JT-SHT-1100 A3 A4 A5 Paper Sheet Cutter

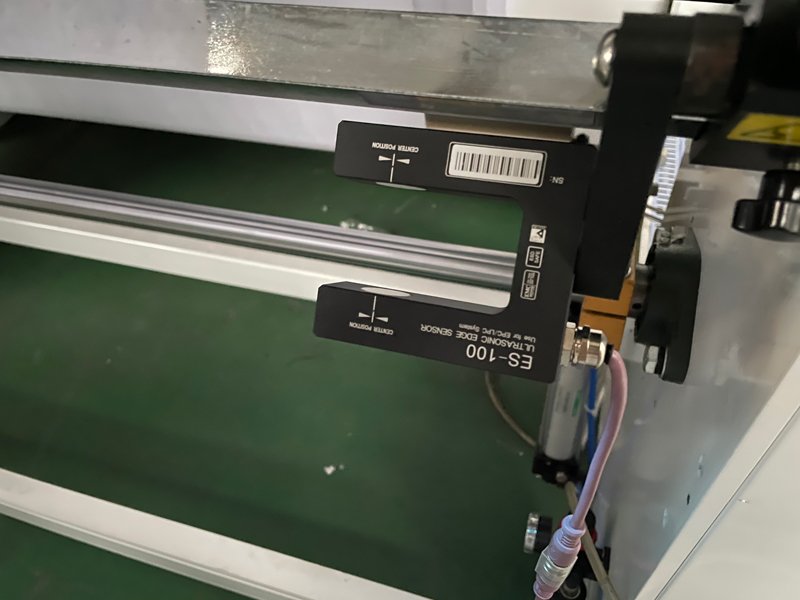

- Weinview PLC and Touch Screen

- Frequency inverter motor

- Yaskawa frequency inverter

- Automatic tension control system

- Specification

- Video

| Item | JT-SHT-1100 A3 A4 A5 Paper Sheet Cutter |

| Max. Unwinding width | 1050mm |

| Max. Unwinding Diameter | 1200mm |

| Sheeting Length | 0-999mm |

| Sheeting Width | 50-1050mm |

| Max. Speed | 100cuts/min |

| Precision | ±0.15mm |

| Rated Frequency | 50Hz or 60Hz |

| Rated Voltage | Three-phase, four-wire, 380V/220V |

| Unwinding/Rewinding Shaft | 3” (76mm) air expanding shaft (size customizable) |

| Dimension | 3000mm x 2000mm x 1300mm |

| Weight | 4000Kg |

| JT-SHT-1100 A3 A4 A5 paper sheet cutter is suitable for cutting different size paper, such as burger paper, A4 paper, regular papers, glass paper, plastic film (PVC, OPP, PET, CPP). |

| 1. Adopts Weinview PLC and Touch Screen and meter counter. All the working parameters can be displayed on the control monitor. Only need to set up the material thickness and initial tension data, the Micro-computer will calculate the accord data, and keep the machine working automatically until the end. |

| 2. Adopts with frequency inverter motor which is used to control the sheeting cutter movement, solid stable. |

| 3. Adopts with Servo motor from Yaskawa for the material feeding. The precision can be highly controlled by 0.2mm. |

| 4. Adopts with automatic braking device: 20kg/ m2 * 1PC to control the material feeding tension. |

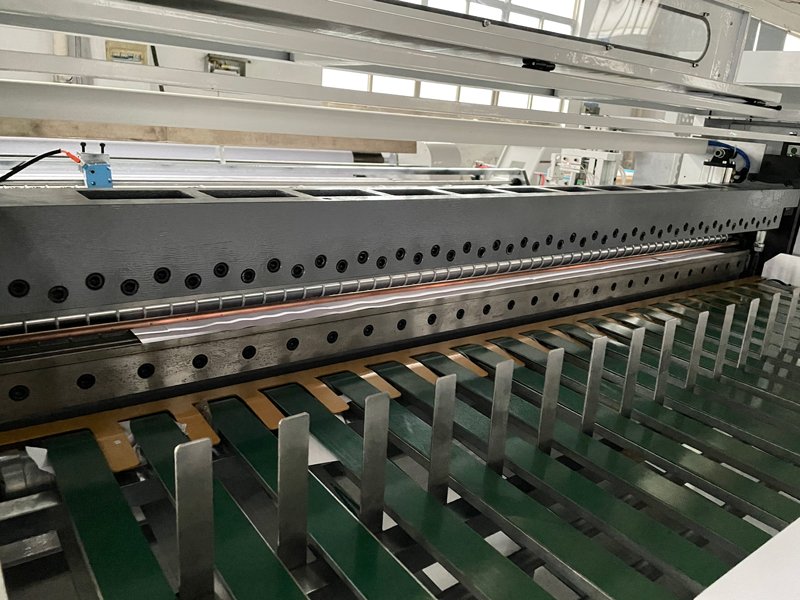

| 5. Adopts with specially treated alloy sheeting cutter, which has merit for long working life and endurance. |

| 6. Adopts automatic tension control system which is used to keep constant tension for material working. |

| 7. Equipped with an auto counting system. |

| 8. All the electric circuit is in conformity with the CE certification. |

| 9. Equipped with an emergency stop switch to realize the emergency stop at any point of the machine. |

| 10. Adopts air blower to blow waste material off. (It’s for thinner materials) |

JT-SHT-1100 A3 A4 A5 Paper Sheet Cutter

Last updat time:16/10/2023

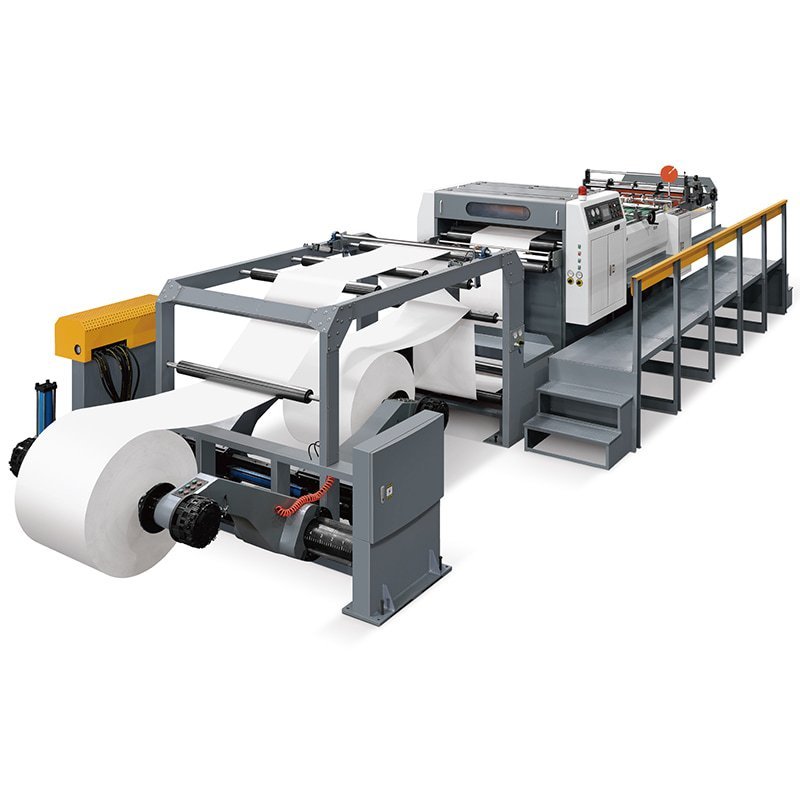

JT-SHT-1100 A3 A4 A5 paper sheet cutter is a machine used to cross-cut A3, A4, A5, film, aluminum foil sheet, it is generally used in the industrial production of the flexible packaging industry and paper industry.

This JT-SHT-1100 reel to sheet cutting machine has won the favor of customers in many countries such as the United States, Bangladesh, and other countries due to its compact and practical advantages.

For example, the following photo is taken by our CTO Jimmy, when US customers were standing next to our JT-SHT-1100 paper reel to sheet cutting machine.

The ability to export to the US market and win the trust of US customers, it is enough to show the excellent quality of JT-SHT-1100 A4 sheet cutting machine.

In addition, Bangladesh’s customer Res Group also purchased the JT-SHT-1100 ream paper cutter from we Jota.

Res Group has a very close relationship with us Jota. Before buying an automatic A4 paper cutting machine from our Jota, Res Group had already purchased a slitter rewinder from our Jota for slitting adhesive labels.

So far, this veteran slitter reminder has worked diligently at the Res Group’s factory for 15 years.

Before producing its own small adhesive label rolls, Res Group has been engaged in the trade of adhesive labels.

Later, in order to develop bigger and transform into manufacturing, they contacted we Jota to purchase a slitter, and our connection was established.

Res Group has a thorough understanding of the Jota paper reel cutting machine.

In the process of using our Jota paper ream cutter machine, in order to improve the efficiency of cutting large sheets of stickers, they themselves modified the paper sheet cutter.

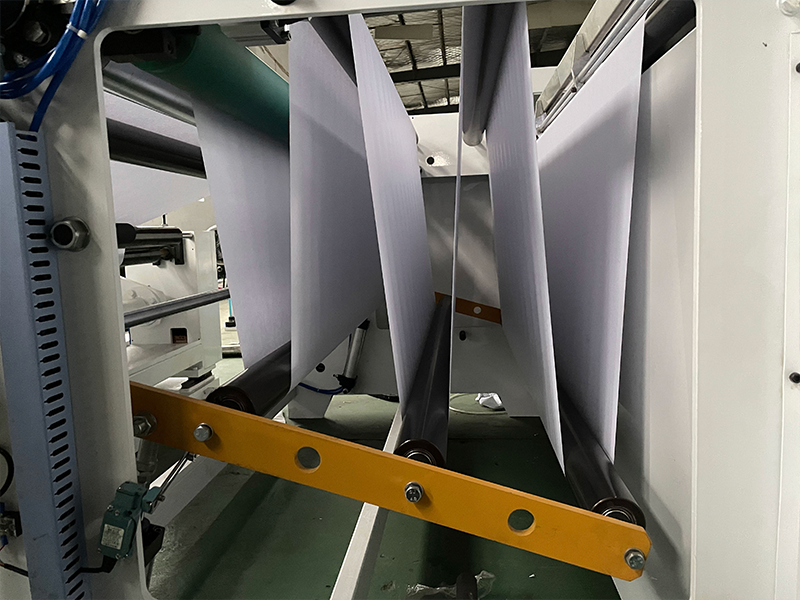

The modified sheeter can cut two rolls at the same time, one roll on the left and one roll on the right.

Such modification even exceeds our engineers’ expectations.

Res Group also has suppliers in the Shandong province of China. Shandong suppliers visited them in Bangladesh and saw Res Group’s self-reformed A4 A3 paper cutting machine.

The Shandong supplier felt it was very useful. So Shandong suppliers contacted we Jota and bought two from us, use our Jota A4 sheet cutter machine as same as they saw at Res Group.

Res group started as a trader and has been focusing on the Bangladesh market for decades. Now it is already the leading adhesive label supplier all over the Bangladesh market.

Generally speaking, the A3 ream cutter is composed of the following parts:

Unwinding section;

Transmission section;

Slitting department;

Sheeting section;

Control section;

Waste disposal section.

Each section has some unique advantages and selling points. You are welcome to send an inquiry on our company’s website. Our company’s sales will reply to you in time, and guide you to know more secrets about the JT-SHT-1100 paper roll sheeter machine.

A3, A4, A5 Paper Sheeter Machine FAQ Guide

- What Is an A3, A4, A5 Paper Sheeter Machine?

- What Types of Papers Standards Can I Use with My Heavy-Duty Paper Roll to Sheet Cross Cutting Machine?

- Why Should I Use a Photocopy Paper Sheeter Machine in My Paper Mill Business?

- Do You Have a Double Layer Cross Cutting A5 Paper Cross Cutting Machine?

- Why Should I Pay Attention on The Paper Roll to A4 Sheet Cross Cutting Machine Drives and components?

- Who Is the Best Automatic Roll to Sheet Paper Cutting Machine Manufacturers?

- What Are the Advantages of Your Heavy-Duty Paper Sheeter Machine?

- What Determines the Price of a Programmable Paper Sheet Cutting Machine?

- Why Should I Consider a Double Layer Cross-Cutting Paper Roll Sheeter Machine from A Single Layer Cross Cutting Paper Roll Sheeter Machine?

- Why Is the Dance Roller an Important Component for The Heavy-Duty Paper Sheeter Machine?

What is an A3, A4, A5 Paper Sheeter Machine?

An A3, A4, A5 paper sheeting machine is a machine that is used to cut large paper rolls into A3, A4, and A5 size paper sheets.

The machine cuts the paper sizes to the precise lengths and widths.

This machine is designed for slitting and sheeting.

It can sheet a wide range of papers to produce copier paper direct from reel to sheet to save costly wastage.

Our machine is highly optimized to meet your business needs.

You can use it in the industrial production of the flexible packaging industry and paper industry.

You probably have used an A4 paper today.

This assures you that the machine is a very important component in your paper mill business.

The paper making industry is a booming business with increased demand for photocopy paper.

All our sheeterare integrated with the latest technology to ensure maximum productivity.

For instance, the A3, A4, A5 paper sheeter machine is equipped with HMI controls.

The HMI controls all the operations of the paper sheeter machine. The operations range from:

- Starting of the machine

- Speed acceleration that includes

- Sheet counting that includes speed meter batch counter.

- Photocopy paper sheeter machine de-acceleration

- Stopping the A4 paper cutting machine after pre-setting the number of sheets.

- Clearing sheets on the paper roll to A4 sheet cutting machine conveyor.

- Restarting of the paper roll to sheet cutting machine.

The automation of the paper roll to sheet cutting machine ensures that you get the most from it.

You will not need to employ extra machine operators.

This also helps the operator to just pick the sheets from the stacking table after each batch.

Jota Machinery paper roll to sheet cutting machine have fully automatic A4 paper production lines.

They also have semi-automatic independent paper cutting lines and A4 paper stacking and packing capabilities.

Stacking and packing is available with various types of sheeter machines for A4 copy paper converting.

We have years of experience in sheet machine manufacturing.

At Jota Machinery we always ensure that all our machines use the latest technology.

We employ Europe’s paper sheeter machine new technology and use world famous brand components.

All this is aimed at making sure the A3, A4, and A5 paper making production lines are reliable and precise.

Paper roll to sheet cutting machine is suitable for cutting big rolling packaging materials.

These materials may include paper, paper-plastic, and multicolor laminated material.

It is installed with sheeting knives to cut out a multiple of different sizes of paper sheets. These paper sheets include but not limited to:

- A2, A5, A4, A3, A0 paper sheets

- Hamburger wrapping paper.

- Butcher wrapping paper sheets.

- Hot dog wrapping sheets.

- Photocopy paper.

- Aluminum foil sheeting.

All our paper roll sheeter machines are customizable.

You can also use them in sheeting different types of paper materials.

Call us or visit our website for more information on paper roll sheeter machines.

What Types of Papers Standards Can I Use with My Heavy-Duty Paper Roll to Sheet Cross Cutting Machine?

Knowing the type of sheeting paper you want to produce is very important.

It comes in handy when you want to buy a new A5 paper cross cutting machine.

Some of the reasons that make it necessary to understand the different types of paper sheets to use with your heavy-duty paper sheeter machine include:

- The information will help you choose the best type of paper roll to sheet cutting machine.

- The knowledge is necessary in guiding you of the best paper roll material to use.

- It helps in the configuration of your programmable paper cutting machine.

- Understanding the type of paper sheets to use will help in cutting costs associated with wastages.

- The type of paper to produce will also guide your business objectives and customer segmentation.

At Jota machinery, we will guide you on the different paper to use with your A4 sheet cross cutting machine.

It is also important that you understand the various standards that guide paper sheet production.

There exists well laid down procedures, processes, and regulations of paper sheet production.

Our paper roll to sheet cross cutting machine meets all these standards. This means that you will get to produce paper sheets that meet the specified quality standards.

Some of the international paper sizes standards include:

The ISO paper size concept

In the ISO paper size system, the height-to-width ratio of all pages is the square root of two.

In other words, the width and the height of a page relate to each other like the side and the diagonal of a square.

This aspect ratio is especially convenient for A4 paper size.

This system guides the production of some common paper sheets such as the A4 and A3 paper sheets.

The ISO paper sizes are based on the metric system.

This means that our photocopy paper sheeter machine can be configured to produce paper sheets that meet those metrics.

The B series has been introduced to cover a wider range of paper sizes.

This is specifically for applications where the ISO A series does not provide an adequate format.

The C series of formats has been defined for envelopes.

It is worth noting that the configurations for the different sizes of paper sheets should be always in millimeters.

Application of ISO standards

The ISO standard paper size system covers a wide range of formats.

But not all of them are widely used in practice.

Among all formats, A4 is clearly the most important one and widely used for daily office use.

Some main applications of popular formats include but not limited to:

- A0, A1: Technical Drawings, Posters

- A1, A2: Flip Charts

- A2, A3: Drawings, Diagrams, Large Tables

- A4: Letters, Magazines, Forms, Catalogs, Laser Printer and Copying Machine Output

- A5: Note Pads

- A6: Postcards

- B5, A5, B6, A6: Books

- C4, C5, C6: Envelopes for A4 Letters: Unfolded (C4), Folded Once (C5), Folded Twice (C6)

- B4, A3: Newspapers, Supported by Most Copying Machines in Addition to A4

- B8, A8: Playing Cards

Some of the common paper types you can use with our thin paper roll automatic shitting machine include:

- Aluminum foil

- Packaging materials.

- Butcher paper wrappers

- Sandwich wrapping paper

- A3 Sheets of Card

- A4, A5, A2 Paper Business

- Hamburger wrapping paper

- Food packaging composite film

There are so many paper sizes and materials to choose from.

It all depends with your customer.

At Jota machinery, we will advise you on the best paper material for your paper mill business.

You can also reach us for the same.

Why Should I Use a Photocopy Paper Sheeter Machine in My Paper Mill Business?

Photocopy sheeter machine is one of the most common paper sheeter machines.

This is because it is used for sheeting various sizes of photocopy paper.

As we all know, photocopy paper is one of the most common types of paper.

A3, A4, and A5 are some of the different sizes of photocopy paper sheets. A4 is the most commonly used photocopy paper.

Having said that, there are many reasons that make it necessary to have this machine. Some of these reasons include:

Cost effective.

At Jota Machinery, we always ensure that you get the best paper roll to sheet cutting machine at affordable prices.

You are guaranteed value for money when you place your order with us.

The best thing is that you do not even need to come to our China offices.

Just place your order through our online platform.

Our work will be to ensure that your paper roll sheeter machine reaches you.

We ship internationally following strict international shipping guidelines.

At Jota Machinery, we will also assist you in getting the best shipping agents in the market.

This will save you valuable time and money.

We will also assist you in the payment of the required duties and licenses.

It is important to also be proactive in your shipping processes to avoid certain charges.

These charges may include warehousing fees and extra taxes associated with storage.

We ensure that we help you avoid extra charges on your automatic paper cross cutting machine.

Quality and multifunctional Photocopy Paper Sheeter Machine.

As earlier stated, we at Jota Machinery ensure that quality is adhered to.

Our paper roll cross cutting machines are the best in the market. The quality processes at Jota Machinery are continuous.

We ensure that quality is adhered to from the material acquisition stage to the final product.

We also ensure that our paper roll sheeter machine meets the industry’s standards.

We are open to quality audits and ensure we adhere to the rules and regulations.

We ensure that every automatic A4 paper cross cutting machine meets the client’s country standards.

By adhering to the set standards, we ensure that you get the best paper sheeter machine in the market.

Feel free to call and inquire on the certification requirements.

It is worth noting that different roll cross cutting machines will require different certifications.

This ranges depending on their use, size, and design configurations.

Clean cut

Our photocopy sheeter machine is equipped with quality sheeting knives.

The sheeting knives cut through an up and down movement.

This ensures that your paper sheets get a clean, clear cut.

The photocopy paper sheeting machine also has slitting capabilities.

The slitting is integrated with sheeting where the jumbo paper sheet is slitted then sheeted simultaneously.

The cutting head initiates its up and down sheeting movement immediately after the roll enters the sheeting chamber.

Our machine can achieve as high as 300 cuts per minute.

This process of cutting ensures that lead times are achieved. Increased lead time is achieved due to the decreased production time.

The paper sheeting knives are specially fitted with a built-in cutting head for easy sharpening whenever it is required.

Similarly, it integrates a blade components lubrication system that allows for optimum operation of the photocopy machine.

Integration of the latest technology

At Jota Machinery, we ensure that we integrate the latest technology in manufacturing paper roll to A4 sheet cross cutting machine.

All the components of the A4 sheet cross cutting machine are the latest in the market.

Our machine is available both in automatic and manual modules.

This gives you a great flexibility when it comes to choosing the correct machine.

You can easily adjust the sheeting knives from the HMI controls.

The HMI control can also be used to operate the dance rollers.

You can also use the digital screen monitor in adjusting the tension of the paper web.

The tension control is an important aspect of the paper roll to sheet cross cutting machine.

With the existence of the automatic tension control, the whole running process tension is constant.

At Jota machinery, we have incorporated and integrated the above technologies with your paper roll sheeter machine.

The control is centrally placed to monitor the working of your photocopy paper sheeter machine.

You can also carry out machine diagnostics using the central monitoring system.

Our machine is incorporated with the latest technology.

In case of a breakdown, the digital screen will indicate the course of the issue.

Various uses

Our A4 paper cross cutting machine can be used in different ways.

Not only will you be able to cut clean and neat photocopy paper sheets.

You will also be able to customize the photocopy paper sheeter machine to make products such as A2, A3, A4, and A5 paper sheets.

At Jota Machinery, we are flexible in our design processes.

We will design the photocopy paper sheeter machine according to your specifications.

This will give your business more room to diversify your products.

It also means that you can cut the jumbo paper sheet into sizes you want.

Having the ability to put your paper rolling machines into various uses means your customer base will grow.

This is by having a wider product portfolio.

Do You Have a Double Layer Cross Cutting A5 Paper Cross Cutting Machine?

Yes, we do have a double layer cross cutting machine.

This type of machine can sheet more than one roll at a time.

This means that you will have production of paper sheets twice the speed compared to a single layer cross cutting A5 paper cross cutting machine.

The double layer cross cutting A5 machine can be customized.

You can customize it to either a 2 layer or 4-layer paper cross cutting machine.

All these features serve to increase the capacity of the double layer cross cutting A5 paper cross cutting machine.

Why Should I Pay Attention on The Paper Roll to A4 Sheet Cross Cutting Machine Drives and components?

A4 sheet cross cutting machine are an important fixture in any paper milling factory.

This is because they are the finishing machines in the production line.

For efficiency, you should ensure that all the components of the paper sheeting machine are reworking perfectly and in sync.

One of the most important components you should keep an eye on are the various drives.

When drives are performing optimally, be assured of high-quality paper sheets.

The drives ensure that the sheeting is coordinated.

The coordination is achieved through control of speed and torqued through continual cycles.

Drivers ensure that your paper sheeter machine speed from stop-to-full-speed and back-down-to-zero-speed is consistent.

Inaccuracies in the performance of drives can lead to such problems as:

- Rough edges on your final paper sheets

- Sheet breaks

- Offsets and tie-ups

- Telescoping

- Wastages leading to lost profit.

- Downtime affecting production lead times.

Important information you should have on A4 paper cutting machine drives include:

Technology

We ensure that our paper roll to sheet cutting drives is equipped with the latest technology.

Our drives integrate both the DC and AC modules.

DC drives are durable and require minimal maintenance while making it easy to integrate communication and software tools.

For efficiency purposes, A4 sheet cross cutting machines are available in 2- or 4-layer varieties.

This ensures that you can produce multiple paper sheet stacks at the same time. Aspects such as the parent roll width are an important element in any sheeter machine.

For instance, if the A4 width is 210mm, the parent roll should be 4 or 5 times larger.

This is about 1050mm and 5mm waste stream. It ensures that you get the most out of the parent jumbo paper sheet.

The unwind motor regulates and ensures tension for the jumbo paper roll.

A second drive controls the lead in the paper roll that directs the paper to the sheeting chamber.

For our automatic A4 paper cross cutting machine, we have installed it with the dance roller to keep a constant tension.

The NIP roller is also installed to guide the paper roll to the slitting head.

Our drives are heavy-duty and factor in the size of rolls and motors on the sheeter machine. This eases the acceleration and deceleration of the motors.

Continuous high-speed production

To achieve high-speed production, ensure that your paper roll to A4 sheet cutting machine incorporates the latest drives.

Improved drives built from the latest technology will ensure roll quality and improved speeds.

Ensuring that your drives are in good conditions leads to less shutdown due to drive malfunctions.

Paper roll to sheet cutting machine should integrate numerical set points, graphical set points, diagnostics, TNT controls, recipes, and permissive.

All these aspects will ensure efficient continuous high-speed production.

Tension control

Drives are an integral part of our slitter machines.

The unwind section is fitted with drives that assist in ensuring maximum tension that is required for clean paper sheets.

It ensures that the quality of sheeted paper is of good quality.

Master control

All the drives in our paper sheeter machines are integrated with the master control.

This gives you freedom on adjusting the speed, torque, and tension of the paper roll to sheet cross cutting machine.

Other advantages of having a master control include:

- Easy roll profile optimization

- Automatic start and stop configurations.

- Product receipt capabilities leading to efficiency in setting up orders and product consistency.

- Graphical and numeric set points

- Easy diagnostic modules.

- Merging of the drive hardware with the control equipment

- Flexible and easy to use system providing increased performance.

Reduction of inefficiency and maintenance costs

In ensuring efficiency and low maintenance costs, ensure that your drives are replaced per the manufacturing schedule.

Components supporting the drives should also be replaced before they become obsolete.

Obsolete parts of the drives are expensive to repair.

Some common problems associated with worn-out drives include insulation breakdowns due to fractured wiring.

Another problem is constant attention due to problematic drift. Breakdown of thyristor assemblies and fuses is another problem due to faulty drives.

At Jota Machinery we ensure that the latest technology is used in the manufacturing of our paper sheeter machine drives.

This is achieved through retrofitting the drives with digital, high-performance components.

Who is the Best Automatic Roll to Sheet Paper Cutting Machine Manufacturers?

Jota Machinery is your go to place for all your automatic roll to sheet paper cutting machine needs.

We deal with a wide range of paper sheeter machines.

We are known for our superior customer services when it comes to matters paper roll to sheet cutting machine.

Compared to other paper sheeting machine manufacturers, we aim at creating a long-term relationship with you.

Jota Machinery will be readily available to assist you from the placing of an order phase to the installation phase.

We are also readily available to ensure that you utilize your paper sheeter machine effectively.

As a leading automatic roll to sheet paper cross cutting machine manufacturer, we are:

- An industry and trade integrated company

- We have a diligent and professional team ready for your service.

- We use the latest technology in all our automatic roll to sheet paper cutting machine.

- Be assured of the highest quality product.

- We offer one of the best industry leading services.

At Jota Machinery, we boast of years of experience as top sheeter machine manufacturers.

Our paper roll to sheet cross cutting machine designers and engineers are flexible.

You can always share and integrate your machine specifications with them.

This ensures that the final paper sheeter machine is made to your exact specifications.

All in all, we offer tailor made solutions that exceed your expectations.

For your ultimate satisfaction, we will handle your automatic paper cross cutting needs from design to production.

You can also ask for a prototype to understand how your final paper sheeter machine will work.

Expect the best services from design to prototype to production and beyond.

As a leading paper roll to sheet cross cutting machine manufacturer, Jota Machinery offers excellent after sale services.

We will assist you in the shipping of your paper reel to sheet machine.

Our customer care agents will guide you on the best way of handling customs and related costs.

This is besides directing you to the best and cost-efficient couriers for your paper roll to sheet machine.

Our after-sale service footprint is across the world. We will come where you are and ensure your utmost satisfaction.

Being a leading thin paper roll automatic sheeting machine manufacturer means that we have a wide portfolio of machines to choose from.

At Jota machinery, we strive to expand our product portfolio to meet your needs.

Our sheeter machines can be used in different aspects in the paper milling industry.

Some of the alternative configuration options that are available for our sheeter machines include:

- Single layer cross cutting sheeter machine

- Slitting paper sheeter machine

- High capacity unwinds

- Double layer cross cutting sheeter machine

- We also have multiple unwindpaper sheeter machine.

You can also contact us when in need of programmable paper cross cutting machine materials and components.

We offer the highest quality of components for your paper sheeting machines.

Most of our components are produced with the industry leaders in small parts manufacturing.

Be assured that our A4 paper cross cutting machine is manufactured, assembled, and tested in-house in our factory.

Our team is always on stand-by in case of any issues with your paper ro to sheet machine. In case of any breakdown or emergency, feel free to call us.

What Are the Advantages of Your Heavy-Duty Paper Sheeter Machine?

Some of the advantages of our heavy-duty paper sheeter machine include:

Optimized structure

Our paper sheeter machines are highly optimized to meet your paper mill business needs.

The structure of the paper sheeter machine is made up of components from renowned parts manufacturers.

This ensures that the machine is bearable and also stable when it comes to sheeting paper.

To ensure clean cuts of high quality, the paper sheeter machine is equipped with specially treated alloy sheeting cutters.

This type of cutter has merit for long working life and endurance.

It means you will not have to keep changing the cutter.

Another important component is the NIP roller that guides the paper roll into the integrated slitting and sheeting head.

All these serve to ensure that you produce quality paper sheets for your customer.

Multifunctional

Our programmable paper cross cutting machines are multifunctional.

They can be used in cutting different types of paper.

These may range from butcher wrapping paper, photocopy paper, hamburger wrapping paper, hotdog wrapping paper and so on.

The list of products that can be produced by our paper sheeter machines is endless.

The best thing with our paper sheeter machine is that you can customize it to your exact specifications.

Reach out to us and liaise with our design engineers and technicians. We will be able to guide you through the process.

Technology

At jota Machinery, we are always researching the latest technology to integrate with our paper sheeter machine.

For instance, our paper roll sheeter machine Wein view PLC and Touch Screen and meter counter.

All the working parameters can be displayed on the control monitor.

You will only need to set up the material thickness and initial tension data.

The Micro-computer will calculate the accord data, and keep the machine working automatically until the end.

It is also equipped with a frequency inverter motor.

The frequency inverter motor is used to control the sheeting cutter movement.

This ensures that the paper sheet cut is solid and stable.

Our paper roll to A4 sheet cross cutting machine also adopts the Servo motor from Yaskawa for the material feeding.

The precision can be highly controlled by 0.2mm. precision means that the paper sheets produced will be of very high quality.

What Determines the Price of a Programmable Paper Sheet Cutting Machine?

There are several things you should put into consideration when choosing a programmable paper sheet cutting machine.

The factors will determine the programmable paper sheet cutting machine price. Some of these considerations include:

Material Used

Different programmable paper sheet cutting machine are used for different applications.

If you need a fully integrated paper roll sheeter machine, you will have to pay more. Paper roll sheeter machines also have different capacities.

A3, A4, A5 paper sheeter machines cost more than the low-capacity ones.

High capacity means the ability to produce a high number of paper sheets.

Most of the high capacity A3, A4, A5 paper sheeter machines have double layer cross cutting capabilities.

How the machine is integrated also determines its price.

The specific use of the A3, A4, A5 paper sheeter machine can be customized.

Customization options may also lead to a slight increase in the overall price of your machine.

It is recommendable to liaise with our sales agents. They will be able to guide you in the best options that will suit your finances and business.

The configurations of the paper sheeter machine

The configurations of the A3, A4, A5 paper sheeter machine also will determine its price. The configurations include the working mechanisms of the A3, A4, A5 paper sheeter machine.

Customized configurations for your heavy-duty paper sheeter machine will likely lead to slightly higher prices.

We advise you to go through our product catalog before making your order.

This will help you in making the right decision when it comes to the paper sheeter machine configurations.

Some of the configurations that you can put in mind may include the mode of control of the paper sheeter machine.

You can also consider some configurations such as hydraulic driven automatic jumbo roll loading.

The NIP roller is also another important configuration that we have integrated with our thin paper roll cross cutting machine.

For further inquiries on the configurations of your paper sheeter machine, contact us.

How designers and engineers will be available to guide and assist you.

You can also visit us in our China factories for one-on-one inquiries. Also visit our website or contact us directly through our contacts.

The Structure of the photocopy paper sheeter machine.

The parameters or structure of the paper sheeter machine are an essential determinant of the overall price.

Parameters such as unwinding width and unwinding diameter will determine the overall price.

The lesser the parameters the lesser the overall price of your photocopy paper sheeter machine.

Some components such as the unwinding shaft can be customized.

This can be achieved through the increasing of the rewinding shaft. An adjustment of the components will lead to slightly higher prices for your paper sheeter machine.

For more information on the parameters of our automatic paper cross cutting machine, contact us.

The quantity of the paper roll to sheet cross cutting machines bought.

At Jota Machinery, we can handle any number of paper rolls to sheet cross cutting machine you need.

Be assured of a discount in orders that exceed two units. All in all, we ensure that you get the best paper roll to sheet cross cutting machine prices.

At Jota Machinery, we are business centric. If you are a startup, feel free to visit us. We will offer you the best paper roll to sheet cross cutting machine prices in the market.

Other costs

There exist several other costs that you should be aware of that may influence the price of your machine. These costs may include:

- The taxes that will be charged on your paper roll to sheet cross cutting machine.

- The warehouse charges.

- Insurance charges for your on-transit cargo.

- Customs and duties.

- Payment transactions costs.

- Other unforeseen charges.

But you should worry not. At Jota Machinery we ensure you have a smooth sail.

We will assist you through your order and delivery process. We will guide you from the order placement process to the delivery to your factory.

Feel free to call our customer care center for any inquiries regarding your order processing.

If you are not sure of certain payments contact us. You can also seek help from professional freight forwarders or shipping agents.

Why Should I Consider a Double Layer Cross-Cutting Paper Roll Sheeter Machine from A Single Layer Cross Cutting Paper Roll Sheeter Machine?

A double layer cross cross-cutting paper sheeter machine is a machine that can cut two rolls at the same time.

Mainly one roll on the right and one roll on the right.

The double layer cross cutting machine has 2 unwinding sections.

This means that it can process two large rolls of A4 paper at the same time. The output of A4 paper per unit time is twice that of a single-layer machine.

A single layer cross-cutting paper sheeting machine on the other uses a single roll at the same time.

This means that it only produces sheeted paper in single output.

The paper sheeter machine can be configured to either meet either of the configurations.

For an established business, we encourage you to use the double layer paper sheeter machine.

It will enable you to increase the production of the paper sheets.

This will automatically lead to increased business for your paper mill business.

If you are a beginner you can start with the single layer cross cutting paper roll sheeter machine. It can be upgraded to a double layer cross-cutting paper roll sheeter machine.

It is worth noting that our paper sheeter machine can be customized to be a big poster trimmer.

The double layer cross-cutting paper sheeter machine can be used in production of different types of paper sheets.

These include A3, A4, A5 sheets, burger paper, hot dogs’ paper, sandwich wrap paper sheets, and aluminum foil sheets.

Other products include wax paper, butcher paper, hamburger paper, and baking paper. It can be utilized to produce an assortment of papers for fresh food wrapping paper.

Why is the Dance Roller an Important Component for The Heavy-Duty Paper Sheeter Machine?

The dance roller is an important component for the heavy-duty paper sheeter machine.

This is because it is specifically configured to guide the paper sheet into the slitting and sheeting head and hold it into place.

The dance roller also serves to keep a constant web tension that ensures that the parent web does not break.

Our sheeter machine is also optimized to facilitate both the light weight and high-speed movement.

This is done while maintaining high accuracy.

The cutting and slitting speed depends on the type of paper roll to sheetmachine that you are using.

Some sheeting machines such as the scissor type sheeter can reach 120 cuts/min.

The transmission section has been optimized specifically with the material feeding part (NIP roller).

The mechanical structure of the cutter head for thin paper has also been optimized.

The NIP roller is an important component especially when it comes to sheeting thin paper. It acts like a clamp, holding the paper sheet and leading it into the sheeting chamber.

It is optimized to grip on thin paper sheets easily. That is why it is made of rubber.

By optimizing the NIP roller and the cutter head, we have ensured that our sheeter machine is specifically suited for cross cutting.

The paper sheeting machine is especially suitable for cross-cutting 20g-50g paper sheets.

With the NIP plate, you can avoid the wind being generated during every time’s cross-cutting process.

The paper sheet will not float up, and each paper sheet can be neatly stacked into a chop.

The NIP roller is important for feeding paper into the slitter head. It controls the width of the paper to be cut.

For instance, if the paper roll is too thin or too wide, the slitter head might not accept it.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in A3 A4 A5 Paper Sheet Cutter, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine