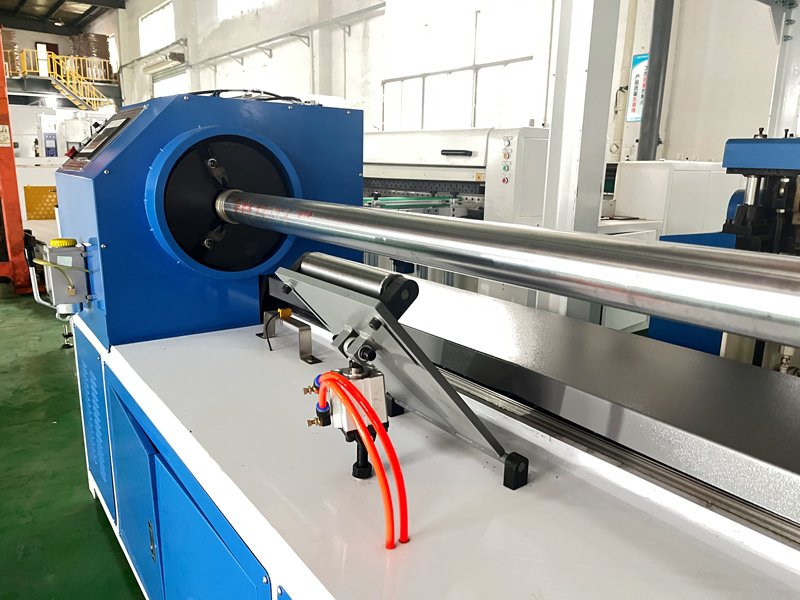

JT-120A Paper Tube Making Machine

- Paper Layer 3-16

- Paper Core Thickness 1mm-10mm

- Paper Core Diameter 20mm-200mm

- Paper Core Length 500mm-5000mm

- Specification

- Video

| Parameters | |

| Item | JT-120A paper tube making machine |

| Paper Layers | 3-16 |

| Paper Core Thickness | 1mm-10mm |

| Paper Core Diameter | 20mm-200mm |

| Paper Core Length | 500mm-5000mm |

| Max. Machine Speed | 0-20m/min |

| Raw Material |

| Kraft Paper |

| Features |

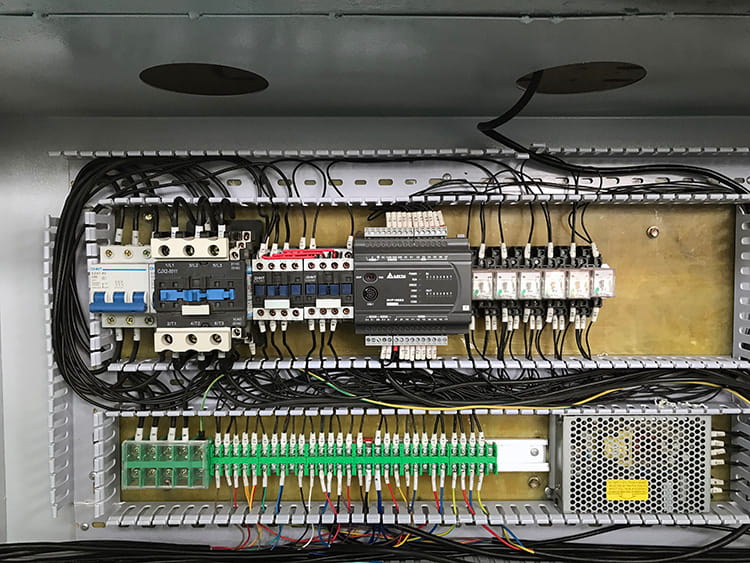

| Delta PLC control and automatic meter counter, all the parameters can be set up on the control panel. |

| HIGHTECH touch screen from Taiwan, all the parameters can be displayed on the HMI interface, easy operation. |

| Imported frequency inverter drives the AC motor, the machine working is more stable. |

| Independent electrical control box equips with input plug, the after-sale troubleshooting and repairing will be much easier. |

| Dialogue monitor, automatic operation memory and store, automatic fault display. |

| Multi cutter for cutting the paper core, high precision, and more bearable. |

| Extreme quiet design transmission parts after special treatment, with high efficiency and low maintenance. |

| Double side glue coating devices, the paper core is more sticky and stronger. |

| 2 photocells for the paper core length tracking, after reaching the preset length, the paper core will be cut off. |

| Circuit system with remote control function, if circuit or machine fail, the engineer can assist you in solving problems via machine communications tools and software. |

JT-120A Paper Tube Making Machine

Last Update Time:22/11/2022

In Leon, Mexico, where he lives, Mr. Omar runs a business that sells glue and stretch film. He is very successful in business and has a lot of factories under his name, however, why did he purchase a paper tube making machine?

Let us go on this story.

Mr. Omar’s Stretch Film

In the past, he used to purchase paper tubes from Sonoco, a well-known local American company. Later, as the business volume increased, he decided to make paper tubes himself.

Most of his paper tubes are used to wind the stretch film, the thickness is no more than 8mm, and the length is about 450mm, so we recommended Jota’s JT-120A paper tube making machine to him.

In 2016, Mr. Omar took his beautiful wife to Shanghai for a trip and visited our company by the way (our factory is only 60km away from downtown Shanghai and 90km away from Pudong Airport).

Mr. Omar and His Beautiful Wife

Mr. Omar and his wife visited our factory and CNC center and were very satisfied with our equipment demonstration.

They decided on the spot to order a complete set of paper tube production lines, including kraft paper slitting machine, paper core making machine, and paper core cutting machine.

Subsequently, our Jota CEO Bruce and CTO Jimmy went to Leon City to assist Mr. Omar in installing this equipment.

When we arrived at Leon, we were treated warmly by Mr. Omar. Jota CTO Jimmy was especially loved by Omar’s big pet dogs.

Mr. Omar prepared a variety of delicious Mexican food for us, such as Tacos and Tequilla.

He also took us to the home stadium of the Leon team to watch a football match and experience the atmosphere of Mexican football.

This makes us feel the strong atmosphere of Central and North American football, which we admire as Chinese.

Club Leon’s Home Match

Because Omar had paper tube orders that needed to be purchased from outside, when the machine started to run normally, he could finally make these orders by himself.

Everything is running smoothly, and now he is supplying paper tubes to outside customers.

In the days to come, we have maintained close contact with Mr. Omar.

He has also visited China many times and purchased other models of automatic paper core cutting machines.

Mexico to China, Leon to Kunshan, although the distance is 12000Km, our hearts are always together.

As a professional paper tube machine supplier, Jota Machinery not only provides stable quality equipment but also provides various business consulting and global market trends.

Paper Tube Making Machine FAQ Guide

If you are looking for a kraft paper tube-making machine to manufacture paper tubes, JOTA machinery can support you.

To find a new opportunity or investment option, consider launching a tiny paper tube business. It’s a low-cost option with speedy effects.

Plastic film, printing packaging, and building, among other things, all require the use of paper tubes.

JOTA offers three distinct types of kraft paper tube-making machines to meet your needs: a kraft paper slitter rewinder, a tiny paper tube producing machine, and a paper tube recutting machine.

Let’s move toward the details and specifications of the paper tube-making machine.

- Necessary Things You Need to Know About Paper Tube Making Machine

- A Fully Automatic Solution to Sky Rocket Your Business

- Purposes of Kraft Paper Tube Making Machine

- Advantages of Paper Tube and Paper Tube Making Machine

- Branding Through Paper Tubes

- Weight Carrying Capacity of a Paper Tube

- Industries That Benefit from Paper Tubes

- Jota, Your Ultimate Business Booster

- Jota’s Production Capacity

- Life Span of Machine

- Running Span

- Facilities Jota Offers

- Jota’s Packaging and Shipping Facilities

- Various Types of Paper Tube Making Machine to Serve Multiple Industries

- Find an Authentic Manufacturer to Support Your Business

- Reasons to Invest in Paper Tube Making Business

- Ways to Run, Compete and Maintain Your Business

- The demand of Paper Tubes in Different Industries

- Jota Is Your Best Tube Making Machine Supplier

- A Wide Range of Machines to Fulfil Customer’s Demands

- Factors to Consider While Purchasing a Paper Tube Making Machine

- Optional Functions of Tube Making Machine

- Things You Need to Know Regarding Machine Maintenance

- Paper Tube V.S. Plastic Core Tube

- Useful Information Regarding Shipments

- From Paper Roll to Paper Tube

- Certifications Awarded to Jota Machinery

- Precious Reviews by Jota’s Stable Clients

Necessary Things You Need to Know About Paper Tube Making Machine

You can find different varieties of paper tube producing machines all over the world as basic industrial packaging machines.

Sections of Paper Tube Making Machine

The kraft paper tube making machine is usually broken down into the following sections:

- Unwinding

- Gluing

- Winding

- Inline cutting

- Controlling

The process of unwinding and gluing pieces is very similar across manufacturers.

The motor and gearbox drive the winding of paper tube-making equipment, so you must consider the motor brand and power, as well as the gearbox speed ratio.

The rolling force of the kraft paper tube increases as the motor power and gearbox ratio rise.

The kraft paper tube grows tighter, tube quality improves, and terminal clients prefer it more.

If the speed ratio is too high, however, the paper winding speed will be poor and the production efficiency will suffer.

As a result, a balance between quality and speed must be struck, and a proper motor power and gearbox speed ratio must be chosen.

Furthermore, there is R&D personnel to execute PLC programming, which ensures that the control program runs smoothly.

It also helps to avoid systematic software failures, reduces the likelihood of shutdowns, and further avoids shutdown losses.

Easy Steps for Making Paper Tube

The following steps make up the majority of the paper tube production process.

- Jumbo roll paper slitting

- Glue modulating

- Tube rolling

- Tube cutting

- Tube drying

- Tube precision cutting

- Polishing

- Packaging

Working

- Kraft paper ribbon unwinder, starch adhesive spreader, paper core winding device, and cutting devices are the primary components of the paper tube manufacturing machine.

- The kraft paper unwind is used to unwind kraft paper ribbons under controlled tension.

- To suit your requirement for diverse paper tube thicknesses, it should have several working unwinding locations. A 10mm thick paper tube has 24 layers in total. Meanwhile, light tension on the unwinder should be maintained to retain the kraft paper ribbon in straight positions.

- The kraft paper ribbon will next be dipped in a water base glue tank to be coated with glue. It is recommended that the kraft paper be completely immersed in the glue tank, then scrape off any excess glue before moving on to the next station.

- The next process is the winding mechanism of the kraft paper tube. It uses belts to produce a multi-layer of paper ribbons into a paper tube core. You can pick between two head kraft paper tube making machinesand four head kraft paper tube making machines for different paper tube thicknesses.

- The kraft paper tube recutting apparatus is in the final stage. A portion of the paper tube will be recut for the desired length.

- If you are interested in buying the spiral tube making machine, you can contact JOTA.

Gluing System

The paper tube manufacturing machine has a unique gluing system.

It uses two types of glue such as sodium hydroxide and borax in the same quantity.

This mixture of glue is poured into the glue tank of the paper tube-making machine.

The machine uses the glue from the tank throughout the making of the paper tubes.

Raw Material

In a paper core manufacturing machine, the raw material kraft paper, glue, and auxiliary equipment are used.

Raw Material Types and Specifications

The types of raw material in the paper core manufacturing machine consists of pre-slit kraft paper reels (we can supply a Slitter Rewinder at an additional fee if pre-slit reels are difficult to come by) and glue.

Important Specifications of Raw Material

Its specifications include:

- Plastic film (PVC, PET), kraft paper, aluminum foil, non-woven fabric, and other materials can all be slotted and rewound using a paper core production machine.

- All parameters are shown on the screen using a Siemens PLC control system and a 7” High-tech graphic HMI. Simply set the roll diameter, material thickness, and original tension, and the machine will function on its own.

- Three asynchronous servo motors and three Yaskawa AC drives are used.

- Automated pneumatic material loading, which is both convenient and time-saving.

- The extreme sensitivity of the ultrasonic web guiding system keeps the material in the required place.

- Unwinding tension control with an electromagnetic brake.

- For rewinding tension control, an embedded encoder in a synchronized servo motor is used.

- Discharge of completed reels is automatic.

- Transmission shafts with dynamic and static balance.

- Slit length is measured automatically using a rotary encoder.

- Activates the emergency switch.

- System for removing waste.

Machine Specifications

The specifications of paper core manufacturing machine include:

- Paper layers are 3-12

- Paper core thickness is 1mm-5mm

- The Paper core diameter is 10mm-100mm

- The Paper core length is 500mm-2000mm

- machine speed is 0-30m/min

After knowing the specifications, the next you need to know the classification of the paper pipe making machine.

A Fully Automatic Solution to Sky Rocket Your Business

The kraft paper tube production machine is designed to work automatically.

It is a fully automatic machine that performs all of its functions on its own.

This fully-automatic feature reduces manual hard work and thus reduces the time consumed.

Due to this reliable feature, the production speed is high and it ultimately boosts your business profit.

Useful Features of Spiral Tube Making Machine

The main features of the kraft paper tube making machine are:

- All of the parameters for Delta PLC control and automatic meter counter can be set up on the control panel.

- HIGHTECH touch screen from Taiwan, all parameters may be presented on the HMI interface, and it’s very simple to use.

- The AC motor is driven by an imported frequency inverter, which makes the machine more stable.

- After-sale troubleshooting and repair will be much easier with an independent electrical control box equipped with an input socket.

- Automatic operation memory and storage, as well as automatic fault display, are all available on the dialogue monitor.

- Cutting the paper core using a multi cutter is more precise and comfortable.

- After careful treatment, ultra-quiet transmission parts with high efficiency and low maintenance.

- The paper core is durable and stronger – thanks to the double-sided glue coating devices.

- 2 photocells for tracking the length of the paper core. Once the length is reached, the paper core is cut off.

- If a circuit or machine fails, the engineer can help you solve difficulties using machine communications tools and software.

Specs of Machine Main Parts

The main parts of the paper tube manufacturing machine include:

- Unwinding unit

- Jumbo role slitter

- Glue modulator

- Tube roller

- Tube cutter

- Tube dryer

- Tube precision cutter

- Polisher

- Packaging unit

Purposes of Kraft Paper Tube Making Machine

The purpose of a paper tube-making machine is to produce paper tubes as they are high in demand.

Paper tubes are versatile and can be used for a variety of purposes.

These include:

- Shipping and mailing

- Cartridge production

- Crafts

- Concrete pillar building

- Structural support (posters, paper towels, etc.)

- Storage (papers, art, food, etc.) and

- Gardening pots are all common uses for paper tubes.

After knowing about the purposes let’s find out the various advantages you can get from paper tube manufacturing machines.

Advantages of Paper Tube and Paper Tube Making Machine

Paper tube is widely used in textile, chemical fiber, paper, plastic film, non-ferrous metal, and other sectors because of their low cost, lightweight, easy recycling, and lack of contamination.

Paper tube making machines and paper have numerous advantages which are as under.

Seamless Paper Tube of Superior Quality

The seamless, extremely smooth, dust-free surface of the paper tube is especially appropriate for high-speed winding of ultra-thin plastic film, metal foil, paper, and EVA film.

Paper Tube with Great Strength and Smoothness

- It has no seams

- It has no surface waves

- It has high smoothness, high strength, and high straightness

- It also has high roundness, and high surface hardness which is moisture-proof and dust-free.

- It is suited for high-speed wrapping of thin materials like high-grade plastic film and metal foil

A tube with a high tensile strength

- High compressive strength and steady surface gap

- Cost-effective and widely utilized in paper, film, and other large load-bearing and high-speed winding industries.

Extra-thick tubing

- The thickness of the paper tube is 25.4mm, or up to 75mm in some cases.

- It allows for high-speed winding of glass fiber, non-woven fabric, and other materials.

- It’s also employed in a variety of industries, including construction, decoration, and others.

A Paper Tube with a Large Diameter

- Durable

- Suited for stainless steel, color steel plate, aluminum foil, copper tape, cardboard, and construction sectors, with big, robust load-bearing capacity.

- It is low cost, energy efficient, and environmental protection.

Branding Through Paper Tubes

Branding has become much easier with the help of paper tubes.

You can equip your machine with the flexo printing machine as JOTA does.

The flexo printing machines help you to print your paper tubes in several colors and designs.

Moreover, JOTA also offers a labeling machine through which you can label your machine according to your brand name.

This mixture of labeling and printing helps to garner a great mass of people.

When people see the brand names of the paper tubes, their next step is more likely to visit that store or the website of the particular brand.

In this way, at the cost of one, you can have multi-functions with your paper tube-making machine.

Weight Carrying Capacity of a Paper Tube

A paper tube can hold weight according to its shape and size.

Some tubes are designed to hold smaller weights such as food products, cosmetics, and medicines.

However, some tubes are designed to lift heavier weights such as wires, machines, and other heavy storage things.

These heavy-duty paper tubes are utilized as shipment tubes.

Your articles are safe inside these strong and durable spiral paper pipes.

Industries That Benefit from Paper Tubes

Paper tubes are applied in a large number of industries.

In the cosmetics industry, paper tubes are used to cover essential oils, perfume bottles, talcum powders, and other cylindrical shape products.

In the food and storage industry, paper tubes are used to store may products.

Moreover, paper tubes are used as the core for rolling plastic films, tissue papers, foil papers, etc.

In tissue papers, the paper tubes are used as a support to roll the tissue papers over them.

Similarly, for foil papers and plastic films, the paper tube is used as a core and the foils are rolled over it.

Jota, Your Ultimate Business Booster

The reasons why should you choose JOTA are as follows.

- JOTA is a high-end production industry that produces the latest machinery sticking to the new trends.

- It manufactures a wide range of machines depending upon your desire and requirement.

- It helps you to choose the best manufacturers near you.

- It helps you in maintaining your machines by providing maintenance guides.

- It assists you in repairing your faulty machine products.

- It provides efficient contact services.

- JOTA also manages to ship the required machines in time, without the risk of breakage.

- All of it machines are CE certified

In short, JOTA builds complete trust with its client and provides best services.

Jota’s Production Capacity

You can get the order of 2-3 machines per month from JOTA which is quite appreciable and business grooming.

Jota manufactures 20 – 30 sets per month conveniently. It means multiple customers can get their orders on time.

Life Span of Machine

The life span of the machines manufactured by JOTA is about 35-40 years which confirms the credibility of the manufacturing of JOTA.

Moreover, it eradicates the cost of investing money on different brands for getting a good machine for your business.

Running Span

The running span of the paper tube-making machine is 12-24 hours and even more.

As far as you maintain it correctly and regularly, it can run for several hours non-stop.

Facilities Jota Offers

Jota provides you with numerous facilities. Some are:

Quantity of Order (Bulk/Small MOQ)

You can order in bulk and as well as in small range.

If you are to start a new business, you should start ordering on a smaller scale in order to avoid any scams.

Once your trust develops over a certain brand, you can order in bulk to meet the need of your clients.

Jota’s After-Sales Services

Your interaction with Jota Machinery isn’t limited to the purchase of a thermal paper roll slitting machine or spare parts for it.

JOTA also provides its customers with a variety of sales services.

JOTA’s expert team of employees provides after-sales servicing for thermal paper roll slitting machines. These services are as follows:

Consulting

To ensure that your business output grows, Jota Machinery offers consultation services.

This can be accomplished either directly from the Jota Machinery team or by providing access to our suppliers’ considerable knowledge and skills.

To improve the operation of a thermal paper slitting machine, this after-sales service can be provided in a variety of methods. Consultancy can be used in a variety of situations.

- Identifying the suitability of a kraft paper tube production machine for a customer’s needs.

- Providing advice on the production efficiency of a fully automatic paper tube-making machine.

- Identification of the most appropriate solutions for customer needs.

- Recommending the required maintenance actions for paper tube making machine.

- Paper tube making machine manufacturing quality and productivity are being optimized and improved.

Workforce Training

A highly productive staff is one that is empowered. As a result, your employees should be given a thermal paper roll slitting machine that they can use confidently.

On-site training for thermal paper slitting machines is always available from Jota Machinery. This can be done by our local team or with the assistance of one of our key suppliers.

We can customize your paper tube manufacturing machine to fit your company’s diverse skills and levels.

Trials and Evaluation

As an industrial organization, you’ll need to know that your kraft paper tube production machine is in good functioning order at all times. Paper tube-making machine technology must provide efficiency, resulting in an increase in input.

However, determining whether a paper tube-making machine is operating properly is difficult for everyday operators. As a result, you’ll need the advice of a professional.

Your paper tube-making machine can be tested using Jota machinery. It can also assess your requirements to guarantee that you get the optimum paper tube manufacturing machine.

This after-sales service is available on-site by bringing a paper tube-making machine for testing.

Maintenance

On-demand, you’ll have access to a team of skilled technicians that can assist you with mechanical, control, and electrical issues.

The following are some of the maintenance after-sales services that the Jota Machinery support staff may assist with:

- Provide paper tube making machine breakdown and maintenance assistance.

- Installing and commissioning a kraft paper tube making machine is required.

- Complete the action of identifying and reducing parts.

- Maintain the thermal paper slitting machine on-site.

As part of the preventative maintenance service, JOTA can conduct on-site audits and maintenance activities for the paper tube-making machine on a regular basis.

Spare Parts Provision

JOTA improvises the spare parts for your ease.

If you are facing any problem in getting the spare parts, or in the maintenance of the spare parts, you can contact JOTA immediately. The JOTA team is always ready to assist you anytime.

Lead Time

The lead time that JOTA provides for the manufacturing and shipping of your machines is not more than one and a half months.

You can get your machine earlier if you are from a nearby location.

If you are an international client, the shipment time depends on the mode of shipment you choose.

Warranty

JOTA provides you with machines that have 1-2 years of warranty.

At this time, you can get your machine and spare parts overlooked at JOTA.

Installation Guidance

JOTA gives you proper installation guidance.

JOTA updates its website with:

- User manual for installation and operation, wire connection diagram, and tension controller guide

- Video tutorial for installation and operation.

- Remote video calls may help on a one-to-one basis.

- Installation and operation instructions are on-site.

In this way, you can get complete guidance on the installation and operation of the machine and its parts.

Operation Guidance

Jota gives full operation guidance to their customers, so you don’t have to be worried about how you’ll operate the machine.

JOTA has prepared a guidance map that helps you understand each and every aspect of the machine.

Moreover, for easy and quick understanding, JOTA also prepares videos of the working and manufacturing process so that you can grab the idea of the operating system.

Jota’s Packaging and Shipping Facilities

The paper tube manufacturing machine is cleaned and checked properly before packaging.

It is electrically tested to reduce any faults or malfunctioning.

It is then fully lubricated to prevent rust and corrosion.

It is then double-packed in cardboard and shockproof material.

After double packing it, the machine is ready to be shipped across various countries through the airline, or cargo shipping.

Various Types of Paper Tube Making Machine to Serve Multiple Industries

There are different types of paper tube making machines. These machines include:

- 50A small-sized paper core making machine

- 120A medium-sized paper tube manufacturing machine

- 200A large-scale paper core making machine

- 50C multi-cutter paper tube winding machine

50A Small Sized Paper Core Making Machine

This model of the paper tube-making machine is designed to make small-sized paper cores such as those used in the smaller tissue or plastic film rolls.

50A Small sized paper core making machine has winding that makes small size paper tubes.

Specifications

- Paper Core Thickness 1mm-5mm

- Paper Core Diameter 10mm-100mm

- Paper Core Length 50mm-2000mm

- HIGHTECH Touch Screen from Taiwan

Parameters

- Paper Layers are between 3-12

- Paper Core Thickness is 1mm-5mm

- Paper Core Diameter is 10mm-100mm

- The Paper Core Length is 500mm-2000mm

- Machine Speed is 0-30m/min

Raw Material

Craft paper is used as a raw material for this paper core making machine.

Features

Its main features include,

- Delta PLC control and automatic meter counter, all the parameters can be set up on the control panel.

- HIGHTECH touch screen from Taiwan, all the parameters can be displayed on the HMI interface, easy operation.

- Imported frequency inverter drives the AC motor, the machine working is more stable.

- Independent electrical control box equipped with an input plug, the after-sale troubleshooting and repairing will be much easier.

- Dialogue monitor, automatic operation memory and store, automatic fault display.

- Multi cutter for cutting the paper core, high precision, and more bearable.

- Extreme quiet design transmission parts after special treatment, with high efficiency and low maintenance.

- Double side glue coating devices, the paper core is more sticky and stronger.

- 2 photocells for the paper core length tracking, after reaching the preset length, the paper core will be cut off.

- Circuit system with remote control function, if the circuit or machine fails, the engineer can assist you in solving problems via machine communications tools and software.

120A Medium Sized Paper Tube Manufacturing Machine

This paper core making machine has a winding unit for making medium-sized paper tubes such as medium-sized tissue rolls or film rolls.

Specifications

- Paper Layer 3-16

- Paper Core Thickness 1mm-10mm

- Paper Core Diameter 20mm-200mm

- Paper Core Length 500mm-5000mm

Parameters

- Paper Layers 3-16

- Paper Core Thickness 1mm-10mm

- Paper Core Diameter 20mm-200mm

- Paper Core Length 500mm-5000mm

- Machine Speed 0-20m/min

Raw Material

Kraft paper is used as a Raw material.

Features

It has the following features.

- Delta PLC control and automatic meter counter, all the parameters can be set up on the control panel.

- HIGHTECH touch screen from Taiwan, all the parameters can be displayed on the HMI interface, easy operation.

- An imported frequency inverter drives the AC motor, the machine working is more stable.

- Independent electrical control box equipped with an input plug, the after-sale troubleshooting and repairing will be much easier.

- Dialogue monitor, automatic operation memory and store, automatic fault display.

- Multi cutter for cutting the paper core, high precision, and more bearable.

- Extreme quiet design transmission parts after special treatment, with high efficiency and low maintenance.

- In double-sided glue coating devices, the paper core is more sticky and stronger.

- 2 photocells for the paper core length tracking, after reaching the pre-set length, the paper core will be cut off.

- Circuit system with remote control function, if circuit or machine fail, the engineer can assist you in solving problems via machine communications tools and software.

200A Large Scale Paper Core Making Machine

It is a big sized paper core making machine that can make paper cores for storage and wires holding purposes.

Specifications

- Paper Layers 3-24

- Paper Core Thickness 1mm-18mm

- Paper Core Diameter 20mm-254mm

- Paper Core Length 500mm-5000mm

- Machine Speed 0-20m/min

Raw Material

Kraft paper is used as a raw material.

Features

Its features include:

- Delta PLC control and automatic meter counter, all the parameters can be set up on the control panel.

- HIGHTECH touch screen from Taiwan, all the parameters can be displayed on the HMI interface, easy operation.

- An imported frequency inverter drives the AC motor, the machine working is more stable.

- Independent electrical control box equips with input plug, the after-sale troubleshooting and repairing will be much easier.

- Dialogue monitor, automatic operation memory and store, automatic fault display.

- Multi cutter for cutting the paper core, high precision, and more bearable.

- Extreme quiet design transmission parts after special treatment, with high efficiency and low maintenance.

- Double-side glue coating devices, the paper core is more sticky and stronger.

- 2 photocells for the paper core length tracking, after reaching the preset length, the paper core will be cut off.

- Circuit system with remote control function, if circuit or machine fail, the engineer can assist you in solving problems via machine communications tools and software.

50C Multi Cutter Paper Tube Winding Machine

This paper core making machine model is installed with multi-cutters for cutting the paper cores into various shapes at the same time.

Specifications

- Paper Tube Winding Cutting 2 In 1

- Paper Tube Winding Machine with Multi Online Cutters

- Paper Tube Thickness 1mm-5mm

- Paper Tube Diameter 25mm-150mm

- Paper Tube Length 70mm-5000mm

Parameters

- Paper Layers 3-12

- Paper Core Thickness 1mm-5mm

- Paper Core Diameter 25mm-150mm

- Paper Core Length 70mm-5000mm

- Machine Speed 20m/min

Raw Material

The raw material used for this machine is kraft paper.

Features

The 50C multi cutter paper tube making machine has the following features.

- Delta PLC control system and auto meter counter, all the working parameters can be set up on the control panel.

- HIGHTECH touch screen from Taiwan, all the parameters can be displayed on the HMI interface, easy operation.

- An imported frequency inverter drives the AC motor, the machine working is more stable.

- Independent electrical control box equipped with an input plug, the after-sale troubleshooting and repairing will be much easier.

- Dialogue monitor, automatic operation memory and store, automatic fault display.

- Multi cutter for cutting the paper core, high precision, and more bearable.

- Extreme quiet design transmission parts after special treatment, with high efficiency and low maintenance.

- Double side glue coating devices, the paper core is more sticky and stronger.

- 2 photocells for the paper core length tracking, after reaching the pre-set length, the paper core will be cut off.

- Circuit system with remote control function, if circuit or machine fail, the engineer can assist you in solving problems via machine communications tools and software.

Paper Core Making Machine

This machine produces kraft paper cores to provide a solid base for rolling plastic films, papers, non-woven fabric, and aluminum foil.

Contractors and builders utilize ultra-strong paper cores to construct concrete pillars and supports.

In the packaging sector, the paper core is commonly utilized.

Paper core making machine manufactures paper tubes or paper cores which are frequently used to package fragile objects, cosmetics, calligraphy and painting works, and artwork.

The paper core is sturdy enough to give cushioning and protection for inside objects while still being environmentally friendly and waterproof.

Paper core is also used in the following industries.

Coins, tea, coffee, and sugar storage; fireworks

The spiral paper tube is made by winding many layers of kraft paper together, which is done using a spiral paper core winding machine.

Manufacturing Process

The manufacturing process of the paper core making is written below.

Raw Paper Slitting

The slitting machine is used to convert larger rolled papers into narrower paper rolls.

Modulating Glue

This step uses two types of glue in similar proportions, these glues are sodium hydroxide and borax. These glues are added to the paper tank of the paper core making machine.

Core Winding and Cutting

In this step, the narrowed roll papers are added to the unwind stand, and tanks are filled with glue.

The machine runs and paper strips are spirally wound into shape. After this, the cutters cut the strips into desirable lengths.

Paper Tube Loading

The cut paper tube is placed into a container with casters.

Paper Tube Drying

The paper tube cart or container is pushed into the baking room and the automatic dryer is turned on.

The paper tube takes 8 to 15 hours in getting dried and the temperature increases from 50 to 65 degrees.

Paper Tube Precision Cutting

The paper tube is cut again with the help of precision cutters.

Polishing

After cutting, the paper tubes are polished.

Packaging

The last step is the packaging. The paper tubes are stored for packaging goods.

Furthermore, paper tube winding machines, paper tube rolling machine, paper pipe making machine and spiral tube making machine are also known as paper core winders or paper core making machine.

All the machines serve the same purpose of making paper cores.

Paper cores come in a variety of sizes and are utilized in a variety of industries, including packaging, transportation, and so on.

Jota Machinery is a leading maker of paper tube rolling machines.

JOTA’s major advantage as a company specializing in developing paper core making machines for many years is that we can create customized machines for you based on your specifications, smoothly linking with your production scene.

Furthermore, our factory and CNC center can show you in real-time via WhatsApp video call at any time, protecting you from being duped by a shell corporation.

Find an Authentic Manufacturer to Support Your Business

It’s difficult to find an authentic paper tube-making machine manufacturer. Before deciding on an authentic manufacturer for your company, you must conduct extensive research.

There are numerous manufacturers of spiral paper core winding machines.

However, picking the perfect one might be tricky. Here are some things to think about.

Their facility’s dimensions

The size of their facility is a major consideration; often, the larger the facility, the better;

Their reputation

Paper core production machine is expensive, so it is necessary to stay with companies with a strong reputation.

Warranty

Most paper core production machine vendors provide clients with quality assurance, which is usually in the form of a guarantee.

Most manufacturers provide 1-year warranty for their products.

To avoid being a victim of a scam, there are a few things you should think about. These are the methods.

Methods to Find an Authentic Manufacturer

- Attend international trade events, exhibitions, and trade fairs, or

- Travel to China and schedule one-on-one meetings with numerous paper tube-making machine manufacturers.

- Compare the material, quality, and cost of different enterprises by visiting industrial clusters and Chinese wholesale markets.

Qualities of an Authentic Manufacturer

When it comes to choosing an authentic kraft paper tube-making machine manufacturer for your company, it should have the following qualities.

- Global business history

- Customer service team

- On-time delivery

- Economical

- High-grade raw material

- Customized solutions

- Quality control

- Factory testing

- After-sales services

Let’s celaborate!

Global Business History

A well-known company that makes machines for making paper tubes has a long history of success. You can tell if a manufacturer is real by how loyal their national and international clients are.

International clients always buy machines from reputable manufacturers because of the high quality, low prices, and on-time delivery.

Customer Service Team

A good kraft paper tube-making machine manufacturer will provide you with a helpful customer support team.

You can reach out to the company at any time and ask pertinent questions.

On-Time Shipping

Dealing with a reputable manufacturer ensures that you receive prompt and on-time deliveries.

Your paper tube-making machine is manufactured fast thanks to developed infrastructure, quick raw material supply chains, and efficient staff.

After that, the machine is delivered on time by our trustworthy shipping partners.

Cost-Effective

A good manufacturer will give you high-quality devices at a reasonable price. Genuine manufacturers care about your money and want your company to succeed.

As a result, you can purchase devices at cheap prices with low delivery costs.

Raw Material of the Highest Quality

A legitimate manufacturer, among other things, uses high-grade raw materials to build your machine.

Jota machinery, for example, uses components from reputable manufacturers. The reason for this is that your machines can function well and provide you with a quick return on investment.

Personalized Services

It’s a fantastic benefit that you get from a genuine manufacturer. Customized paper slitter rewinders are available to meet your specific company needs.

An authentic supplier, such as Jota Machinery, can develop a specific machine for you, whether it’s a component or the specifications of the paper roll.

Quality Assurance

At each stage of the manufacturing process, the ideal manufacturer inspects the quality. The QA/QC staff oversees every stage of the process, from obtaining raw materials through final testing.

Factory Testing

Before sending the machine out, the manufacturer extensively tests it.

It’s to ensure that your machines meet international safety requirements and work well in your facility after they’re installed.

After Sales Services

Another outstanding feature of a genuine manufacturer is the availability of after-sales services.

Your equipment comes with a particular warranty period, installation and maintenance instructions, and spare parts.

Reasons to Invest in Paper Tube Making Business

There are various business trends happening around the world and the paper tube manufacturing business is one of them.

The kraft paper tube-making machine business has started to have its roots almost in every country of the world.

The reason is that, due to the modern shape of the paper tubes and their variable sizes, people are attracted to hem greatly.

They are helpful in packaging for food, retail, pharmaceuticals, and cosmetics industries.

So, for a business that is expanding day by day, you must consider investing.

Here a Question Rises, Is It Profitable?

Many foreign customers have profited from running this business due to its numerous advantages.

Similarly, if you buy two paper tube-making machines and start making little paper tubes, the paper tubes you make will stack up like a mountain, boosting your business and allowing you to take on additional orders.

Furthermore, cutting paper with a Jota slitting machine might earn you a lot of money, as people all over the world profit from utilizing this equipment.

In order to enhance the business profit, JOTA also proposes some business plans.

Give it a Start

There are people who do well and others who do poorly in any industry, and the paper tube manufacturing business is no exception.

You can start with little steps and by having one production unit only.

JOTA suggests that you follow the procedures below in order to start a paper tube manufacturing business.

Procedure to Follow

- Conduct market research

- Profit assessment

- Factory confirmation

- Purchasing of raw materials and machines

- Recruiting operators

- Promotion of paper tube businesses

- Expansion/maintenance of the paper tube business

You can contact Jota sales to acquire complete paper tube producing business plan documentation.

Ways to Run, Compete and Maintain Your Business

Following is a little guide to how you can flourish your business in the market.

Run

To run a successful business, it is necessary to have a competitive team that can manage the workload as well as can assist the customers with ease.

Their skills should be highly polished.

Moreover, you should higher high-potential engineers who can help you in the manufacturing and well-running of the machines.

You should build an excellent control system so that no hindrance comes your way.

Compete

In order to compete with the other manufacturers, you should do a study on their products and modes of working.

By having the details of the specimens of the other manufacturers, you can focus on building better machine products than them.

In this way, you can compete in the market.

Maintain

As far as the maintenance of your business is concerned, you should consider maintaining the machines first.

Because healthy machines will result in the healthy production of your paper tubes.

Machine Maintenance

For maintenance, you should consider the following steps.

Lubrication

You must add lubricating oil to the oil cups, moving surfaces, and oil eyes on a regular basis. Because of the high friction on the paper tube slitting machine, you should lubricate it frequently.

Quantity of Lubricant

Always make sure you spray the proper amount of lubricant oil on the gear train.

The entire roll slitting machine system will work smoothly and evenly as a result of this.

Wiping

It’s important to remember to wipe away any residual lubricants that get on regions that aren’t supposed to be lubricated.

Fastening

Check for any slack spots when fastening. You should retighten any loose parts in your roll slitting machine to avoid any damage or injury.

Rubber Roller

Make sure the rubber roller does not come into touch with the oil used on the rolled paper slitter.

Steel Roller

Make sure the rust on the steel roller is removed. This should be done on the roll slitting machine’s other parts as well.

Maintenance of Parts

Ensure that the electrical control components are protected from vibration and pollution. At all times, all electrical parts should be maintained dry and clean.

You must also keep an eye out for worn-out parts in addition to basic care and maintenance.

You can observe changes over time in your machine parts, and it could become worse if you don’t look after the machines.

You can also notice a decrease in overall performance, this is because of the need to replace worn-out replacement parts and problems.

These are only a few of the cautions, and they should be enough to make you nervous.

If any of these problems occur, it’s time to upgrade your roll slitting machine.

System Upgrade

If you’ve bought your paper slitting equipment from a reputable manufacturer, they can help you with all the upgrades or replacements needed.

However, there are three types of paper-slitting machine equipment that may need to be upgraded. They are as follows:

Controls

If your CPU fails, your entire system may stop working. The programmable logic controller includes a CPU (PLC). Your operator interface or human-machine interface should be replaced (OI).

This will provide you far more control while also making the operator’s job easier. HMIs and OIs may come in a variety of screen sizes, depending on your unique requirements. They all have various capacities when it comes to paper slitting.

Drives

You should consider changing all of the drives in the system for better efficiency and control.

Variable-frequency AC drives should be used to replace the old ones. The voltage ranges are subject to change. The 480VAC is, however, the most prevalent.

Motors

If you want to save a lot of energy, you should always replace your old motors with new ones.

It will lead to lower energy expenses in the long run. Switch to AC motors if you’re currently utilizing DC motors and wish to significantly lower your energy consumption.

In this way, you can manage to run a reputable business by following all the details and instructions given above. However, in case of any query, you can talk to the JOTA professionals.

The demand of Paper Tubes in Different Industries

Paper tubes are cylinder-shaped components manufactured by rolling and adhering many plies of kraft paper. They are utilized for a range of things like structural support and mailing systems.

As previously said, paper cores are employed in a multitude of industries, including the automobile, textile, and many others.

Paper core pipe winding machines are used to make the majority of kraft paper tubes.

The demand for paper tubes is increasing popularly due to their sleek design and appealing appearance.

It is observed that people get more attracted to versatile paper tubes.

Variable Sizes

Paper tubes come in a variety of sizes and this feature makes them best-selling.

You can avail of paper tubes of different sizes at JOTA.

The average paper core diameter at JOTA is 20mm to 200mm, while the average length is from 500mm to 5000mm.

However, you can get your own customized size of paper tubes.

Variable Thickness

Similar to the variable size, paper tubes have variable thicknesses as well.

JOTA manufactures paper tubes from a paper core of 1mm to 10mm thickness.

Jota Is Your Best Tube Making Machine Supplier

JOTA is the best manufacturing company for it provides exuberant services and client assistance.

It offers spare parts; helps you find the manufacturers around you and guides you regarding your problems.

It has a team of professionals who look into the details of every machine being manufactured.

In short, it is a brand you trust when thinking of buying any machine for your business.

Ways to Contact Jota

There are several ways to contact JOTA.

- You can contact me through email.

- You can talk to the team of professionals on call.

- You can video call the JOTA team in case of any assistance regarding the machine.

- You can log in to the official website to make your own account at JOTA, in this way you can contact us without any interruption

- Or, the best and recommended way is, to visit the Jota factory personally.

Benefits of Personal Meetings over Online Orders

Today, almost more than half of the business has become online and people often get looted and scammed.

To avoid this scam, you should prefer personal meetings over online buying. The benefit of personal meetings over online orders is that

- You can check the product by hand

- You can see the condition of the product

- You can see the shipping process and can meet the team for further satisfaction.

Despite the scam, there are some good running brands that provide their services online and JOTA is one of them.

International customers have approved the online shipping and buying system of the JOTA machinery.

Ways to Arrange a One-to-One Meeting

There are several ways to arrange a one-to-one meeting.

- You can go to the particular website of the brand and ask them for the meeting.

- You can email them for the one-to-one meeting.

- You can go to their working unit and have a scheduled meeting from there.

- Set the time and venue with mutual understanding.

- Before leaving your country, make sure you have map and contact details with you.

A Wide Range of Machines to Fulfil Customer’s Demands

There is a wide range of machines that JOTA offers pertaining to modern technology and trends. The products are as follows:

- Thermal paper slitter rewinder machine

- Slitting rewinding machine

- Jumbo Wrapping paper rolls sheeter machine

- Fully automatic toilet tissue paper roll making machine

- Cardboard Tube cutting machine

- Thermoplastic CFRP CFRTP Prepreg manufacturing machine

- Automatic facial tissue paper making machine

- Paper drinking straws machine

- Label die cutting machine

- Flexo printing machine

In addition to these machines, JOTA also manufactures different models and auxiliary equipment for these machines to meet the need of the customers.

Factors to Consider While Purchasing a Paper Tube Making Machine

Purchasing a paper core or kraft paper tube production machine is a huge step for your company, so make sure you purchase the proper one.

Here are a few things to bear in mind while making a purchase.

High Output

It’s crucial that your machine be capable of producing a big volume of paper tubes per minute.

Strong Tubes

This contributes to the longevity of paper tubes; the stronger the tube, the more popular it is on the market.

Excellent Control Panel

A good control panel is always useful to the operator.

Exceptional Abilities

At all times, your devices should be capable of putting in high-performance levels; don’t settle for anything less.

Customizations

You can add your own customizations at JOTA.

JOTA gives you the full liberty to choose the features, size, and auxiliary equipment for your machine.

Automatic System PLC Control

An automaticPLC control system is a remarkable feature that JOTA uses in the manufacturing of its machines.

It has a touch sensor and you can adjust the functioning and size of the machine in the required manner.

Easy Operation

The kraft paper tube production machine has an easy operating system.

The modern technology installed in the manufacturing of the machine makes it easier to operate.

Moreover, the videos and complete guidance map also enhance the understanding regarding the operation of the machine.

Fast Changeover

The fast changeover system allows the paper tube-making machine to work in demand by removing or adding certain equipment.

Production Speed

The production speed of the paper tube-making machine is very high due to the fully automatic functioning of the machine.

Jota’s slitter rewinders facilitate high-speed production.

It can slit the rolled papers up to 500m/min.

Machine Power Consumption

The power consumption of the paper tube-making machine is not high because it has reduced friction.

JOTA installs its machines with friction-reducing equipment that helps in the less consumption of energy.

This reduced power consumption in return reduces your cost and gets you profit in the paper tube-making business.

Machine Cost

Do some additional research on a paper core manufacturing machine, no matter how good you believe it is.

The price range of paper core production machines in China is fairly wide.

The cheapest one costs only 8,000 US dollars and the most expensive one costs almost 70,000 US dollars.

Some European manufacturers do not disclose their paper core winding machine prices, but their high-end machines, particularly paper tube production lines, are unquestionably more than 70,000 US dollars.

Paper tube production machines can produce paper tubes with diameters ranging from 6mm to 1,250mm.

Machine Size

The size of the paper tube-making machine depends upon the features and equipment you want to add in the model.

The regular size of the machine goes about 20ft high. It can vary by adding auxiliary equipment such as a flexo printing unit, cutters, rollers, etc.

Machine Weight

The weight of the kraft paper production machine also depends upon the size. However, it can weigh up to several tons due to the inline equipment.

Optional Functions of Tube Making Machine

The optional functions of the kraft paper tube-making machine include printing.

JOTA includes flexo printers with their paper tube-making machines, eliminating the need to purchase a separate printing machine.

You can make paper tubes as well as print them with the help of your paper tube making machines.

This feature not only saves time but also money, allowing you to expand your business.

The flexo printers are typically designed for a specific paper size range; the thermal paper size setting on your printer will differ.

Printed Tubes

Printed tubes are created by wrapping custom printed art paper around plain Kraft paper tubes on the outside. This is the artwork you see on the round tubes. It is not printed directly onto the tubes, instead, it is wrapped in the printed paper.

JOTA can apply various premium finishes, such as hot foil stamping with gold or silver foil and other color foil, in addition to full color printed artwork.

However, we strongly advise you to create your own branded custom cardboard tubes for your products to promote your brand and make it easier for consumers to recognize your brand in the future at a slightly higher cost than plain tubes.

Preprinted Paper/Adding a Printer with Machine

If you want to save money, you can buy basic kraft paper tubes that are pre-printed and put your own unique labels on them.

Plain tubes are offered in three colors: brown, white, and black.

Other than pre-printed paper tubes, you can add a printer to your kraft paper tube production machine.

This feature can enhance the productivity of your machine and help you save costs.

JOTA installs flexo printers with its kraft paper production machine which makes it a two-in-one functioning machine.

You can buy one machine with two different functions at one cost.

It will make your business earn more profit.

Jota introduces 4 types of printers.

- Label Flexo Printing Machine

- Colors Flexo Printing Machine

- Colors Thermal paper Flexo Printing Machine

- Flexo Press

All these printers are adjusted accordingly. You can demand any of the printers you want and JOTA will assist you with it.

For contact, you can log onto the official website of JOTA.

Things You Need to Know Regarding Machine Maintenance

Maintaining a paper tube-making machine is a critical process because it runs at high speed.

The paper tube manufacturing machine is available to you 24 hours a day, 365 days a year.

Maintenance procedures for kraft paper tube-making machines must be carried out on a daily basis.

Always make sure the paper slitter’s criterion is clean, smooth, and free of dust and debris.

You should also check that the paper tube-making machines’ sliding parts are in good working order.

To keep track of wear and tear, you should follow our maintenance program. Maintain regular change, adjustment, and commutator records to assist the paper slitter last longer.

JOTA recommends following a machine lubrication routine.

Oil

It’s critical to maintain your paper tube making machine lubricated.

Many moving parts of a paper tube manufacturing machine need to be lubricated.

This guarantees that the paper tube making machine performs to its full potential.

When exposed to dirt particles over an extended period of time, the oil becomes dangerous.

If you don’t oil the bearings on moving elements like the rollers as needed, you risk harming them.

It could cause valves, seals, and joints to become clogged. The performance of your paper tube manufacturing will be ensured if you change your oil on a regular basis.

When oiling the sections that require it, make sure to use clean oil. This is to guarantee that the paper tube machine is in excellent working order.

Regular Maintenance

Different maintenance procedures are required for different kraft paper production machines. This is due to the fact that they are all set up differently.

Before beginning maintenance procedures on your kraft paper-making machine, you should follow all safety measures.

- Examine every component of the paper tube manufacturing machine. Look for any parts that are loose or broken. Check the levels of lubricant in moving equipment such as rollers and cutters.

- Following the Jota Machinery fully automatic paper tube manufacturing machine maintenance manual, cross off all of the difficulties.

- Clean all of the pieces that can be dusted, including the rollers. Use just the cleaning products that have been advised, and stay away from bleach.

- You should clean all the bright surfaces.

- To make the surface more durable, coat it with rustproof oil. Use anti-rust oil if the thermal slitting machine has been idle for a while.

- All of the working parts should be lubricated. Use the specified oil and make sure it’s of good quality. The use of inferior oil will cause wear and tear on the moving parts.

- Examine the wiring of all electrical components. Make sure there are no unsecured cables or ones that have come loose from their terminals.

- Any worn cables should be replaced, and the diagnosis should be written down. You can use a blower to clear dust particles from the wiring every now and then. Never use a moist towel on the paper roll slitting machine’s electrical wires.

- Also, examine the cutters for round discs. Check them for signs of wear and tear and replace them as needed.

- To avoid cuts from the round disc cutters, make sure you’re wearing protective shoes. Some round disc cutters require regular sharpening. Make sure you sharpen them according to the instructions in JOTA’s maintenance manual.

- Keep track of the maintenance schedule. Maintaining your paper slitting machine without permission is not a good idea.

- Any component that requires adjustment or replacement should be identified as soon as possible. You can contact JOTA if you are unsure how to proceed with the replacement.

- Keep track of all important maintenance tasks, such as part replacements and electrical component concerns. This will make future paper tube manufacturing machine maintenance methods possible. It’s also useful for figuring out what’s causing a problem.

- Regular training should be provided to the workers and operators of the paper tube manufacturing machine. This is necessary in order to keep up with the latest thermal paper roll slitting machine technologies.

Paper Tube V.S. Plastic Core Tube

Plastic tubes are plastic shapes created using the extrusion technique.

Plastic extrusion is the process of pushing melted raw plastic material through a die to form a shape. The extruded plastic hardens to form the final shape as it cools.

The plastic tube is a lightweight, adaptable material that is extensively used as fluid and gas flow lines in pneumatic, hydraulic, industrial, medical, and other applications.

On the other hand, paper tubes are made with either kraft paper or cardboard paper.

Paper tubes are cylinder-shaped components made by rolling and sticking multiple plies of kraft paper, they are used for a variety of applications such as structural support, and mailing systems.

Useful Information Regarding Shipments

Shipping Ways

You have three options for importing your paper slitter rewinder.

- You can choose to import the machine yourself if you are familiar with shipping methods and import complexities.

- If you’re new to the industry, you can engage a reputable shipper to deliver the equipment to your location

- Or you can ask Jota Machinery to do it for you.

Whichever route you use, make sure you discuss the incoterms before finalizing the orders.

Shipping Routes

The trading terms and conditions for payment methods are known as Incoterms. Every manufacturer has its own payment system; discuss it with the manufacturer ahead of time about the installments to be safe.

Three routes are utilized for shipping:

- By plane

- By train

- By ship

The most popular mode of transport is by sea. Ships transport big machinery in a safe and cost-effective manner.

Air travel, on the other hand, is quick but more expensive. Traveling by train is more time-consuming.

Shipping Cost

The shipping cost depends upon the size of the container.

If your container size is 20ft, it will cost 1400US$ on average.

Shipping Time

Different factors have an impact on the time it takes to ship from a foreign country or native country.

To begin with, the distance between the loading port and the destination port determines the travel time.

Another factor to examine is which foreign city is responsible for the shipment.

Weather conditions have a negative impact and have even contributed to the predicted journey time being delayed.

Shipping Time by Sea

By sea freight service, however, shipment time between foreign shipments to your country is approximately 23 to 24 days.

You must prepare yourself for a two- to three-day delay due to the loading process at the departing port.

Consider the time it takes to unload products from a container in your country.

Shipping Time by Air

If you wish to export your goods via air, the transit duration will depend on the weather.

The travel time of a shipment is affected by factors such as weather.

The transit time includes the time spent loading and unloading products.

If you’re shipping by air, it’ll take only 3 to 5 days for your cargo to arrive at its destination.

In actuality, when the airplane’s average speed is 560 miles per hour, this time is an estimate.

From Paper Roll to Paper Tube

Normally, kraft paper large rolls can be converted into finished paper tubes using a comprehensive paper tube manufacturing production line.

Three machines are usually included in this paper tube and core production line:

- Slitting Machine for Kraft Paper

- Spiral cores Machine

- Recutting a Paper Tube

The above three machines are our Jota’s major promotional good. Please contact us for a consultation.

Slitting Machine for Kraft Paper

- It is an Automatic pneumatic loading system from Taiwan

- Siemens PLC control and 7” graphic HMI

- 3 synchronized servo motors and 3 Yaskawa AC drive

- Edge Position Controller (Web Guiding)

- Paper Layers are 3-24

- Paper Core Thickness is 1mm-18mm

- Paper Core Diameter is 20mm-254mm

- Paper Core Length is 500mm-5000mm

- Machine Speed is 0-20m/min

Spiral Cores Machine

- It is a winding Medium Size Paper Core

- Paper Layer is 3-16

- Paper Core Thickness is 1mm-10mm

- Paper Core Diameter is 20mm-200mm

- Paper Core Length is 500mm-5000mm

- Machine Speed 0-20m/min

Raw Material

Raw material for this operator for paper tube making machine is Kraft Paper

Features

- Delta PLC control and automatic meter counter, all the parameters can be set up on the control panel.

- HIGHTECH touch screen from Taiwan, all the parameters can be displayed on the HMI interface, easy operation.

- Imported frequency inverter drives the AC motor, the machine working is more stable.

- Independent electrical control box equips with input plug, the after-sale troubleshooting and repairing will be much easier.

- Dialogue monitor, automatic operation memory and store, automatic fault display.

- Multi cutter for cutting the paper core, high precision, and more bearable.

- Extreme quiet design transmission parts after special treatment, with high efficiency and low maintenance.

- Double side glue coating devices, the paper core is more sticky and stronger.

- 2 photocells for the paper core length tracking, after reaching the preset length, the paper core will be cut off.

- Circuit system with remote control function, if circuit or machine fail, the engineer can assist you in solving problems via machine communications tools and software.

Paper Tube Re-cutter

- It is a Multi-Cutter Paper Core Cutting Machine

- 10mm Diameter Core Cutting

- Jumbo Tube Length 40-900mm

- 10-76mm Diameter Range Tube Cutting

- Tube Thickness 0.5-5mm

Features

- The paper tube cutting machine adopts pneumatic control round blades for cutting.

- Easy to operate, economic model.

- High speed and relatively high precision.

- Suitable for cutting different length, inner diameter, thickness paper cores.

- Round blades and paper tubes rotate synchronously to realize quick cutting.

- The automatic terminal paper core discharging system, reduce manual workload.

- Two motors, one drives mandrel rotating with paper core, the other drives blades rotating.

The paper tube generated by the core pipe production machine is quite lengthy. This type of long paper tube is subsequently reduced to a specified length by the paper tube re-cutter before being sold in the terminal market.

The paper tube cutter is classified into three types based on the operation:

- Manual paper tube re-cutter

- Semi-automatic paper tube re-cutter

- Automatic paper tube re-cutter

You can select the appropriate type based on your specific production requirements and budget.

Certifications Awarded to Jota Machinery

At Jota, we make sure to meet all of the safety regulations that are required throughout the construction of a toilet paper machine.

Jota’s top goal is your safety. As a result, the quality assurance and quality control teams collaborate with the engineers.

The raw material, assembly, and packaging are all inspected by the QA/QC staff at each stage.

Several national and international certificates have been awarded to Jota machines. Such as

- Certificate of conformity (CE)

- Patent certificates issued by QA Technic

As a result, you can rest assured that your money is safe with Jota. Please feel free to reserve your toilet paper making machine right now to help your company grow.

Precious Reviews by Jota’s Stable Clients

Client 1

Mr. Tamir is an Egyptian who lives and works in Saudi Arabia. He has lived in the beautiful port city of Dammam for more than ten years.

Mr. Tamir used to work in a local paper tube factory, which used a historical Turkish paper tube making machine.

As the local market in Saudi Arabia became more and more open, the new king encouraged more and more industrial policies.

Many Saudis began to invest in setting up printing factories, buying paper core making winding machines, kraft paper slitting machines, trademark printing machines, adhesive label die cutting machines, etc.

Because of this, the demand for small paper tubes is increasing all over Saudi Arabia.

After investigating this market repeatedly, Mr. Tamir felt that the small-size paper tube was still a blank market in the local area, and decided to enter the small-size paper tube industry, specializing in providing small kraft paper tubes winding to local customers.

Therefore, Mr. Tamir came to China for the first time in 2017 and inspected a number of paper tube production equipment suppliers.

When visiting our company JOTA, we discussed a detailed paper tube business plan for newcomers like Mr. Tamir and made a detailed schedule. We also showed him around our factory and CNC center.

The guests felt impressed by our Jota Machinery’s mechanical expertise and proficient English communication skills and decided to cooperate with us on the spot.

The solution we give to Mr. Tamir is a complete line of small paper tube production, including a slitting machine (JT-SLT-1300C), a kraft paper tube winding machine, and a tube cutting machine.

According to the actual situation of a newcomer into this industry, we also recommend Mr. Tamir purchase some auxiliary equipment such as air compressors and forklifts, as well as all the accessories required by the machine.

After all the machines were shipped to Saudi Arabia, our engineers flew to Saudi Arabia to help customers start by laying out the power wires, turning the customer’s empty factory into a paper tube production line factory.

Client 2

Dr. Hector Martinez first contacted us in 2007. At that time, they used a Mexican local paper core making machine, that local machine has low-tech and low-efficiency, and the finished tube qualification rate was unacceptable.

Later, Dr. Hector Martinez contacted us to learn more about our Jota’s paper tube production line.

On the eve of New Year’s Day in 2008, he ordered a complete set of production lines, including kraft paper slitting machines, paper tube winding machines, various tube cutting machines, and so on.

Since then, Dr. Hector Martinez has occupied a lot of markets in Guadalajara. His company has grown bigger and bigger and passed the ISO9001 quality management system certification.

In 2017, Dr. Hector Martinez contacted us again, planning to purchase a multi-cutter paper tube-making machine.

Dr. Hector Martinez has a large number of terminal customers, these terminal customers have a large demand for thin paper tubes.

After several rounds of negotiations, Dr. Hector Martinez purchased another fully automatic paper tube production line in 2018. After almost ten years of hard work, Dr Hector Martinez finally replaced all the paper tube production equipment with automated ones.

If you are interested in tube winding machine or paper tube business, you are welcome to send inquiries on our website, and we will definitely reply to you in time.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Thermal Paper Roll Slitting Packing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine