have profited from running this business due to the numerous advantages of die cut stickers.

Furthermore, making die cut stickers with a Jota die cut sticker manufacturing machine might earn you a lot of money. As people all over the world make a profit from utilizing this equipment.

JOTA also recommends certain business concepts in order to increase business profit. The following features are included in the plan:

- Preliminary market study

- Profit Assessment

- Choosing a Production Location

- Purchasing of Equipment and Raw Materials

- Recruiting Operators

- Business Marketing for Die cut stickers

- Die cut sticker Business Maintenance and Expansion

Furthermore, you can also look at the following video for additional information about the Jota company.