JT-SLT-2500C Two Drum Paper Slitting Rewinding Machine

Two Drum Paper Slitting Rewinding Machine

- Max. Unwinding Width 2500mm

- Max. Unwinding Diameter 1500mm

- Max. Rewinding Diameter 1500mm

- Max. Speed 500m/min

- Specification

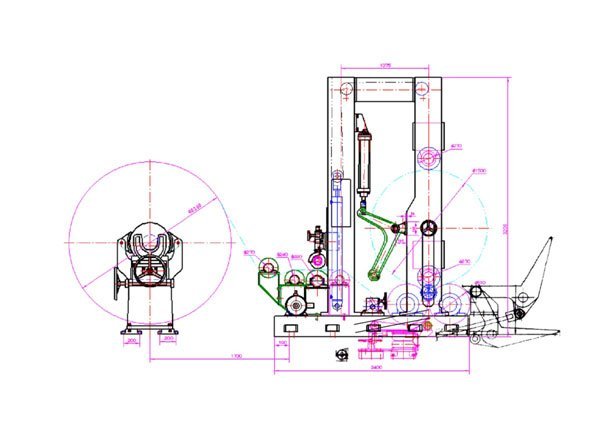

- Drawing

- Video

Parameters

| Max. Unwinding Width | 2500mm |

| Max. Unwinding Diameter | 1500mm |

| Max. Rewinding Diameter | 1500mm |

| Paper Thickness Range | 40gsm-450gsm |

| Max. Speed | 500m/min |

| Unwinding/Rewinding Shaft | 3’’ (76mm) air expanding shaft (Size Customizable) |

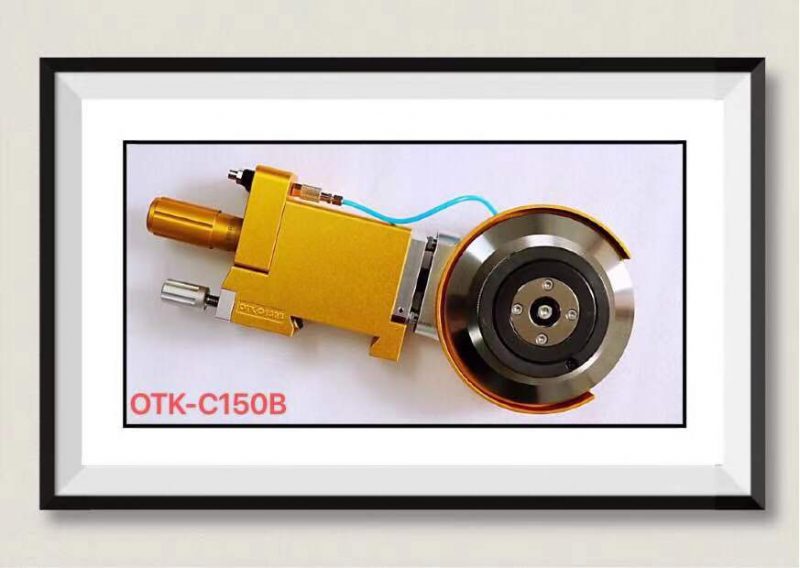

| Upper Rotary Blade | 9SiCr, φ200mmxφ170mmxφ40mm |

| Lower Rotary Blade | 9SiCr, φ190mmxφ90mmxφ2mm |

| Rated Power | 37Kw |

| Total Weight | 7000Kg |

| Overall Dimensions | 2530mm*6700mm*3700mm |

| Configurations and Features |

| JT-SLT-2500C high-speed kraft paper slitting rewinding machine suits the cutting of various ultra-large jumbo roll paper materials, such as special paper, coated paper, cardboard paper, kraft paper, etc. |

| 1. PLC control system and touch screen HMI, all the parameters are shown on the touch screen. You just need to set up jumbo roll diameter, paper thickness, original tension, etc, the machine could work automatically. |

| 2. Hydraulic jumbo roll loading, consists of an unwinding rack, air brake, shaftless thimble, longitudinal adjustment device, hydraulic station, etc. Good stability and large carrying capacity. |

| 3. Paper guiding roller, ensures the parent web enters the slitting device at a constant angle. |

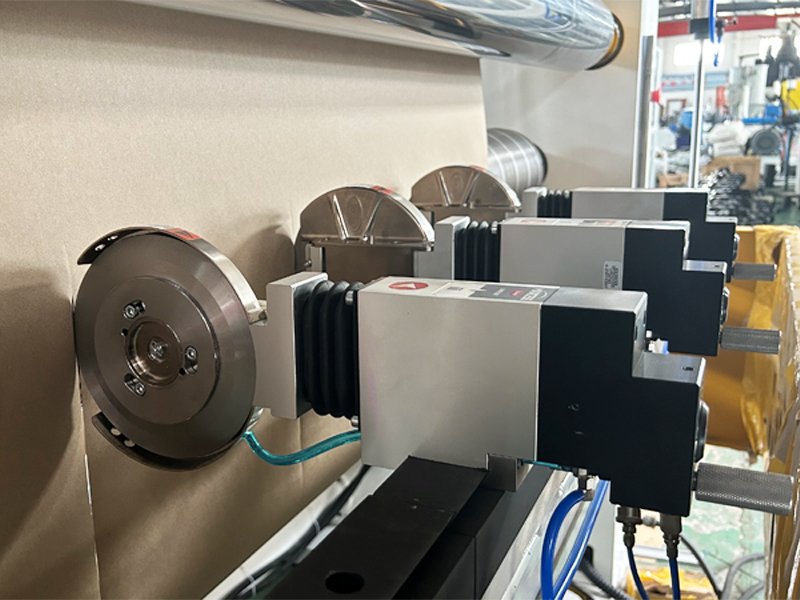

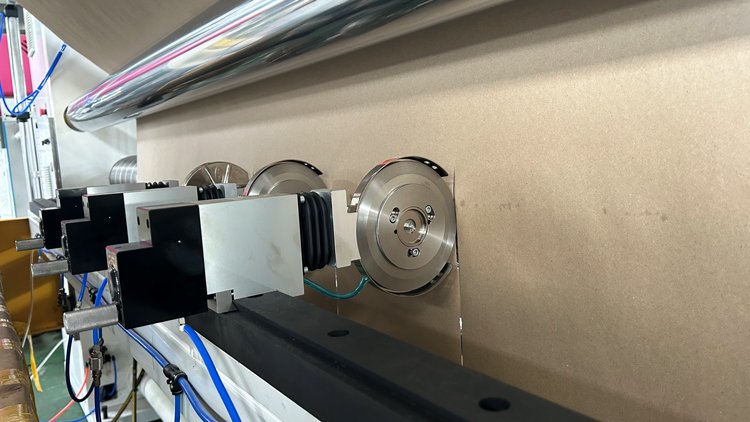

| 4. Longitudinal slit section, upper round knife unit (Crossbeam, cylinder, knife holder, round knife, linear guide), and lower round knife unit (knife shaft, round knife, bearing base, inverter motor). |

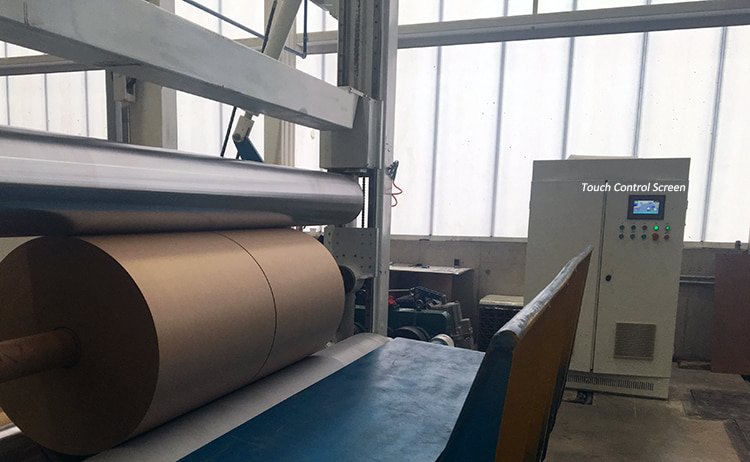

| 5. Two drum support rollers, support and drive the finished paper roll to rotate. |

| 6. Lay-on roller unit (lay-on roller, cylinder, sprocket, slide base, crossbeam). |

| 7. Active banana roller device, its direction could be adjusted according to paper thickness, flatten the paper in the best direction according to operational requirements. |

| 8. Finished roll ejecting unit (ejecting roller, swing arm, air cylinder). |

| 9. Rewinding roll lock core, it is composed of a hand wheel, a lead screw, an inner sleeve, a ratchet, and a bolt, its usage is locking and releasing rewinding shaft. |

| 10. Lowering platform, discharge the finished roll from two drum support roller to the ground. |

| 11. Web threading device, it consists of a pneumatic tire and paper guide frame, its function is automatically drawing web paper out between two drums. |

| 12. Machine frame, it contains bottom rails, front uprights, back uprights, and crossbeams, reasonable shape, good rigidity, and high strength, and works safely at high machine speeds. |

| 13. Transmission system, it is composed of a motor, gearbox, brake, base, etc., it drives the front drum support roller to rotate. The coupling between the reducer and the motor has a brake wheel, when the paper breaks or the machine stops suddenly, the brake wheel cooperates with the brake to act as an emergency brake. |

JT-SLT-2500C High-Speed Kraft Paper Two Drum Slitting Rewinding Machine

Last Update Time:18/08/2023

One of we Jota’s Chile clients purchased 2 sets JT-SLT-2500C high-speed kraft paper two drum slitting rewinding machine, and they sent back a feedback video to us.

In order to assist this client in successfully running these 2 machines, we Jota’s engineers flew from China to Chile and spent a month in Chile.

From ground base construction to finished roll discharging, we Jota’s engineers guided customers carefully, until the customer side’s engineers fully grasp it.

This Chile client was quite satisfied with we Jota’s attentive service during we Jota engineers’ 1-month stay in Chile.

Customer satisfaction is always we Jota’s relentless pursuit.

Before this Chilean client purchased JT-SLT-2500C two drum surface kraft paper slitter rewinder machines from us, they have bought 1 set Jota Machinery old version 2100mm width kraft paper slitting machine.

This old version of a kraft paper slitter/rewinder was used for many years by a client in Chile, whose business grew and got better over time.

They got better and better until they were Chile’s best paper converter.

In their factory, there are a lot of machines, some of which are from Europe.

Their factory changes kraft paper, whiteboard paper, specialty paper, photocopy paper, and a lot of other kinds of paper.

This Chilean customer’s business is growing, so they want to increase their production capacity.

They chose to buy a 2500mm width kraft paper roll slitting machine from us because they want to do this.

JT-SLT-2500C Two Drum Slitter Winder Machine

With 2 sets of JT-SLT-2500C slitter machines, the Chilean client’s production capacity could be increased. Because the original design of the JT-SLT-2500C has many useful features.

The two drum craft paper winder machine has several important parts, such as unwinding, web guiding, and threading, longitudinal slit, rewinding, finished roll ejecting and discharging, control system, etc.

The two-drum surafce slitter winder has a hydraulic shaftless jumbo roll loading system for the unwinding part.

What’s more, the hydraulic system’s loading capacity is stronger.

That means, the JT-SLT-2500C roll cutter slitter is able to load and bear 2500mm width, 1500mm diameter kraft paper or whiteboard paper jumbo roll.

With regard to the longitudinal slit section, it adopts pneumatic shear cutting.

The upper pneumatic circular knife unit consists of a crossbeam, cylinder, knife holder, round knife, linear guide, it is imported from Taiwan, cutting resistance is minimum and the wear resistance is maximum, slitting accuracy could reach the micron level.

What’s more, we also could supply the automatic knife positioning system to realize the slitting width adjustment freely, which will help the time saving, and labor risk reductions.

And lower round knife unit is composed of a knife shaft, round knife, bearing base, inverter motor.

For JT-SLT-2500C two drum surface slitter rewinder’s rewinding section, as the machine equips with two drums, these two drums not only support and drive rewinding shaft rotating but also reduce roll vibration.

Besides, there is a lay-on roller riding on rewinding roll during machine running, which ensures the final rewinding effect is great.

After rewinding is finished, it comes to finished roll discharging.

Rewinding shaft with finished rolls will be ejected out by ejecting unit first, rolls down to lowering the platform, then lowering platform turns down a certain angle, these finished rolls are unloaded to the ground.

Of course, we couldn’t ignore the most important control system, it is the brain of Chile’s client’s JT-SL-2500C two drum high-speed slitting machine.

This Chile client bought 2 sets JT-SLT-2500C from we Jota, the first one is dashboard panel control without touch screen.

The customer still think it is more convenient to control with touch screen, so we Jota customized touch screen control as Chile client’s request.

Now, Chile client’s 2nd JT-SLT-2500C rotary shear slitting rewinding machine is quite convenient for use with touch screen.

So, if you also want to customize your own dreamy jumbo roll kraft paper slitting rewinding machine, we Jota is definitely worthy of your trust.

You could also enjoy the same service as Chilean clients. What you need to do now, is just simply submit your request to us, we are always ready to offer one-on-one service to you.

JT-SLT-2500C High-Speed Paper Slitting Rewinding Machine FAQ Guide

You’ve come to the right place if you’re looking for a machine that can cut your paper rolls into smaller rolls.

JOTA has a high-speed machine for cutting and rewinding paper that fits your needs best.

Also, its high productivity is sure to help your business and make you a lot of money.

Let’s unravel the qualities and details of the specific machine.

1. What’s a paper slitting rewinding machine?

Paper slitting rewinding machine is closely related to all kinds of paper, such as thermal paper, office copy paper, substrate paper, craft paper, white paper, etc.

A simple piece of flexible packaging equipment is a slitting machine.

It usually involves unwinding, slitting, cutting, and rewinding to turn large rolls of material into smaller rolls.

The machine that cuts and rewinds are a smart piece of equipment.

One frequency inverter is often used to control the rotation of the main feeding system (NIP roller) and the slitting round disc knife. The other two frequency inverters control the speed and tension of the rewinding.

Since each material is different, its functions will also be different.

Today, we’ll talk about the machine that cuts and rewinds paper.

Because there are so many different kinds of paper mother rolls, we only use coated paper and white cardboard with gray paper cardboard, which is more common in the printing and packaging industries.

A paper slitting rewinding machine, with a width range, is from 800mm to 3500mm, the unwinding diameter is from 1000mm to 1500mm, and the winding diameter is from 800mm to 1500mm. The speed range is from 200m/min to 500m/min.

In conjunction with the work of high-speed slitting machines, the pneumatic round disc knives are generally adopted.

Due to their small runout, high precision, and wear resistance, pneumatic knives have been used by high-end equipment.

The current size of the air knife is D150 x D80mm, and the hardness HRC is 62-64 degrees.

The pneumatic round disc knife doesn’t jump much when it’s spinning quickly, and it can cut at speeds of more than 1000m/min. Most of the market accepts it because it works so well.

Jota machinery has accumulated considerable experience in paper slitting machines.

We have a deep understanding of the characteristics of various papers, especially for the control system of large paper slitting machines.

We have our own electrical engineers who can control all the systems has their own understanding.

So when you buy this type of paper slitting machine, you must also consider the optimization of the control system.

Both hardware and software are an essential part of the paper-slitting machine.

All types of paper, such as thermal paper, office copy paper, substrateion paper, craft paper, white paper, and so on, have a tight link with the high-speed paper slitting rewinding machine.

Rollers

The rollers used in the high-speed paper-slitting rewinding machine are all-steel rollers with a diameter greater than D250mm.

The D450mm bottom roller binds the paper cardboard well after it enters the rewinding station.

It guarantees that the high-tension requirements are met during high-speed rewinding and slitting.

Specifications

A high-speed paper-slitting rewinding machine has an unwinding diameter of 1000mm to 1500mm. While the winding diameter is 800mm to 1500mm.

The width is from 800mm to 3500mm. The pace ranges from 200 to 500 meters per minute.

Control System

At JOTA, we have our own electrical engineers who can control and understand the entire system.

The soft program can perfectly control every minor activity of the slitter rewinder machine.

If you have any questions or thoughts on the paper-slitting rewinding machine, just send us an inquiry.

2. Where is paper slitting rewinding machine used?

The paper slitting rewinding machine is used by various industries. These industries are as follows:

- Printing and packaging company

- Large paper mills

- Paper distributors

Printing and Packaging Industries

Printing and packaging plants, as well as paper mills

The single-shaft slitting machine’s excellent efficiency makes the process of changing rolls a lot easier and saves a lot of time and effort.

Large Paper Mills

Large paper mills commonly use this slitting technology because of its great speed and efficiency.

The breadth of the enormous roll of paper when it comes out of the coating machine is between 3000mm and 5000mm.

Large rolls of paper are fed straight into a wide-width slitting machine, where they are slit or converted into various sizes and then resold.

Printing Packaging Industries

Paper is one of the basic materials for the printing, there is a high requirement for paper quantity.

3. What materials could be handled by paper slitting rewinding machine?

The high-speed paper-slitting rewinding machine handles a vast variety of materials. Except for the previously mentioned paper, aluminum foil, non-woven fabric, plastic film, fiberglass, CFRP, CFRPT are both supported.

