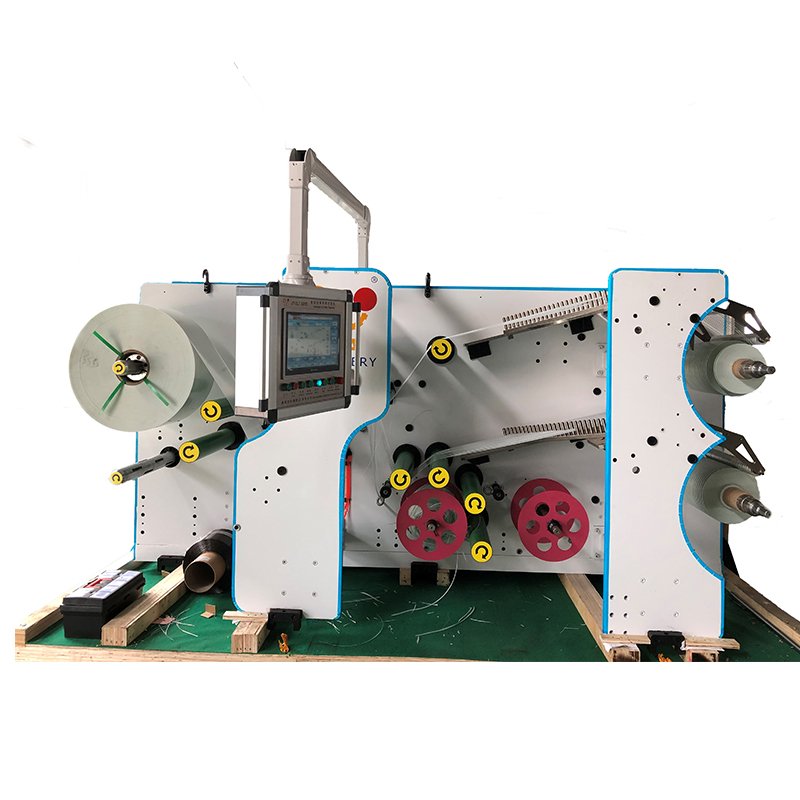

CFRP Fiber Reinforced Phenolic Prepreg Machine

- Resin:Phenolic or Epoxy Resin Solution

- Prepreg Machine Width : 1270mm

- Fabric : Less Than 400GSM

- Resin Content : ±3%

- Production Speed:0-3m/min

Jota CFRP CFRTP Hot Melt Prepreg Machine

Our Jota CFRP CFRTP prepreg manufacturing machines are ideal machines for CFRP CFRTP prepreg production.

CFRP and CFRTP prepregs are essential raw materials for the production of high-performance carbon fiber and glass fiber composite materials.

If you are looking for prepreg machines, please send us an inquiry on this website.

CFRP CFRTP Prepreg Conversation

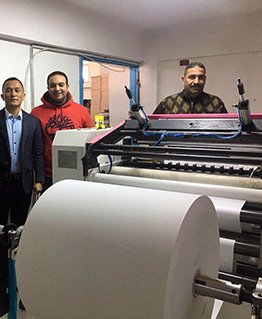

Jota Machinery: Your Reliable CFRTP CFRP Prepreg Machine Manufacturer in China

Jota is the original CFRTP CFRP prepreg machine manufacturer here in China.

With our own factory and CNC center, equipment quality could be effectively guaranteed.

Please send us an inquiry to make a WhatsApp video call, let’s show you our real-time factory and CNC center.

Jota CNC Center

Machining Material

- Visible high-quality components.

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi.

- Self-supporting CNC processed sheet metal, precision parts.

- Assembly raw materials provided by long-term cooperation suppliers.

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Focus Factory

- Dear Customer

- Professional Team

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

CFRP Fiber Reinforced Phenolic Resin Prepreg Manufacturing Process

Fiber reinforced composites have brought about a revolution in industries such as aerospace, automotive, and construction, thanks to their exceptional strength, durability, and lightweight properties.

Phenolic resin, derived from the reaction between phenol and formaldehyde, has emerged as a versatile and high-performance option for manufacturing these composites.

When combined with reinforcing fibers, phenolic resin creates a composite material known as fiber reinforced phenolic resin prepreg.

Jota Machinery will examine and investigate the application of phenol formaldehyde resin and epoxy resin in the prepreg machine, with a specific emphasis on fabrics weighing less than 400gsm.

It delves into the advantages and applications of fiber reinforced phenolic resin prepreg, highlighting its unique properties and the advancements in prepreg machine technology that have improved efficiency, quality control, and energy efficiency.

Impregnation Method and Prepreg Machine Specifications:

The impregnation process of fiber reinforced composites heavily relies on the choice of resin solution.

Commonly used options are phenol formaldehyde resin solution and epoxy resin solution, each offering specific properties.

Phenol formaldehyde resin solution provides excellent thermal stability and fire resistance, while epoxy resin solution offers superior mechanical properties such as high strength and toughness.

The selection of the resin solution depends on the desired characteristics of the final composite product.

The prepreg machine designed for fabrics weighing less than 400gsm features a width of 1270mm.

The machine ensures consistent quality throughout the production process by maintaining the resin content in the fabric within a tight tolerance of ±3%.

Additionally, it offers adjustable production speeds ranging from 0 to 6 meters per minute, providing flexibility to meet project requirements.

Phenolic Resin Prepreg Impregnation and Drying Process

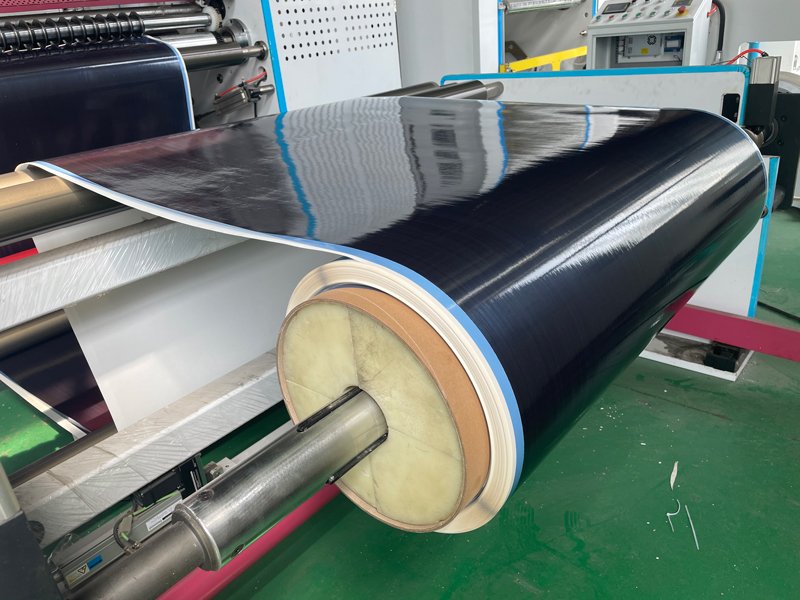

The prepreg machine utilizes a meticulous impregnation method that evenly applies the resin to the fabric.

The fabric undergoes a precise sequence of rollers and guides to ensure thorough impregnation while removing excess resin.

Subsequently, the impregnated fabric enters a controlled drying oven where the solvent evaporates, leaving behind a cured and consolidated resin matrix.

This highly controlled process ensures uniform distribution of the resin within the fabric, resulting in high-quality prepreg material.

Advancements in Prepreg Machines:

Continuous advancements in prepreg machine technology have significantly improved efficiency and productivity in the manufacturing process.

Notable advancements include:

Automated Control Systems

Modern prepreg machines are equipped with advanced control systems that provide precise control over critical parameters such as resin flow rate, impregnation pressure, and drying temperature.

This automation reduces human error, improves process repeatability, and ensures consistent quality throughout production.

Quick Changeover

Prepreg machines now feature quick changeover capabilities, facilitating seamless transitions between different fabric weights and resin solutions.

This enhanced flexibility enhances production efficiency and enables the machine to cater to diverse customer demands.

Energy Efficiency

Prepreg machines incorporate energy-saving features such as improved insulation, optimized heating elements, and efficient exhaust systems.

These advancements contribute to reduced operating costs and minimize the environmental impact of the manufacturing process.

Quality Assurance Systems

In-line monitoring systems are integrated into prepreg machines to detect defects such as resin voids or dry spots during the impregnation and drying processes.

Real-time monitoring ensures consistent quality control and enables timely corrective actions, resulting in high-quality prepreg material.

Advantages and Applications of Fiber Reinforced Phenolic Resin Prepreg

Fiber reinforced phenolic resin prepreg offers several advantages that make it highly suitable for various industries:

Thermal Stability

Phenolic resin provides excellent resistance to high temperatures, making fiber reinforced phenolic resin prepreg ideal for demanding thermal environments, such as aerospace engine components or high-temperature industrial applications.

Fire Resistance

Phenolic resin is inherently fire retardant, making fiber reinforced phenolic resin prepreg an exceptional choice for applications that require high fire resistance, such as aircraft interiors, transportation vehicles, and fire-resistant building materials.

Chemical Resistance

Phenolic resin demonstrates excellent resistance to a wide range of chemicals, making fiber reinforced phenolic resin prepreg suitable for applications exposed to aggressive chemical environments, such as chemical storage tanks, pipes, and protective linings.

Mechanical Performance

Fiber reinforced phenolic resin prepreg offers high mechanical performance when combined with reinforcing fibers. It exhibits exceptional strength, stiffness, and impact resistance, making it suitable for structural components in aerospace, automotive, and sporting goods industries.

Applications of Fiber Reinforced Phenolic Resin Prepreg

Fiber reinforced phenolic resin prepreg finds extensive applications across industries:

Aerospace: It is widely used in aircraft interiors, structural components, engine parts, and thermal protection systems due to its fire resistance, lightweight properties, and thermal stability.

Automotive: Fiber reinforced phenolic resin prepreg is utilized in engine parts, brake pads, and lightweight body panels, contributing to improved vehicle performance, safety, and weight reduction.

Construction: It finds applications in building panels, cladding, and fire-resistant doors, providing enhanced fire resistance, durability, and ease of fabrication.

Industrial: Phenolic resin prepreg is employed in chemical storage tanks, pipes, and corrosion-resistant equipment due to its chemical resistance and ability to withstand high temperatures.

Conclusion:

Fiber reinforced phenolic resin prepreg, resulting from the combination of phenolic resin and reinforcing fibers, represents a versatile and high-performance composite material.

It offers advantages such as thermal stability, fire resistance, chemical resistance, and excellent mechanical performance, making it invaluable across industries.

Continuous advancements in prepreg machine technology have played a significant role in enhancing efficiency, quality control, and energy efficiency, thereby driving the wider adoption of fiber reinforced phenolic resin prepreg in various applications.

As technology continues to advance, this composite material is poised to play an increasingly significant role in creating innovative and sustainable solutions for complex engineering challenges.

For further inquiries or to obtain additional information about the solution impregnation prepreg machine, please do not hesitate to contact us.