Your Ideal Slitting Rewinding Machine Manufacturer

- Professional sales, engineer team

- 7*24h Service

- Online video call support

- Has assisted many customers in solving problems

Your ideal paper slitting rewinding supplier

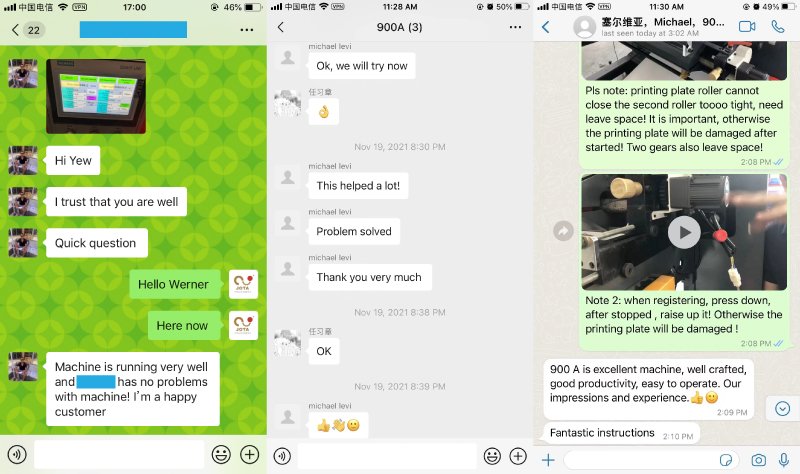

When we followed up with customers, we found that many customers are entering this industry for the first time, so not only are they a little rusty in purchasing, but also in some aspects of machine operation.

As our CTO Jimmy said in previous videos: When he was helping a customer to debug a machine, he met an African customer. He only knew that the equipment he purchased could help him produce what he needed, but he didn’t know how to operate and what was needed. Which raw materials and so on. So we help customers buy raw materials from scratch, teach customers how to open the machine, adjust the machine and so on.

At present, due to the epidemic, we can only provide online video debugging. After the epidemic, we can also arrange for engineers to provide on-site service.

So far we have assisted many customers to successfully operate the machine and join the production.

Welcome to Jota Machinery

Jota Machinery (Kunshan) Co., Ltd founded in 2002 and located in the beautiful city of Kunshan. As Kunshan City relates to Shanghai City and Suzhou City, the traffic is very convenient.

As a professional manufacturer of slitting rewinding machines, Jota Machinery has integrated and adopted Taiwan’s advanced design and technology based on years of professional experience and technology accumulation in the slitting and rewinder industry and selected high-quality brand electrical and pneumatic control components as the basic The configuration ensures the quality and first-class operation performance to make the product perfect day by day. Our company can provide customers with complete and timely installation and commissioning, operation training and after-sales service.

All machines are processed in accordance with CE standards, and the packaging uses export standard wooden boxes to ensure the highest quality. Welcome your inquiry and looking forward to establishing long term cooperation relationship with you.

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

At present, due to the epidemic, we can only provide online online debugging services for the time being. After the epidemic, we can arrange professional engineers to debug the machines in your company.

- Your technical team is necessary

- Clarify the problems encountered during the operation of your equipment

- Listen to the opinions of our engineers and follow our suggestions

Thermal Paper Slitter Frequently Troubleshooting and Solution

What do you need to do when you buy the machine from us? Are you overwhelmed by electricity and buying raw materials?

Jota Machinery has been committed to serving customers well at every stage from pre-sale, during-sale to after-sale. For this reason, we have opened this section to teach you how to solve the thermal paper slitter frequently troubleshooting and solution.

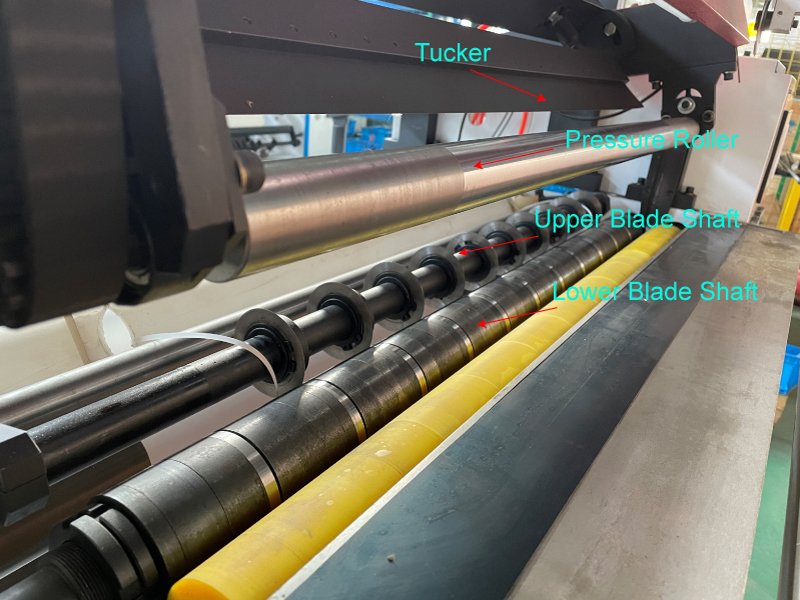

Let us know the structure of our machine firstly:

We will provide relevant operation videos for our different devices to facilitate your learning. If you don’t know how to do it after watching these videos, you can contact our sales team.

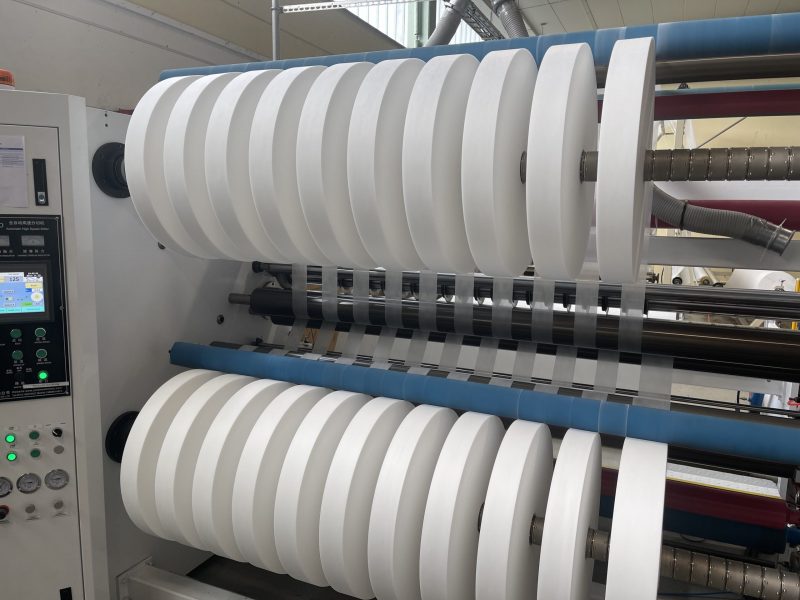

Thermal paper slitting rewinding machine

- How to load the jumbo roll to the unwinding stand?

- How to adjust the slitting width of our slitting machine?

- How to adjust the language of the constant tension controller?

- How to use a constant tension controller?

- How to check the horizontal of the machine?

- How to solve rewinding is too loose issue?

- How to solve tower shape rewinding?

- How to adjust pressure roller?

- How to use the heat shrink film packing machine?

- How to connect the machine to the air compressor?

- How to set parameters?

- How to install an ink wheel?

- How to feed the paper to each roller?

- How to fill the air to expanding shaft?

How to load the jumbo roll to the unwinding stand?

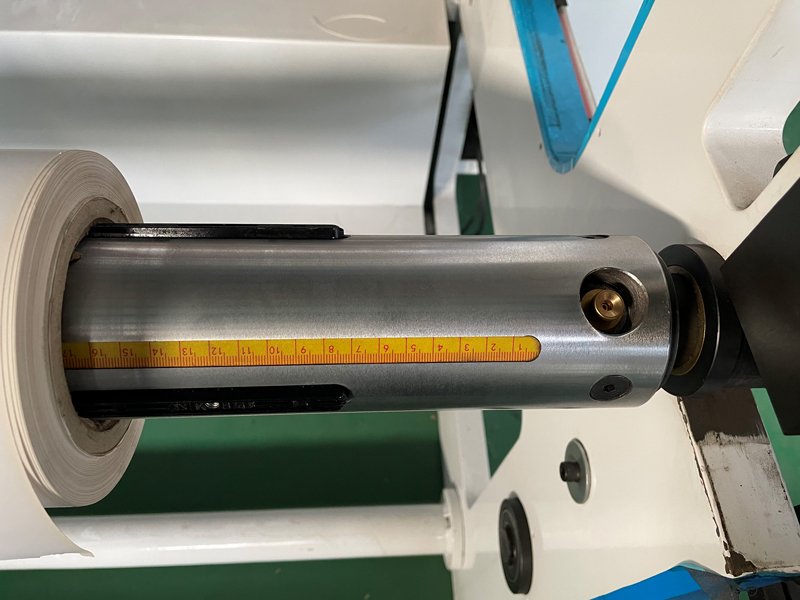

Our machine basically uses a 3-inch air shaft, and the other 6-inch shaft is also optional. If the inner diameter of your material paper tube is of special specifications, then you need to buy a mold to fit it.

Operation steps for loading

- Take off the 3-inch air expanding shaft from the machine

- Thread the air expanding shaft into the paper tube

- Push the parent roll onto the unwinding stand

- Lift the jumbo roll via remote controller

- Lock the air shaft

- Inflate the air shaft

You can review the below operation video about loading jumbo roll to unwinding stand

Chain lift loading

- Thread the air-expanding shaft to jumbo roll.

- Move the jumbo roll the hooker

- Press Up bottom to load the jumbo roll

- Fill the air to expanding shaft(No standard order, you can also fill it after threading the shaft to jumbo roll)

- Press Shaft Lock bottom to lock the air expanding shaft

step of loading jumbo roll:

- Load the air expanding shaft to the paper core

- Load the jumbo roll to the unwinding stand

- Press up the bottom to lift the jumbo roll

- Lock the shaft

- Fill the air to expanding shaft

How to adjust the slitting width of our slitting machine?

When you adjust the slitting width you need to adjust the lower slitting blade firstly then change the slitting width of the upper slitting blade.

- Install 56mm and 79mm slitting width

- Adjust upper blade

Usually, we can help you pre-install the default slitting width of our slitting machine. We can provide the related spacer for you to install another slitting width. If you don’t know how to install the slitting width then check this.

The thickness of our lower blade is 10mm thickness then 56mm is 2 pcs 20mm spacer,1 pcs 6mm spacer and 1 pcs lower blade. 40mm+6mm+10mm =56mm

The install method of 79mm is 2 pcs 20mm spacer,1 pcs 7mm spacer, 2 pcs 6mm spacer ,1 pcs 10mm spcacer, 1 pcs 10mm lower slitting blade. 40mm+7mm+12mm+10mm+10mm=79mm

Adjustment for upper blade: when you finished adjusting the lower slitting blade then you also need to change the upper blade to the same slitting width. There is a screw in the upper blade after releasing it then you can adjust.

Screw size: M6

If you still feel confused then review this video

How to adjust the language of the constant tension controller?

Tension control is the essential part for the machine tension controller of JT-SLT-900 is built-in PLC, our C type machine i.e JT-SLT-1400C, JT-SLT-1400C have each independent controller, you should adjust the tension on it.

Normally we will set the default language as English, if received the machine is not English then follow the below instruction to change the language

- Click the Enter bottom

- The password for language is 508. Click the + in adjust bottom then click Enter bottom

- Press adjust the bottom and choose C03, choose English then press Enter bottom

- The language will change to English

Following this step, you can also change the language back to Chinese.

How to use a constant tension controller?

Usually, we will provide a user manual. If you want to adjust the tension controller, please read this manual first, if you don’t understand anything, you can contact our sales engineer.

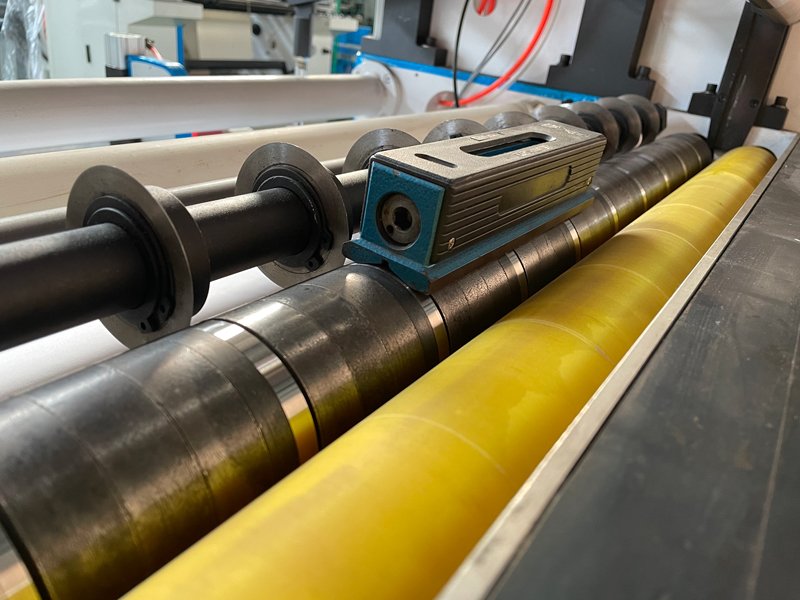

How to check the horizontal of the machine?

If you want to check the horizontal of the machine then you need to have one levels instrument. You only need to check the horizontal lower blade shaft and pressure roller then make some proper adjustments.

Lower blade shaft

Pressure roller

How to solve rewinding is too loose issue?

There is one function on the machine called Drift Meter, you can adjust the pressure via this bottom. There is no standard recommended pressure, how much you need to adjust is based on the current rewinding effect. We suggest you consult with us then make changes after our guide.

How to solve tower shape rewinding?

The solution for this issue is still Drift Meter. The proper pressure is based on the current effect. Kindly share the rewinding effect with our sales manager then we will give you proper pressure. Follow our steps one by one then you will get good rewinding.

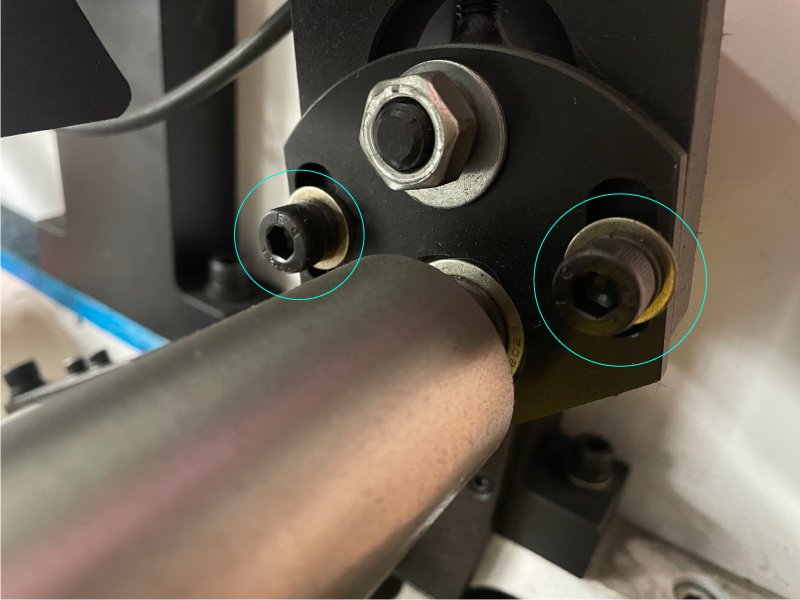

How to adjust pressure roller?

If the pressure roller is not at a horizontal level you should adjust it. Remember ONLY adjust the right side!

Only release the two screws marked in the circle then adjust the wheel scale. Rotate the roller clockwise to go up, and rotate the roller counterclockwise to go down

How to use the heat shrink film packing machine?

Usually, we will provide you the operation manual for this set machine, below is the normal operation video for this machine.

How to connect the machine to the air compressor?

Connect the air filter regulator with your air compressor.

How to set parameters?

When the slitting machine has been sent out all the parameters debug done already if you only cut the thermal paper then don’t need to adjust it. If you want to cut other material then contact our sales to set the parameter.

How to install an ink wheel?

The function of ink wheel is to notify your raw material will run out. If will auto marks the red line based on the parameter you set. The tool you need is one set wrench.

Follow below to install the ink wheel. If you can’t use ink wheel correctly then contact your sales manager.

How to feed the paper to each roller?

How to fill the air to expanding shaft?

There is a mouth on the air expanding shaft, fill the air to the mouth after shaft be threaded to the jumbo roll