Coated Papers

Coated paper is a high-quality printing paper made of base paper coated with white paint.

It is mainly used for printing the covers and illustrations of high-end books and periodicals.

4. What are the advantages of JT-SLT-2500C high-speed paper slitting rewinding machine?

As the JT-SLT-2500C paper slitting rewinding machine is a big machine, it supports max. 2500mm width material web, big unwinding width is the most obvious advantage.

What’s more, the unwinding width could be customized to support 3200mm, if you have such a requirement, please feel free to contact us.

Its advantages include:

- It ensures the best possible slit edge quality.

- The material can be rewound onto different core sizes or slit from a master roll.

- It can do multiple cuts can be done simultaneously.

- The slitting machine’s primary function is to unwind a large mother roll, cut and slit it using a knife (round disc knife or razor blade knife). Then it rewinds the narrow-finished rolls or small diameter rolls.

- The level of productivity is really high and it works with great speed.

- 20 ATM or POS rolls are created on average per minute which results in a monthly output of 20*60*8*22=211,200 small rolls. This is highly profitable for your business.

- It has Siemens PLC with a touch control screen and visible quality.

- You can optionally add the parts in the high-speed paper slitting rewinding machine, and production efficiency could undoubtedly be improved.

- Furthermore, the unwinding width can be adjusted to support 3200mm webs. You can contact JOTA for your required paper rewinding machine.

How Does a Paper Slitter Rewinder Machine work?

The working mechanism of a slitter rewinder machine is not as complicated as you may think.

We have designed our paper rewinders to be as simple as possible. We have also factored in efficiency and ease of use.

Paper rewinder slitters have three main components that include the unwind, the slitter, and the rewind.

The three parts work simply. Three processes occur when you feed the jumbo paper roll into the paper slitter.

Unwinder

The unwinding sections of a paper slitter work by unwinding the jumbo paper roll. This is done by feeding the jumbo paper roll into the unwinder drum.

The Slitter

The slitter section of a paper slitter rewinder machine is the most important section of the machine. This section of a splitter machine impacts the quality of your paper processing.

We ensure that we equip our paper rewinders with knives with minimum cutting resistance.

The wear resistance is at the maximum. The round disc cutters installed on our paper slitters can also reach micron levels.

The pneumatic cutters consist of a crossbeam, cylinder, knife holder, round knife, and linear guide.

For more information on how our paper slitter machines work visit our YouTube channel on

What Type of Drive Does Your Paper Slitter Rewinder Machine Have?

Paper slitting machines are an important fixture in any paper milling factory.

This is because they are the finishing machines in the production line.

For efficiency, you should ensure that all the components of the slitter machines reworking perfectly and in synch.

One of the most important components you should keep an eye on are the drives.

Technology

We ensure that our slitter rewinder machines drives are equipped with the latest technology.

Our drives integrate both the DC and AC modules. DC drives are durable and require minimal maintenance while making it easy to integrate communication and software tools.

Tension Control

Drives are an integral part of our slitter machines.

The unwind section is fitted with drives that assist in ensuring maximum tension that is required for clean slits.

It ensures that the quality of slitted rolls is of good quality.

Will You Assist In The Installation Of The Paper Slitter Rewinder Machine And Should I Be Aware Of The Installation Procedure

Yes, Jota Machinery will assist you in the installation procedure of the paper slitter rewinder machine.

We will make sure that the paper slitting rewinder is running successfully.

It is important to be aware of the installation procedure as it is not a very complex process.

The installation of a slitter rewinder machine entails a series of steps from making the base up to a completed discharging machine.

Our professional Jota Machinery engineers will give you clear guidance on the steps entailed.

We will elaborate the entire process until your engineers on the ground understand the entire process.

What Are Some of The Considerations I Should Put In Mind Before Buying A Paper Slitter Rewinder?

Paper slitter rewinder machines are heavy manufacturing machines and thus you invest a lot in buying them.

Therefore, it is important to do thorough research to find the best paper slitter suitable for your needs.

At Jota machinery, we can supply you with very good quality paper slitter rewinder machines.

Latest Technology

The paper slitter rewinder machine which you select must have the latest technology features this includes features like the twin shaft technology.

This will ensure downtime operation of very high speed.

At Jota Machinery, we have a slitter rewinder machine which the latest technological features.

An example of such an upgraded machine is our 2500mm kraft paper roll sitting machine.

We have an advanced paper slitter rewinder machine in that the web threading device draw paper out automatically.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine