JT-PB-610 Fully Automatic Paper Shopping Bag Making Machine With Handle

- One-Stop Paper Carry Bag Making Machine Supplier

- Square Bottom Paper Shopping Bag Making Machine

- V-type Food Snack Paper Bag Making Machine

- Paper Bag with Puncher, Flat Handle, Twist Handle are available

- All sizes of paper bags are available on our machine.

- Specification

- Video

PARAMETERS

Parameter | |

Unwinding Width | 510/610-1230mm |

Jumbo Roll Diameter | Φ 3’ (76mm) |

Max Unwinding Diameter | Φ 1500mm |

Paer Thickness | 80-140gsm |

Paper Bag Width | 200-400mm (With Handle) |

150-400 (Without Handle) | |

Paper Tube Length | 280-550mm (With Handle) |

280-600mm (Without Handle) | |

Bottom Width Of Paper Bag | 90-200mm |

Machine Speed | 150pcs/Min |

Total Power | 34kw |

Machine Weight | 18000kgs (40HQ*1) |

Machine Dimensions (L*W*H) | 15000 * 6000 * 2500mm |

Flat Handle Rope Height | 100mm |

Handle Patch Width | 45-50mm |

Handle Patch Length | 152mm |

Diameter Of Handle Patch Paper Roll | Φ1200mm |

Handle Patch Paper Roll Width | 90-100mm |

Rope Distance | 75mm |

Handle Patch Thickness | 100-140gsm |

Handle Rope Thickness | 100-120gsm |

Flat Handle Rope Width | 12mm |

Paper Thickness | 80-140gsm |

Paper Type | White Kraft Paper, Brown Kraft Paper |

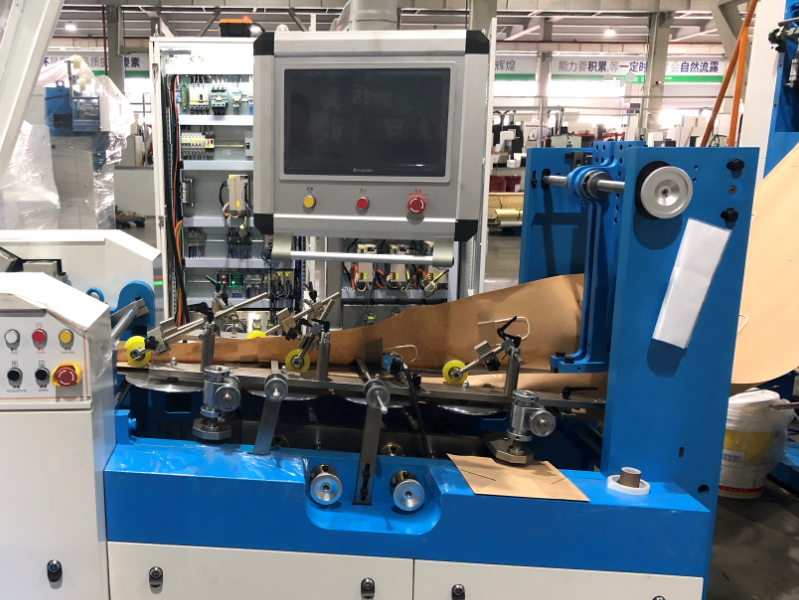

JT-PB-610 Fully Automatic Paper Bag Making Machine

Last Update Time:12/05/2022

You’re probably interested in learning more about fully automatic paper bag making machines with handles as well as their pricing if you’re thinking about getting into the paper bag business.

Currently, paper shopping bags are quite popular. Therefore, the paper bag manufacturing industry is lucrative.

Compared to plastic bags, bags made of kraft paper are preferable. Because they are 100 percent recyclable, biodegradable, and reusable.

Paper shopping bags are popular among food sellers, merchants, and even manufacturers due to their eco-friendly and sustainable characteristics.

Today’s FAQs guide revolves around paper bag-making machines. You’ll learn more

So let’s get started…

JT-PB-610 Fully Automatic Paper Carry Bag Making Machine With Handle FAQ List

What is a Fully Automatic Paper Carry Bag Making Machine?

A fully automatic paper bag making machine is the equipment that is used for forming the paper carry bags automatically. It can be used in printing houses and packaging industries. The machine includes a complete set of equipment for forming the paper bags, and it has a PLC control system. It can reduce labor operator by 50%, so it can bring great benefits to enterprises.

It’s also great because it has PLC control, which means less operator error. And if you’re looking to save some money on labor costs, this is the perfect solution for you! You’ll be able to run the machine by itself instead of having someone do it manually or having a bunch of workers running around.

The machine can do everything from unwinding the paper, feeding it into the machine, forming the tube and bottom of the bag, folding handles in place with servo motors, stitching handles together with servo motors,

and folding paper over the top of itself (if needed), and collecting finished products in one place (instead of having them scattered all over).

You won’t have any problems with quality either—the machine uses high-precision servo motors so everything will be perfectly measured out every time without fail!

Did you also know that such polyethylene bags take 1000 years to biodegrade? Yes, I know this is scary news. But it’s the truth of the matter.

Because of that, at least 77 countries in the world have imposed some sort of full or partial ban on the use of plastic bags.

The result?

More and more companies are phasing out single-use plastic bags in favor of more eco-friendly paper bags.

So it’s time to change your ideas. Let’s protect our global from now on.

Kraft paper bags can be used to contain all manner of items and substances. They’re used to package food, grocery, pharmaceutical products, baking food etc.

And so, the paper bag-making system has to be versatile enough to meet your paper bag manufacturing needs

What Are the Major Parts of a Paper hand Bag Making Machine?

The paper bag machine is the most advanced and complete equipment for forming the paper bags, which is mainly composed of fully automatic control PLC control, such as the paper unwinder, paper feeder, bag tube

forming, bag bottom forming, hand rope unwinder, handle folding, handle stitching and paper bag collector.

This machine features high precision and servo motor.

Below, we’ll break down the different parts of paper making machine and the role each one serves in the paper manufacturing process. Keep reading to learn more.

-Unwinder Stand:

When it comes to unwinding heavy paper rolls, you need a machine that can do the job. Our unwinder is just that—a powerful structure with a steel board casting structure that will unwind your mother rolls in no time.

It uses magnetic brakes for auto-tension control/ fully automatic tension control, so you don’t have to worry about having to adjust the machine yourself. It’s also high sensitive, making it easy to use and operate.

The main feature of the unwinder is that it has high sensitive and stable performance, can be adjusted automatically by the electric control system, which makes the whole process more convenient and efficient.

-Paper Feeder:

We’re here to assist you to maintain the paper feeder running well in your paper bag production machine.

- Rubber Roller D150mm For NIP Roller: These rubber rollers are combined with servo motors to provide a smooth, consistent feed that keeps up with your printing pace. Intended to function in tandem with other elements of the machine: Our paper feeders are designed to work in tandem with other sections of the machine, so you won’t have to worry about anything getting out of sync.

- Main speed control: Our paper feeders are capable of keeping up with color or black-and-white printing. They’re intended to move your paper at a precise speed, which means no more jams or misfeeds—just smooth operation every time.

- High precision: We understand that when you send something out into the world, it’s critical that it appears as nice as it possibly can—why that’s we use high-precision motors and other components in our products to assure consistent quality output!

The dancer roll system helps the film web in maintaining a constant motion. Hence, the feeders and dancers are crucial in maintaining proper tension and feeding accuracy.

– Paper Bag Forming Machine

We are proud to present our new line of paper bag forming machines. We have been developing this product for quite some time now, and we are excited to finally introduce it to the world!

This machine is designed with you in mind. It is made to be user-friendly and easy to use, with a variety of adjustable features that allow it to work with different sizes of paper bags. This means that you can use it for

both large and small jobs!

Our machine uses pressure rollers to fold your bags into shape, gluing them together using hot melt adhesive glue. (with imported hot melt glue spreader).

With CNC machining parts in high precision, all rollers are synchronized so that they all move at once, ensuring smooth folds every time.

The pressure also can be adjusted depending on what kind of paper you’re using—whether they need more or less pressure than usual will determine how much force you’ll put on them during this process.

-Rope Forming Machine.

We know that you’re busy, and we want to make it as easy as possible for you to get the most out of your machine. Our paper bag making machine has an option for paper handles, which means that when you upgrade,

you can skip the step of having to buy a separate machine to make your handles!

The process is simple: Paper Ribbon Unwinder folds the ribbon into narrow rope or twist; Handle shaping CNC machining parts in high precision; High pressure for forming; Servo motor control; Online with the

shopping paper bag making machine; Sensor to ensure the stitch precision.

If you’re ready to start making bags in bulk but don’t have the time to handle all of the extra steps, check out our industrial paper bag making machine today!

Feeding is also a technical process. To ease the workload, a secondary system known as the dancer roll system is used.

After feeding the raw materials into the paper bag-making machine, the infeed rollers take charge and deliver them to the feeders.

The feeders synchronously convey these materials to the unit’s sealers and cutters again. They also ensure the appropriate paper handbag sizes are fed to the machine.

In addition, the feeders work hand in hand with print mark sensors to guarantee accurate delivery of the printed web.

Once the feeding process is complete, the raw materials go through the forming process. At this stage, the material is sealed.

During this stage, you will realize that the cutters and the sealers all move in a perpendicular direction. This motion results in the cutting or sealing of the paper bags.

Depending on the design of the bag you’re looking to produce, you may need to perform extra operations during the forming stage.

Such operations may include hole punching, handle making, tamper-proof sealing, spouting, and caping, among others.

More often than not, the paper bag-making machine will come with auxiliary accessories for performing these operations.

– Control Unit

The Control Unit is the nerve brain of the paper bag-making machine. You’ll be able to control or drive the machine from this main section.

No doubt the whole operational basis of the machine relies on this part. Consequently, the control unit should be of the highest technological capacity.

The paper handbag-making machine’s control unit is made of the mainframe servo motor control and the touch screen display monitor.

You can set different operational parameters right from the touch screen display monitor. This includes setting the bag length and speed of the device.

The touch screen display also lets you monitor the paper handbag manufacturing process in real-time. And you can change the parameters if need be.

-Discharge Rack

The discharge rack part is the paper bag-making machine’s ultimate end section. It’s where the stacks are ejected.

This part features the stacking devices and conveyor belt. The rack part configurations usually vary by the design of the machine.

For some machines, the belt stacks each bag into one compartment before being conveyed downstream in stacks.

For other machines, the operator will need to manually eject the stacks. Yet in other machines, the rack transmits each bag into the next device.

The discharge rack part is usually driven by a servo to ensure accuracy and efficiency. Servo motors do not suffer from vibration issues and are thus accurate.

-Puncture Part

In this segment, the paper bag-making machine punctures holes in the bag. You can create two types of perforations, which include the shaft and the handle.

The hole or handle punctures are often located between the machine’s feeder sections. Read your user manual for the exact location.

In some paper bag-making machines, handle punctures aren’t standard accessories. Instead, they’re provided as additional accessories.

Other extra accessories include tamper-proof sealers, zippers, and more. Also, the position of these add-ons depends on their roles.

The punctured parts of the device may be driven by pneumatic or servo systems. But they can as well use other systems.

Now that you know how the paper bag-making machine operates, let’s discuss the different types of machines.

How Are the Types of Paper Bag Making Machines?

There are about seven different types of paper bag-making machines available today. But for the purpose of this guide, we’ll discuss the two common options.

These include a square bottom paper bag making machine, and a V-type sharp bottom paper bag-making machine.

Square Bottom Paper Bag Making Machine

The square bottom paper bag-making machine is also named the shopping paper bag machine. it is an adaptable machine that produces paper bags with square bottoms. Which is the majority of the industrial paper bags in our work life.

This machine utilizes rolling paper as the raw material. It creates 100% biodegradable paper bags for shopping and food handling.

You’ll want to know that the square bottom shopping paper bag making machine is automatic. As a result, you can operate and control it via a computerized programmable system attached to a servo motor.

It also has a touch screen interface system that allows you to produce paper bags with various specifications.

If you need more information, just send us an inquiry

V-type Sharp Bottom Paper Bag Making Machine

V-type sharp bottom paper bag making machine is designed to form sharp V-type bottom paper bag from big jumbo paper rolls. It is also a popular star in the industrial paper bag field.

The machine can utilize Kraft paper, coated paper, grease-proof paper, ribbed Kraft paper, and medico paper, among others.

V-type sharp bottom paper bag making machine utilizes a fully automatic process. Hence, it’s ideal for making different kinds of paper bags.

With this machine, you can produce snack paper bags, bread paper bags, food paper bags, and dry fruit paper bags, among others.

Conclusion

Without a doubt, paper bag-making machines continue to play a very important role in every aspect of our lives.

Indeed, there are more than a dozen uses for paper bags. From simple uses like carrying random goods to more complex uses like wrapping up drugs in pharmaceuticals, the use of paper bags can never be underestimated.

Subsequently, the types of paper bags you can produce will depend on which paper bag-making machine you’re using.

And now that we’ve covered nearly every aspect of paper bag-making machine, I trust you now have what it takes to start your paper bag-making business.

We know there are many other companies out there who claim that they make high-quality equipment like ours—but at Jota Machinery, we believe in quality over quantity every time! That’s why our machines are

always updated with new technologies that make them more powerful than ever before.

If you’re still stuck and don’t know which model to choose, don’t worry. Just send us an inquiry or phone call, our professional team will satisfy your requirment.