Automatic Cash Register Till Roll Core Hopper Machine

- Start and stop are controlled by sensors.

- Simple operation and will not damage the plastic tube.

- The main body adopts European standard aluminum profile, beautiful appearance.

- Low noise, in line with industry standards

- Specification

- Video

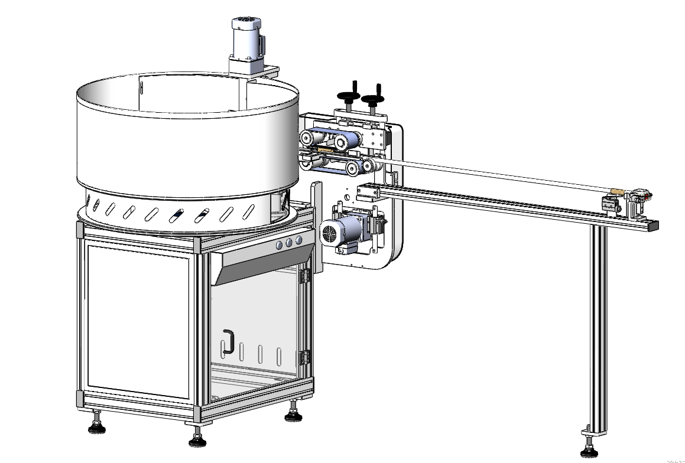

| Name | Automatic Cash Register Till Roll Core Hopper Machine |

| Function | Auto Load The Paper Core, Plastics Core to Rewinding Shaft |

| Min. Inner Core Diameter | 12mm |

| Max Inner Core Diameter | 24mm |

| Working Speed | 15 Times/Min |

| Size | 800*2000*1200mm |

| Voltage | 0.4Kw |

| Weight | 350 KGS |

| Feature |

| 1. The Latest Fully Automatic Core Loading System In The Industry, Combined With The Practical Experience Of Customer Feedback, We Made More Optimizations In Details. |

| 2. The Main Body Is Made Of European Standard Aluminum Profile, Which Is More Compact, Convenient and Beautiful In Appearance. |

| 3. The Stirring Motor At The Bottom Transmits Power To The Sorting Tray Through The Addition Of A Plum Blossom Coupling, Which Reduces Vibration Compared With Before, Reduces The Direct Strength Acting On The Tube Core, And Avoids Breaking The Tube Core. The Tube Jam Is Avoided, The Whole Movement Is Smooth, Silent And Efficient, And The Material Handling Tray Is Clean And Dust-Free. |

| 4. The Adjustment Is Simpler And More Flexible To Match A Variety Of Specifications Of Die. |

| 5. By Adjusting The Speed Ratio Between The Tube Core Conveying Motor And The Gear, The Conveying Speed Is Improved. |

| 6. It Is Connected To The Cutting Host Computer, And The Whole Process Is Controlled By PLC. |

Automatic Cash Register Till Roll Core Hopper Machine

Last Update Time:27/03/2022

When we’re starting doing thermal paper slitting machine business, we load the paper core to rewinding shaft manually.

Till now, we have developed automatic cash register till roll core hopper machine instead of manual operation.

- 1st version is manual load

- 2nd vibration paper core loading machine

- 3rd centrifugal force controlled paper core hopper

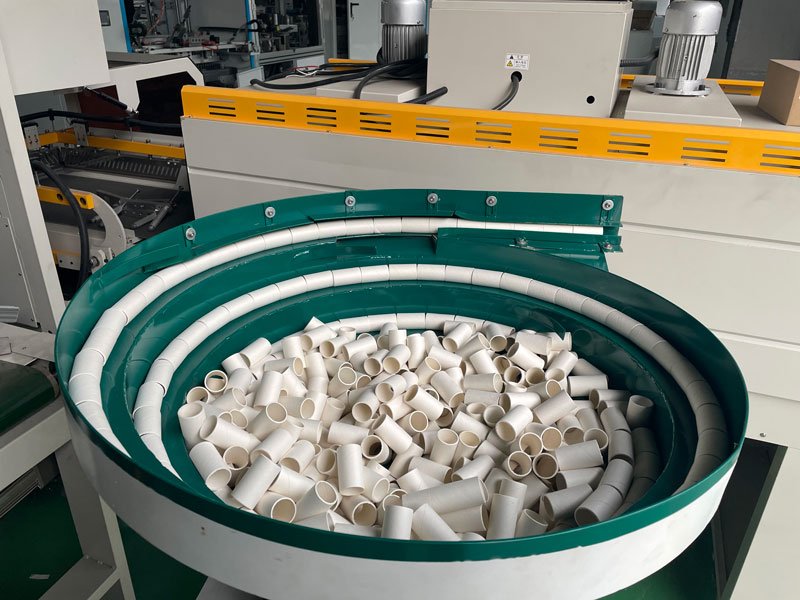

Paper core and plastics core for cash register till roll

1st version manual loading:

We put the plastic tube in a container. When we operate the thermal paper slitting machine, we have to pick up the plastic tube and thread it to the rewinding shaft one by one. Although this is relatively convenient, whether there is an automatic type to replace the current manual mode? This is not only faster but also without manual operation

When we communicated with the design engineer, he agreed with us, so after our testing and debugging, our 2nd version vibrating cash register till roll core hopper machine was born.

2nd version manual loading:

Vibration paper core loading machine

The inside of the paper core loading machine is spiral. When the core hopper machine is started, the hopper will vibrate and the plastics tubes will be sent along the channel to the reel one by one.

The entire operation is partially automated, but the core problem we found in the course of use is that it is very noisy, and sometimes there are even stuck tubes. During our debugging process, the engineer put forward the following suggestions to us.

• Stuck paper tubes or plastics core

The plastic pipe is transported in the automatic cash register till roll core hopper machine as if we were driving on the road. Once the car in front stopped, due to the need to obey the traffic rules, he could only rest assured to wait for the road ahead to be clear before continuing on. Because the internal design of the core hopper machine is spiral, once the front plastic tube or paper tube is stuck, the next tube will be stuck too.

• Too noisy

The sound produced by the paper tube loading machine during the automatic pipe threading process is very loud, which seriously affects the experience. If we sell this core hopper machine, the impression score will decrease

We give this feedback of the debugging results to the design engineer, after online demonstration, production and debugging finally gave birth to our paper core loading machine controlled by centrifugal force.

3rd centrifugal force controlled paper core hopper

Automatic Cash Register Till Roll Core Hopper Machine

When we put the rewinding shaft on the feed rod, the bottom of the rewinding shaft will touch the sensor, so that the plastic tube rotates in the hopper due to the curved design inside, the plastic tube or paper tube will be smoothly transported out. Then one by one, it is automatically threaded to the rewinding shaft in an orderly manner. This is the principle of the paper pipe loading machine after the revision.

Compared with the traditional plastics core loading machine, we have made improvements in the following aspects:

• The new fully automatic paper core loading system

Combining the practical experience of customer feedback, we have made more optimizations in the details, such as: the stuck pipe phenomenon of the traditional pipe machine. By changing the sheet metal parts in the material tray to machined parts, it is easier to adjust. Add a certain radian to the angle to make the die delivery smoother.

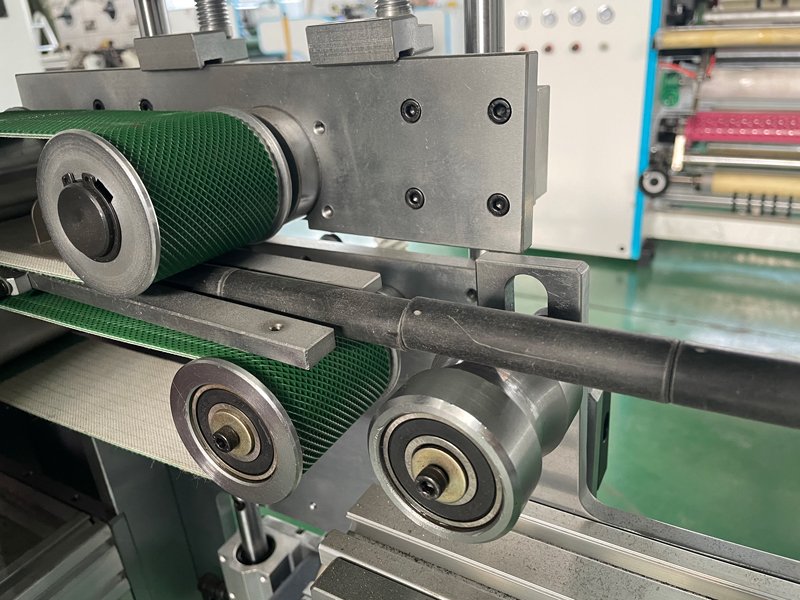

• On the transmission system

The stirring motor at the bottom transmits power to the sorting tray by adding a plum blossom coupling, which reduces vibration compared with before, reduces the direct strength acting on the tube core, and avoids breaking the tube core, thereby avoiding Stuck tube. The pressure tube belt adopts a mesh belt to increase friction.

• In terms of speed

By adjusting the speed ratio between the paper core conveying motor and the gear, the conveying speed is increased.

• Operation

It is connected to the slitting rewinding machine and controlled automatically. The adjustment is also simpler and more flexible to match a variety of specifications of paper tube, paper core or plastics core.

• Appearance

The main body of the cash register till roll core hopper machine is made of European standard aluminum profile, which has a more compact structure and a beautiful appearance; the sheet metal adopts a chrome plating design to prevent rust; the shape of the hopper is made of 304 stainless steel.

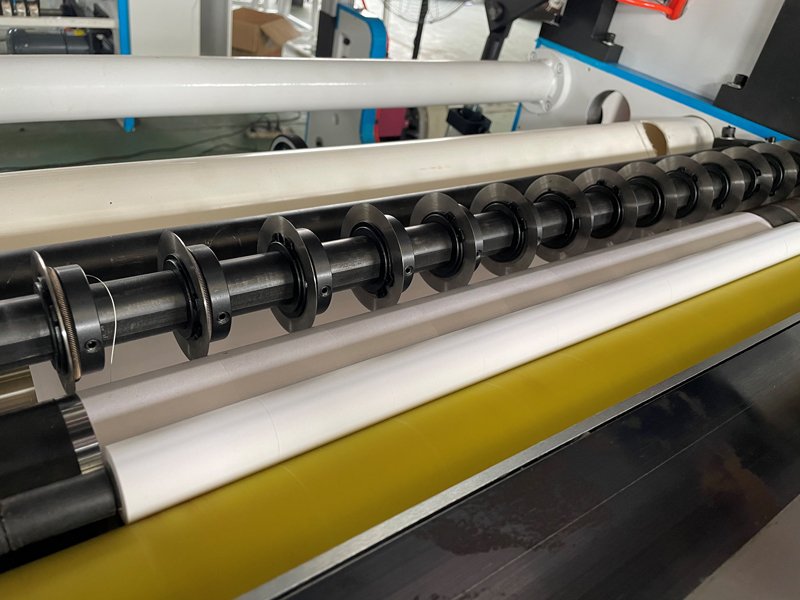

Plastics core in rewinding shaft

• Land occupation

With a smaller footprint, it can be matched with our fully automatic thermal paper slitting machine, semi-automatic thermal paper slitting machine, 900mm thermal paper slitting machine and other slitting machines to achieve fully automatic control.

Jota Machinery Industrial (Kunshan) Co.,Ltd has always adhered to the rigorous working style and the concept of providing customers with high-quality equipment. Even for small things, we will repeat the operation test, feedback and improve the three processes. If you want to do thermal paper business, please contact our sales, we will serve you wholeheartedly.

FAQ about automatic cash register till roll core hopper machine

- What’s the function of auto core hopper?

- How does core hopper work?

- How does the device stop automatically after threading the plastics core?

- How much space do I need to place the machine?

- Is this is necessary parts for themal paper slitting rewinding machine?

- Is there any thermal paper slitting rewinding machine with core hooper?

- What’s the configuration of core hopper?

- What’s the voltage of core hopper?

What’s the function of auto core hopper?

When you use finished small rolls then you will see there is inner plastics core in the small cash register till rolls, but do you know how to got this ? If you operated the thermal paper slitting machine then you will know the principle. We can manual load the inner plastic core to the rewinding shaft while you can also use our core hooper to help you threading the inner plastic core to shaft.

This device can help you save the manual loading core.We recommend you equiped one device for cutting thermal paper roll.

How does core hopper work?

Firtly put the plastic core to the hopper , secondly put the rewinding shaft to loading section when touch the sensor in the ending the core hopper will auto starting and the core will come out from the path in the core hooper , finally you will get a rewinding shaft wearing the core.

How does the device stop automatically after threading the plastics core?

Two sets of sensor

There are two sensors .

The sensor at the front controls the stop operation of the inner plastics core threading, and the sensor at the rear controls the start procedure of the core hooper.

When the plastic tube touches the front sensor, he will know the loading will be going end then the sensor will automatically stop. When the rewinding shaft touches the rear sensor, the core hopper loading machine will start.

How much space do I need to place the automatic cash register till roll core hopper machine?

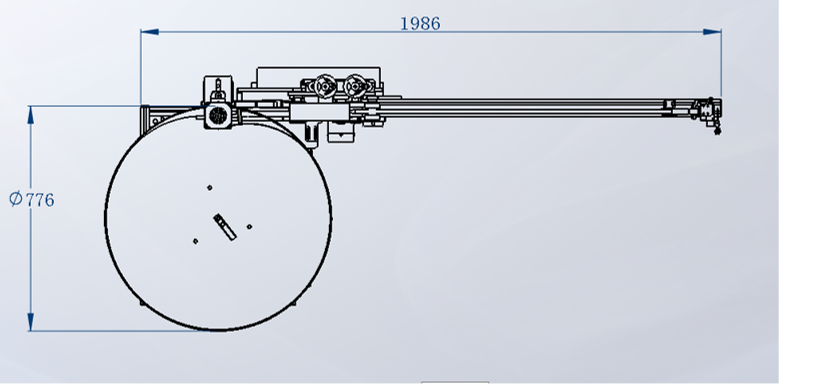

The length of the automatic cash register till roll core hopper machine is 1986 mm and diameter of core bowl is 776 mm . Automatic cash register till roll core hopper machine often sell with cash register paper roll slitting machine .

If you want to know more details to contact with our sales manager.

Is this is necessary parts for themal paper slitting rewinding machine?

Automatic cash register till roll core hopper machine is not the essential device, but we recommend you purchase one to increase the output.

Is there any thermal paper slitting rewinding machine with core hooper?

Our fully automatic thermal paper slitting machine , semi-automatic cash register till roll production line equipped with core hooper. Our JT-SLT-900 thermal paper slitting rewinding machine also can do this type. We recommend you send us an inquiry about the thermal paper business.

What’s the configuration of core hopper?

Our company adopts famous brand parts for machine including electric switcher, cylinder, bearing, PLC, HMI , linear guideway etc. Not matter small device we also adopts famous brand.

- The pneumatic components is SMC/Taiwan AirTac

- The sensor is Omron

- The linear guide way is Taiwan Hiwin

What’s the voltage of automatic cash register till roll core hopper machine?

The industrial voltage is 380V, you can provide us the voltage in your country and we support customize the voltage. Contact us for more details

We Jota could also manufacture the following related machines, if you are also interested in any type, please feel free to send us an inquiry.

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine