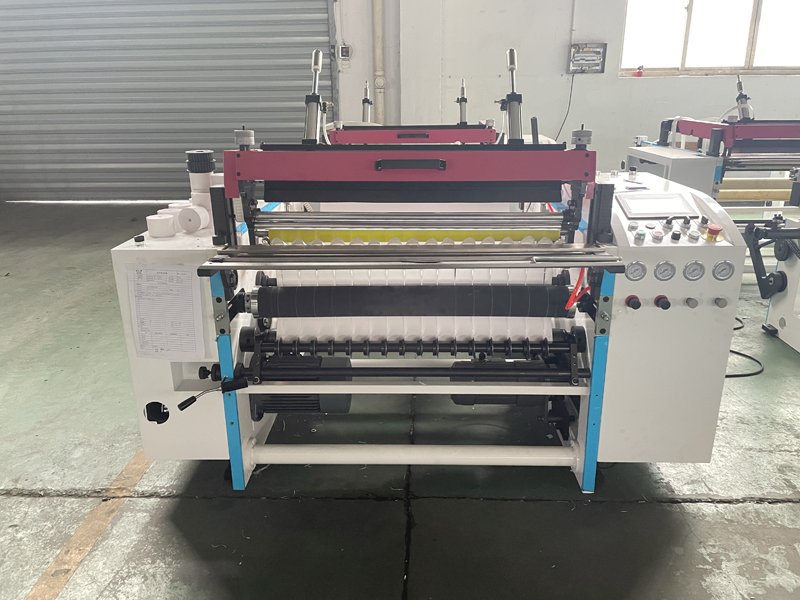

Thermal Roll Coreless Winding Machine JT-SLT-700

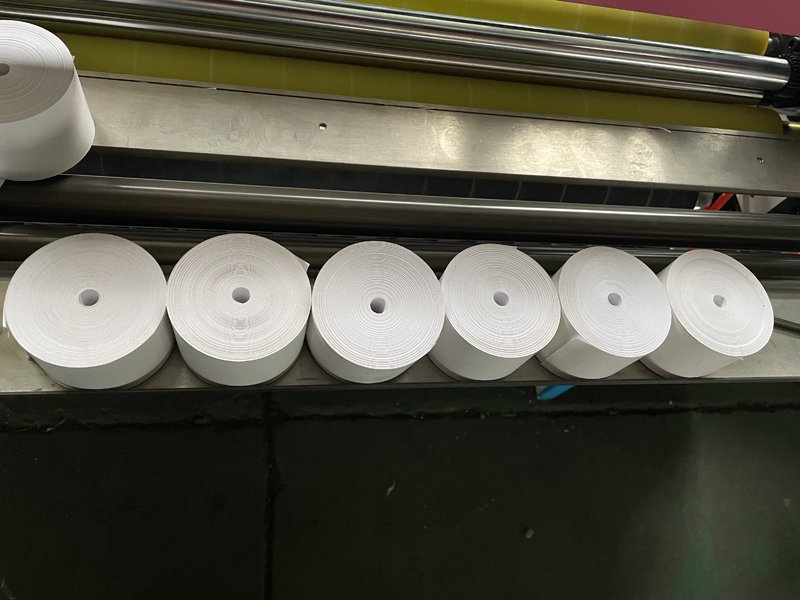

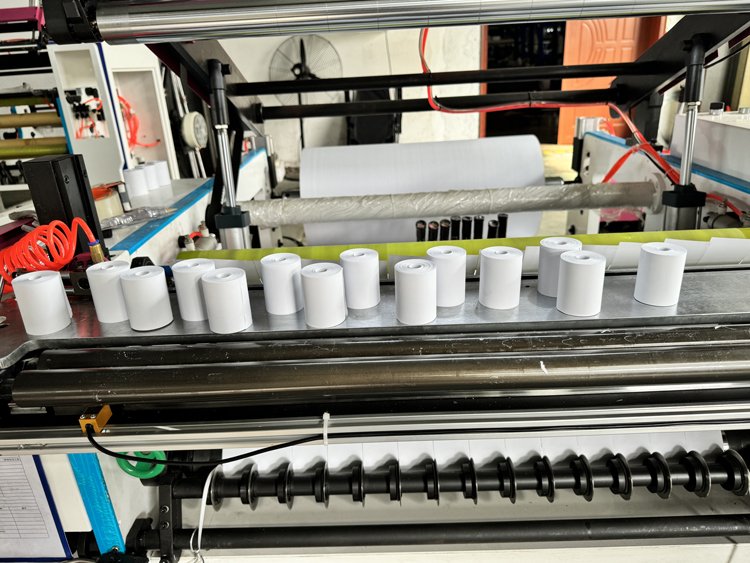

- 1st coreless slitter

- Small and exquisite

- Space-saving

- No core cost

- Coreless till roll for mobile POS

- Specification

- Video

| Max. Unwinding Width | 700mm |

| Max. Unwinding Diameter | 1000mm |

| Max. Rewinding Diameter | 160mm |

| Min. Slitting Width | 25mm |

| Max. Machine Speed | 110m/min |

Why Jota Thermal Roll Coreless Winding Machine

Last Update Time: 18/10/2023

On November 12th we shipped a coreless type thermal paper slitting machine to a customer in Ecuador by sea

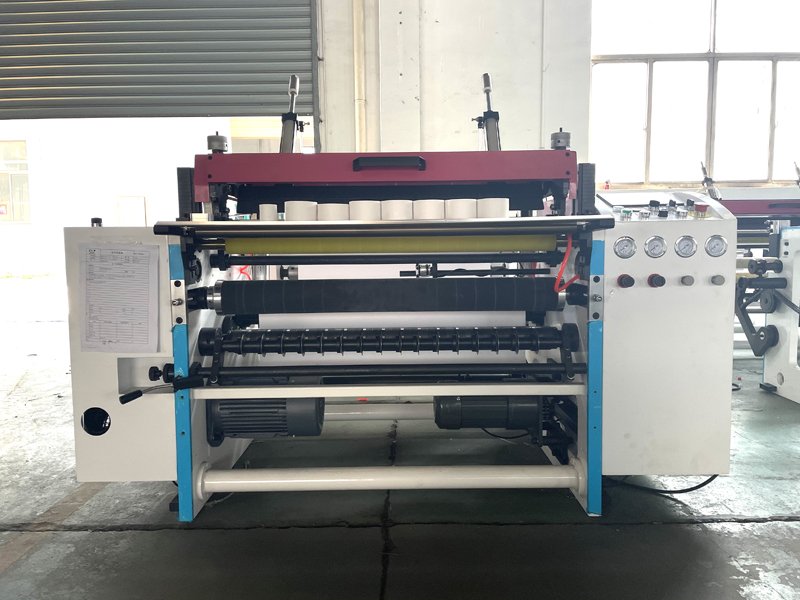

JT-SLT-700 thermal roll coreless winding machine is the 1st coreless rewind slitter, it is mainly used for making coreless ATM receipt POS roll, coreless thermal paper rolls, or POS roll is widely used in mobile POS or POS systems.

Mobile POS/POS could be a dedicated wireless device, such as a mobile, or tablet, it could play the role of an actual cash register or point of sale terminal.

Some of the freshmen don’t know how to do or how to solve the issue when operating our slitting machine then we made a page for frequent troubleshooting and solution. Kindly check this page

Generally speaking, these little stores, retailers are the main users.

Credit Card Payment Terminal

Mobile POS not only permits you to make payments on your smartphone but also allows you to receive payments from your clients’ mobiles.

Mobile payments now are becoming more and more popular in the world, it is also called NFC payment, contactless payment, or mobile wallets.

For example, Apple Pay and Google Pay are popular in the USA, Alipay and Wechat pay are widely applied in every corner of China.

Popular Apple Pay in the USA

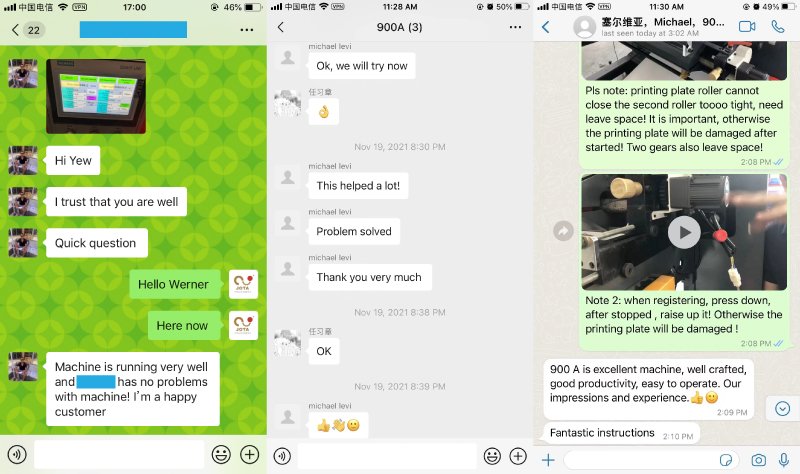

The following points could prove that Jota Machinery is capable of supplying high-quality thermal roll coreless slitting rewinding machines.

In working, you may find a problem, thermal till rolls are not tight, and their edge is not smooth, it influences the next step’s working process, and reduces customer satisfaction, and qualified products ratio.

If yes, it is time to buy a new thermal roll unwinder rewinder machine.

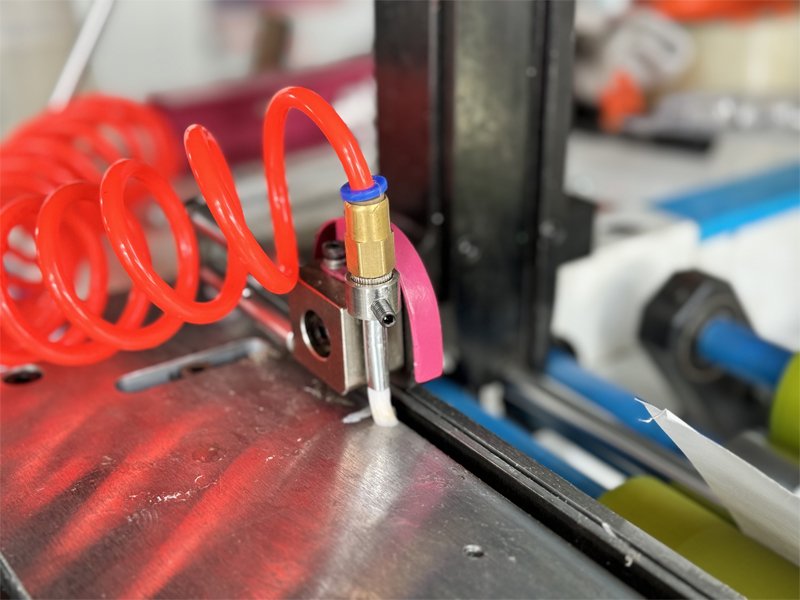

We also supply an inkjet printer for the date coding on the side surface of the thermal paper roll, please check it:

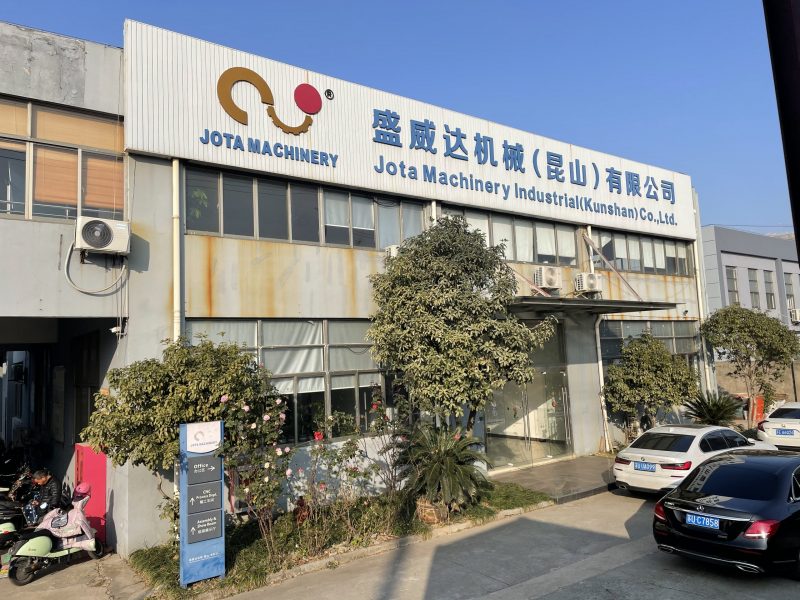

Jota Machinery is a professional thermal paper roll slitting machine supplier in China, we have rich experiences in this industry.

There are 2 factors influences roll tightness and smoothness, one is the tension control system, and the other is the precision regulator.

Automatic Tension Controller

We integrated an inverter motor to simultaneously ensure material tension and strength while working, it keeps your material in safety status, never stress and wrinkle.

Jota Machinery’s thermal roll slitting machine introduces a lay-on roller, precision regulator, and dynamic disc cutters, ensuring that your finished roll quality is satisfying.

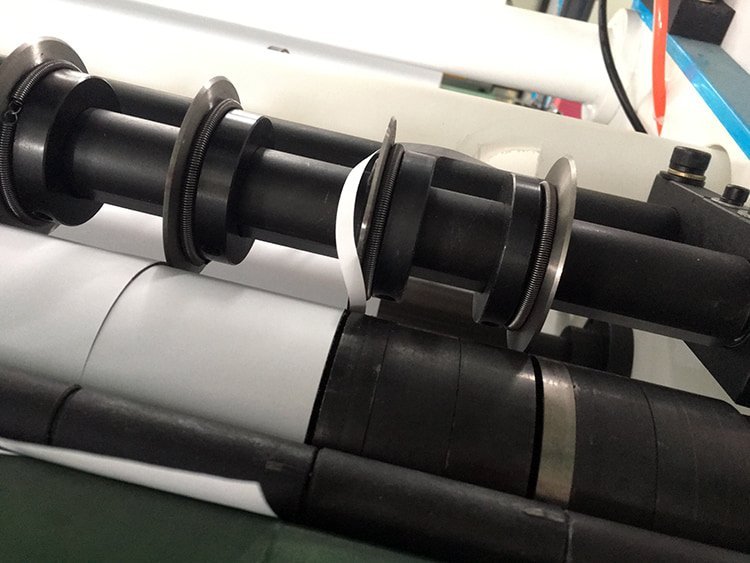

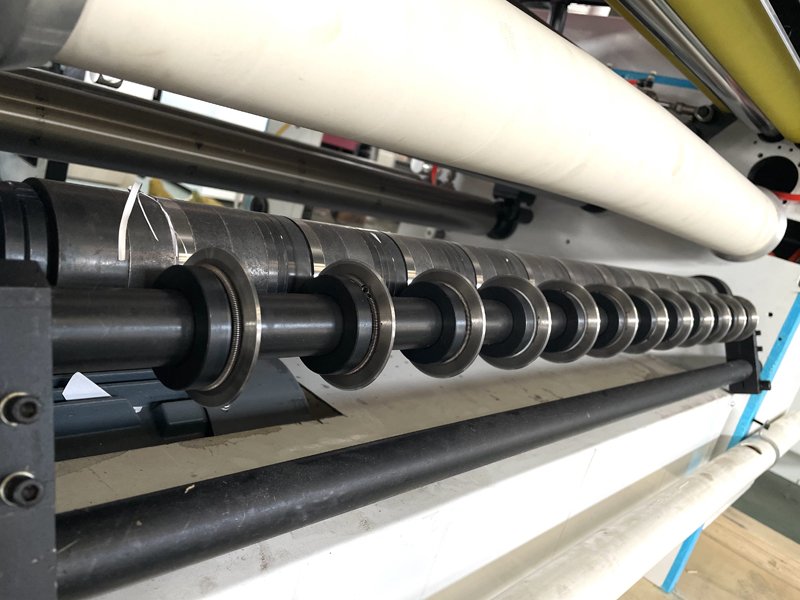

Proactive Lower Circular Knives and Slave Upper Circular Knives

Our thermal paper slitting machines integrate compact structures and optimized frames, which could save space in your workshop.

We have a professional after-sale service team with fluent English ability and industry experience, For any inquiry or consulting, you could get our positive feedback within 8 hours.

Our deep industry knowledge will never let you down, please get an instant quote for this thermal roll coreless winding machine, our engineer has figured out a solution optimizing the winding effect, now the coreless roll winding effect is great.

Jota Factory

We have a professional after-sale service team with fluent English ability and industry experience, For any inquiry or consulting, you could get our positive feedback within 8 hours.

Recently, we Jota has just released fully automatic thermal paper roll slitting packing machine JT-SLT-1400FA, from core feeding to finished roll packing, no need dedicated operator, inline printing function can also be integrated, please send us an inquiry on this website to get more details.

Coreless Winding Machine FAQ Guide

- What is a coreless winding machine?

- What are the configurations of your coreless winding machine?

- Why use a paper coreless winding machine in my paper mill business?

- What factors should I consider when buying a new cash register paper roll slitting machine?

- What are the specifications of your coreless winding machine?

- What is the difference between coreless rolls and core rolls?

- Why do material web guides and tension important aspects for roll slitting machines?

- What are the features of a cash register paper roll slitting machine?

- Is it important to have machine operators operate my paper roll slitting machine?

- What after-sale services for POS roll slitting machines should I expect from you?

- How precision slitting is attained in a Cash register paper roll slitting machine?

What is a coreless winding machine?

Coreless winding machines are machines used to transform large jumbo rolls into smaller rolls without an inner paper core.

Coreless paper rolls are on the rise and in high demand. The machine enables the removal of the need for cores.

Coreless paper rolls have a longer length compared to core paper rolls.

This is because they remove the space taken by the core. Producing this type of roll presents lower costs and less space for transportation and stockage.

Our coreless winding machine is designed for high automation to give top performance. It gives a top performance like excellent production quality and flexibility.

High productivity and an easy operational approach are also capabilities of our roll slitting machine.

The fully automatic function of our coreless rewinding machine allows it to be installed offline as a rewinder machine.

It can also be installed in-line as a winder. This gives it greater flexibility compared to other paper roll rewinding machines.

What are the configurations of your coreless winding machine?

Our coreless winding machine is configured with the latest slitting machine features in the market.

We ensure that we optimize our coreless machines to serve your needs. Some of the configurations that come with our coreless winding machines include:

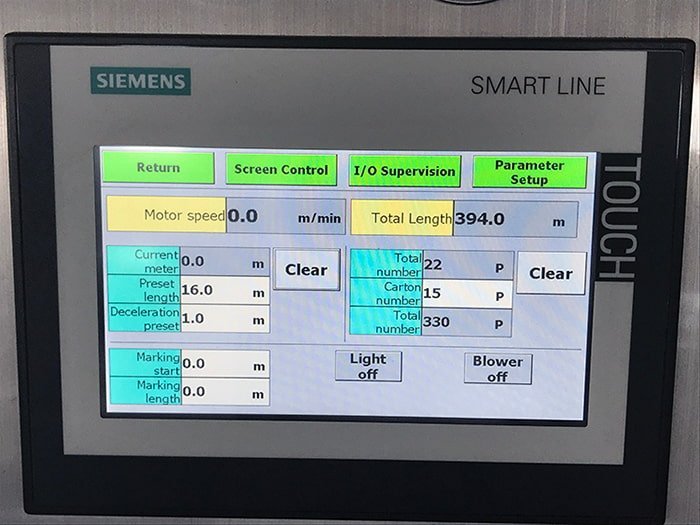

- Our coreless winding machine is equipped with a computer system for easy control. The control system is centralized where all the operations of the coreless machine take place. All the operations from the start of the machine to the diagnostic occurs through the computer system. The computer system is a PLC and HMI.

- The coreless winding machine also has a motor for running the winders.

- A frequency inverter is also installed on the coreless winding machine.

- It has an unwinding shaft of 3”(76mm) air expanding shaft. This is together with a rewinding shaft of a minimum of 8mm for coreless winding.

- It comes with a set of round disc cutters. It has upper round disc cutters and lower round disc cutters. These round disc cutters give a nice and clean shear slitting of the parent roll.

- The coreless winding machine also has magnetic brakes.

- Tension control is also an important configuration that comes with the coreless winding machine. It ensures that the parent roll gets quality slitting and prevents it from tearing.

- The sensors installed in the paper roll winding machine ensure that the pneumatic disc cutters slit the parent roll at the recommended angle.

- It also has a magnetic clutch.

- We ensure that the roll slitting machine is an energy saver. It has a low voltage electrical switch.

- To keep your roll-slitting machine clean, we have installed a blower. The blower ensures that all the debris is blown out of the machine to avoid it from clogging.

Other configurations of the coreless winding machine include a cylinder, relay, and spacer.

An air pressure valve is also installed on our coreless winding machines.

Why use a paper coreless winding machine in my paper mill business?

There are many reasons that you should use a coreless winding machine in your business.

Our machines are made to assist you in growing your business and meeting customers’ demands. Some of the benefits of using our coreless winding machines in your business include:

Coreless Thermal Paper Rolls

Coreless type thermal paper rolls are on the rise.

Many businesses such as banks, eateries, and restaurants are increasingly choosing coreless thermal paper rolls.

You will never go wrong with coreless paper rolls.

Coreless thermal paper rolls offer great value for businesses.

It’s a new trend in 2021 and more companies switch to using them because of the benefits they offer.

Some of these benefits include savings on production and shipping costs.

You will not need to produce cores for your paper rolls.

Expenses associated with shipping cores for your thermal paper rolls will also be cut.

We assure you of optimized coreless winding machines.

This means that you will be able to get the most from the roll-slitting machine. the product will be nearly cut coreless rolls according to your customer’s specifications.

Save Costs, Go for Value

Most thermal paper rolls have a core made of plastic or cardboard to support the structure of the paper wounded onto it.

The core is usually thrown away once the entire roll is consumed.

Coreless come in handy because they remove the core that usually goes to waste after using the paper roll.

Instead of wasting your money, reach out to us in all matterscoreless winding machines.

When using the coreless winding machine, you will not need to procure plastic and paper cores.

This will result in lower production costs.

As a buyer, you will get a low price per unit than before.

You can also configure your paper roll winding machine according to your specifications.

Cost-Effective and Favorable for Buyers

Thermal paper rolls are not created equally, which means they also come in different paper grades and lengths.

Even the length involves a little bit of mathematical computation related to its core size.

If you order the same diameter of paper roll, you will get a longer paper length. This is because as the core is replaced with paper, maximizing every length of it for printing receipts.

Excluding the core increases the length of your paper roll.

For instance, we exclude the core, then the hole will only measure 10mm in diameter.

This is smaller than the regular plastic core size at 12.7mm (1/2″). This is a longer paper roll length.

A paper roll size of 57mm x 40mm has a 12-meter length with a standard plastic core. If we exclude the core, then the paper length can be 13 meters, making it longer and more valuable.

Save Space and Transportation Cost

Coreless paper rolls save more space than core paper rolls.

If you use a coreless winding machine, you can get a smaller core diameter.

This saves more space when you transport the coreless rolls or when packaging them.

For example, the80mm x 80 meters thermal paper roll has a diameter of 80mm with 12.7 mm of the plastic core. But you can shorten the diameter to 77mm for the same length at 80 meters without the core.

You will save the carton cubic space in containers for your orders.

This includes the shipping costs because most logistic companies charge customers per cubic meter.

With a shorter diameter, you can send more paper rolls in fewer containers as you save space for your customers.

Imagine that you use three containers with your existing orders. But with coreless thermal rolls, you’d probably use two for overseas orders.

Coreless Paper Are Environmentally Friendly

The cores are not recyclable as most of them are made of plastic or hard paper.

Also, most users, like cashiers, will throw them away once the paper rolls run out.

It’s like you pay for a core and throw money even if it’s just cents. This is not economical for both the paper mill business and the client.

Moreover, they will likely end up in a wasteland, or worst could be in water resources if not disposed of properly.

As a business owner, you want to fulfill your social responsibility to the environment and be a good steward of resources. Therefore, we encourage you to use our coreless winding machine.

Easy To Maintain and Extends Printers Lifespan

Coreless thermal winding machines are easy to install and maintain. Our machines are optimized to meet your business needs.

We can also send our technician to your location. This is to assist you in the technical aspects of the installation that you may require.

In case of the coreless paper rolls, if one runs out, your cashier doesn’t have to remove the old core.

This saves much time, especially during peak hours when printing receipts is very urgent.

On top of that, the use of paper core also accumulates dust in the printer’s printhead.

That’s why for maintenance, you need to clean it regularly.

Unable to do so will lead to poor print quality because dust and dirt stuck in the printhead will affect the printouts. Therefore, with coreless thermal papers, you lessen the dust accumulation on the printhead.

What factors should I consider when buying a new cash register paper roll slitting machine?

Cash register paper roll slitting machines are important machines for your paper milling business.

They enable you to cut large jumbo rolls into small rolls. These smaller rolls are then used in cash register machines such as the POS and ATM machines.

It is important to keep certain considerations when buying a new cash register paper roll slitting machine. some of these considerations include:

The size of the completed paper roll

When buying a cash register paper roll slitting machine, keep in mind the weight and the finished roll diameter.

This is both for the finished paper roll and the parent paper roll. Both the weight and the finished roll diameter will help you determine the type of roll slitting machine to use.

The size of the finished roil diameter will also determine the type of winder to use.

For instance, If your finished roll diameters are below 800mm (32”), then your best choice should be a center-winder.

The type of winder to use largely depends on the type of finished roll you want. For instance, a paper film roll rewinder will be different from a POS paper roll rewinder.

Some other factors such as ergonomics and tension control also determine the finished roll diameter. The tightness of the finished roll will also determine its diameter and the tension control.

The width of the jumbo paper roll

The width of the jumbo roll will determine many aspects of your coreless winding machine.

Some of the aspects include the size of the finished rolls. It is easier to cut large diameters of finished rolls from a large jumbo roll. The reverse happens when you utilize a smaller jumbo roll.

The number of slitted rolls also increases with the size of the jumbo paper roll.

This is an important consideration that you should put in mind.

How the jumbo paper roll is slitted also determines the type of rewinder to be used on your coreless winding machine.

Center-surface slitter rewinder is very suitable if your jumbo roll material is highly sensitive. Such materials can easily get broken and as such, center-surface is highly recommended.

Wider slit widths make the parent paper more stable. This enhances for the center-winder a much better option. It has a simple design, is very cost-effective, and has good ergonomics.

On the other hand, narrower slit widths are susceptible to more vulnerability to caliper variation effects. It will also be exposed to flutter. All this will affect the quality of your finished roll. This will mainly affect those rewinds that have larger diameters.

The rewinder supports the slitting section leading to clean, quality cuts for your finished coreless paper rolls.

The rewinder type of the cash register paper roll slitting machine

The rewinder type to use for your cash register paper roll slitting machine is also an important aspect to consider.

There are three major types of winders include the single drum winders, the two-drum winders, and duplex winders.

The three types of winders work differently in the different paper roll slitting machines.

For single-drum winders, the paper roll will be wound individually in its independent rewinding station.

The single drum winders are ideal for smaller roll slitting machines that produce smaller coreless paper rolls.

A cash register paper roll slitting machine with a two-drum paper winder is the most common machine.

Two drum surface slitters are commonly used to slit and rewind paper and board products.

Most of the two drums wider roll slitting machines typically slit either with a score method or a shear method.

They can slit from very narrow widths, about 2 inches, to very wide widths, more than 150 inches. And they can slit and rewind a broad range of products from tissue to very dense board.

Another most popular winder machine for roll slitting machines is the duplex winder.

A duplex winder is used to wind papers that are otherwise difficult to wind. These types of rewinders are used where certain substrates cannot be wound on a single shaft.

These materials, such as most films, will interweave or create other problems unless the slit cuts are alternated up and down on two rewind shafts.

The type of slitting to be used on your coreless winding machine

The type of slitting method is also another aspect that you should consider for your coreless winding machines.

Different slitting methods give different results when it comes to finished rolls. The slitting methods also determine the width and diameter of the finished coreless paper rolls.

For instance, the razor blade is mainly used in abrasive roll slitting machines to slit light and non-abrasive materials.

This is used for small paper rolls productions where you have a limited budget. It is an economical slitting process.

A slitting method like shear cutting on the other hand is popularly used.

This type of slitting uses round disc cutters or pneumatic cutters. This kind of slitting technique uses a set of two rotary knives to get the same cutting effect produced by a pair of scissors.

The shear cut slitting technique is used in slitting heavy gauge materials. Such materials include foil, thicker sheet, or film, and most of the laminates.

The best thing about shear cutting is that it gives out clean cuts.

Our paper roll slitting machine utilizes this type of slitting method. The benefit of the shear cut slitting technique in a roll slitting machine is the accuracy. The width of the slits and their close tolerances is always accurate.

Another method of slitting is the score cut. It is rarely used in modern paper roll slitting machines.

It is among the old method of slitting that are not well applicable or integrated with the new generation of slitting machines.

The score cut roll slitting technique involves the crushing of the material on one part. It uses a dull knife pressing the material on a hard surface.

Although the score cutting can be easily applicable for slitting adhesives that are pressure sensitive.

What are the specifications of your coreless winding machine?

Some of the specifications of the coreless winding machine include:

- A maximum unwinding width of 700mm.

- As maximum unwinding diameter of 1000mm

- The coreless winding machine also has a maximum rewinding diameter of 160mm.

- Minimum slitting width of 25mm

- The roll slitting machine also has a maximum machine speed of 110m/min.

- The maximum parent web width is around 900mm.

- The unwinding shaft is 3” air expanding shaft.

- The rewinding shaft is customizable. It can be set at 0.5” and 1’ depending on your specifications.

- The voltage is 3 phase, 4 wire, and 380V/220V respectively.

- The power of the coreless winding machine is 2.95Kw

- It comes with a weight of 1200Kg.

At Jota Machinery, we offer room for customization of the coreless winding machine. You can reach out to us with your designs and liaise with our design engineers.

What is the difference between coreless rolls and core rolls?

When buying a coreless winding machine, it is important to be aware of the difference between core and coreless rolls.

Core rolls are finished paper or film rolls with a plastic or paper core. The core is usually not used after you finish the paper roll.

On the other hand, coreless rolls are paper rolls without a core. The core is removed to create more space for the paper roll.

Coreless rolls are a new trend in the market. This is because of their many advantages over the core rolls.

Our paper roll slitting machine can help you produce both the core rolls and the coreless rolls.

Earlier paper roll slitting machines were only used to produce one type of roll.

For coreless roll slitting machines, they could not produce core roll. When it came to core roll slitting machines, they could not produce coreless rolls.

However, with improved technology and demand from roll-slitting machine buyers, a combined machine came up. The combined machine can produce both coreless rolls and core rolls at the same time.

The combined two-type roll slitting machine saves you money thus increasing your revenue.

Before the uptake of the coreless and core winding machine, there are a few steps you needed to undertake.

You will need to change the shaft. Once you are done producing your coreless rolls, you would need to change the shaft and produce the core rolls.

With today’s technology, you will only need to adjust the tucker and you will be ready to produce core rolls. The tucker is located on top of the thermal paper roll slitting machine.

Buy our coreless winding machine to tap into this new market. We guarantee you of value for your money when it comes to coreless winding machine solution.

Why does material web guide and tension an important aspect for roll slitting machine?

A web guide is essential in most unwound stands thus as it keeps the web-centered on the machine. Normally, the web guide is fixed to suit a full range of widths for your products.

The adjustable side is attached to the frame of the roll slitting machine. The web guide requires to be manually set for every product according to the width you want.

Currently, we have several edge sensors in the market which do not need manual adjustment. In the case of different web widths within certain ranges, web guides reduce the changeover time.

You will be required to go to new web widths, and this reduces waste by eliminating operator error in the web guide setting.

Web tension is easier and more stable to sense before the wind-up position than after the payoff position. This is because the roll for winding possesses less eccentricity as compared to the unwind roll.

The roll on the payoff is larger in diameter as compared to the rewind roll. It is mounted on a bladder mandrel and has been lagged for some period.

It is for this reason that a load cell roll offers more benefits over dancer rolls as a web tension sensor before rewind. This is because there is need for less space and it is less expensive to operate and purchase.

What are the features of cash register paper roll slitting machine?

Tension Control System

The coreless winding machine is equipped with an integrated inverter motor.

This is used to ensure material tension and strength. Material and tension strength is ideal when it comes to slitting. It ensures that the jumbo paper roll gets clean cuts and that the winding paper roll does not have spaces.

Tension control systems is also vital in ensuring your material is safe from stress and winkles. This is ideal for quality coreless paper rolls production.

Precision regulator

To ensure finished quality coreless paper rolls, our coreless winding machine is installed with a precision regulator.

Precision regulator guides the round disc cutters and ensures that the parent roll does not deviate. This is ideal in the slitting process where a deviation may cause uneven slitting and poor-quality coreless paper rolls.

The coreless paper winding machine is also equipped with a lay-on roller.

The lay-on roller ensures material tightness which is important during the slitting process. The dynamic disc cutters are set in a way that they can cut the jumbo paper roll continuously.

Compact structure

All our coreless winding machines are made with your business in mind.

We have integrated compact structures and optimized frames. This means that you will not need a lot of space to install the coreless winding machine.

English

Our coreless winding machine operations are outlined in English.

We recognize that machines configured in Chinese might be a little bit complicated to operate. So, we have ensured the operational manual is in English.

Is it important to have machine operators to operate my paper roll slitting machine?

Yes, it is important to have trained personnel to operate and also maintain your paper roll slitting machine.

The paper roll slitting machine is a bit complicated. It also made of different parts and components that need some level of knowledge of the machine to maintain.

We recommend that any operator receives training on the operation of the paper roll slitting machine.

The training on the paper roll slitting machine should incorporate certain factors. Some of these factors include:

- The paper roll slitting machine operator should be trained on the safety procedures while working.

- Be trained on the various components of the paper roll slitting machines. These components may include slitters, shaft stands, rollers, winders, and centralized controls.

- The operator should be trained on the correct maintenance procedures. This should be done following the guidelines on the roll slitting machine maintenance manual.

- The coreless winding machine operator should also be aware of the electrical configurations. This is important to avoid hazards and also solve connections related issues.

- All roll slitting machine operators should be aware of the basic standard operation procedures (SOP). This is essential in guiding them of the correct procedures to follow when operating the roll-slitting machine.

- It is important to train the operators on the correct personal protective equipment to use. This is an important aspect in the operation of paper roll winding machines. Personal protective equipment they should use includes steel toe shoes and mechanical gloves. This will help in preventing pinch points and also injuries.

It is important for the machine operators to be aware of the maintenance processes of the roll-slitting machines. The maintenance processes and procedure is usually in the machine manual. It indicates the procedure that must be followed in the maintenance of your paper roll slitting machine.

Some of the recommended routine maintenance procedures for coreless winding machine parts include:

Oil

Oil in, when used for long, dirt particles, convert the oil into risky agents which may scratch the inner cylinder walls and pipes.

This might lead to blockage of valves, seals, and joints. Therefore, it is important to frequently change your oil as this will ensure the efficiency of your paper rewinder. Also, ascertain that the oil flows at the appropriate speed to ensure that the machine works perfectly.

Electric motors

Electric motors of paper roll slitting machines need periodic maintenance. It is important to ensure clean air flows sufficiently through the motor. This is because if the temperature of the electric motor increases, its performance will decrease.

You can also extend the life of the electric motor by lubricating the bearings of the main shaft.

Ensure that you grease the shaft bearing after about 2000 hours of usage.

Eliminate all the dirt inside the electric motor and in case of any damaged seals, replace them.

Before commencing the maintenance procedure, ensure all power is switched off.

What after sale services for POS roll slitting machine should I expect from you?

At Jota Machinery, we always strive to ensure that you get the best services from us.

We will gladly follow up on your machine purchase from us. Some of the after-sale services that we offer include but are not limited to:

Installation

We will help you in the installation of your paper roll winding machine.

You can send us a request and we can arrange for our technician to fly to your destination.

Our design engineers always ensure our machines are easy to install. Our technicians are also available to help you out in the installation process.

You can visit our website to review our customer after-sale service.

It is important to be aware of the installation procedure as it is not a very complex process.

The installation of a coreless winding machine entails a series of steps from making the base up to a completed discharging machine.

Our professional Jota Machinery engineers will give you clear guidance on the steps entailed. We will elaborate the entire process until your engineers on the ground understand the entire process.

Maintenance

We ensure that all our coreless winding machines come with maintenance manuals.

These guide you in maintaining your coreless winding machine. It also outlines the necessary safety protocols to undertake before you begin the maintenance procedure.

It is important that you go through the maintenance manual before you start operating the machine.

This is also done before the installation of the coreless winding machine. In case you do not understand the maintenance procedure it is important that you contact us.

Parts and Accessories

At Jota Machinery, we ensure that our roll slitting machines are easily available.

It is recommended that you use the original parts from Jota Machinery. This will ensure that the replaced parts and components are compatible with your coreless winding machine.

Jota Machinery always strives to make sure that our customer’s need is met efficiently. We ship the paper roll slitting machine as a whole set or as parts that you will need to assemble.

Some of the main parts of the paper roll winding machine that Jota Machinery can ship to you include:

- Paper web threading

- Supporting rolls

- The structure of the bearing

- Pressure roll

- Slitting section

- Tilting table

- Core clamping mandrels

- Spreader rolls

- Unwinding stand

- Paper roll winding machine pneumatic circuit

- The hydrostatic drive

- Coreless winding machine electric parts like cabling, control board and switchboard boxes.

- Coreless winding machine guards

- Paper roll slitting machine drive

Coreless Winding Machine Replacement and Upgrade

At Jota Machinery, our technicians are always on call. You can reach to us for your coreless winding machine upgrade. We can also send you parts to upgrade specific parts of your coreless winding machine.

It is important to upgrade your machine to the latest technology. This can be done in parts. You can achieve this by changing parts and components to the latest in the market.

We can also replace the whole coreless winding machine. Reach us to us for the latest coreless machines in the market. All our machines are priced fairly and expect value for your money.

To upgrade to the latest technology, reach us to us. You can also send us your specific design ideas for a specific pat of your coreless winding machines.

Shipments and Regulations Assistance

We will assist you through your order and delivery process. We will also guide you from the order placement process to the delivery to your factory.

Feel free to call our customer care center for any inquiries regarding your order processing. If you are not sure of certain payments contact us. You can also seek help of professional freight forwarders or shipping agents.

We will also guide you on the extra charges that you might come across on your shipments. Some of these costs include but not limited to;

- The taxes that will be charged on your paper roll winding machine.

- The warehouse charges.

- Insurance charges for your on-transit cargo.

- Customs and duties.

- Payment transactions cost.

- Other unforeseen charges.

Exercise duties payable are mainly incorporated in the final price of our paper roll slitting machines.

We work hard to ensure that there are no hidden charges for your purchases.

We encourage you to pick your machine immediately after manufacturing. This will avoid you incurring extra charges. These charges include cost of storage and warehousing.

We will also advise you on the best way to go about your shipping and taxes.

Sometimes problems might occur from the taxes you need to pay here in China and those you need to pay in your home country.

As much as we will offer guidance, it is important to seek clarification on the same from local authorities.

How precision slitting is attained in a Cash register paper roll slitting machine?

If you have been in the paper slitting industry, you have severally encountered some conversion terms. Examples of the terms include sheeting, slitting, and rewinding.

What you mostly obtain from organizations is a list showing the following:

- Listing of maximum roll widths

- Measurements of the roll

- Capabilities for slitting, sheeting, and rewinding

However, it is unlikely for you to find an outline of what these services entail. If you are wondering the differences that are there between each service, we have outlined it below:

Sheeting

Sheeting paper refers to the conversion of the large paper rolls into sheets of paper. This process uses a coreless winding machine to convert the coreless rolls into rolls of specific size.

Slitting

At Jota Machinery, slitting entails cutting of long stock roll into thinner segments using a roll slitting machine. We can use slitting paper which is as thin as 3/8 inch or wide as 110 inches.

This will be dependent on the specifications that you require.

Rewinding

Once the paper roll slitting machine has slit the paper, new segments that are thinner are rewound. We can rewind the thinner segments into any size coreless to the diameter or footage.

In relation to all the aspects of paper conversion, the most important factor is precision. At Jota Machinery, we strive to ensure that every measurement of each customer is perfect.

Every cut on our customer’s orders must always be spot on. In some other cases the rewound rolls which come off a paper roll slitting machine may be used for other purposes.

Therefore, it is important to make sure that the paper roll slitting machine winds it perfectly. This will also help in avoidance of wasting time and money or causing a jam.

Use of exact measurements, updated paper roll slitting machine and technology manufacturing is enhanced. As leading roll slitting machine manufacturers, we ensure that our machines are precise.

It is important to establish the specifications, price and capabilities when looking for paper coreless winding machine. In addition, ensure that the paper products are very precise. You can contact us at Jota Machinery to find out more about precision slitting and other techniques.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine