JT-AUX-900 Semi Auto Thermal Paper Production Line

- One-stop production

- -60% labor cost

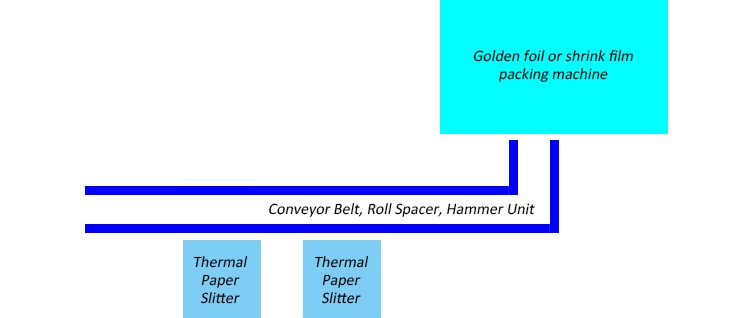

- 1 packing line marries 2 or more slitting machines

- Higher production efficiency

- Specification

- Video

PARAMETERS

| Model | JT-AUX-900 Semi Auto Thermal Paper Production Line |

| Web Width | 900mm |

| Web Diameter | 1000mm |

| Max. Rewinding Diameter | 160mm |

| Min. Slit Width | 25mm |

| Max. Speed | 150m/min |

| Unwinding Shaft | 3” Air Expanding Shaft |

| Rewinding Shaft | 0.5”, 1” are available (or as your request) |

| Voltage | 3 phase, 380V, 50Hz |

| Torque | 100N.m |

| Power | 20Kw |

| Weight | 2100Kg |

| Overall Dimensions (L x W x H) | 5212mm x 2025mm x 1680mm |

| SPECIFICATIONS |

| JT-AUX-900 semi-auto thermal paper production line is used for slitting and rewinding all kinds of thermal paper roll, including thermal fax paper roll, ATM paper roll, ECG roll, till roll, pos roll, adding machine roll, debit machine paper rolls, receipt printer thermal roll, thermal printer roll, etc. |

| FEATURES |

| Siemens PLC and touch control screen, all the parameters are displayed on the screen. |

| Master drive motor is Siemens inverter motor, Inovance AC drive control. |

| Motor-driven chain lifts jumbo roll up or down automatically. |

| Dynamic or static balancing drive roller. |

| Redline marking system, printing red line on finished roll tail. |

| Round blades for slitting, automatic waste disposal by air blower through tube. |

| Automatic tucker, quickly triggers rewinding. |

| Fully automatic tension control PCB to keep constant tension. |

| Auto meter counter, when it reaches the preset length, the machine stops automatically. |

| The overlapping problem could be avoided with lay-on roller. |

| Emergency switch. |

| Automatic core loader, automatic tail cutting gluing unit, roll spacer, hammer unit, shrink film packing machine. |

Why JT-AUX-900 Semi Auto Thermal Paper Production Line?

Last Update Time:12/09/2023

On August 6th, we ship one set of JT-AUX-900 semi-automatic thermal paper roll production lines to Ethiopia.

The video below shows a machine debugging session in our workshop.

JT-AUX-900 semi-automatic thermal paper production line can achieve one-stop production from jumbo roll unwinding to till roll packaging with only one operator.

Of course, there are numerous other features that clients, such as our Georgia client Ivan, appreciate.

Some of the freshmen don’t know how to use or fix our slitting machine, so we made a page with the most common problems and how to fix them.

Initially, Ivan was ready to purchase a thermal paper slitter rewinder from another supplier, he requested the supplier make a video call, to show their real factory.

This call was never connected, then Ivan was lucky to receive our marketing mail, we were always ready to facetime with our clients, and lively show our workshop and CNC center to clients.

Jota Factory

As a professional thermal paper slitter rewinder manufacturer in China, we have fully utilized the advantages of the Chinese manufacturing industry chain, ensuring our machine quality is high-end, and the price is competitive.

Special to semi-auto thermal roll slitting machines, we could share many aspects with you.

For example, the usage, the working principle, etc.

With regard to the usage of semi-auto thermal roll slitting machine, it is mainly used for cutting jumbo roll thermal paper into small till rolls, small till rolls could be put in the cash register, POS, or ATM as printing substrate, and it is a popular in our daily life, visible everywhere.

Then, let me introduce our semi-auto thermal paper slitting machine’s working principle.

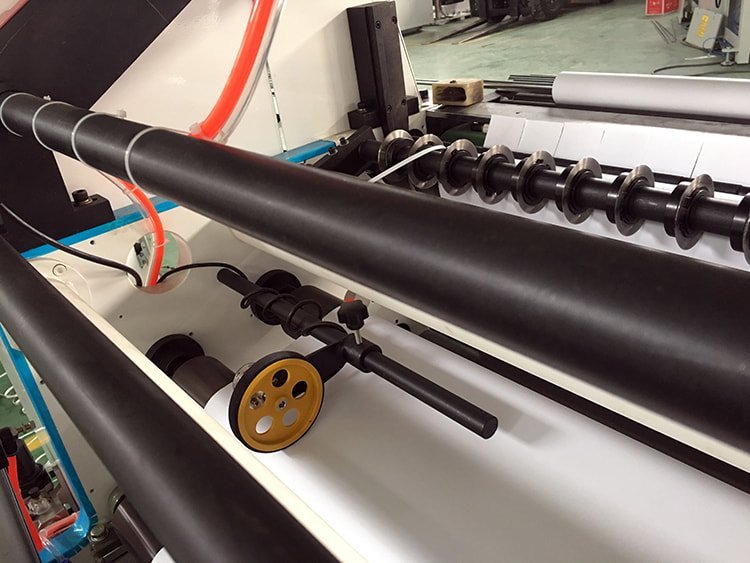

Generally, the thermal paper web is unwound from a thermal paper jumbo roll, runs through drive rollers, and nip rollers, and then comes to the slitting section.

Drive Rollers

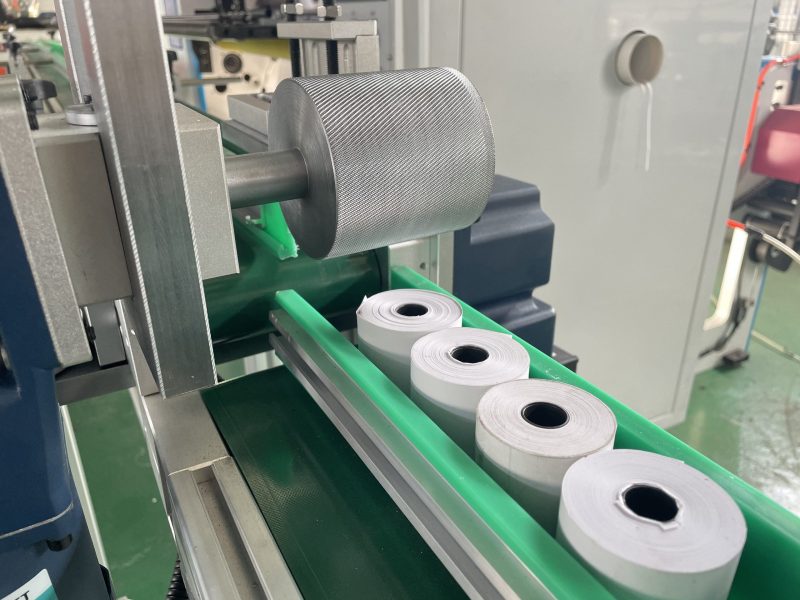

Jota’s semi-automatic thermal roll slitting machine equips with a dual slitting knife system, proactive lower circular knives, and slave upper circular knives to ensure high precision slitting, and effectively minimize material waste.

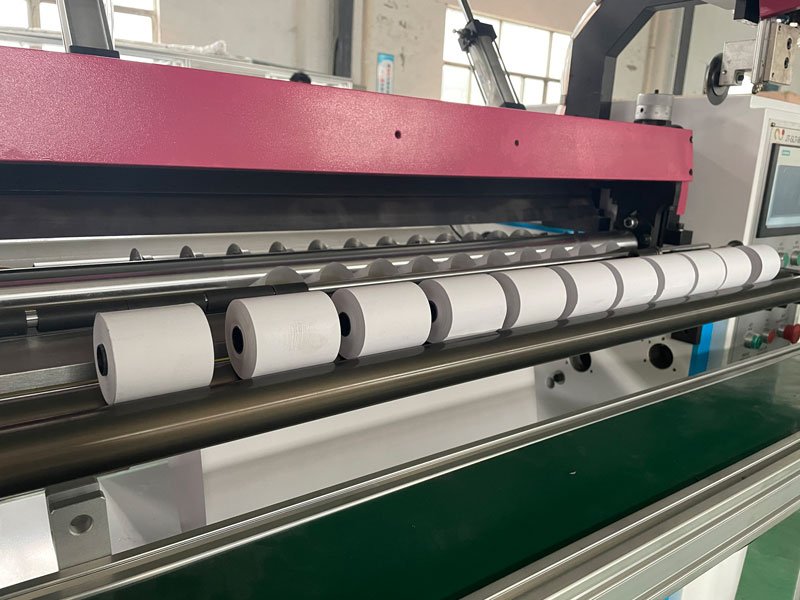

After slitting, separate strips of thermal paper are then rewound on the plastic/paper core of the rewinding shaft, small till rolls are made in this way.

Finished Till Rolls

Ivan chose the JT-AUX-900 semi-automatic thermal paper production line mainly due to several unique selling points, such as one-stop production, 1 packaging line that could serve 2 thermal paper slitter rewinders, etc.

With 2 thermal paper slitter machines working together with 1 common paper roll wrapping machine, the small till roll output doubles.

If you plan to purchase a semi-automatic thermal paper production line, please contact us immediately.

Our rich experience in this industry could assist you greatly save time and energy.

Even if you don’t buy a machine from us, we could also provide some professional suggestions based on our expertise.

After all, we Chinese always remember our ancestor’s saying, 1 more friend is 1 more way.

In addition to the JT-AUX-900 thermal paper production line, Jota also sells independent thermal roll-making machines, such as the economical thermal roll slitting machine JT-SLT-900 and high-end cash register paper roll slitting machine JT-SLT-900C.

Recently, Jota has just released a 1400mm width fully automatic thermal paper roll slitting packing machine JT-SLT-1400FA, from core feeding to finished roll packing, with no need dedicated operator, inline printing function can also be integrated, please send us an inquiry to Jota Machinery to get more details.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine