High Configuration Film Packing Machine

- Fully Automatic

- Easy Operation

- Europen Standard

- Beautiful Layout And Small Space

Heat Shrink Film packaging Machine

If you are now seeking a fully automatic thermal paper production plan then we recommend you try our heat shrink film packaging machine.

This set machine can help you automated pack the small roll to finished goods you need.

Feel free to contact us for more details

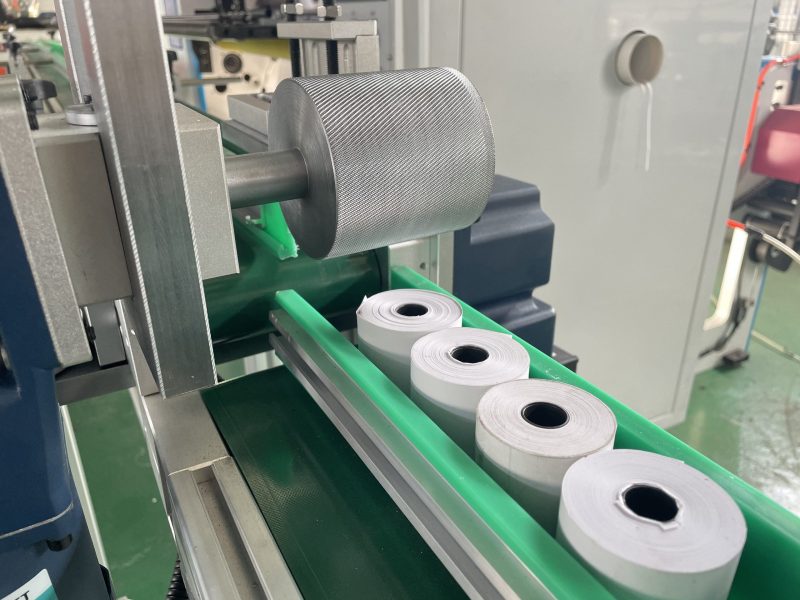

Packaging process for heat shrink film packaging machine

Normally this set machine is combined with the conveyor line then becomes a production line.

The detailed working flow is like below:

Convery – Small roll cut off – Hammer – Sealing – Heating

Machine Characteristic

- All famous brand parts

- Anti-corrosion structural material surface spray or nickel plating treatment

- The seal is not only stable but also has low noise

- Adopt anti-stick and high temperature resistant alloy sealing knife

- Tight packing, no loose

- The packing type can be customized

- Qualified POF shrink film

- The seal knife is plated with DuPont Teflon without film

- Focus Factory

- Dear Customer

- Professional Team

You need double layer POF shrink film for packing machine.

The power for this machine is 3 Phase, 380V.

Yes. Not only packing machine need air, our thermal paper slitting machine also needs air support.

This machine can use independently.

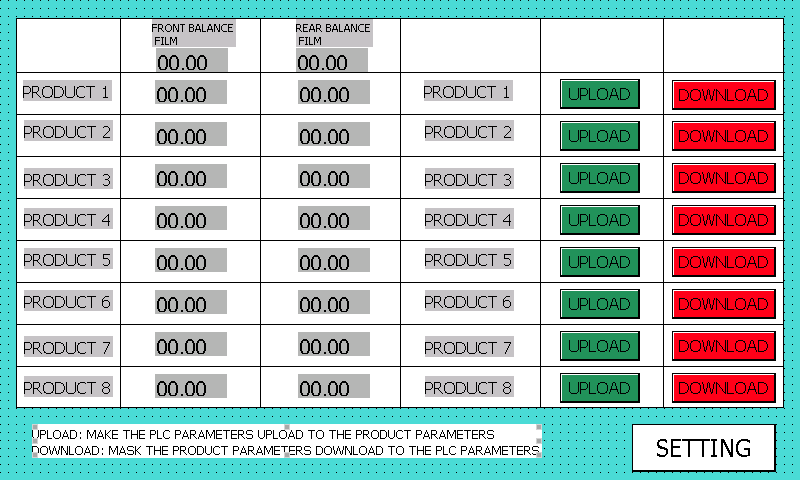

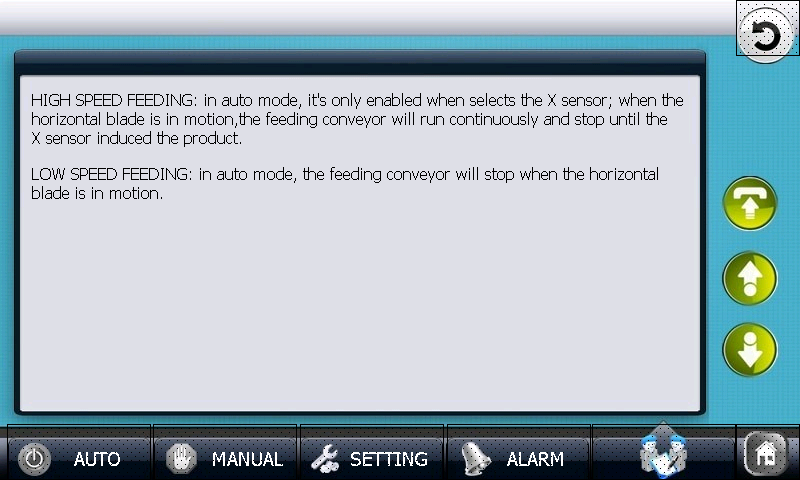

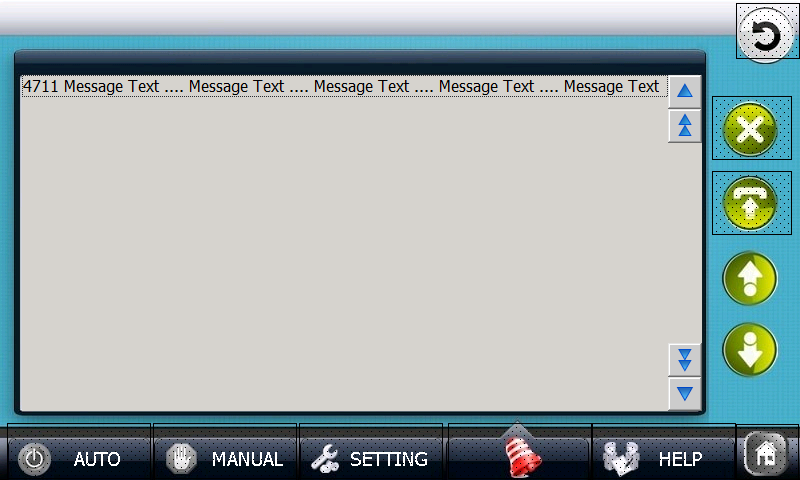

Tutorial For Heat Shrink Film Packaging Machine

- Main Technical Specifications

- Machine Installation

- Operation Note

- The Function For Control Panel And Each Button

- Shrink Film Transmembrane Diagram

- Packaging Position Setting

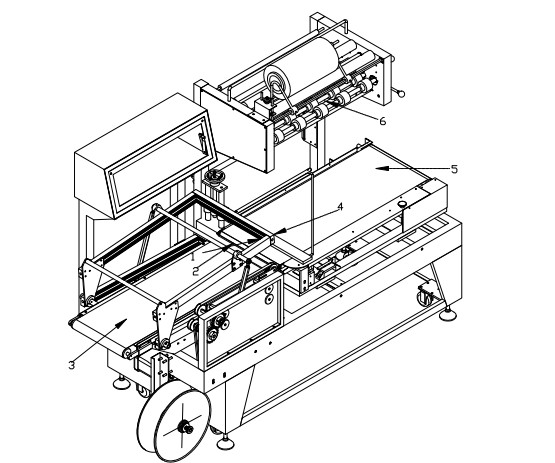

- Sealing Machine Component Parts

- Waste Disposal

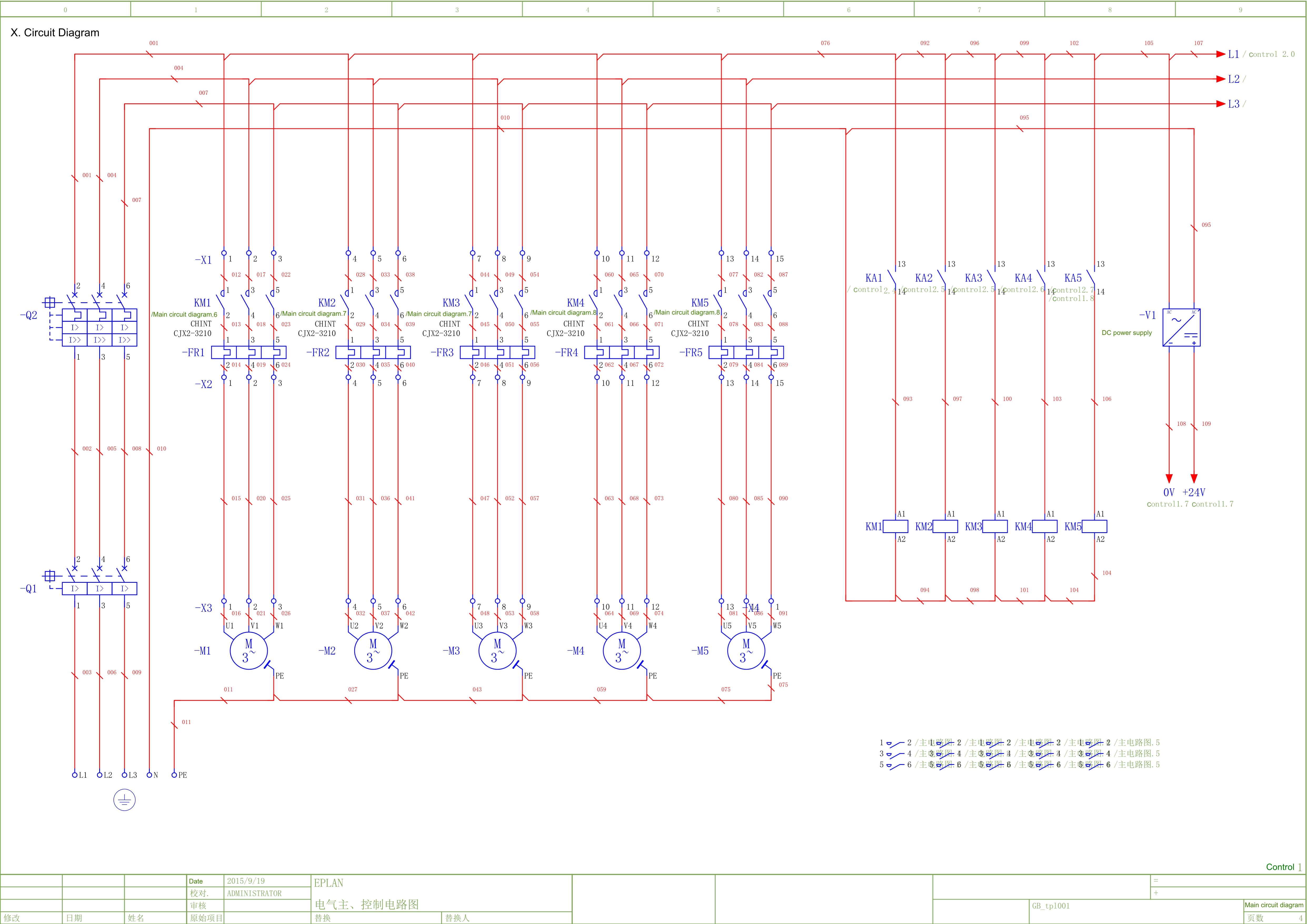

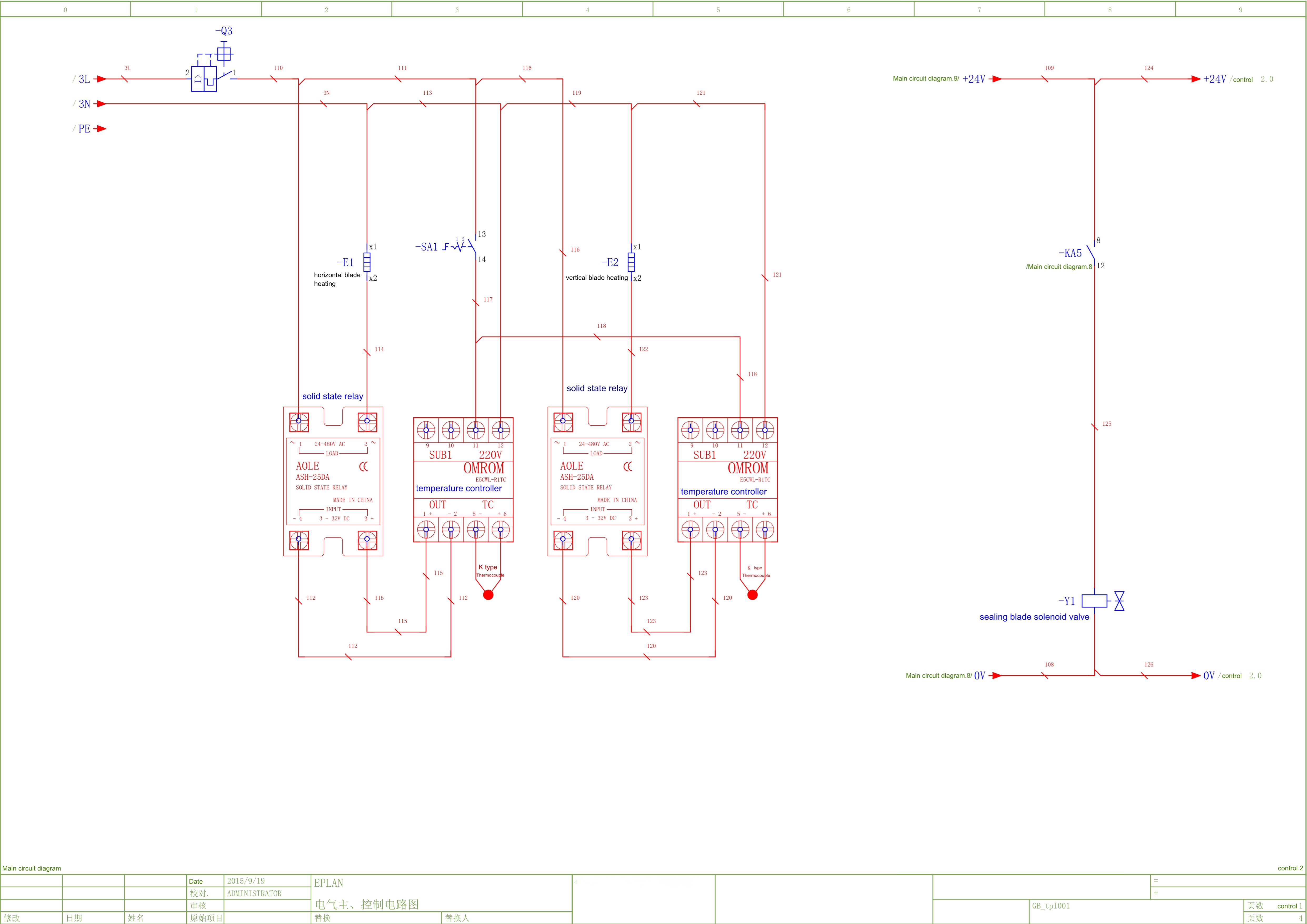

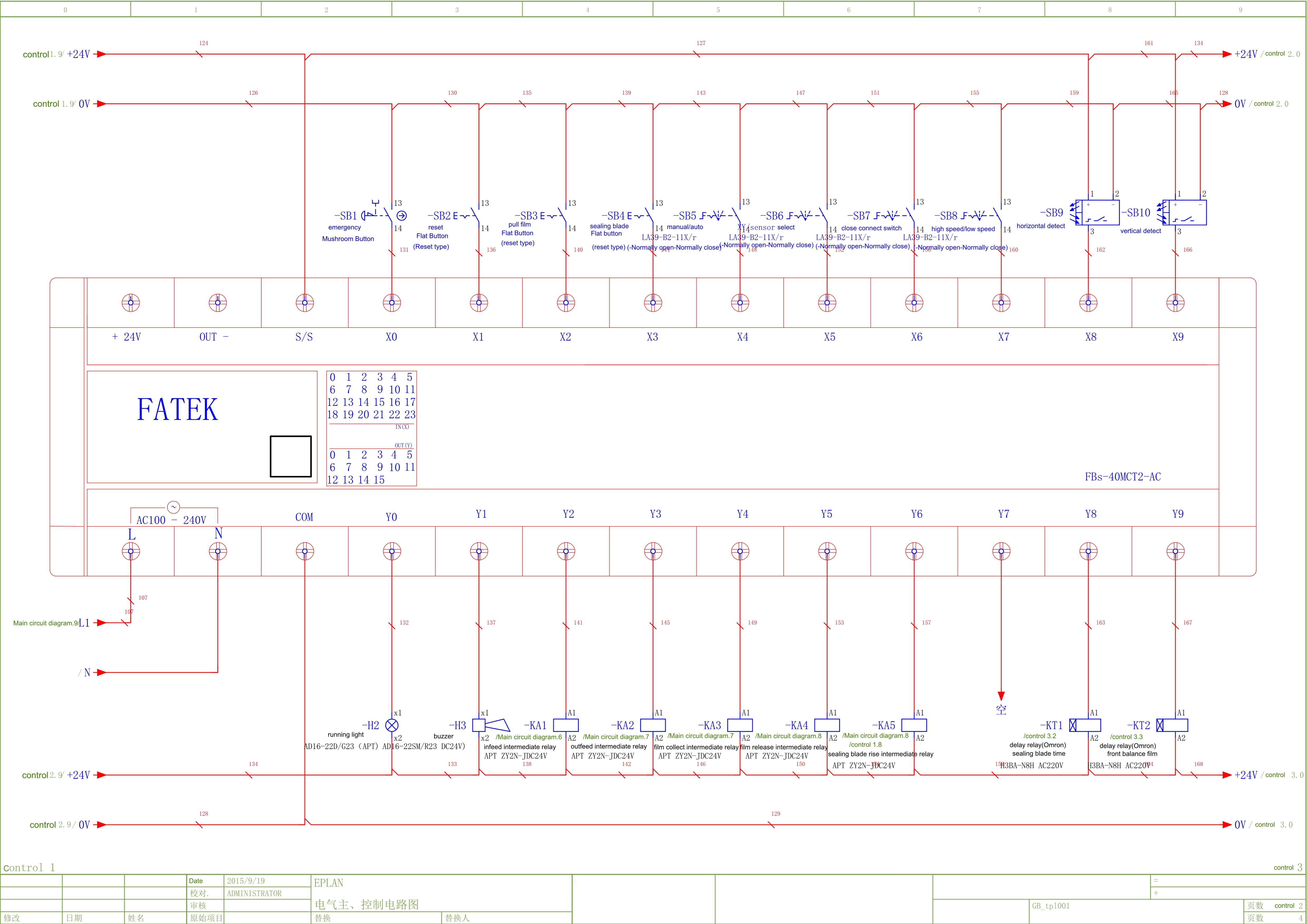

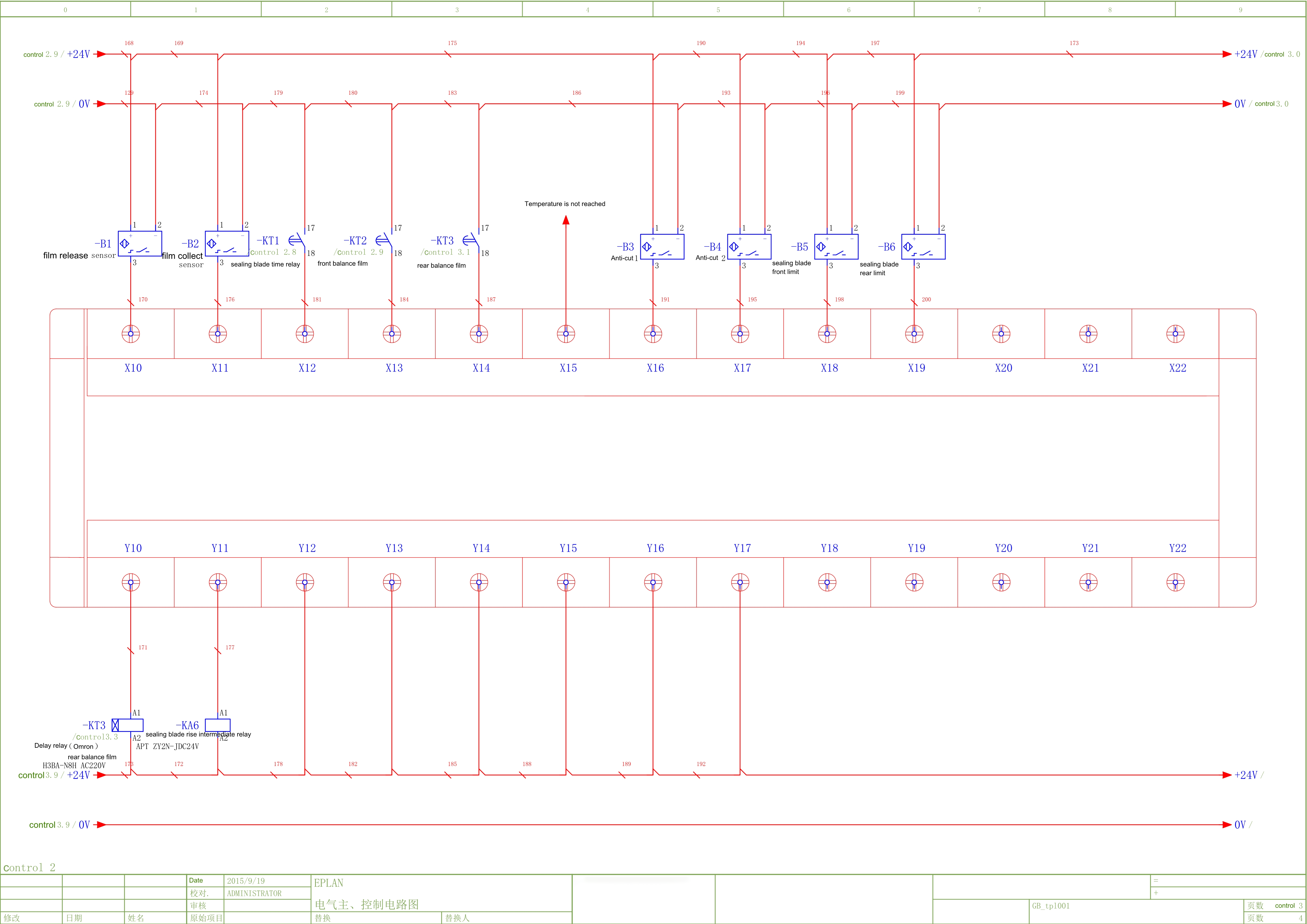

- Circuit Diagram

- Operation Sequence

- Maintenance of Machine

Main Technical Specifications

- Dimensions: length 2075;wide 923 ~ 1169; high 1510mm ~~ +50 (adjustable)

- Working height: 725mm ~ +50 (adjustable)

- Effectively sealing dimensions: width 380;length 500mm

- Sealing: Trilateral sealing

- Packaging: by L-type sealing line into tripartite seal packaging

- Conveyor: belt conveyor

- The conveying speed of supplying the conveyor belt :17.8m/min

- Shrink film speed: 13.9m/min

- Waste treatment speed: 15.2m/min,

- Power: AC / 1 ¢ 220/220V 50/60HZ

- The air pressure source: 6kg/cm ²

- Supply conveyor belt motor: AC / 1 ¢, 220V, 4P, 60W

- The discharge conveyor belt motor: AC / 1 ¢, 220V, 4P 60W

- Shrink film supplied to the motor: AC / 1 ¢, 220V, 4P, 25W, (Brake)

- Waste take-up motor: AC / 1 ¢, 220V, 4P, 60W, (Brake)

- Sealing heater: AC / 1 ¢, 220V (straight) 1200W (cross) 1200W

- Waste treatment: coiling

- The size of shrink film: 100-500mm (folding drum film)

Machine Installation

- Open the package box upper cover, remove the packing box of the four side plates;

- Screw machine at the bottom of the four foot bolt;

- Out of the machine body, placing it into the stable and no vibration;

- Removing machine body protective film

- Conveyor for preventing rod during transport shipment we fall, at the bottom of the feed rod is installed on the hook, before starting it’s first removed, or the machine will not work properly;

- Adjusting machine at the bottom of the foot bolt, to adjust the machine level and prevent the machine in operating when the sliding;

- According to the nameplate voltage wiring, note: be sure to connect the ground wire.

- The machine has three voltages:1/ 3phase 220V 50/60Hz

Operation Note

- Do not put your hand in the operation to seal by the sword

- Make sure the power cord is properly oriented operating, If correct, face to the plate, the conveyor belt from right to left walking (if the reverse, the raw material can not roll out)

- When things go wrong, turn off the power switch, then repair, repair manually switch to implement sealing work, then open the switch.

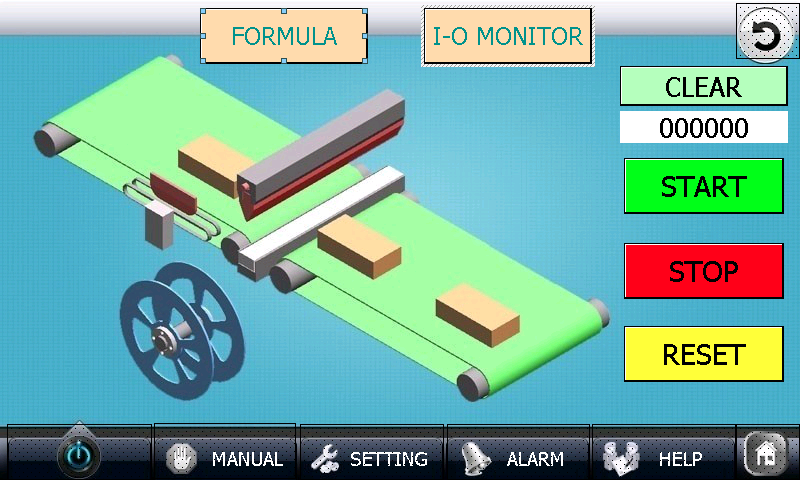

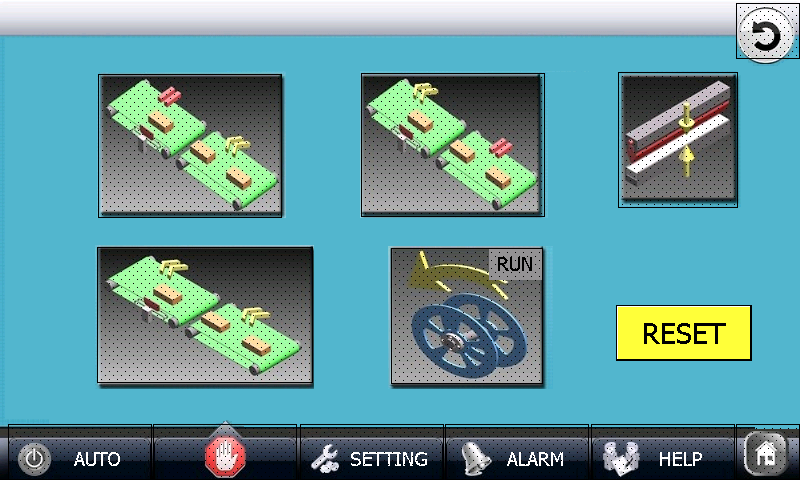

The Function For Control Panel And Each Button

You can click each picture to view the big size version

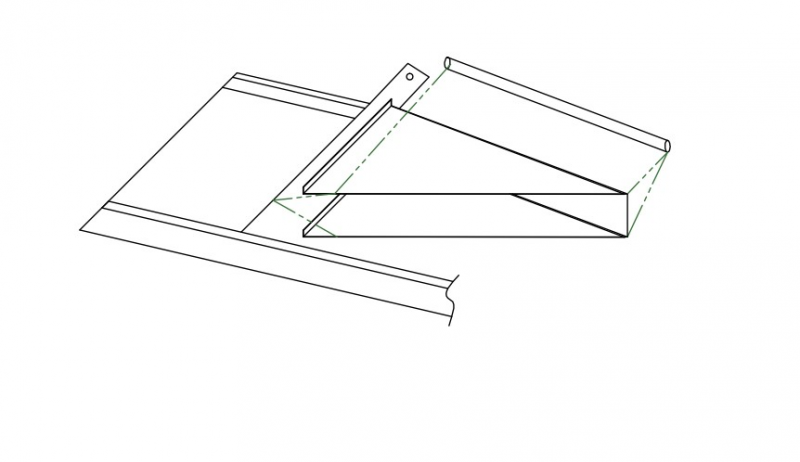

Shrink Film Transmembrane Diagram

- As shown in general at the top of two rollers of raw materials will be arranged, please pay attention to the opening of the contraction film must be to the left, and the need to pay attention to the raw materials are placed in both sides of the roller are indicative of line, too the left raw material easy to break, Too right raw material inversion is possible after not being able to work fluently

- Please follow the form of raw materials through the rollers, and then in accordance with the form of raw materials reflexed through the triangle palate expander.

Packaging Position Setting

- Height adjusting handle

- Height adjusting handle to adjust height make products smooth through

Sealing Machine Component Parts

- knife

- knife seat

- outlet conveyor belt

- triangular expansion device

- entrance conveyor belt

- film punching device

Waste Disposal

- After the start, then have several times sealing action, when clamp film chain behind the outflow of waste around 1m, string parallel guide film pulled up to the waste volumes barrel volume to be fixed.

- When the coiling barrel rolls up, The current side pads are straight-pull unloaded, please turn to the next fixed pad screw, then you can take all the waste.

Circuit Diagram

You can click each figure to view the big size version

Operation Sequence

- After the power switch is turned on, each thermostat, please adjusted to the optimum temperature, but due to room temperature, use of raw materials, and thickness, there may be certain differences.

- According to the packaging adjust the height of the triangular plate expander, fit the width of the objects you need to adjust width. Adjusting screw, the height adjustment cam plate to expand above the height of the adjustment screw,

And keep the object distance of one centimeter. - The width of the set aside is the distance between the stop position with the horizontal centerline of the sealing knife packaging and set it in the packing height of more than 1/2.

- The packaging stop time controller (belt conveyor stop time) is also a distance to the centerline of the sealing knife with the packing material is stopped, to set in the packaging will be the continued height of 1/2。

- By packaging the height of 6cm or more occasions, set the raw materials reserved length (usually 0.02 to 0.04 seconds)

- After the height, width has been set up, According to the installation of shrink film to install the film.

- When the sealing knife reaches the set temperature, pull out the raw materials, but the open end clamps into the clamp material gap pressed the manual control switch to seal.

- Press the switch to start the conveyor belt, and then, as long as the items placed on the conveyor belt can be self-seal packaging.

Maintenance of Machine

- Machine after work should clear the fuselage and the conveying roller residues and dust;

- Regular inspection conveyor motor gearbox lubrication oil;

- For the overall performance of the machine for a comprehensive inspection per month, and open the distribution box to remove dust, debris;

- Chain operating components every three months to add lubricating oil.