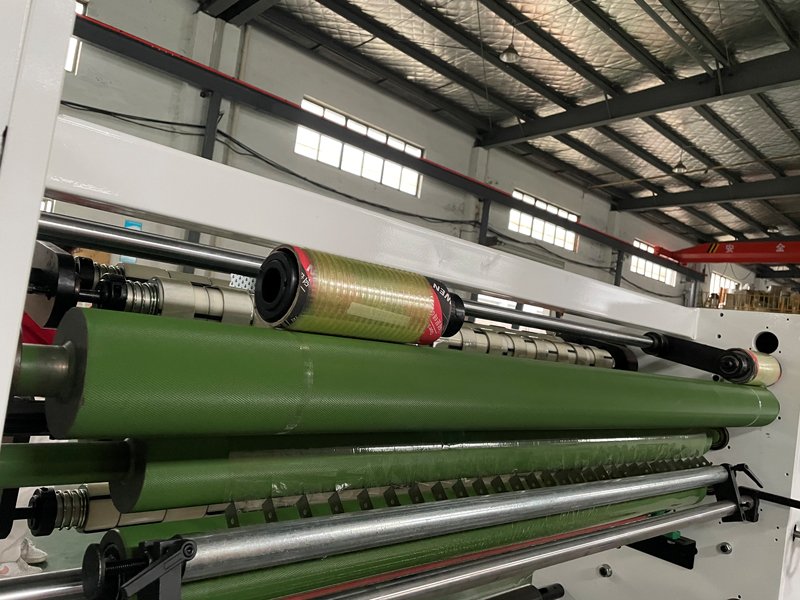

Automatic Adhesive BOPP Tape Slitting Machine

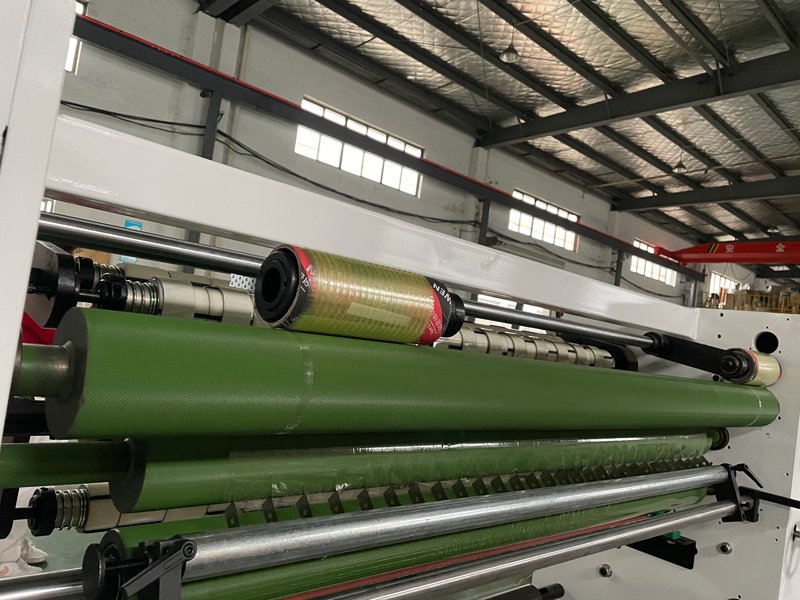

- Roller exchange in manu or auto for alternative

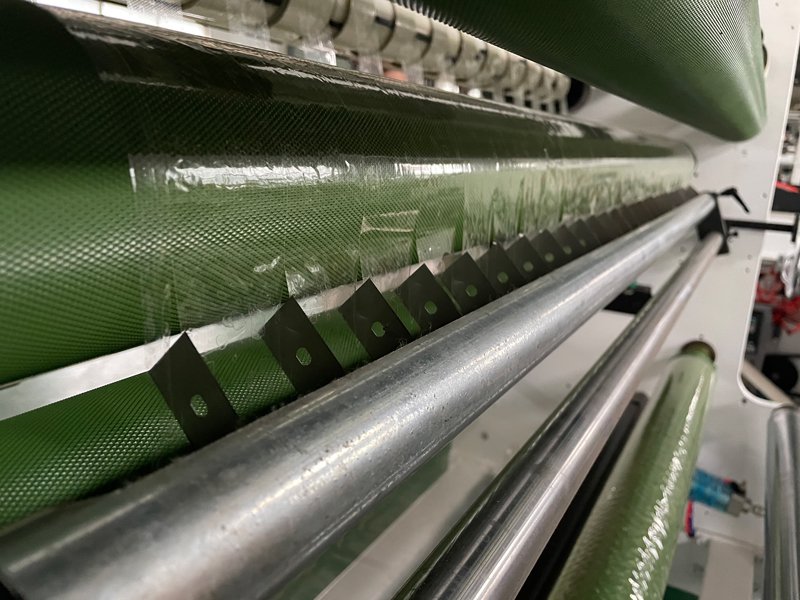

- Razor blade slitting blade

- Two sets of banana roll to avoid any folding.

- Machine equipped with two sets waste trimmer device

- Three Segment meter counter to ensure the length precision.

- Specification

- Video

| Model | JT-202 |

| Description | Automatic BOPP Self Adhesive Tape Slitting Machine |

| Max Unwinding Width | 1650mm |

| Max Unwinding Diameter | 1350mm |

| Slitting Width | 10 – 1500mm |

| Max Rewinding Diameter | 800mm ( 4 Rewinding Shaft For Alternative ) |

| Main Motor | 5HP |

| Voltage | 380V/3 Phase |

| Weight | 1500kg |

| Dimension(MM) | 2400*1800*1450 |

| Feature Of Automatic BOPP Self Adhesive Tape Slitting Machine |

| It Is Specialized In Slitting And Rewinding The BOPP, OPP Adhesive Tapes For Box Sealing. |

| It Adopts The Newest Technology. |

| Three Segment Meter Counter To Ensure The Length Precision. |

| Roller Exchange In Manu Or Auto For Alternative. |

| It Adopts Inverter Motor For The Material Feeding. |

| The Inverter Is From Yaskawa, Japan. |

| It Adopts Imported Electric Appliances For The Stable Function. |

| It Adopts Two Sets Of Banana Roll To Avoid Any Folding. |

Automatic BOPP Self Adhesive Tape Slitting Machine

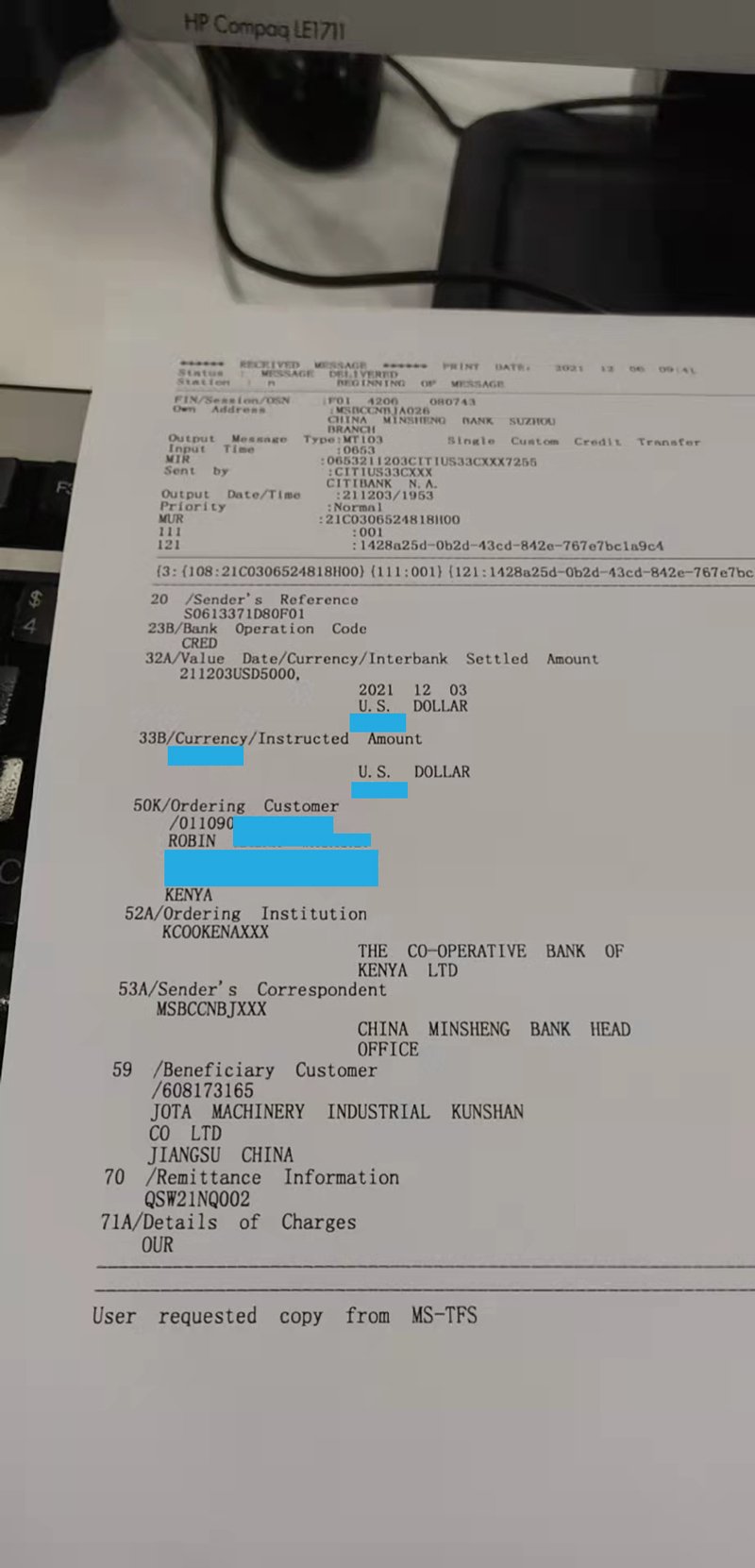

At the end of this year, our sales manager Betty received an inquiry from a Kenyan customer. He wants to buy a machine that can slit kraft paper, plastics film, sealing masking tape, aluminum foil, etc.

Based on our many years of slitting experience, we recommend our multi-functional D-type slitting machine to our customers becuase it can be customized to cut many materials with one device. So we made the first quotation to the customer.

A few days later, we told the customer that if the tape is self-adhesive, another set of equipment is needed. After we sent the video for BOPP self adhesive tape slitting machine, the customer responded that he wanted is this equipment based on the recent market survey. So we made a project book for the BOPP tape production line for the customer: the entire process from paper tube cutting machine, paper core feeding and finally to slitting. After the customer read our project book, we made a second quotation.

After sent the invoice, the customer bought the BOPP production line from us.

Betty got the deal for this set BOPP tape slitting machine

Although it seems simple, there are still many details in the business negotiation that I haven’t written out. If you want to know the story between Kenyan customers and Betty, you can contact us.

Cardboards are immensely used in the paper industries for packaging and carrying our storage and other stuff. The most important thing to seal the cartons is gummed tape. Gummed tape is an adhesive which is used on cartons to pack them so that they don’t open by any means.

Starting a gummed tape slitting rewinding business is extremely beneficial because we don’t see the drop of self adhesive tapes in any time sooner.

Following guide is to help you with your queries. Let’s unravel the qualities and features of a automatic BOPP self adhesive tape slitting machine.

- What is BOPP tape?

- Why should I choose gummed Tape over regular tape?

- What is automatic BOPP self adhesive tape slitting machine?

- What are the benefits of gummed tape?

- How does a BOPP self adhesive tape slitting machine works?

- What are the advantages of BOPP self adhesive tape slitting machine?

- Is my slitter rewinder for gummed tape fully automatic?

- Can I make customizations in the BOPP self adhesive tape slitting machine?

- Can I print with my BOPP self adhesive tape slitting machine?

- What is the price of BOPP self adhesive tape slitting machine?

- Is my slitter rewinder for BOPP tape certified?

- Who is the best manufacturer of BOPP self adhesive tape slitting machine in China?

- Why should I choose jota for BOPP self adhesive tape slitting machine?

What is BOPP tape?

BOPP tape is a type of self adhesive tape that is created from natural materials like paper or potato starch. It features a natural glue adhesive that becomes sticky when moistened, making it completely recyclable.

BOPP self adhesive tape is a heavy-duty, water-activated adhesive that bonds to most corrugated surfaces instantly and produces an industrial grade seal. This can be used for any shipment, big or small, but it’s made for high-volume or industrial shipping. The tape’s fibreglass filament backing provides increased tensile strength, preventing splits and tears.

Simply cut to size, activate the glue on the adhesive side of the paper using a sponge, spray bottle, or rag, and stick to the box. Alternatively, you might utilise a BOPP tape dispenser machine (sold separately).

Why should I choose gummed Tape over regular tape?

There are a number of reasons for why should you choose BOPP tape over regular tape.

- BOPP self adhesive tape is much stronger than normal packing tape and is ideal for sealing cartons.

- It forms a “bond” with your box once sprayed. It makes the entire package stronger and more secure. Better product protection equals fewer damages, lowering the expense of replacing broken or lost items.

- Another big advantage of gummed tape is its resistance to temperature changes. If you need to send or store your packages in humid or frigid circumstances, this is the way to go.

- Tamper-evident BOPP self adhesive tape is a great option. It is impossible to reseal a box after it has been removed, making it clear whether your package has been tampered with.

- Gummed tape-sealed packages appear tidy and professional, reflecting well on both your goods and your brand.

- They’re also simple to print on, making them a terrific low-cost way to promote your business by including a logo or a personalised message in your shipments.

- Gummed tape is 100% recyclable and biodegradable, making it an excellent environmentally friendly alternative to ordinary packing tape.

- To activate gummed tape, you’ll need a tape dispenser that will automatically moisten and cut the tape while delivering the exact amount you require.

- This eliminates unnecessary packaging waste, and a little automation in your packing process will help you pack faster, allowing you to generate more input in less time.

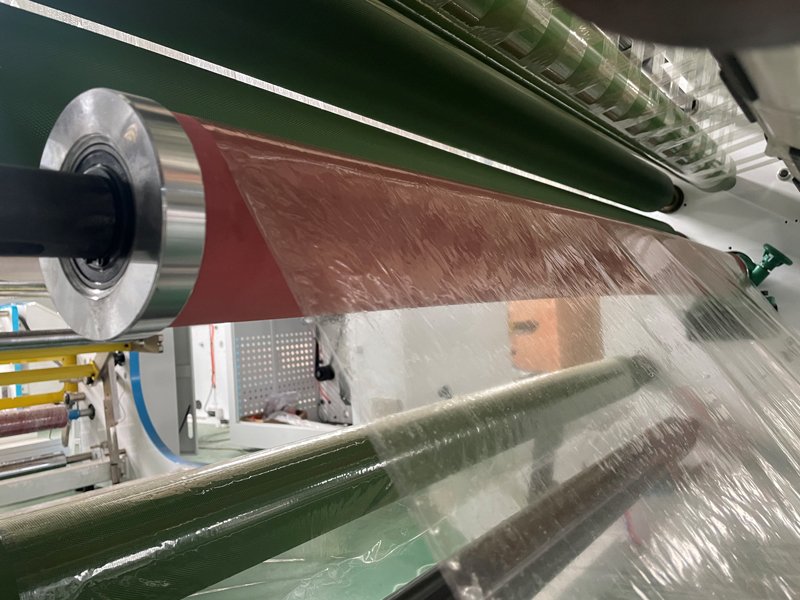

Banana roller for BOPP tape slitting machine

What is automatic BOPP self adhesive tape slitting machine?

As an authentic BOPP self adhesive tape slitting machine manufacturer, Jota Machinery can provide you with a wide range of slitting rewinding machines.

Slitter rewinder machines are widely employed in the material conversion industry to convert a wide range of roll materials.

The following roll materials can be processed using gummed tape slitting rewinder machines:

- Use an adhesive label.

- Textile

- Film or paper

- Nonwoven fabric

- Foil constructed of aluminium

A automatic BOPP self adhesive tape slitting machine is widely used in various industries.

It can produce small finished BOPP self adhesive tape rolls from a large BOPP tape roll.

Furthermore, our automatic knife positioning technology may save you time, and all slitting widths are configurable.

Features

The features of your automatic BOPP self adhesive tape slitting machine are as follows.

- The components of slitter rewinder are a PLC module, an AC drive, several motors, a digital camera sensor, and an automatic tension controller.

- Automatic loading and unloading functions may be included in our BOPP self adhesive tape slitting machine.

- To meet your numerous needs, it also includes a differential friction shaft, rotary encoder metre counter, automatic stop, and automated waste edge cutting.

- Paper cutting and slitting of tape rolls are usually done with circular blades.

- Plastic film rewinding machines, which use razor blades for slitting and rewinding, are known as plastic film rewinding machines.

Jota Machinery can help you choose the right slitting and rewinding machine for your gummed tape width and material.

Figure 1: BOPP Self Adhesive Tape Slitting Machine

What are the benefits of gummed tape?

There are countless benefits of gummed tape. Some of them are as follows.

- The professional, high-quality aesthetic is ideal for high-volume, heavy-duty, or industrial shipping.

- In any weather situations, the waterproof tape backing keeps the box intact.

- It’s simple to unwind from a roll.

- Excellent duct board adhesion.

- Even if the cardboard is low grade, old, or not completely flat, the glue clings to it instantaneously. This eliminates the temptation for packers to add a few extra overlapping strips ‘just in case,’ and tape consumption and packing time are both decreased significantly.

- Recyclable to the fullest extent possible. Bond Tape Green tape is easier to recycle because it is made from renewable natural materials.

- BOPP tape has been certified recyclable by all major packaging research organisations, making it the most ecologically friendly option.

- Unlike normal BOPP tape provides unambiguous evidence if a package’s seal has been tampered with.

- Gummed Tape’s water activated adhesives enter the carton’s fibres, forming a complete bind.

How does a BOPP self adhesive tape slitting machine works?

Slitting machines for self adhesive tape rolls are widely utilised in a range of conversion applications.

One of the most basic cutting and slitting machines is the slitting and rewinding machine. It’s been frequently used in flexible packaging’s slitting process.

The automatic BOPP self adhesive tape slitting machine unwinds the tape roll, slit it with the blades, and then rolls it up by rotating the winding shaft.

Continuous tension must be maintained during the high-speed slitting machine’s operation.

Process of working

- The primary principle is unwinding, slitting, and rewinding.

- Unwinding the mother paper roll, web guide for edge tracking, slitting cutting, and rewinding on a pneumatic air shaft are all included in the machine.

- Place the large mother roll on the unwinding stand to unwind it. A double-layer floor helps to assist this unwinding.

- The portable unwinding stand provides a mobile trip for web guide tracking.

- After passing through the unwinding stand, the paper rolls will come at the slitting devices.

- For diverse material rolls, we provide a choice of cutting procedures. Round disc cutters can cut paper rolls, plastic sheet rolls, electric films, and new energy films, among other materials.

- The razor cutters are motorised, and the lower cutter shaft is active for running. Because of the gear, the upper knife shaft will also be occlusal.

Figure 2: Working of a Gummed tape Slitter rewinder

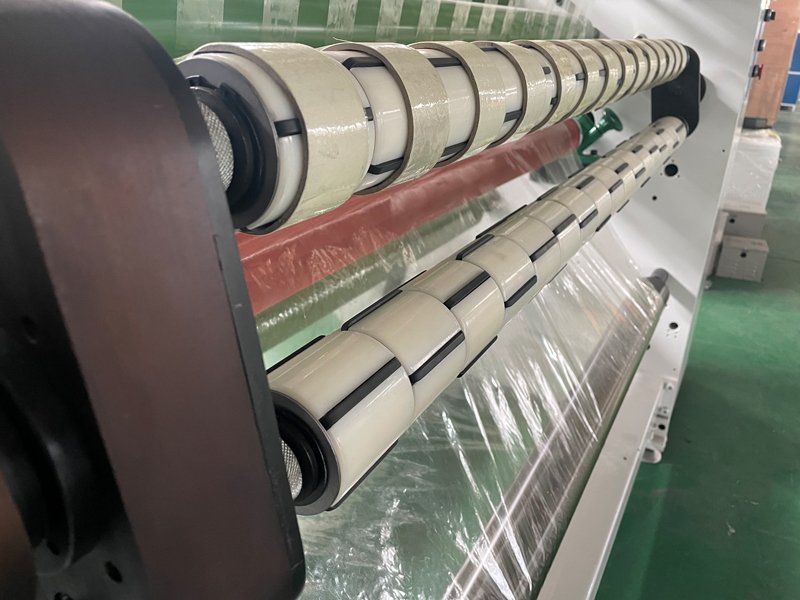

Other Functions

For better understanding, lets read the extra functions of the machine.

- It slits the mother tape rolls into smaller pieces.

- On the other hand, the rewinding function is used to rewind huge mother rolls into small diameter paper rolls.

- The rewinding machine is useful in a variety of situations. It typically rewinds big mother rolls into small tape cores for later use or converts tape rolls to a certain length for subsequent processing.

- The cloth is rewound from the huge roll to the necessary length using a motorised air shaft.

- The electric tapes or sticky tapes are coated with pressure sensitive acrylic, and the centre rewinding process protects the material electric tapes.

- If you’re looking into gummed tape slitting machines, you’ll want to know which cutting knife processes are best and how to keep the tension on your jumbo rolls under control.

- The cloth is rewound from the huge roll to the necessary length using a motorised air shaft.

- The electric tapes or sticky tapes are coated with pressure sensitive acrylic, and the centre rewinding process protects the material electric tapes.

- The other roll is utilised for core loading and roll changing when one of the rollers is in use. It increases output.

- The other way is surface rewinding. A top pressure lay-up roller and two bottom rollers, one of which is motorised.

- Two drum rollers are located on the bottom, while a pressure roller is located on the top. It generates a tight loop that can be used to rewind the paper.

- Our specialist uses two different types of bottom drum rollers: a steel drum roller and a rubber friction roller.

Waste Trimmer device

If you don’t make a decision, someone else will.

Please contact our specialist sales team to send several jumbo roll samples so that we may do a test for you and learn more about the material’s properties so that we can recommend slitting machines.

What are the advantages of BOPP self adhesive tape slitting machine?

There are plenty of advantages of using Jota’s gummed tape slitter rewinder.

- It is cost-effective

- Save electricity

- Produces no waste

- It is noiseless

- Can print and slit at the same time

- Advanced technology and software

- Touchable control screen

- Servo system

- Works for 48 hours straight

- Has 2 years warranty

Thus, all the advantages at one place can help you take your business to another level. Contact us for any queries. We will assist you in your problems.

Is my slitter rewinder for gummed tape fully automatic?

The BOPP self adhesive tape slitting machine is completely automated, from unwinding to winding divisions.

An unwind stand is used to load and secure the parent roll of paper during the unwinding stage. The platform holds the roll in place while allowing it to rotate around its central axis.

The Jota BOPP self adhesive tape slitting machine also comes with a shaftless unwind stand.

The shaftless unwind stand does away with the necessity to thread the unwinding shaft into the jumbo roll. As a result, the time it takes to get started is reduced.

Our BOPP self adhesive tape slitting machine comes with a hydraulic automatic jumbo roll loading system.

It’s an important part of the BOPP self adhesive tape slitting machine.

This is because not having to pay additional operators to load the large paper rolls will save you money.

Figure 3: Fully Automatic Gummed Tape Slitter Rewinder

Can I make customizations in the BOPP self adhesive tape slitting machine?

Customization is what makes your customers want to do business with you. That is why jota offers customised services so that you can get the gummed tape slitting rewinding machine of your dreams.

You can discuss the type of design and features you want in your machine with our service providers, and we will deliver it to your door.

Can I print with my BOPP self adhesive tape slitting machine?

Yes, you may print on cello tape using the stacking tape printing equipment.

The machine was designed to be capable of both printing and slitting.

Because kraft paper possesses printing properties, it can be used for printing.

One side of the bopp tape is glued and cannot be printed, but the other side is not glued and can be printed.

Up to eight different colours can be printed on our stacking tape printing equipment.

Printing is usually done with a printing plate. This allows you to design and print on your gummed tape in a variety of ways.

The water-activated tape slitting machine prints your company’s logo or a customer’s name directly on the surface of the kraft paper tape.

As a result, the aesthetics of the self adhesive tape have enhanced. It can also be used as a marketing tool for your company.

Figure 4: BOPP tape Printing with Slitter Rewinder

What is the price of BOPP self adhesive tape slitting machine?

Slitting equipment costs vary greatly depending on the type of material, tape roll width, unwinding, and winding diameter.

Slitting machines designed for glass fiber and carbon fiber prepreg can cost more than $100,000. The printing slitting machine with a 320mm width costs only a few thousand dollars.

To better assess the price of your preferred slitting machines, please provide us with the following information: material type, gummed tape roll width, diameter, needed slit width, and winding diameter.

We will suggest the best model for you.

Is my slitter rewinder for BOPP tape certified?

Yes, your slitter rewinder for bopp self adhesive tape is certified. We are legally certified to expand our business around the world with our certified machines. Our brand is of international worth. Don’t fear to order at Jota because we respect our customer and provide quality content.

Figure 5: Certified Slitter Rewinder for Gummed Tape

Who is the best manufacturer of BOPP self adhesive tape slitting machine in China?

Manufacturers of self adhesive bopp tape slitting machines can be found all over the world. These European and American companies manufacture high-quality cutting and slitting machines, but they are not cheap.

If your budget allows, one of the above-mentioned vendors can provide you with your desired BOPP self adhesive tape slitting machine

Our Chinese manufacturer’s slitting rewinder machine is a suitable solution if your budget is limited.

Many Chinese suppliers are now pursuing a high-quality development path, and machine quality is becoming increasingly important to them.

When the benefits of China’s entire industry chain are combined, high-quality and competitive costs can be organically integrated.

One of these providers is Jota Machinery.

You can reach out to us for help by phoning, emailing, or submitting a question through this website.

Figure 6: Jota Machinery- the best manufacturer in China

Why should I choose jota for BOPP self adhesive tape slitting machine?

People trust accredited organization; Jota machinery’s employees works around the clock to stay ahead of the competition. As a result, Jota became a globally recognised company.

Jota equipment is a CE-certified manufacturer, and all of its products have been tested and shown to be safe to use. You are welcome to come to the company’s working site and inspect the products for yourself.

Our skilled engineers also offer complimentary videos and testimonials to help you better understand the machinery you’re about to purchase.

You can contact us through our website if you have any questions. We will be available to help you whenever you require it.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine