Water Activated Kraft Paper Gummed Tape Printing Slitting Machine

- 1400mm width Water Activated Gummed Paper Tape Slitting Machine

- 55% more small roll output than 900mm width machine

- Shaftless unwind stand

- Hydraulic jumbo roll loading

- Photoelectric sensor web guiding

- Anti-overlapping banana roller

- Specification

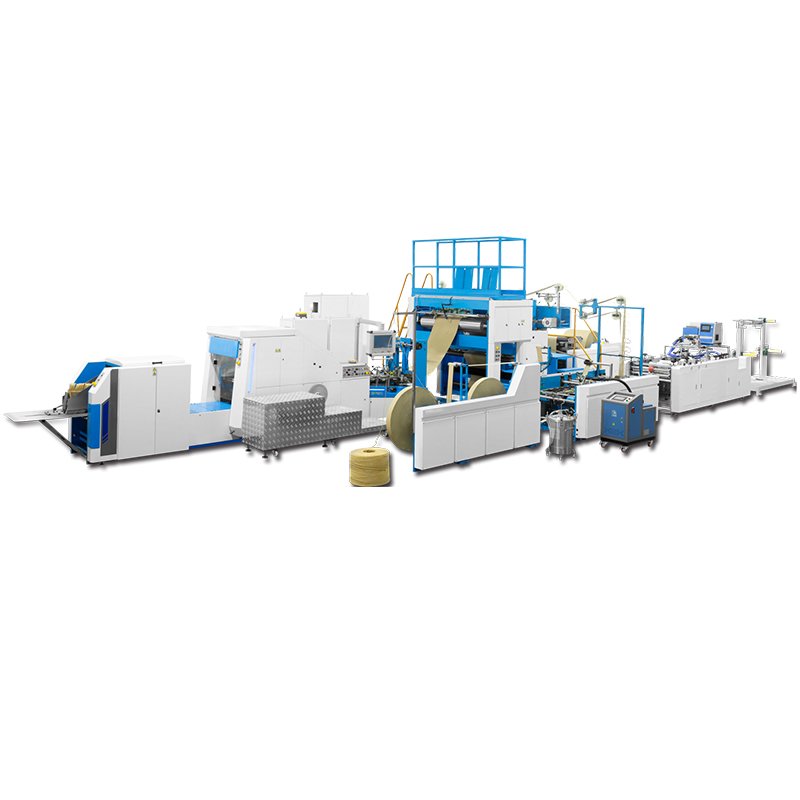

- Slitter Rewinder with Packaging Line

- Video

| Parameters | |

| Item | JT-SLT-1400C water activated kraft paper tape printing slitting machine |

| Max. Rewinding Diameter | 300mm |

| Min. Slit Width | 30mm |

| Web Diameter | 1200mm |

| Web Width | 1400mm |

| Max. Speed | 300m/min |

| Unwinding Shaft | 3″ (76mm) air expanding shaft |

| Rewinding Shaft Diameter | 0.5″, 1″ (size customizable) |

| Total Power | 9.5Kw |

| Voltage | 380V/50Hz |

| SPECIFICATIONS | |

| Water-activated kraft paper gummed tape printing slitting machine is especially suitable for making gum tape rolls, gummed tape rolls, kraft paper tape rolls, cash register roll, ATM roll, ECG roll, POS roll, till roll, etc. | |

Unwinding Section | Shaftless hydraulic jumbo roll loading unit. |

| Fully automatic tension controller. | |

| 20kg/m2 electromagnetic brake from Taiwan. | |

| Photoelectric sensor web guiding. | |

| Direction adjustable balancing roller ensures roller itself always keep in tight touch with the whole web. | |

Printing Section | 1-4 colors optional |

| Ceramic anilox cylinder transferring the ink, long life, wear resistance, corrosion resistance | |

| Dancer roll integrated buffer | |

| Automatic web guiding system | |

| Infrared drying units | |

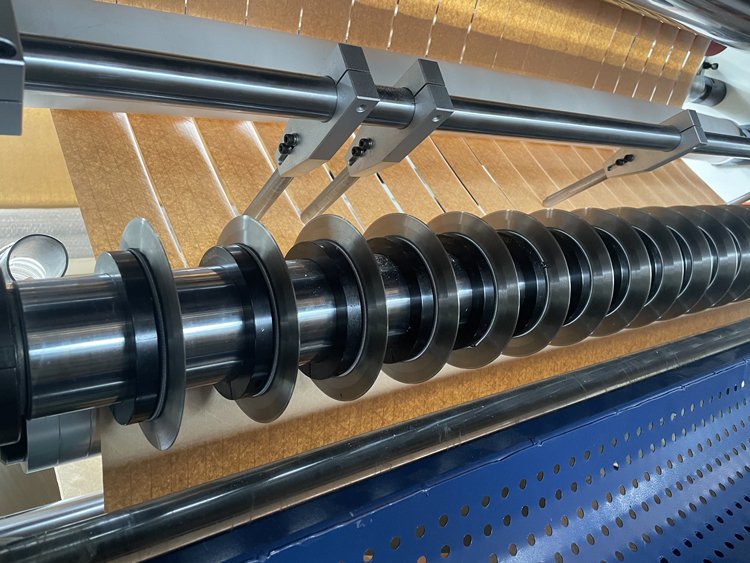

Slitting Section | The upper circular knives are fixed by screws, and the lower circular knives are fixed by an aluminum spacer, which ensures cutting precision. |

| The rotary encoder automatically metering slit length. | |

Rewinding Section | Automatic tucker tucks the tail, convenient for quick trigger rewinding. |

| 90° vertical lay-on roller, capable of moving up and down, ensures more balanced left and right pressure, wider rewinding diameter could be realized. | |

| Overlapping problems could be avoided with a banana roller. | |

Controlling Section | Siemens PLC module, touch screen, and graphic user interface (HMI). |

| Yaskawa AC drives for Siemens master motor. | |

| Schneider low voltage electrical appliances. | |

Waste Removal | Edge waste blower through expulsion tube. |

Optional Parts | Safety guard. |

| 4 corners emergency switches. | |

| Transmission belt. | |

| Shredder. | |

| Safety fence. | |

Why JT-SLT-1400C Water Activated Kraft Paper Tape Printing Slitting Machine

Last Update Time:03/02/2024

In 2022, Jota Machinery’s newly released water-activated kraft paper tape printing and slitting machine began to enter the market. Why?

Due to the increased environmental awareness in all countries in recent years, the use efficiency of water-based kraft paper tapes has increased frequently.

Because some of the freshmen didn’t know what to do or how to address the problem when operating our slitting machine, we created a troubleshooting page.

Please read through this page.

A Korean customer also wished to purchase water activated kraft paper tape printing slitting machine, and this Korean customer sent us a water-activated gummed paper tape jumbo roll.

We can test the machine with the Korean client’s reinforced kraft tape jumbo roll and then share the machine test video with the Serbian customer.

As a result of this synchronicity, both Serbian and Korean clients intuitively perceive the slitting and rewinding impact.

We can test machines according to customer requirements and eliminate customers’ doubts in all aspects because Jota machinery has our own factory and has accumulated rich experiences in the thermal paper roll slitting machine, ready-made gummed tape printing slitting machines, ready-made kraft paper tape jumbo rolls.

Meanwhile, we also supply an Economic Type WAT tape Slitter Rewinder machine, it is only a slitting machine without the inline printing line, please check the video.

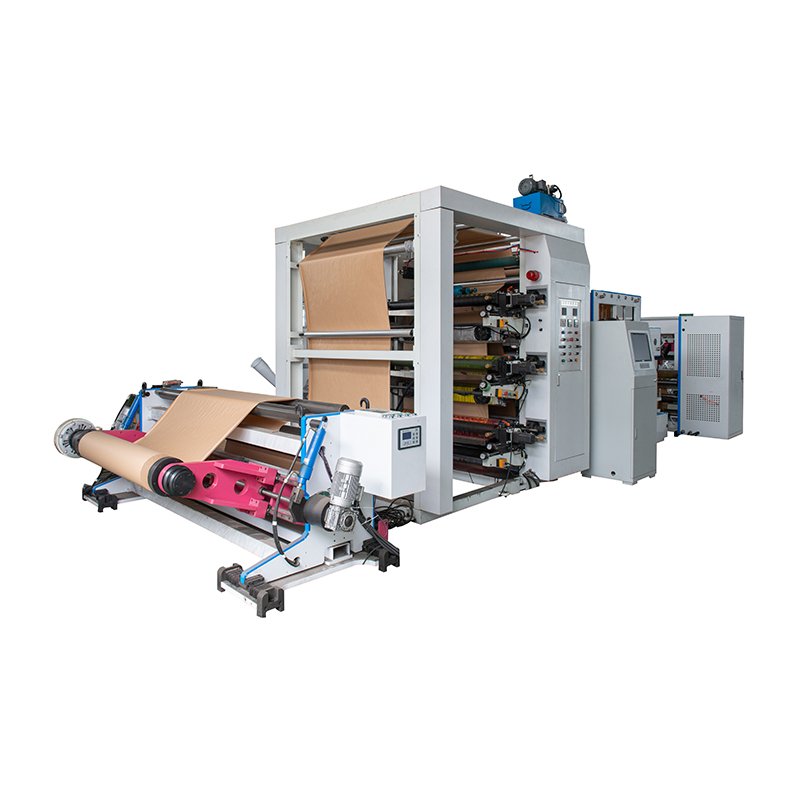

The JT-SLT-1400C’s unwinding part has a shaftless unwind stander.

This means that you don’t have to thread the unwinding shaft into the jumbo roll, which saves time at startup.

The unwinding section also has a hydraulic automatic jumbo roll loading system.

To load or unload jumbo rolls, just press the control button on the machine or use the remote control.

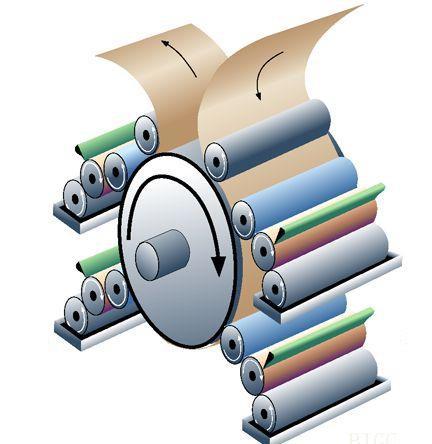

The printing department of JT-SLT-1400C creatively designed the buffer, also called the accumulator, it is composed of servo motors, multiple functional rollers, lead screws, and other components.

Buffer

When a rewinding is completed, the operator must replace the rewinding shaft; the slitting process has stopped, but the printing process continues to operate.

The buffer allows the material to run for a period of time in the buffer, which compensates for the winding shaft replacement time.

Printing and slitting can thus be seamlessly linked to achieving continuous machine operation, increased equipment uptime, and increased production efficiency.

In addition, the printing department introduces a web guidance system, which ensures that the pattern location of the printed jumbo roll precisely enters the slitting section, improving the consistency and beauty of the final tiny roll.

Web Guiding System

The slitting part of JT-SLT-1400C adopts the design of upper and lower circular knife shear cutting, which can fully guarantee the precision of slitting.

Upper Circular Knives

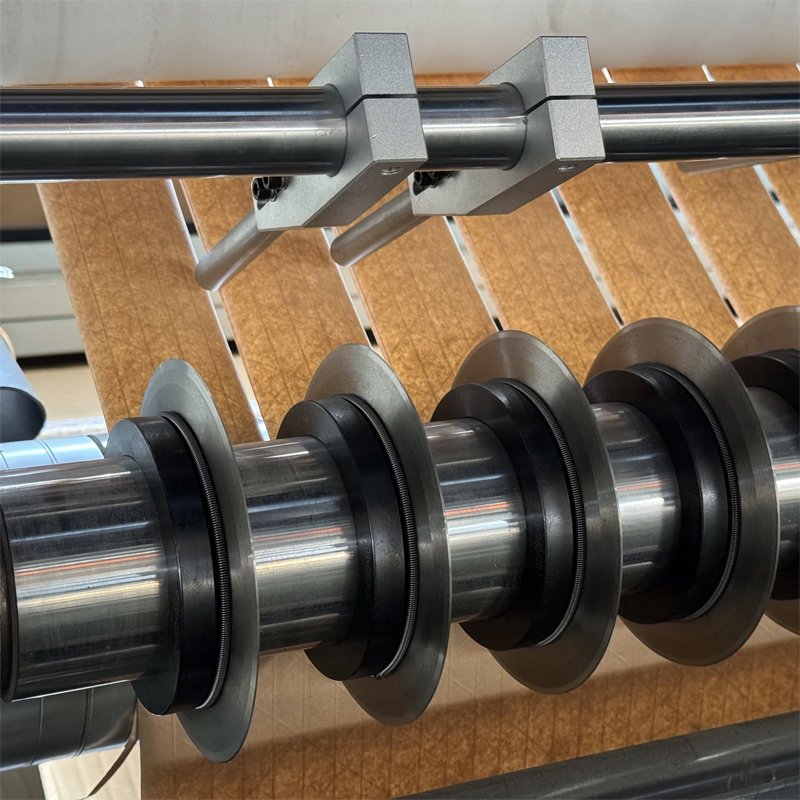

Moreover, Above the upper circular knife, a banana roller is installed.

You also have options for a fully automatic knife positioning system for the slitting width adjustment.

You only need to enter the slitting data on the touch screen, and the slitting size will be calculated automatically.

Fully Automatic Knife Positioning System for Slitter Rewinder

It can efficiently separate the narrow strips of kraft paper tape after slitting, reducing the problem of tape overlapping between neighboring narrow bands and guaranteeing that the borders of each tiny roll are smooth and beautiful, making it simple to entice terminal consumers to purchase.

Today I’ll discuss water-activated paper tape machines.

The water-activated paper tape is rolled on a D25mm paper tube and is 100-200m long.

This shape resembles our cash roll machine.

All paper ribbon rolls are stored in a 0.5″-1″ paper tube.

Is it possible to create them on the same machine because they are comparable in size?

Our experts observed that the water-activated tape is 80-100gsm thick, has a tougher feel, and is slippery due to the adhesive coating.

There is also a reinforced water-activated tape made of two layers of kraft paper and two layers of glass fiber mesh, which is stronger and requires technology and knowledge to process.

Based on the above, we need to enhance the following.

Eye-catching Banana Roller

The winding part of JT-SLT-1400C is equipped with an automatic tucker, it quickly trigger the winding;

The winding division is also equipped with an automatic tail-cutting gluing unit, it can automatically cut and glue the paper tail.

These designs can effectively shorten the time required for a single winding and effectively improve production efficiency.

Automatic Tail Cutting Gluing Unit

There are also many other small details about the design of JT-SLT-1400C, those detailed designs are finished by Jota designers’ hard work.

You are welcome to call or mail us for consultation.

If you are willing to open a water-activated kraft paper tape slitting factory, our industry experience can help you avoid some detours and create your own profits in this industry as soon as possible.

In 2022, more and more customers have inquired about water-activated kraft paper tape-slitting machines.

This environmentally friendly and pollution-free material is bound to be popular all over the world.

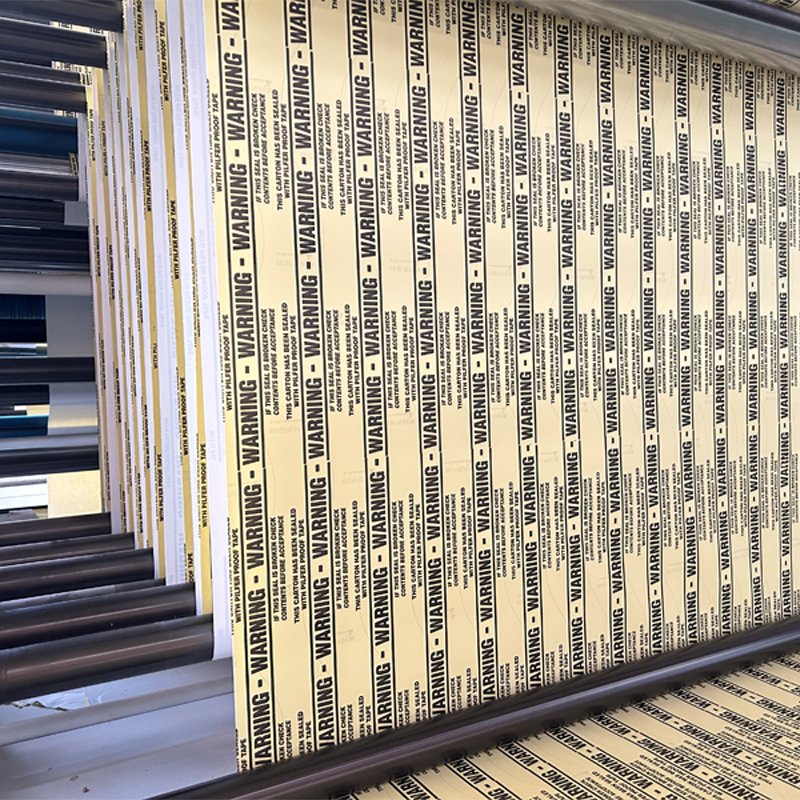

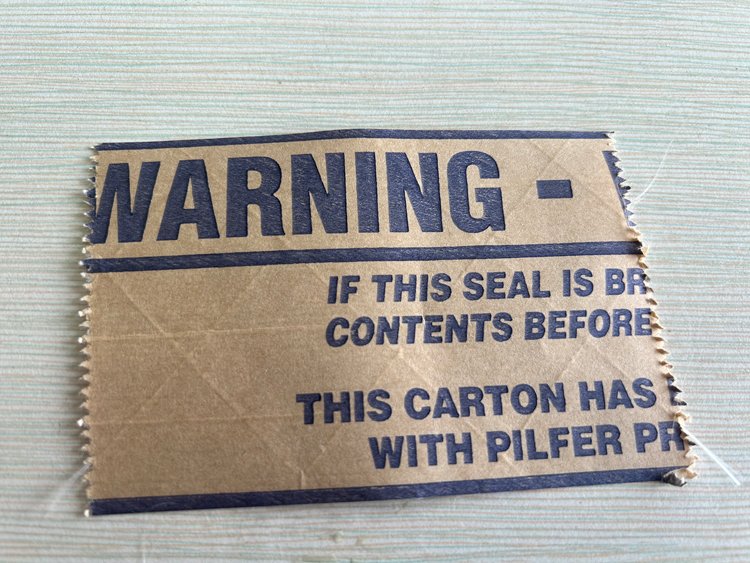

Gum Tape Slit by JT-SLT-1400C Slitting Machine

Water Activated Kraft Paper Tape Printing Slitting Machine Ultimate FAQ Guide

Because of the ease of packing, numerous tapes are now used for a variety of reasons.

I recommend the currently popular water base activated kraft paper gum tape (WAT), which is constructed of kraft paper base paper that has been uniformly coated with edible vegetable starch adhesive, pressure-sensitive adhesive, or a heat-sensitive adhesive before drying in a high-temperature dry oven.

Till now we have upgraded our water activated slitting machine to the 3rd generation.

There are also high-quality tapes that are sandwiched with longitudinal glass fiber filaments or glass fiber mesh to reinforce the water-based activated gum tape (WAT).

This type of tape is environmentally safe and pollution-free, recyclable and renewable resources, anti-unpacking, has high stickiness, has no warping, extended shelf life, and ensures long-term stickiness without moisture.

It is widely employed in a variety of fields.

Because kraft paper has printing qualities, it is feasible to print diverse designs or company logos on its surface to meet various market demands.

Water-free kraft paper tape, high-temperature resistant kraft paper tape, wet water kraft paper tape, white kraft paper tape, layered kraft paper tape, and so forth.

Water Activated Tape Slitting Machine

Water-activated tape printing slitting machine is mainly used for cutting gummed paper tape jumbo rolls and then winding separated gummed tape strips into small finished gum tape rolls.

With regard to Jota water-activated tape printing slitting machine JT-SLT-1400C, it is initially designed for a Turkish client for cutting and winding thermal paper.

Later, when we used different slitting rewinding machines to process the kraft paper tape jumbo rolls sent by Korean customers, the winding effect was not very good.

Because the kraft paper tape is relatively hard, bouncy, and the small roll that comes out is loose, and someone needs to stick the tape head on the paper or plastic core at the beginning.

When we use JT-SLT-1400C to handle the kraft paper tape jumbo roll, the effect is very good.

Finished Water Activated Tape Roll

Your company’s logo or the customer’s company name will be printed directly on the surface of the kraft paper tape, which not only improves the aesthetics but also has an advertising effect.

After printing, you will have better paper tape production and added value.

The characteristics of kraft paper surface are relatively rough and easy ink absorption, we recommend that you have an anilox roll line less than 300LPI.

The ink load per square inch of the 300LPI anilox roller is 8.82g.

Below this figure, the ink consumption amount is too small, and the printing pattern on the kraft paper may not be too clear

Anilox Roller: The size of the grid determines how much ink is loaded. The ink loading capacity of 500LPI is 5.13, which means that the 500LPI anilox roller can transfer 5.13 grams of water ink to one square inch of kraft paper.

The printing speed of the Water-activated kraft paper gummed tape is 70-100m/min.

You can also increase the printing speed to 150m/min by choosing a more advanced doctor blade closed chamber system.

Our Serbian customers’ 3-color tape printing machine has a doctor blade closed chamber and can print 150m/min.

The printing machine works continuously, but the tape slitter intermittently. The printing machine runs slowly while the kraft tape slitting machine is stopped to change the final tape roll.

Once the tape printing press is halted, the tension indicated by the relative material changes, affecting the already stable auto registration system and multi-color printing pattern.

Our engineers created a buffer, or called an accumulator, to store extra paper printing rolls.

The PLC synchronizes the tape printing and slitting machines.

When the tape slitter rewinder is stopped to change rolls, the printing machine works at low speed, and printed kraft paper tape is kept in the buffer.

When the gummed tape slitter rewinder starts working again, the tape printer’s speed rises and the gummed tape slitter runs at the same pace.

Two tape machines form a water-activated kraft paper gummed tape production line.

Our kraft paper tape printing machine offers 1-color, 2-color, 3-color, 4-color, and 8-color options.

Of course, more and more customers are interested in communicating with us about the tape production machine. We also welcome you to join our negotiations.

Compared with the traditional paper business, you can easily start this kraft paper tape business plan, you only need a set of coating and lamination machines, a piece of tape printing machine, and a set of tape slitting manufacturing machines.

If you also want to start your kraft tape business, please contact us, and we shall send you a kraft paper tape business plan for your better understanding.

What Is a Water Activated Kraft Paper Gummed Tape Printing Slitting Machine?

Water activated kraft paper gummed tape printing slitting machine is a machine used for making adhesive tapes.

The machine is a complete set of equipment for a fully automatic roll trademark printing machine and roll slitting machine.

- What Is a Water Activated Kraft Paper Gummed Tape Printing Slitting Machine?

- What Are the Benefits of The Gummed Paper Slitting Machine for My Business?

- What is the Saving Cost Associated with Operation of Your High Speed Gummed Paper Slitting Machine?

- How is Printing, Slitting, and Technology integrated in a Water Activated Kraft Paper Tape Printing Slitting Machine?

Water-activated kraft paper gummed tape printing slitting machine is especially suitable for making a variety of products. It can be modified to suit your business needs and that of your customers.

Note that the usage of a high-speed gummed paper slitting machine can be customized.

The customization is dependent on the application of the machine. for gummed tape, we ensure that our water-activated kraft paper gummed tape printing slitting machines is made using the latest technology.

To get more information on our water-activated kraft paper gummed tape printing slitting, contact us.

You can also visit our website to learn more about our other product portfolio.

What Are the Benefits of The Gummed Paper Slitting Machine for My Business?

In your paper mill business, you can use gummed paper slitting machines for different tasks.

There are a lot of good reasons and benefits for your business to have a gummed paper slitting machine.

Having a paper water-activated kraft paper tape printing slitting machine in your business can help you in the following ways:

- Efficiency And Improved Lead Times for Your Business

- Quality Gummed Kraft Paper Slitting Machine

- Customization Capabilities.

What is the Saving Cost Associated with Operation of Your High Speed Gummed Paper Slitting Machine?

At Jota Machinery, your business success is our priority.

All our gummed paper slitting machines are made with that in mind.

Rom energy consumption to waste material, we ensure you get value for your money.

Our high-speed gummed paper slitting machines are built using the latest technology.

The technology is aimed at ensuring efficiency and cost reduction.

At Jota machinery, we guarantee you profit margins for your business. This is because your business is our business.

How is Printing, Slitting, and Technology integrated in a Water Activated Kraft Paper Tape Printing Slitting Machine?

In One Water Activated Kraft Paper Tape Printing Slitting Machine

Jota water-activated kraft paper tape printing slitting machines come equipped with both slitting and printing capabilities.

We print on your tape items with the latest technologies.

The Water-activated kraft paper gummed tape printing machine prints at 70-100 m/min.

We improve continuously. We promise the best water-gummed kraft paper tape machine.

Contact us for all your tech upgrades. We’ll be happy to help you through the process.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine