Professional Jumbo Wrapping Paper Rolls Sheeter Machine Manufacturer

- Cut size, folio size sheeter

- Single rotary, dual rotary sheeter

- Optional function customization as your request

- Design together with us for your dreamy sheeter

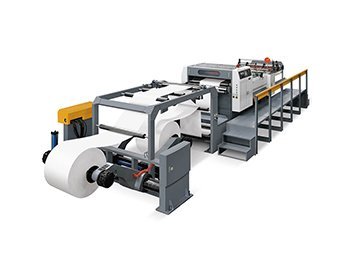

Jumbo Wrapping Paper Rolls Sheeter Machine

Jota jumbo wrapping paper rolls sheeter machine is an ideal equipment for making A1, A2, A3, A4, A5 office paper sheet.

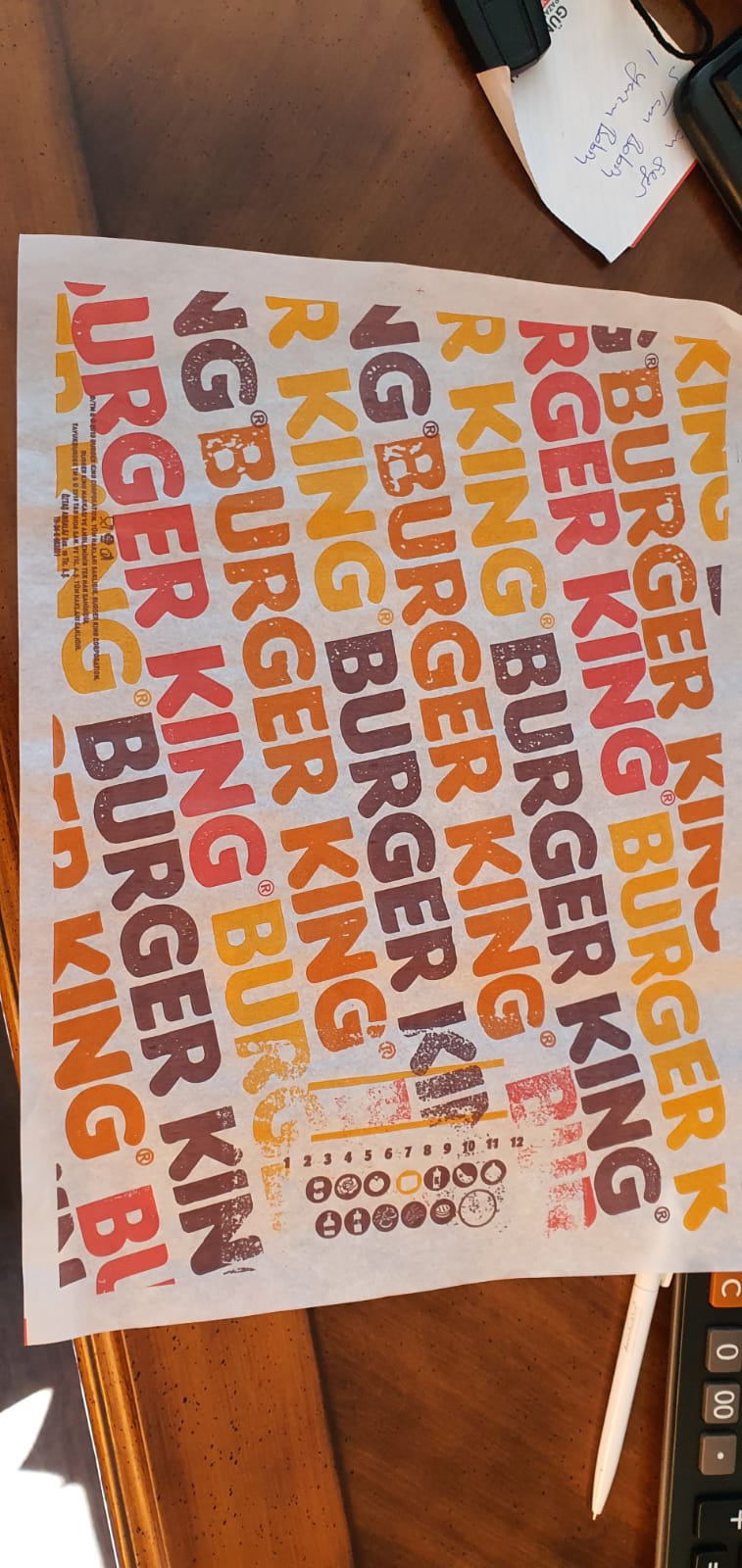

It also could be customized for sheeting hamburger paper, sandwich paper, hot dog paper.

Please speed up your action to contact us, get a comprehensive understanding of Jota roll to sheet cutter.

USA Clients Stand around Our Paper Sheeter

Jota Machinery: China Professional Paper Sheeter Supplier

Paper sheeter reliable supplier Jota has its own factory with a CNC center.

Paper roll to sheet cutting machine’s many important parts could be produced by ourselves.

Thus your purchased paper roll to sheet cutter’s quality and delivery time could be effectively guaranteed.

Jota CNC Machine

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as a backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

Why Jota Jumbo Wrapping Paper Roll Sheeter Machine

Last Update Time: 16/10/2023

Jumbo Wrapping Paper Roll sheeter is manufactured for transforming paper, cardboard, foil, film, fabric rolls into many many sheets of precise length and width.

As sheeter paper is computerized with touch screen control, all sizing requirements could be realized, such as A3, A4, A5, etc.

Except for producing office copier paper, paper sheeter machine could also be introduced to hot dog paper, hamburger paper, sandwich paper production, the demand for these types of paper in North America is quite huge.

What’s more, paper roll to sheet cutting machine could be customized for replacing poster trimmer, compared to traditional poster roll trimmer, paper sheeter is capable of cutting more poster sheets at a higher speed in the unit time.

As paper roll to a4 sheet cutting machine has so many types of usage, you’d better accumulate more knowledge about such machine.

Only after you are familiar with this type of machine, you are more likely to buy your favorite A4 paper making machine with reliable quality and good effect.

For automatic roll to sheet cutter, you first need to know its unwinding width and unwinding diameter, make sure your jumbo roll could be placed on the machine.

Mother Paper Jumbo Roll

If your material is printed with logo or graphics, it’s better for you to choose a paper reel to sheet cutting machine with the web guide system, ensures the sheet cutting in the right position, logo or graphics are complete and beautiful.

When it comes to the roll to sheet cutter’s slitting section, you should be aware of slitting knife quantity, which means you must be clear of your final sheet size, then calculate the slitting knife quantity based on jumbo roll width and final sheet size.

For example, your A4 copy paper jumbo roll width is 1265mm, A4 paper sheet size is 210mm x 297mm:

1265mm=210mmx6+5mm, it means 6 sheets A4 paper output for 1 cut, 5mm edge waste, the slitting knife quantity is equal to the number of A4 sheets plus 1, so you need to install 7 slitting knives on an A4 paper roll cutting machine.

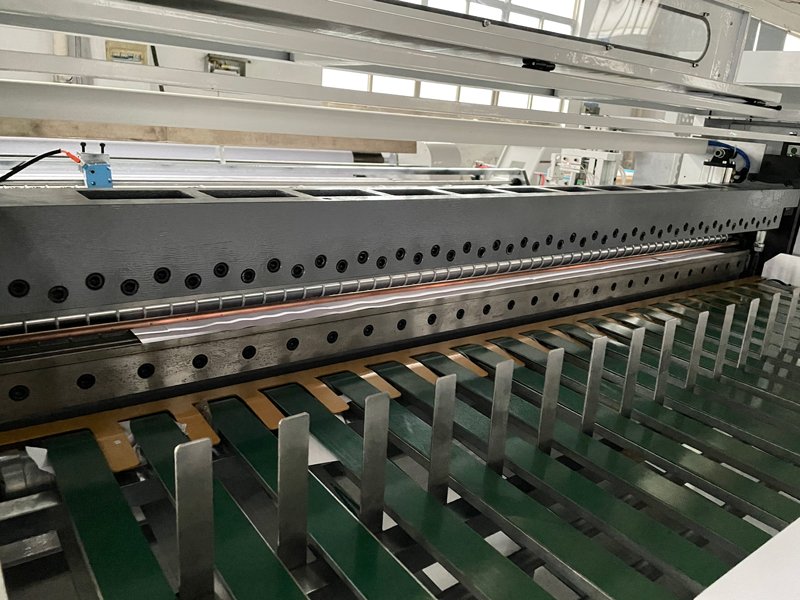

In terms of the roll to sheet paper cutting machine, a very important component is the sheeting blade, which is also called a cross cutter.

Good cross cutter always co-work together with bilateral linear guideway and slide block, moves up and down more smoothly.

Bilateral Linear Guideway and Slide Block

A4 sheet is often packaged into 1 ream for sale, the international standard defines 1 ream as 500 identical sheets.

A4 Paper Ream

Many customers not only consult the automatic paper roll cutting machine but also inquire about the information of A4 paper ream wrapping machine.

There are many types of A4 paper packing machines, such as simple manual shrinkable film packaging machine;

Fully automatic coated paper A4 ream packing machine;

Some automatic A4 paper ream wrapping machines are integrated with A4 paper cutting machines, then 1 set synchronous A4 paper cutting and packing machine is formed.

Such A4 paper cutting and packing machine’s output could reach 15-25 reams/min, if you are looking for an A4 sheet cutter with high output, you could consider this type of fully automatic production line.

Of course, there are many factors that could determine the whole a4 paper roll cutting machine quality, and there are several optional parts could be added as different client’s different request.

If you are planning to purchase one, please feel free to contact us for deep discussion.

Jota Certificates

Paper Sheeter Ultimate FAQ Guide

Paper Sheet

Paper Sheet Types

There are many types of paper, and the types summarized below can be cut into sheets.

Packaging paper

- Whiteboard paper

- White cardboard

- Kraft paper

- Corrugated paper

- Cardboard paper

- Parchment paper

- Machine glazed paper

- Cigarette paper

- Silicone oil paper

- Paper cup or paper bag base paper

- Coated paper

- Cellophane

- Oil-proof paper

- Moisture-proof paper

- Transparent paper

- Aluminum foil paper

- Label paper

Printing paper

- Coated art paper

- Newsprint paper

- LWC paper

- Light paper

- Offset paper

- Writing paper

- Dictionary paper

- Book paper

Industrial paper

- Release paper

- Carbon paper

- Insulating paper

- Filter paper

- Test paper

- Capacitor paper

- Platen paper

- Dust-free paper

- Impregnated paper

- Sandpaper

- Anti-rust paper

Office and cultural paper

- Tracing paper

- Drawing paper

- Art paper

- Carbon paper

- Fax paper

- Printing paper

- Photo paper

- Dust-free paper

- Rice paper

- Thermal paper

- Inkjet paper

Tissue paper

- Toilet paper

- Facial tissues

- Napkins

- Diapers

- Sanitary napkins

- Wet tissues

Specialty paper

- Decorative base paper

- Water texture paper

- Leather texture paper

- Gold and silver cardboard

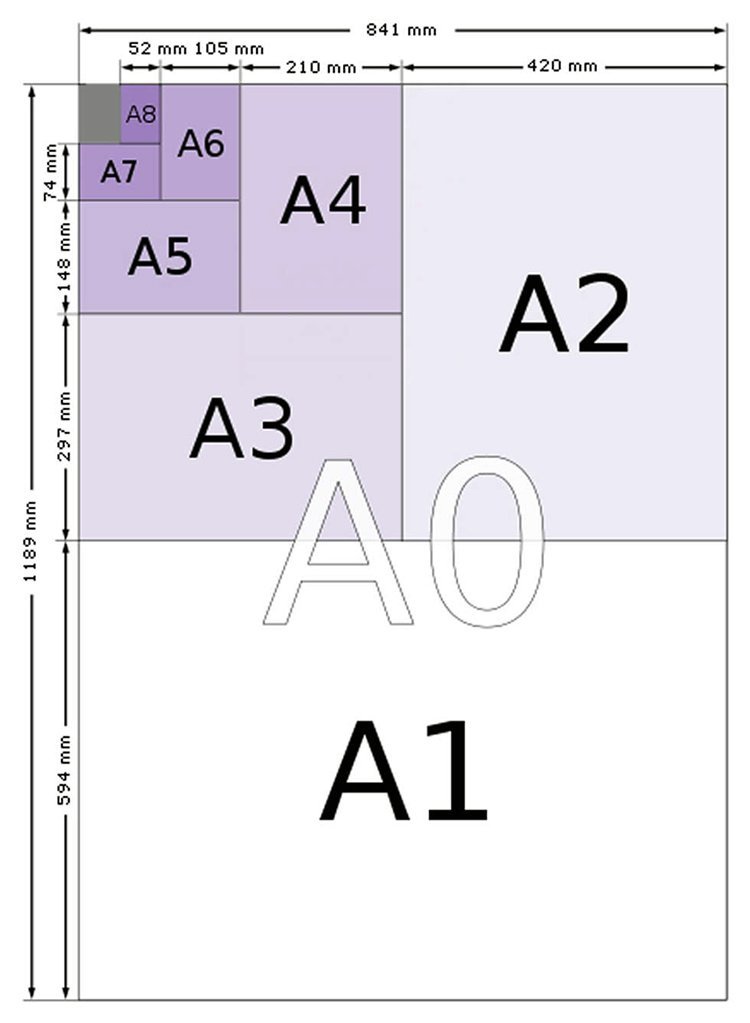

Paper Sheet Sizes

The international standard A-type paper sheet (A0-A10) sizes have been summarized in the following table:

| Size | W x H |

| A0 | 841mm (33.1”) x 1189 mm (46.8”) |

| A1 | 594mm (23.4”) x 841mm (33.1”) |

| A2 | 420mm (16.5”) x 594mm (23.4”) |

| A3 | 297mm (11.7”) x 420mm (16.5”) |

| A4 | 210mm (8.3”) x 297mm (11.7”) |

| A5 | 148mm (5.8”) x 210mm (8.3”) |

| A6 | 105mm (4.1”) x 148mm (5.8”) |

| A7 | 74mm (2.9”) x 105mm (4.1”) |

| A8 | 52mm (2.0”) x 74mm (2.9”) |

| A9 | 37mm (1.5”) x 52mm (2.0“) |

| A10 | 26mm (1.0”) x 37mm (1.5”) |

The dimensions of the international standard B type paper sheet (B0-B10) are shown in the table below:

| Size | W x H |

| B0 | 1000mm (39.4”) x 1414mm (55.7”) |

| B1 | 707mm (27.8”) x 1000mm (39.4”) |

| B2 | 500mm (19.7”) x 707mm (27.8”) |

| B3 | 353mm (13.9”) x 500mm (19.7”) |

| B4 | 250mm (9.8”) x 353mm (13.9”) |

| B5 | 176mm (6.9”) x 250mm (9.8”) |

| B6 | 125mm (4.9”) x 176mm (6.9”) |

| B7 | 88mm (3.5”) x 125mm (4.9”) |

| B8 | 62mm (2.4”) x 88mm (3.5”) |

| B9 | 44mm (1.7”) x 62mm (2.4“) |

| B10 | 31mm (1.2”) x 44mm (1.7”) |

Paper Sheet Price

Take A4 paper sheet for example.

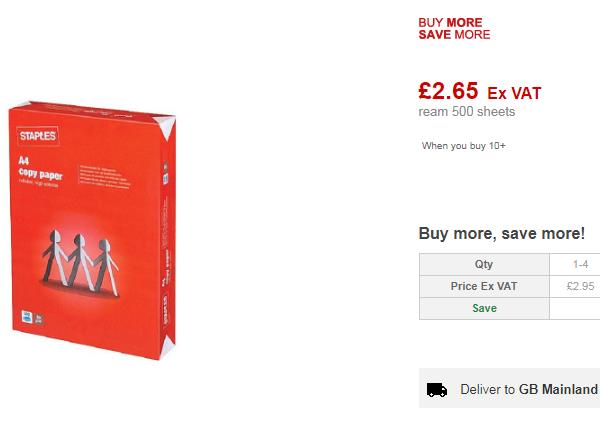

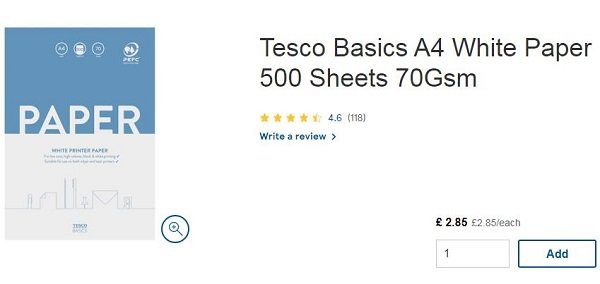

A4 paper is usually sold in the form of 500 sheets per ream, the following 2 photos display 500 sheets A4 paper price:

Paper Sheet HS Code

The HS Code for paper sheet exports from China is 4809900000, and the international HS code is 6 digits, so the international HS Code for the paper sheet is 480990.

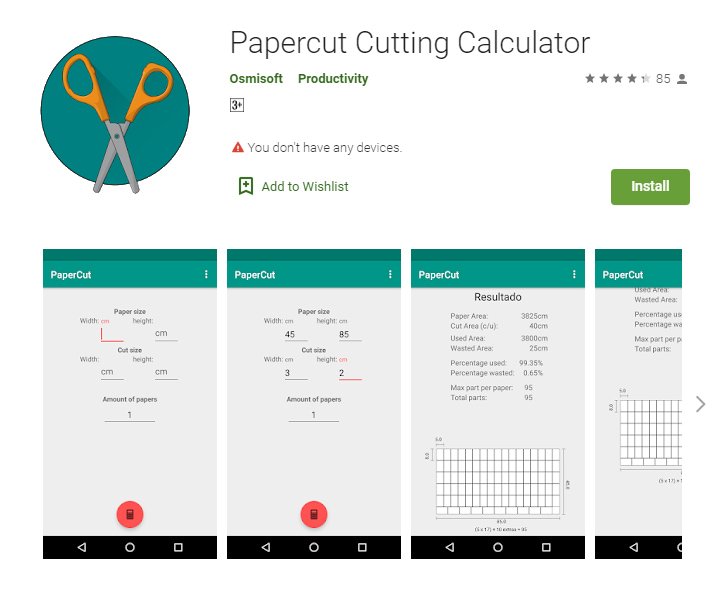

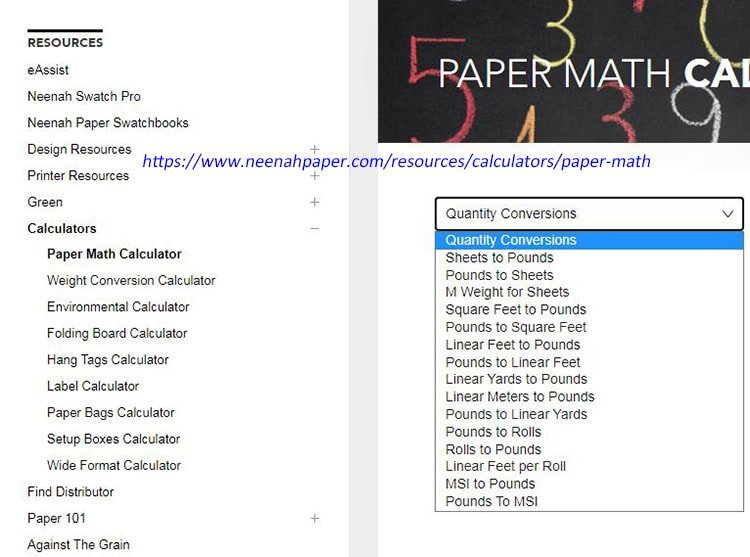

Paper Sheet Cutting Calculator

If you have an Android phone, you can download an app called papercut cutting calculator on google play.

Use this app to calculate the small paper sheets’ quantity cut from a large paper sheet.

You can also log in to the following website to calculate more content related to paper sheet cutting.

Paper Sheets in Spanish

In Spanish, paper sheets are usually referred to as sheets of paper.

Sheet of paper in Spanish is la hoja de papel.

Paper Sheets for Food

Solar insulation paper can be used for keeping food warm.

Such paper is developed in the United States that converts solar energy into thermal energy.

It is like a solar collector.

If you use it to wrap food and place it in a place where the sun shines, it will increase the food temperature and keep it warm.

The heat will not dissipate until the paper is opened.

Jumbo Wrapping Paper Rolls

With the improvement of living levels, the wrapping paper is available everywhere.. For example, Mexican rolls, Turkish rolls, hamburgers and other fresh foods wrappings.

The manufacturing process of wrapping paper is also very simple, that is, a layer of wax, PE, or silicon oil is applied to the base paper through a coating machine, and then dried in the dry oven and rewound into Jumbo Wrapping Paper Rolls.

Some wrapping papers are also baking papers, printed in various colors or patterns, and finally cross cutting by a paper sheeting machine, which is the wrapping paper we see.

The thickness of Jumbo wrapping paper rolls is about 25gsm to 50gsm, The printed patterns on one side and waterproof wax coating on the other side. Because it is very thin and light, The market demand is high.

If you want to do the wrapping paper business, you can consider buying a base paper, which becomes a jumbo wrapping paper rolls after coating.

You only need to buy a paper sheeting machine to cross cut the wrapping paper. In addition, aluminum foil is also very popular in the current market, and aluminum foil can also be converted in the same way.

The weight of jumbo wrapping paper rolls is about 300-400kg.

In order to increase your output, our engineers specially designed a sheeting machine for thin sandwich paper. which has a compact structure and high capacity.

Please see the link below.

A0 Paper Sheet

A0 Sheet Size/Dimensions

A0 paper sheet refers to 1 square meter of silver ratio rectangular paper (height is 1189mm and width is 841mm).

A0 sheet can be cut into 2 pcs A1 sheet, 4 pcs A2 sheet.

A0 Sheet Size in m

The actual size of the A0 paper is 1189mm x 841mm, which is 1.189m x 0.841m when converted into meters, and its area is 0.999949 square meters.

A0 Sheet Size in mm

A0 Sheet Size in mm is 1189mm x 841mm, which means the width of A0 paper is 841mm and the height is 1189mm.

A0 Sheet Size in Feet

Calculated based on 1 foot equal to 304.8mm, 1189mm/304.8mm=3.9 feet, 841mm/304.8mm=2.76 feet, so A0 sheet size in inches is 3.9″ x 2.76″.

A0 Sheet of Paper

A0 sheet of paper is the largest paper of the international standard A paper.

The height of A0 paper exceeds 1 meter, which is equivalent to the height of 16 pcs A4 paper sheet.

Large-size A0 paper is only used in copy shops, and some designers will use it.

Designers mainly use A0 paper to make drawings, and A0 sheet is large enough to ensure that the designer is comfortable in the design, without having to use a magnifying glass in the design process.

A0 paper can also be used to make posters, but the normal size of poster paper is 700mm x 1000 mm and 1000mm x 1400 mm, which is slightly different from the size of A0 paper.

A1 Paper Sheet

A1 Sheets Size

A1 paper sheet, a paper specification of the international standard A paper, which is often called folio paper.

According to international standards, A1 sheets size is 594mm x 841mm.

A1 Sheets of Paper

Similar to the use of A0 paper, A1 paper is usually used to print advertising signs, window display posters, technical and engineering design drawings, and flip charts.

A1 Sheets of Card

A1 sheets of card can play a role in the installation, display, craft making, modeling, art design, and other fields or industries;

A1 sheets of card are also used in popular sketchbooks today;

Some customers purchase A1 sheets of card, put them on the drawings they designed, so as to protect the drawings during transportation.

A1 Sheets of Cardboard

A1 sheets of cardboard are made of single-walled corrugated paper, which has high rigidity and is very suitable for use as partitions in packaging cartons, boxes.

When transporting artworks, you can use A1 sheets of cardboard to protect it during transportation;

A1 sheets of cardboard can also be used for the creation of some handicraft projects.

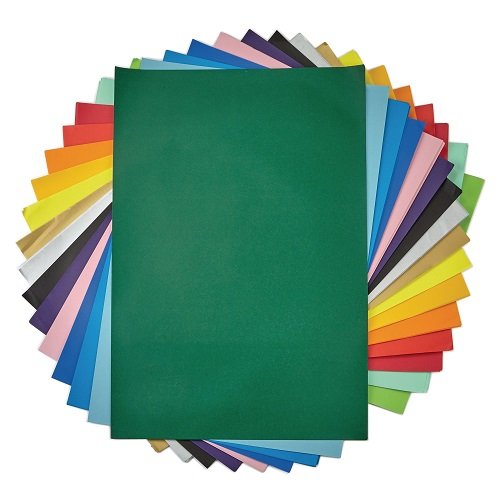

A1 Sheets of Coloured Paper

A1 sheets of coloured paper have many different colors to choose from.

This kind of color paper sheet is smooth and bright, especially suitable for display, attracting the attention of potential customers.

Such paper sheets are often used in the fields and industries of decorative arts, sculpture, modeling, collage, and handicrafts.

A2 Paper Sheet

A2 Sheet Size/Dimension

The A4 sheet size/dimension is 420mm x 594mm, which is twice the size of A3 paper.

A2 Sheet of Paper

A2 sheet of paper is often used when making notices, posters, roll-up banners, and printing artwork, and it is output by laser printers and copiers.

Many documents can be produced or printed on an A2 sheet of paper, items list are summarized in the following table:

| Manual (folded, expanded, multiple pages) |

| Letterhead |

| Magazine Advertising |

| Poster |

| Table of Contents |

| Form |

| Notebook |

A2 Sheet of Card

A2 sheet of card is usually used to make postcards, reply cards, note cards, etc.

You can find many suppliers by searching for A2 sheet of card on the online shopping site Amazon.

How Many A2 Sheets in A0

After the A0 paper is folded in half, there are 2 A1 sheets.

And the 2 A1 papers are folded in half, there are 4 pcs A2 paper sheets.

So there are 4 pcs A2 sheets in A0.

How Many A2 Sheets in A1

After the A1 paper is folded in half, there are two A2 paper sheets, so there are a total of 2 pcs A2 sheets in A1.

Tracing Paper A2 Sheets

Tracing paper A2 sheet is a heavy and strong paper sheet that absorbs graphite, ink, and lead from colored pencils.

Even after this paper sheet is repeatedly and violently rubbed by a pencil, it will not cause wrinkles, tears, or any other problems.

Therefore, the design sketch can be drawn directly on the tracing paper, tracking the design progress will be more convenient.

Make sure to store used and unused tracing paper in a dry place, as it will be damaged by moisture.

A3 Paper Sheet

A3 Sheets Size

A3 refers to the specifications of the paper.

According to international standards, A3 sheets size is 297mm x 420mm, which is twice the size of A4 paper.

A3 Sheet Size in cm

The size of A3 paper is 297mm x 420mm, which is 29.7cm x 42cm when converted to cm.

So A3 sheet size in cm is 29.7cm x 42cm.

A3 Sheets in a Meter

It depends on whether you mean length or area.

In terms of length alone, A3 sheets in a meter mean that the size of an A3 sheet in meters is 0.297m x 0.42m;

In terms of area, the area of the A3 sheet is 0.125 square meters.

A3 Sheets of Paper

A3 sheets of paper are very useful when printing presentation materials, charts, posters, and business plan proposals.

A3 Sheets of Card

The A3 sheets of card’s weight are about 220gsm.

A3 sheets of cards are often used when making handicrafts.

Many posters, presentations, greeting cards, and notices are also made of A3 sheets of card.

A3 Sheets Bundle Price

A3 sheets are usually sold in packages of 250, 500, or 2500 sheets.

The specific bundle price can be found by searching on the Amazon website.

A4 Paper Sheet

A4 Sheet Size/Dimensions/Measurements

A4 paper is defined by the International Standardization Organization ISO 216.

According to this organization’s definition, A4 sheet size is 21cm x 29.7cm (210mm x 297mm).

Most countries in the world adopt this international standard.

A4 Paper Size in Pixels

As the A4 paper size is 210 mm x 297 mm, and 1 inch = 2.54 cm, we can calculate A4 paper size in pixels when the resolution is different.

The following dimensions are the most usual ones:

When the resolution is 72 pixels/inch, A4 paper size in pixels is 842 x 595 respectively;

When the resolution is 120 pixels/inch, A4 paper size in pixels is 2105 x 1487 respectively;

When the resolution is 150 pixels/inch, A4 paper size in pixels is 1754 x 1240 respectively;

When the resolution is 300 pixels/inch, A4 paper size in pixels is 3508 x 2479 respectively.

A4 Paper Size in cm

The size of A4 paper is 210 mm x 297 mm, which is 21cm x 29.7cm when converted to centimeters.

So A4 paper size in cm is 21cm x 29.7cm.

A4 Sheet Price

A4 sheet price varies according to the paperweight and paper quality.

The price of A4 paper is calculated by 500 sheets per ream.

For the price of each ream, please refer to the picture below:

A4 Paper in mm

The width of A4 paper is 210mm and the height is 297mm.

So A4 Paper in mm size is 210mm x 297mm.

GSM of A4 Paper

GSM of A4 paper mainly has 2 types, one is 70gsm, the other is 80gsm.

A4 Paper Business

As the global population grows and the literacy rate increases, the number of educational institutions increases, A4 paper’s demand is also increasing.

Because A4 paper is quite suitable for recording, storing, and disseminating information.

Some emerging countries in Asia, Africa, and Latin America use a small amount of copy paper per capita, and these countries continue to invest in education.

It is expected that in the near future, the A4 paper business in these countries will boom.

For companies or individuals interested in entering the A4 paper business, it is best to open their own factories for production.

For products that are shipped in bulk like A4 paper, in addition to controlling your own production quality, your can also purchase large quantities from the jumbo roll paper supplier.

You can obtain higher bargaining power, and effectively enhance your terminal price competitiveness.

How many A4 papers are in a ream?

There are 500 A4 papers in a ream.

A5 Paper Sheet

A5 Sheet Size/Dimensions

A5 sheet size is 148mm x 210mm (width x height).

This is a very common specification.

A5 paper is the size of A0 paper folded 5 times, so the area of an A5 sheet is 1/32 of A0.

A5 Sheet Size/Dimensions in cm

A5 sheet size in cm is 14.8cm x 21cm.

A5 Sheet Size in Inches

1 inch=25.4mm, 148mm/25.4mm=5.83″, 210mm/25.4mm=8.27″, so A5 sheet size in inches is 5.83″ x 8.27″.

A5 Sheet of Paper

A5 sheets of paper have many uses.

When you need to make diaries, books, invitations, flyers, manuals, etc., you need to use A5 sheet.

A5 Sheet Price

With regard to A5 sheet price, it can be easily found on the Amazon website, please check the following photo for reference:

Kraft Paper Sheet

Kraft Paper Sheets 18 X 24

Kraft paper sheets 18 x 24 is made of 50 pounds kraft paper.

It is not only strong and durable but also easy to handle after disposal.

It is an ideal choice for packaging products.

It only needs to be pre-cut to the size of 18 x 24 before packaging.

The kraft paper sheets 18 x 24 can protect the box and the inside things from damage, and the kraft paper sheets 18 x 24 can be crumpled to fill the gaps in the box.

Kraft Paper Sheets 24 X 36

Kraft paper sheets 24 X 36 can be made of 100% recyclable materials.

These sheets are very soft, absorbent, and can rebound after repeated impacts.

It is recommended that you use such kraft paper sheets 24 X 36 to protect metal parts and tools from grease, oil, and water.

Kraft Paper Sheets for Printing

Kraft paper sheet printing can be realized by flexo printing, gravure printing, offset printing, screen printing, and other processes.

As long as you are familiar with the essentials of printing technology, familiar with the compatibility of printing inks and kraft paper, reasonably select and allocate inks, and control equipment parameters, you can get the best printing effect.

In kraft paper printing, in order to get better color reproduction, it is more difficult than printing with SBS paper.

Since ordinary kraft paper itself is dark brown, the effect of printing ink is very different from that of printing on bleached paper.

Therefore, it is best to use brightly colored inks and use more eye-catching colors, so that the printing effect is better.

Kraft Paper Sheets for Packaging

Kraft paper packaging has the advantages of easy processing, low cost, suitable for printing, lightweight, foldable, non-toxic, tasteless, and pollution-free.

But whether it is white kraft paper or yellow kraft paper packaging, they also have disadvantages such as poor water resistance, and poor strength when it is wet.

Therefore, when using kraft paper packaging, it is necessary to use the advantages and avoid the weaknesses of kraft paper sheets for packaging.

Kraft Paper Sheets Wholesale

Many suppliers on Amazon sell kraft paper sheets, some of them even do kraft paper sheets wholesale business.

You can select some of those suppliers, then contact them.

Through google search, Nassco wholesales kraft paper sheets, you can also contact Nassco for more details.

Paperboard Sheets

Paperboard Sheets Cost

With regard to paperboard sheets cost, please check the following photo for reference:

Paperboard Sheets A4

Paperboard sheets A4 can be used in the following aspects:

- Bookmaking or covers

- Handicrafts

- Scrapbooking

Of course, you can also imagine more ideas about using paperboard sheets A4.

White Paperboard Sheets

White paperboard sheets are usually made of high-quality bleached wood pulp, which is a very high-quality paperboard.

This kind of cardboard is often used to print cards and is also used in the packaging of hardcover books and valuables.

Such white paperboard sheets are also the first choice for food packaging and high-end retail product packaging.

Products packaged with this kind of sheets include:

- Tobacco

- Dairy products (butter, ice cream, milk)

- Meat

- Perishable baked products

- Medical products

- Cosmetic

- Wet food

- Frozen food

Large Paperboard Sheets

Large paperboard sheets are mainly made from various pulps.

Thick paper sheets with intertwined fibers are often overlooked or ignored because of their inconspicuousness.

However, even though it is just cardboard, it is extremely useful.

Because of its good fracture layer, good flatness, good toughness, beautiful appearance, etc., it is widely used in the packaging industry, stationery and toy supplies industry, etc., and is especially popular.

Paper Sheet for Baking

There are three main types of paper sheets for baking on the market today:

- Ordinary greaseproof paper

The surface of this paper is light-free greaseproof paper.

Its main purpose is to put it under the food when baking bread, cakes, and biscuits, it can keep the baking pan clean.

- Translucent paper

Many sellers call it oil paper, also known as glassine paper, satin paper, wax paper.

The surface of this paper is supercalendered, and the surface presents a shiny luster.

- Food grade silicone oil paper

On the basis of translucent paper or greaseproof paper, coated with food-grade silicone oil through a special process.

![]()

Poster Sheets

Poster Sheets Paper

Poster sheet paper refers to the printing of texts and exquisite images on paper media, then poster sheets paper achieve the purpose of promotion.

Plastic Poster Sheets

Plastic poster sheets are tear-resistant, waterproof, durable, and flexible.

They can be used as a medium for artistic creation, including dry-erase markings.

Some people use it for campus projects such as multi-color collage and 3D artwork creation.

Clear Poster Sheets

Clear poster sheets are ideal products to replace glass poster frames and glass picture frames.

Many families will use them because they can be cut into any desired size.

Blank Poster Sheets

Blank poster sheets are ideal for stencil printing, letterpress printing, and various entrepreneurial projects.

Because it is not only large enough to cover a large number of creators’ ideas, but also the characters on blank poster sheets can be written large enough so that readers can read each word from a long distance.

It is very suitable to introduce this kind of blank poster sheet when holding science meetings and business presentations.

Printed Poster Sheets

Printed poster sheets are promotional stickers posted in stations, shopping malls, airports, and other crowded places.

They are usually made by printing exquisite patterns and creative advertising copywriting on paper sheets.

Butcher Paper Sheets

Waxed Butcher Paper Sheets

Pack the hamburger patties with waxed butcher paper sheets, and store the packaged hamburger patties in the refrigerator to keep your food tender and fresh, and to prevent your meat from sticking together.

If you like baking biscuits, food, toffee, chocolate, etc., waxed butcher paper sheets are also needed.

In addition, you can even use waxed butcher paper sheets as a liner for cheese boards.

White Butcher Paper Sheets

White butcher paper sheets have the characteristics of puncture resistance and tear resistance.

Because it is uncoated and unwaxed, it is an ideal paper sheet for wrapping sandwiches, seafood, meat, pastries, etc., makes the appearance tidier.

Wrap meat with white butcher paper sheets to keep the meat moist.

Custom Butcher Paper Sheets

Custom butcher paper sheets are butcher paper sheets with printed patterns, advertisements, slogans, etc.

It is an excellent choice for wrapping meat, seafood, and other foods.

Because it contains printed patterns, advertisements, slogans, etc., it can help butcher shops, seafood retailers, and delicatessens to carry out brand promotion, and it is very popular among these types of merchants.

Black Butcher Paper Sheets

The black butcher paper sheets are made of high-quality food-grade materials, which are not only durable but also flexible and reliable.

In addition, it is easy to use and easy to dispose of.

It is very suitable for picking up or packing greasy food.

It can also be used as a lining for scales or baskets.

It has become an essential packaging material in the foodservice or food retail business.

Their presence provides a sanitary barrier to food and helps keep food fresh for a long time.

Brown Butcher Paper Sheets

Brown butcher paper sheets are actually kraft paper sheets.

Its raw material is natural puree.

It is an excellent choice for healthy and environmentally friendly packaging!

Based on the durable and strong characteristics of brown butcher paper sheets, they are widely used in packaging various products, such as barbecue, fresh-cut meat, sandwiches, burgers, french fries, Christmas gifts;

Because brown butcher paper sheets can absorb excess oil from food, avoid human body and clothing contact with oil;

During outdoor BBQ, brown butcher paper sheets can be used as barbecue paper to insulate the food, avoid scorching the food;

Some tray linings and placemats also use brown butcher paper sheets.

Peach Butcher Paper Sheets

Peach butcher paper sheets are also called pink butcher paper sheets, like most other types or colors of butcher paper sheets, they are mainly applied in BBQ meat smoking, foods wrapping, etc.

When someone is smoking brisket or pork butts, such peach paper sheets are also very useful.

Kraft Butcher Paper Sheets

The basic weight of kraft butcher paper sheets is 40 pounds.

It has excellent tear resistance and rupture strength.

In addition, its cleanliness and liquid resistance are also excellent.

It is regarded as an ideal choice for packaging material in food services and supermarkets.

For example, meat, fish, poultry, hot and cold sandwiches, etc., can all be packaged using kraft butcher paper sheets.

Some restaurants even use natural kraft paper sheets as a liner for tables.

Butcher Paper Sheets 18 X 24

When packing luncheon meat, sandwiches, plants, and flowers, butcher paper sheets 18 x 24 is very useful;

It is also used as a disposable table cover by vendors, and some people use it to package gifts.

Sandwich Paper Sheets

Sandwich Paper Wrap Sheets

Sandwich paper wrap sheets are cut according to the preset size.

In addition to packaging sandwiches, they can also be used to pack greasy food, biscuits, etc., to prevent customers’ hands from getting oily and keep them clean.

Sandwich Wrap Paper Custom

Sandwich wrap paper custom is sandwich wrap paper printed with vivid patterns, attractive slogans, many sandwich shops use this kind of wrapping paper to pack their sandwiches.

By the way, to promote their brands and increase their brand awareness.

Sandwich Wrap Paper Foil

Sandwich wrap paper foil is laminated with paper and aluminum foil.

It has excellent heat-locking performance and is a popular choice for packaging hot food.

Wrap hot sandwiches, hot burritos, hot hamburgers, and baked potatoes with sandwich wrap paper foil.

After heating, they will be evenly heated and taste more delicious!

Sandwich Wrap Paper Roll

Sandwich wrap paper rolls can be cut into many many sandwich wrap paper sheets, sandwich wrap paper sheets are usually used for packing sandwiches, no doubt about that.

But it can be also applied in packing Christmas gifts, festival gifts, etc.

Sandwich Wrap Paper with Logo

In order to maximize the role of sandwich wrap paper, these sandwich shop merchants will print their own shop logo on sandwich wrap paper, sandwich wrap paper with logo can effectively promote their stores and increase the visibility of their stores.

Hamburger Patty Paper Sheet

What is a Patty Paper?

Patty paper is usually a 5.5″ or 6″ square thin waxed paper (without wax), which is widely used for hamburgers, meatloaf, etc.

Is Patty Paper Wax Paper?

Patty paper sometimes is called waxed paper, it is because patty paper’s appearance is quite similar to wax paper, but it doesn’t mean patty paper contains wax, many patty papers are without wax.

Is Patty Paper the Same as Parchment Paper?

Patty paper is very similar to parchment paper, and its purpose is basically the same.

Parchment paper can be used as a potholder in the oven to prevent food from sticking to the plate.

Patty paper can be used as flat sheets and pop-up sheets.

Aluminum Foil Sheet

Aluminum Foil Sheets for Hair

Aluminum foil sheets for hair refer to some aluminum foils that are strong enough, such strong aluminum foils can withstand the effects of dyes and bleaching agents.

Aluminum foil sheets for hair are also very ductile.

Highlighted and under-displayed hair can be effectively separated by this aluminum foil.

Most salons and stylists have always chosen aluminum foil sheets for hair, because the cost of aluminum foil is relatively low, and it is flexible and easy to operate.

Can You Use Aluminum Foil on a Baking Sheet?

Spread the aluminum foil on the baking tray, and then put the chocolate cakes, grilled vegetables, etc. on the aluminum foil.

After these foods are baked, they can be easily cleaned, only the used aluminum foil needs to be cleaned.

Are Aluminum Foil and Tin Foil The Same Thing?

Compared with aluminum foil, tin foil is harder, stronger, and more difficult to tear.

However, food wrapped in tin foil usually has a slight tin smell.

Because of this, tin foil is gradually being replaced by the aluminum foil for food packaging.

Which Side of The Aluminum Foil Goes Down?

In fact, no matter you put the shiny side up and the dull side down, or put the dull side up and the shiny side down when you are cooking, it almost gets the same cooking effect.

Is Aluminum Foil Toxic When Heated?

Heating aluminum foil can produce toxins.

Because aluminum foil paper contains a certain amount of aluminum and lead, a chemical reaction may occur when heated, causing metal substances such as aluminum and lead to overflow.

Although the amount of overflow is small, the metabolism of metal substances in the body is very slow.

If consumed for a long time, it may cause poisoning;

And if the food is wrapped in tinfoil or aluminum foil during the barbecue, the acidic sauce on the food, aluminum, and tin foil are heated at the same time, and the chemical reaction will be accelerated.

Plastic Film Sheet

Plastic Film Sheets HS Code

According to China HS code database, plastic film sheets HS code is 3926901000.

Plastic Film Sheeter

Jota Machinery’s plastic film sheeter has many attractive selling points, the most attractive one is that Jota plastic film sheeter can be customized according to your scenario requirements.

Then Jota plastic film sheeter can seamlessly connect to your production and saves more and more your priceless time and energy.

Plastic Film Sheeting Machine Manufacturers

As one of the professional plastic film sheeting machine manufacturers, we sincerely welcome you to send your plastic film jumbo roll to us, we can test your jumbo roll with our Jota plastic film sheeting machine.

The testing process can be lively broadcast to you via Whatsapp video call.

Paper Sheeter Machine

- What is Paper Sheeter?

- Paper Sheeter Machine Manufacturers

- Paper Sheeter Parts

- Sheeter Knives

- Synchro Fly Folio Size Paper Sheeters

- Rotary Sheeter

- Industrial Paper Sheeter

- The Cutting Edge of Sheeters

- Paper Sheeter Machine Price

- Paper Sheeter Machine Where to Buy

- Paper Sheeting Training

- Paper Sheeter Machine Operator

- Which Cross-Cutting Method Does Jota Paper Sheeter Adopt?

- What Kind Of Material Can Be Cut By Jota Paper Sheeter?

- Is Jota Paper Sheeter Workable For The Hamburger Sandwich Wrap Paper?

- Can The Paper Sheeter Cut The Adhesive Label?

- Can The Paper Sheeter Cut A1, A2, A3, A4, A5 Paper?

- What Kind Of Paper Sheeter Is Better For Cutting Newsprint?

- Can Some Thin Films Be Cut By Jota Paper Sheeter?

- Can The Paper Sheeter Cut The Printed Materials?

- Can The Paper Sheeter Cut 2 Rolls At The Same Time?

- Does Jota Paper Sheeter Have Automatic Counting Function?

- Does The Paper Sheeter Need An Automatic Stacker?

- Does The Paper Sheeter Have An Automatic Label Tab Insertion Device?

- How Wide Is The Widest Paper Sheeter?

- What Is The Longest Crosscut Length Of Paper Sheeter?

- Do I Need To Remove Static Electricity When Cutting Plastic Sheets?

- What’s The Guarantee Of The Paper Sheeter?

- What Is The Voltage Of The Paper Sheeter?

- How Often Do Paper Sheeter Knives Need To Be Sharpened?

- If The Sheet Cut By The Paper Sheeter Is Not Square, How To Solve It?

- Will The Cross-Cutting Scratch The Surface?

What is Paper Sheeter?

Paper sheeter converts the rolled material into pieces of square sheet through slitting and sheeting.

Finished sheets are further used for the next offset printing or die-cutting steps.

It is a common machine used in the printing and packaging industry.

Paper Sheeter Machine Manufacturers

There are many paper sheeter machine manufacturers all over the world, such as the following famous players.

- Rosenthal and Quantum – USA

- Pasaban – Spain

- BW Papersystems – Germany

- Line O Matic – India

- CHM – China

We Jota is also an original manufacturer with self-supporting research and development team, factory, CNC center.

Paper Sheeter Parts

The meaning of parts can be accessories or divisions.

The paper sheeter accessories are mainly some tools needed by paper sheeter machine maintenance, such as wrenches, screwdrivers and so on.

The division of automatic roll to sheet cutter mainly includes the unwinding part, the web-feeding part, the slitting part, the sheeting part and so on.

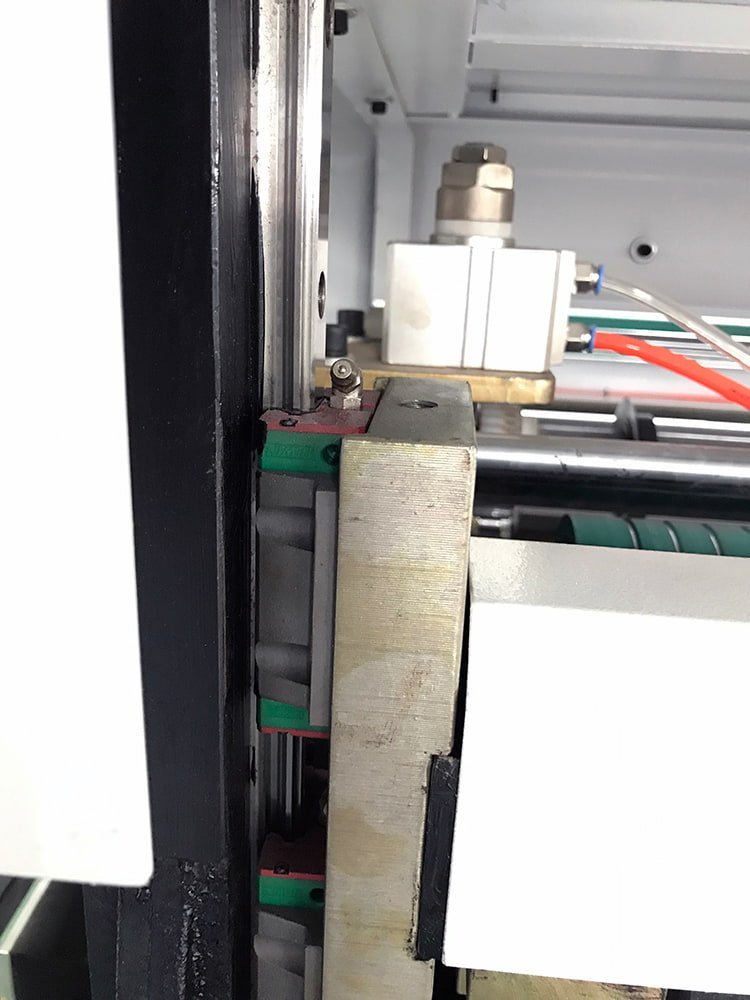

Sheeter Knives

The paper sheeter machine requires high cross-cutting accuracy, no burrs, and no indentation.

Due to the requirements for paper sheet cutting accuracy, the paper roll to a4 sheet cutting machine’s blades sometimes have to achieve micron-level accuracy, and the sheeting blades should have the lowest cutting resistance and the greatest wear resistance.

Blade material

Use imported high-quality steel, such as:

- Tungsten carbide

- High-speed steel

- Alloy tool steel

- SKH-51

- SKD-11

- SKS7

- SK2

- Cr12Mov

- H13

- 9CrSi

- 6CrW2Si

- W6Mo5Cr4V2

- YG8

- K30

Blade heat treatment

Select a large diameter vacuum quenching furnace, heat treatment is uniform, and the blade hardness is HRC53-75.

Finishing

CNC processing machinery is used to ensure that the blade accuracy reaches 0.01mm-0.02mm.

Synchro Fly Folio Size Paper Sheeters

Synchro fly folio size paper sheeter is an industrial machine that accurately cuts paper and cardboard web into special length x width sheets.

Compared with single fly folio size paper sheeter, this synchro fly folio size roll to sheet cutting machine can effectively reduce the dust deposition generated during work.

Compared with ordinary cut size paper roll to sheet cutting machine, the production efficiency of synchro fly folio size roll to sheet cutter is much higher, but the price is correspondingly much higher than that of cut size sheeter.

Rotary Sheeter

The rotary sheeter is a commonly used machine in the printing and packaging industry.

The design concept of this machine is to convert the reeled jumbo roll material into sheets.

Such machine’s common unwinding widths are 1400mm, 1700mm, 1900mm, and the cross-cutting accuracy is controlled by a servo motor.

The produced sheets can be discharged by conveyors or stackers.

As high-end equipment for single-sheet cross-cutting, rotary sheeter has faster production speed and higher production efficiency.

In fact, the rotary sheeter is almost the same as synchro fly paper sheeter introduced earlier.

Industrial Paper Sheeter

Industrial paper sheeter is mainly designed for printing and packaging industry.

Such industrial paper sheeter can release paper, cardboard, foil, film, fabric jumbo roll from unwind stand, transport these materials web for inline slitting and sheeting, output material sheets are produced.

The Cutting Edge of Sheeters

In the flexible material converting industry, “clean-cut” is not just a slogan, it is an important factor in determining whether a customer buys a sheeter.

Before placing an order to purchase a roll to sheet paper cutting machine, the customer will definitely ask to watch the actual demonstration effect, and will also carefully check whether the paper sheet cutting machine’s cutting edge is smooth and free of burrs.

When the automatic paper roll to sheet cutting machine cross-cuts, the upper and lower blades must almost completely crush each other, preventing the in-between material from being caught by the two knives.

The current blades are all CNC processed, and the cross-cutting accuracy can be controlled between 0.01-0.02mm, so the edges of the material after cross-cutting look very neat.

Paper Sheeter Machine Price

The paper sheeter machine’s price differs according to the types, unwinding width, layer amounts, etc.

So if you are planning to purchase a paper sheet cutter machine, please determine the appropriate type, unwinding width, and number of layers according to your actual production scenario requirements before you can better confirm the machine price.

Of course, Jota is always willing to assist you better-understanding paper roll to sheet cutting machine price, just mail or call us for a quotation.

Paper Sheeter Machine Where to Buy

As mentioned before, many manufacturers supply paper sheeter, famous brands include Pasaban, BW Papersystems, etc.

If you have enough time and energy, you can search paper sheeter machine on Google, many paper sheeter machine supplier’s websites will be listed.

We Jota Machinery also manufacture reel to sheet cutting machine, please send us an inquiry on this site, our professional sales’ one-on-one VIP service is waiting for you.

Paper Sheeting Training

Paper sheeting training mainly includes the following points:

- Wear personal protective equipment;

- Keep in mind the safety hazards and safe work regulations;

- Identify the paper sheet cutter machine’s typical components;

- Grasp the sheeter machine working principle, operation process, and safety precautions.

Paper Sheeter Machine Operator

Paper sheeter machine operator refers to workers who operate the paper roll to sheet cutter machine, their responsibility is to use the paper sheet cutter machine to process the big roll-shaped paper into many many sheets of paper.

Which Cross-Cutting Method Does Jota Paper Sheeter Adopt?

We Jota can provide two types of the cross-cutting method for sheet cutting machine.

One is the paper sheeter of the scissor-type, the cross-cutting knife moves vertically and cuts the material like scissors. This machine is cheap and the speed is 120times/min;

The other type is a high-speed rotary blades paper roll to sheet cutting machine, which cuts the paper with a rotating blade and then automatically stacks it at a speed of 300times/min.

What Kind Of Material Can Be Cut By Jota Paper Sheeter?

Almost all kinds of paper and paper cardboard, thickness ranges from 20gsm-500gsm, like:

- Newspaper

- Offset copy paper

- Kraft paper

- Paper cardboard

- Sticker adhesive paper (scissor type)

- Some plastic film

- Plastic sheet board (scissor type)

Is Jota Paper Sheeter Workable For The Hamburger Sandwich Wrap Paper?

Yes, due to the light and soft characteristics of sandwich wrap paper, we’ve developed a kind of double-layer roll to sheet cutter for the hamburger sandwich paper.

As the double layer roll to sheet cutting machine has 2 unwind stands, the upper and lower 2 sheets of paper enter the slitting and sheeting stations at the same time, total thickness increases.

In this way, the paper sheets will not flutter elsewhere during the sheeting process.

Can The Paper Sheeter Cut The Adhesive Label?

Adhesive label can be cut by Jota’s paper sheeter.

According to the property of the glue in the middle of the sticker, use a scissor-type paper sheet cutter.

Can The Paper Sheeter Cut A1, A2, A3, A4, A5 Paper?

Yes, it needs to be equipped with a slitting station, and the slitting and sheeting functions are integrated into one machine.

What Kind Of Paper Sheeter Is Better For Cutting Newsprint?

The rotary blade paper sheeter can cut 4 layers or 6 layers at the same time, it’s most suitable for cutting newsprint.

Because the accumulated thickness can make the rubber roller work more efficiently.

Can Some Thin Films Be Cut By Jota Paper Sheeter?

Yes, our engineers will put a spring on the feeding rubber roller to solve the feeding problem.

Can The Paper Sheeter Cut The Printed Materials?

Yes, to cut printed materials, the paper sheeter should be equipped with photoelectric eyes to track the printed color scale, ensure that every cut is a complete image.

Can The Paper Sheeter Cut 2 Rolls At The Same Time?

Yes, depending on the material properties, 2 or 4 rolls can be cut.

However, the total thickness should not exceed 500gsm.

Does Jota Paper Sheeter Have Automatic Counting Function?

Jota paper reel to sheet cutting machine is controlled by microcomputer or PLC, only need to preset the number of sheets, the machine will work automatically, and record the number of sheets and batches.

Does The Paper Sheeter Need An Automatic Stacker?

If your material is relatively hard and large, it’s better to add an automatic stacker for improving production efficiency.

Does The Paper Sheeter Have An Automatic Label Tab Insertion Device?

During the paper sheeter running process, each time after stacking 100 sheets, it needs to insert a label tab.

This is an optional function, you could choose to add it or not according to your requirements.

How Wide Is The Widest Paper Sheeter?

According to the Pasaban website’s info, their paper sheeter’s max. unwinding width has reached 7000mm.

This is the widest paper sheeter we have noticed.

What Is The Longest Crosscut Length Of Paper Sheeter?

Generally, the length of the paper sheeter is within 1999mm, but we can customize the machine with a cross-cutting length exceeding 8m for you.

Do I Need To Remove Static Electricity When Cutting Plastic Sheets?

Yes, it needs to remove static electricity.

Generally, the static eliminator will be installed on the paper sheeter for removal.

What’s The Guarantee Of The Paper Sheeter?

The guarantee is 1 year, and the whole life technical support can be provided.

What Is The Voltage Of The Paper Sheeter?

The standard voltage is 380V, it can also be customized according to your requirements.

How Often Do Paper Sheeter Knives Need To Be Sharpened?

We will equip 2 blades of the paper sheeter for exchange, every 6-9 months need to be sharpened basically.

If The Sheet Cut By The Paper Sheeter Is Not Square, How To Solve It?

It can be solved by adjusting the angle of the rubber roller.

Will The Cross-Cutting Scratch The Surface?

No, all rollers have been surface hardened.

- What is a paper sheeter machine?

- How does a paper sheeter machine work?

- Does your paper sheeter machine have printing capabilities?

- What factors should I put in mind before buying a paper sheeting machine?

- What are the parameters of the A4 paper sheeting machine?

- What are the configurations of the automatic paper roll to sheet cutting machine?

- What slitting methods does the paper sheeter use?

- Where can I get the best paper sheeting machine manufacturer?

- What is the difference between a single layer cross-cutting and double layer cross-cutting paper sheeter machine?

- Is there a maintenance protocol for automatic paper roll to sheet cutting machine?

- Is your automatic paper roll to sheet cutting machine standardized?

- How do you ensure clean cuts for your paper sheeter machine?

What is a paper sheeter machine?

Paper sheeting is the process of cutting paper or other similar materials inro specific lengths.

It also involves cutting paper into specific widths.

A paper sheeter machine on the other hand is a machine that is used in the cutting.

It can be set to cut materials or paper into the specific lengths and width.

Paper sheeter machines are equipped to cut large jumbo rolls into smaller sheets of paper they have the ability of taking large rolls and create smaller sheets of materials for any needs.

Sheeters can feed rolls of material or run in-line to convert the output of an extruder, calendar, laminator or other web equipment. Most of the sheets that are cut by a paper sheeter are used as end products.

It is also worth noting that you can get different paper sheeters in the market.

At Jota Machinery, we have two types of sheeter machines.

The first one is the scissor type sheeter machine.

It has a cutting mechanism where the blade cuts the paper sheet through up and down movement. It is ideal for cutting paper sheets with a larger width.

The second type of paper sheeter machine is the rotary knife sheeter machine.

These two types of sheeter machines defer in their slitting method.

Sheeters are also used in packaging or manufacturing processes. Some of these processes include;

- Laminates glass processing

- Wrapping of medical devices.

- Composite products.

- Thermoforming

- Auto interiors

- Die cutting

- Laminating

- Digital printing.

You can also incorporate slitters on your paper sheeter machine.

The slitters will help out in cutting the width of your paper.

This is in addition to cutting the length to specific measurements.

There are other add-ons that you can incorporate with your paper sheeter machine.

A common add-on is the printing processes.

You can incorporate our paper printing machine to print on the cut sheets.

We also offer room for you to configure and custom the paper sheeter machine to your specifications.

The good thing with a paper sheeter machine is that you can use different materials with it. It is a very flexible and easy to use machine.

You can use the sheeter machine to sheet different types of products. Some of these products include:

- Cardboard

- Paper

- Packaging paper

- Foil

- Hamburger wrapping paper.

- Hot dog wrapping paper

- French fries wrapping paper.

- Coated wrapping paper

- Foil

- Plastic film

- Different fabrics

Our paper sheeter machine can handle small rolls and turn them into whatever length sheets you need.

For example, A4 paper sheeting machines are built to handle extreme operations.

They can handle the rigors of 24/7 operation in an industrial environment.

Some of the alternative configuration options that are available for our sheeter machines include:

- Slitting paper sheeter machine

- High capacity unwinds

- We also have multiple unwinds paper sheeter machine.

At Jota Machinery, we ensure that we optimize our paper sheeter machines.

This ensures that the rigors of 24/7 operation in an industrial environment.

You can also configure the paper slitter to options such as cut to mark, automatic stacking and precision pick and place.

How does a paper sheeter machine work?

A paper sheeter machine is used to cut large jumbo rolls into different sizes of paper sheets.

These paper sheets may include rolling packaging materials.

Some of the rolling packaging materials may include paper, paper-plastic, and multicolor laminated material.

To understand the working mechanism of a paper sheeter machine, you should consider its various sections.

Although the paper sheeter might defer a bit in their working mechanism.

They all have basically almost the same working mechanism. The different sections of the paper sheeter machine include:

The unwinding section

A paper sheeter machine starts the operation once it’s fed with a large roll of a given material.

The large roll is commonly referred to as Jumbo.

The jumbo roll is fed into the slitter by the unwind.

From there, the jumbo or the master roll is slit into different widths.

Unlike other machines, the paper sheeter machine cuts the slitted paper into different lengths.

The unwinding sections of a paper sheeter machine works by unwinding the jumbo paper roll.

This is done by feeding the jumbo paper roll into the unwinder drum.

We manufacture both the two drum winder slitter machines and four drum winder paper slitter machines.

The drum winders are equipped with hydraulic shaftless jumbo roll loading system.

Our paper sheeting machine have a significant loading capacity.

You can get paper rewinders with a capacity of more than 1050mm width, 1200mm diameter of jumbo paper roll capacity.

The paper sheeter machine is also equipped with a frequency invertor motor.

The frequency inverter motor is used to control the sheeting cutter movement.

This ensures that the cut paper sheets are solid and stable. It also serves to minimize paper wastage and the paper sheeting machine downtime ratio.

Our paper sheeter machines automatically draw web paper out into the longitudinal slit section.

This means that you will not have to put the web through the bottom of two drums. This will save you time, labor, and shorten the debugging time.

Transmission section

The transmission phase of the paper sheeter machine is where the slitted jumbo roll is prepared for slitting.

We have optimized out paper sheeting machine to meet your paper sheeting needs.

For example, we have a modified sheeter that can cut two rolls at the same time. One roll on the left and another roll on the right.

Our paper sheet machine is also optimized to facilitate both the light weight and high-speed movement.

This is done while maintaining high accuracy.

The cutting and slitting speed depends on the type of paper sheeter machine that you are using.

Some sheeting machines such as the scissor type sheeter can reach 120 cuts/min.

The sheeter machine also adopts with Servo motor from Yaskawa for the material feeding. The precision can be highly controlled by 0.2mm.

The transmission section has been optimized specifically the material feeding part (NIP roller).

The mechanical structure of the cutter head for thin paper has also been optimized.

By optimizing the NIP roller and the cutter head, we have ensured that our paper sheeter machine is specifically suited for cross cutting.

The paper sheeting machine is especially suitable for cross-cutting 20g-50g paper sheets.

Slitting Section

The slitting and sheeting sections of the paper sheeting machine are integrated.

This is to ensure that the process flows harmoniously with the production of quality paper sheets.

The slitting section is where the jumbo a paper roll is slitted into desirables rolls.

These rows have the desired widths for the type of paper sheet to be produced.

For instance, the production of A5 paper sheet will require the paper sheeter machine to be configured accordingly.

The slitter head will be adjusted to cut rows that have widths measuring the size of the A5 paper sheet.

After being cut to the required size, the paper sheet row moves to the sheeting section.

The slitting section is also equipped with the NIP roller.

The NIP roller is important for feeding paper into the sheeting head.

It controls the width of the paper to be cut.

For instance, if the paper roll is too thin or too wide, the sheeting head might not accept it. This ensures that you have clean cut and quality paper sheets.

Sheeting Section

The sheeting process is where the unwinder paper roll is cut into different sizes.

Depending on the configuration, it can cut paper sheets into different lengths and width.

For a paper sheeter machine, it can cut paper into A2, A3, A4, and A5 paper.

Our paper sheeter machine is also suitable for cutting various materials. These include office copy paper, plastic film (PVC, OPP, PET, CPP), hamburger paper, sandwich wrap paper, and hotdog paper.

The sheeting section is also equipped with a specially treated alloy sheeting cutter.

The alloy sheeting cutter has merit for long working life and endurance.

This is together with an auto counting system. The auto counting system helps in counting the required sheets of paper per batch.

As earlier stated, the A4 paper sheeting machine can either adopt the scissor type of cutting or the rotary type.

A rotary sheeter machine for cutting paperboard. Scissor-type reel to sheet cutting machine with a width of 1600mm for cutting newsprint.

At this section, you can also integrate the printing process such as the flexographic printing process.

This can be achieved by linking the paper sheeting machine with machines such as flexographic printing machines.

You can also equip the paper sheeting machine with various width PE coating and lamination machines.

Control section

The control system of our paper sheeter machine is centered.

This means that you will be able to control the various aspects of your paper sheeter machine from a centralized point.

You will not need various points of controlling the various sections of your paper sheeting machine.

The paper sheeter machine comes with a programme control system. All the parameters can be displayed on the control monitor. You can also use the control monitor to start and switch of the paper sheeting machine automatically.

The monitor integrates the latest technology in the market when it comes to machine control systems.

Our A4 paper sheeting machine adopts a powerful Wein view PLC and Touch Screen and meter counter.

All the working parameters can be displayed on the control monitor.

You will only need to set up the material thickness and initial tension data. The Micro-computer will calculate the accord data, and keep the machine working automatically until the end.

Waste Disposal section

We have equipped our automatic paper roll to sheet cutting machine with a special waste outlet.

For the waste outlet to work perfectly, you need to connect the hose to the waste outlet. All the waste edges pass through the hose with the siphon fan’s huge vacuum suction.

The air blower installed in our paper sheeting machine is specially adopted for thinner materials.

This means that your machine will remain clean throughout the production process.

Does your paper sheeter machine have printing capabilities?

No, our paper sheeter machine does not have printing capabilities.

It is not possible to integrate the printing capabilities in line with our paper sheeter machine.

This is because printing is a continuous process. On the other hand, the sheeter is an on and off machine.

On and off means that the sheeter machine cuts the paper sheet fed in intervals.

It is also constantly adjusted to cut different types and sizes of paper sheets. This makes it difficult for printing to be integrated with the paper sheeter machine.

The best way to include printing capabilities is to have an off line printing machine.

This can be used to print on the paper sheet roll before slitting and sheeting. Another alternative is having a printing machine off line that can print on the already done paper sheets.

It is worth noting that the paper sheets can support different prints and printing method.

This means that you have room for a wider selection of printing methods for your paper sheets.

You can either print on both side of the paper sheeter or on only one side of the sheeter. This depends with the customers’ need and the use of the paper sheeter.

You can contact us for guidance on how to go about the paper sheet printing process.

What factors should I put in mind before buying a paper sheeting machine?

A paper sheeting machine is an important machine in any paper milling business.

This is because paper sheets are needed in almost all the activities we do in a day.

From buying a hamburger in your favorite joint to the paper you do your assignment on. paper sheets are applicable in our daily life.

That is why we at Jota machinery assure you of a paper sheeting machine made purposely made for your business.

Some of the factors that you should consider before choosing a paper sheeting machine include;

The type of paper sheeter machine

Paper sheeter machines have different capabilities. This makes it important for you to consider the type of paper sheeter machine.

For instance, the type of cutting installed on the paper sheeter machine is something you should consider.

Our paper sheeter machines come in two different types.

The first is thee scissor type sheeter. The second is the rotary knife sheeter machine. By being aware of the type of paper sheeter machine you need for your business, you will be able to optimize it.

The different types of sheeter machines also work differently and are configured differently.

Choose a machine that corresponds to your business needs. At Jota Machinery, we will guide you on the best machinery to use.

The price of the paper sheeting machine.

The price of the sheeter machine is also something that you should put in mind.

The price can be affected by different factors. Some of these factors may include;

- Material used for your paper sheeter machine: Different paper sheeter machines are used for different applications. If you need a fully integrated automatic paper roll to sheet cutting machine, you will have to pay more. Automatic paper roll to sheet cutting machine also have different capacities.

High-capacity paper roll to sheet cutting machine cost more than the low-capacity ones.

High capacity means the ability to produce high number of small size paper sheets.

How the machine is integrated also determines its price.

- The configuration of the paper sheeting machine: The configurations of the paper sheeting machine also will determine its price. The configurations include the working mechanisms of the paper sheeting machine.

Customized configurations for your paper sheeting machine will likely lead to slightly higher prices.

We advise you to go through our product catalog before making your order.

This will help you in making the right decision when it comes to the paper sheeting machine configurations.

Some of the configurations that you can put in mind may include the mode of control of the paper sheeting machine.

You can also consider some configurations such as hydraulic driven automatic jumbo roll loading.

All these serve to push the automatic paper roll to sheet cutting machine slightly higher.

Flexibility of the paper sheeting machine.

Flexibility of the paper sheeting machine is another consideration that you should put in mind.

Some capabilities such as integration of printing are an example of paper sheeting machine flexibility.

Another flexibility consideration is the ability of the machine to work with different materials.

At Jota machinery, we will be able to configure the paper sheeting machine to your desired configurations.

The paper sheeter machine should be able to work with your desired materials seamlessly.

If you are not sure of the type of paper sheeter machine that you require, kindly contact us.

The capacity of the A4 aper sheeting machine

The parameters of the paper sheeting machine are an essential determinant of the overall price.

Parameters such as unwinding width and unwinding diameter will determine the overall price.

The lesser the parameters the lesser the overall price of your thermal paper slitting machine.

The parameters also will determine the capacity of your paper sheeting machine.

It is important to first determine the parameters that you need for your paper sheeting machine.

For instance, the number of the unwind stands, sheet out, and printing capabilities are parameters that you should consider.

You can get a paper sheeter machine with 2 Upper and lower double unwind stands.

This will work differently from a paper sheeter machine with a single unwind stand. That is why the capacity of your paper sheeter machine is an important consideration.

The type of the automatic paper roll to sheet cutting machine.

The type of the automatic paper roll to sheet cutting machine that you need will also greatly affect the operation of your business.

It is important that you have all the information about the machine you want at hand.

Paper sheeter machines are available in different capacity, specification, configurations, and parameters.

Different paper sheeter works differently.

For instance, a scissor type sheeter has a different cutting mechanism compared to a rotary cutter sheeter machine.

The type of cutting affects aspects such as the speed of the paper sheeter.

The scissor type paper sheeter machine’s speed is a maximum of 120 cut per min. On the other hand, the rotary paper sheeter machine achieves speeds up to 350 cuts per min.

The main reason that we insist on the type of paper sheeting machine to consider is because they work differently.

Take the scissor type paper sheeting machine. It is mainly used to cut sticky paper, printed paper, or plastic film sheet. It is a machine that is suitable for thing paper sheets a good example being the hamburger wrapping paper sheet.

On the other hand, the rotary paper sheeting machine is suited for hard material cutting.

Hard materials such as paper board and other paper products sch as kraft paper.

A rotary paper sheeter machines comes in handy in cutting such paper products into sheets. Most of these paper products are great in applications such as printing or die cutting.

To understand more on the different types of paper sheeting machines, contact us.

We will be able to guide you through all the relevant information on the paper sheeter machine. Feel free to share with us your ideas and specifications for your paper sheeting machine.

What are the parameters of the A4 paper sheeting machine?

Our paper sheeting machines comes with different parameters.

This is because we strive to make a paper sheeter machine that meets your specific needs.

The parameters are configured to suit the needs of your business.

A hamburger wrapping paper sheet machine will be configured to meet those specific requirements.

It will be a bit different from one that needs to produce office copier paper sheets.

Some of the common parameters of our A4 paper sheeting machine include:

- Our paper sheeter machine come equipped with a maximum unwinding width of 1050mm.

- It also has a maximum unwinding diameter of 1200mm.

- The sheeting length of the automatic paper roll to sheeter cutting machine is 0-999mm.

- It also has a sheeting with of between 50mm and 1050mm.

- The maximum speed of our rotary paper sheeter machine is 350 cuts/min.

- The precision of our paper sheeter machine is ±15mm. This means that it can cut your paper sheets to the exact set widths and specific length.

- The rated frequency of our A4 paper sheeting machine is 50Hz or 60Hz. It will depend with your specific order.

- The rated voltage is a three phase, four-wire, and 380V/220V.

- The unwinding and rewinding shaft of the paper sheeter machine is customizable. You can opt for a 3” (76mm) air expanding shaft.

- Our A4 paper sheeting machine has a dimension of 3000mm x 2000mm x 1300mm.

- The weight is around 4000Kgs.

What are the configurations of the automatic paper roll to sheet cutting machine?

Our paper sheeter machine is suitable for cutting different sizes of paper rolls.

These may include paper such as burger paper, A4 paper, regular papers, glass paper, or plastic film (PVC, OPP, PET, CPP).

The paper sheeter machines can be configured slightly differently. This can be achieved according to the type and size of the material being cut.

Some of the configurations of our paper roll to sheet cutting machine include:

- The roll to paper sheet cutting machine adopts Wein view PLC and Touch Screen and meter counter. All the working parameters can be displayed on the control monitor. Only need to set up the material thickness and initial tension data. The Micro-computer will calculate the accord data, and keep the machine working automatically until the end.

- It also equipped with a frequency inverter motor. The frequency inverter motor is used to control the sheeting cutter movement. This ensures that the paper sheets cut is solid and stable.

- Our A4 paper sheet cutting machine also adopts the Servo motor from Yaskawa for the material feeding. The precision can be highly controlled by 0.2mm. precision mean that the paper sheets produced will be of very high quality.

- We have also installed a braking system on our paper sheeter machine. It is equipped with an automatic braking device. It is usually a 20kg/ m2 * 1PC to control the material feeding tension. This ensures that your paper roll does no tear when being fed into the slitting head.

- To ensure clean cuts of high quality, the paper sheeter machine is equipped with specially treated alloy sheeting cutter. This type of cutter has merit for long working life and endurance. It means you will not have to keep changing the cutter.

- The paper sheeter machine also adopts automatic tension control system. The automatic tension control system is used to keep constant tension for material working. This prevents the parent paper roll from tearing. It also ensures that the paper does not crisp when being cut and assist in production of high-quality sheets.

- To ensure that the cut sheets can be packaged immediately after slitting or being cut. The paper sheeting machine is equipped with an automatic counting system. The automatic counting system counts the cut paper sheets. It enables the paper sheeting machine to stack the correct number of paper sheets together.

- The electric circuit of the paper sheeter machines follows all the necessary standards. All the electric circuit is in conformity with the CE certification.

- The A4 paper sheeting machine is also equipped with an emergency stop switch. The emergency stop switch assists to realize the emergency stop at any point of the machine. This is an important aspect in any machine especially in avoiding further damage to the machine.

- Another important configuration of the paper sheeter machine is the blower. Our paper sheeter is equipped with air blower to blow waste material off. It ensures that the waste does not clog the machine.

What slitting methods does the paper sheeter use?

Different paper sheeter machines use different slitting methods. The slitting method used depends on several things including:

- The size of the final paper rolls you want.

- The width of the paper sheets you need.

- The tension of the web needed.

- The material used for the production of paper sheets.

- The location of the round disc cutters.

Sheer slitting method

This type of slitting method involves two round disc cutters.

They are usually placed at the bottom and top of the paper sheeter machine.

The two-disc cutters work to give a cut just like how a pair of scissors works.

That is why a machine with this type of cutter is known as a scissor type sheeter machine.

In slitting machine jargon the top disc cutter is known as the male knife. The bottom one is known as the female or anvil.

Sheer slitting method is preferable when working with relatively thick or sticky materials.

Thick sheets, cardboards, kraft aper, and laminates are examples of thicker materials. To produce consistent quality cuts, proper tension must be maintained.

Rotary slitting

Rotary slitting is a type of slitting that utilizes very sharp round disc cutters that are razor like.

It is the most suitable slitting methods because it provides very clean cuts.

Most of our paper sheeting machines are equipped with these type of round disc cutters. They are useful especially in cutting of clean edges.

Difeerent paper sizes such as A3, A4, and A5 sheets require different paper sheeter machine adjustments.

It is here that the rotary round disc cutters come in handy.

They help cut out the slitted paper sheet row into the desired widths. It also ensures that the paper sheets have clean and smooth edges. It cuts out any waste and ensures straightness.

Some of the most used materials for razor slitting include:

- Solid Tungsten Carbide for remaking products such as Paper, Polyester, Cellophane, and Nonwovens

- Solid Ceramic for applied in materials such as Films, Copper Foil, magnetic Tapes, and Nylon LLDPE.

- Ceramic Coated and TiNI coated applied in Aluminum Foil, Label Stock, PVC, OPP, Stretch Film

Rotary slitting is also widely used for paper sheeting machines with unsupported web.

An unsupported web set-up requires an entry and exit idler roll. This serves to minimize material fluctuation as it passes through the slitting section. It also stabilizes the web, creating a defined tension allowing for it to be slit properly.

At Jota Machinery, we can customize your paper sheeting machine’s web-set up according to your specifications.

Where can I get the best paper sheeting machine manufacturer?

Jota Machinery is your go to place for all your paper sheeting machine needs.

We deal with a wide range of paper sheeting machines. We are known for our superior customer services when it comes to matters paper sheeting machines.

Compared to other paper sheeting manufacturers, we aim at creating a long-term relationship with you.

We will be readily available to assist you from the placing an order phase to the installation phase.

We are also readily available to ensure that you utilize your paper sheeting machine effectively.

As a leading paper sheeter machine manufacturer, we are:

- An industry and trade integrated company

- We have a diligent and professional team ready for your service.

- We use the latest technology in all our paper slitter machines.

- Be assured of the highest quality product.

- We offer one of the best industry leading services.

Some of the reasons that we are the paper sheeting machine manufacturers include:

Efficiency

Our paper sheeting machines are the best in efficiency.

We ensure that we mitigate unnecessary machine breakdown. We have manufactured our paper sheeting machine following the best industry practices.

Well-priced

Be assured of well-priced high speed A4 paper sheeting machines from us. We value your business profitability hence ensure our machines are well priced and affordable.

Rich experience in paper sheeting machine production

Jota machinery has accumulated rich experiences on paper sheeting machine over the years.

Be assured of well knowledgeable business partner for your paper mill business.

Save on costs

Our paper sheeting machine is manufactured with cost reduction for your business in mind.

The automatic paper roll to sheet cutting machine is automated to reduce the number of machine operators. It also has mechanisms for material waste reduction.

High speed

We ensure that our A4 paper sheeting machine are integrated with the latest technology.

Our design engineers are always looking for the best ways to enhance your experience with our machines.

We have a continuous R&D department. For instance, our A4 paper sheeting machine is equipped with the latest control systems.

What is the difference between a single layer cross-cutting and double layer cross-cutting paper sheeter machine?

A double layer cross cross-cutting paper sheeter machine is a machine that can cut two rolls at the same time.

Mainly one roll on the right and one roll on the right. The double layer cross cutting machine has 2 unwinding sections.

This means that it can process two large rolls of A4 paper at the same time. The output of A4 paper per unit time is twice that of a single-layer machine.

A single layer cross-cutting paper sheeting machine on the other uses a single roll at the same time.

This means that it only produces sheeted paper in single output. The paper sheeter machine can be configured to either meet either of the configurations.

At Jota Machinery, we encourage you to use the double layer paper sheeter machine. It will enable you increase the production of the paper sheets. This will automatically lead to increased business for your paper mill business.

It is worth noting that our paper sheeting machine can be customized to be a big poster trimmer. The double layer cross-cutting paper sheeter machine can be used in production different types of paper sheets.

These include A3, A4, A5 sheets, burgers paper, hot dogs’ paper, sandwich wrap paper sheets, and aluminum foil sheets. Other products include wax paper, butcher paper, hamburger paper, and baking paper.

It can be utilizing to produce an assortment of papers for fresh food wrapping paper.

Is there a maintenance protocol for automatic paper roll to sheet cutting machine?

Maintenance is an important aspect when it comes to automatic paper roll to sheet cutting machine.

We strive to produce quality automatic paper roll to sheet cutting machine requiring minimal maintenance.