Thermal Paper Roll Slitting Machine

- 10000 rolls/8h output on average

- Siemens PLC, motor, HMI

- 37mm thickness machine frame

- NSK bearings, Airtac cylinders

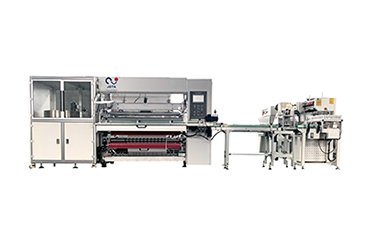

- Popular Thermal Paper Slitting Machine all over the world.

- Specification

- Video

PARAMETERS

| Item | JT-SLT-900 Thermal Paper Roll Slitting Machine |

| Max. Unwinding Width | 900mm |

| Max. Unwinding Diameter | 1000mm |

| Max. Rewinding Diameter | 160mm |

| Min. Slit Width | 25mm |

| Max. Speed | 150m/min |

| Unwinding Shaft | 3” Air Expanding Shaft |

| Rewinding Shaft | 0.5”, 1” are available (or as your request) |

| Voltage | 3 phase, 380V, 50Hz |

| Power | 2.95Kw |

| Weight | 1200kg |

| Overall Dimensions(L*W*H) | 1900mm x 1900mm x 1500mm |

| SPECIFICATIONS |

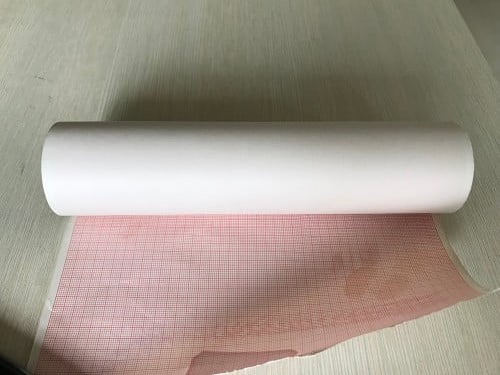

| Jota thermal paper roll slitting machine is used for slitting and winding all kinds of thermal paper, including fax paper, ATM paper, ECG paper, medical record paper, self-adhesive trade marks, non-woven cloth, films, adding machine paper, swipe machine paper, etc. |

| FEATURES |

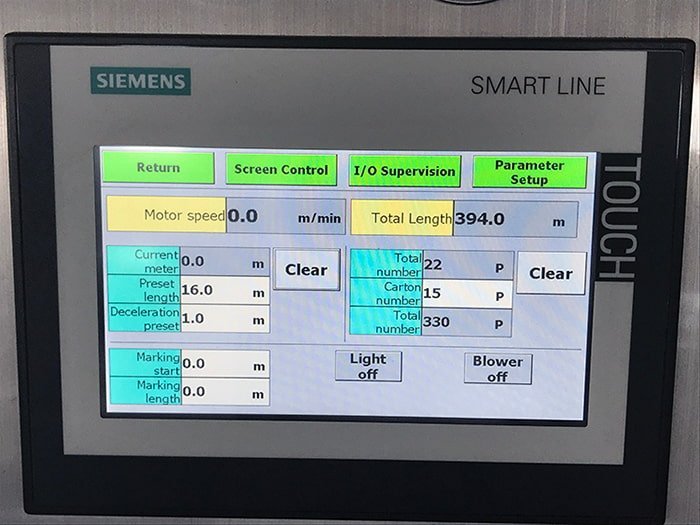

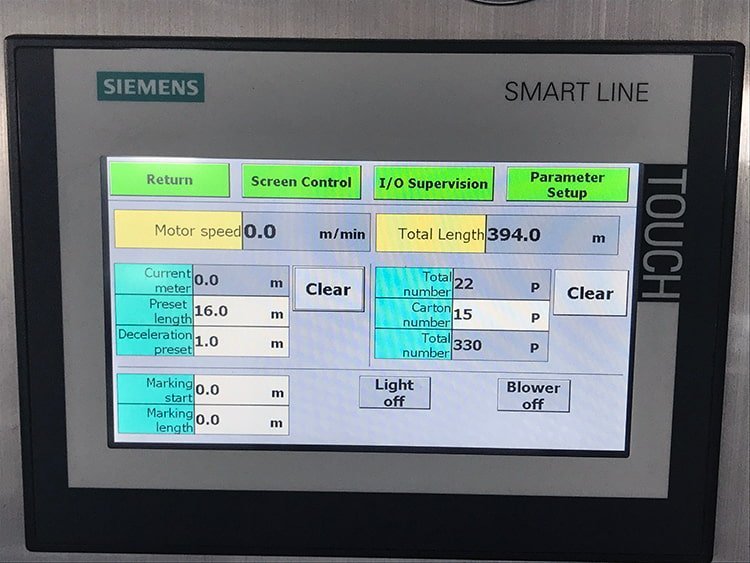

| Siemens PLC and touch control screen, all the parameters are displayed on the monitor, and it will automatically work. |

| Master motor is Siemens inverter motor, Inovance AC drive control. |

| Motor-driven chain lifts jumbo roll up or down automatically. |

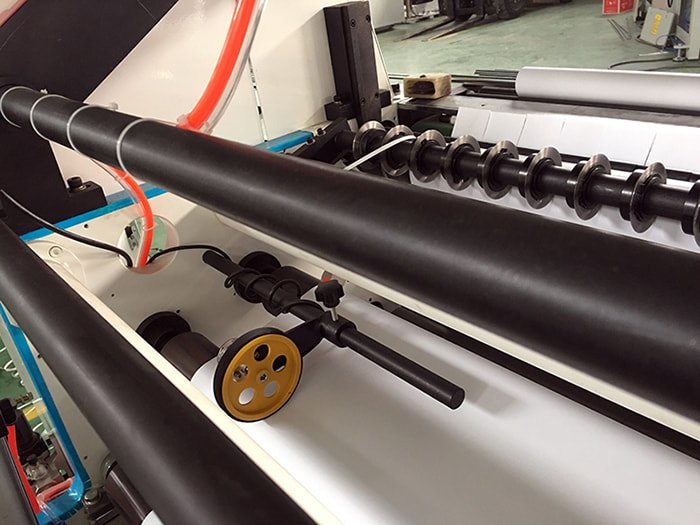

| Dynamic or static balancing transmission roller. |

| Redline marking system, printing red line on finished roll tail. |

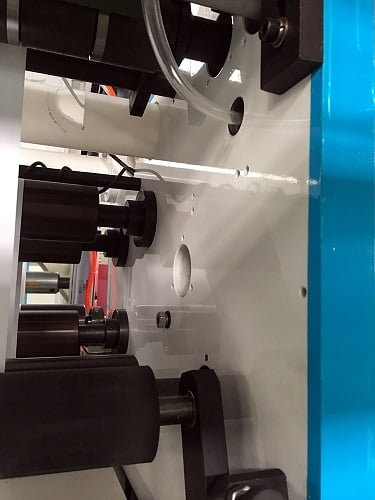

| Round blades for slitting, automatic waste removal by air blower through tube. |

| Automatic tucker, quickly triggers rewinding. |

| Hall switch and tension control board to keep constant tension. |

| Auto meter counter, when it reaches the preset length, the machine stops automatically. |

| The overlapping problem could be avoided with lay-on roller. |

| Emergency switch. |

JT-SLT-900 Thermal Roll Slitting Machine

JT-SLT-900 thermal roll slitting machine is always Jota Machinery’s best selling product, not only because it is an economical model, but its quality is also high, the price is competitive.

So, Egypt’s big customer K.M.S Group also purchased this cash register paper roll slitting machine.

Egypt big client K.M.S group

K.M.S Group’s choice fully proves that Jota Machinery is a reliable cash register paper roll slitting machine supplier, you could trust us without any fear.

K.M.S Group chose JT-SLT-900 cash register paper roll slitting machine mainly because it has some attractive selling points.

In the unwinding section, JT-SLT-900 cash register paper roll slitting machine applies a motor-driven chain, it is able to lift up and down thermal paper jumbo roll automatically, ensures jumbo roll loading and exchanging is much easier, greatly saves operator labor.

3″ Air Expanding Shaft

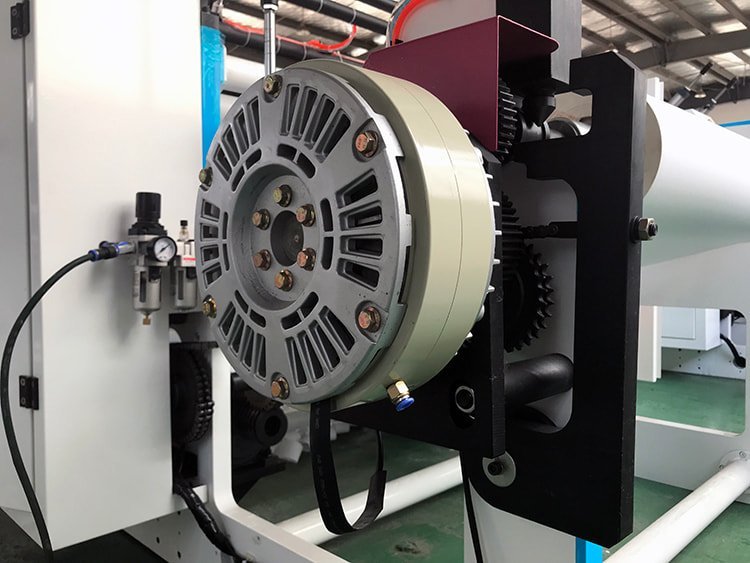

With jumbo roll diameter decreasing, unwinding shaft’s driving torque decreases at a linear ratio.

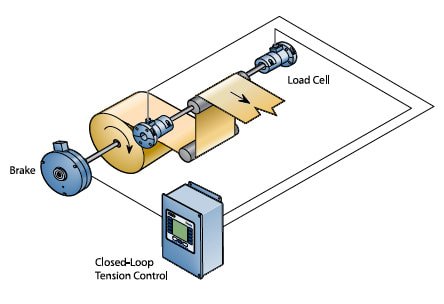

With electromagnetic brake installed, it is useful for torque compensation, makes sure JT-SLT-900 thermal paper slitter rewinder keeps constant tension while working.

Electromagnetic Brake

Constant tension is the most important factor for cash register paper roll slitting machine.

In order to detect real-time web tension, JT-SLT-900 cash register paper roll slitting machine equips with hall switch pointing to unwinding shaft.

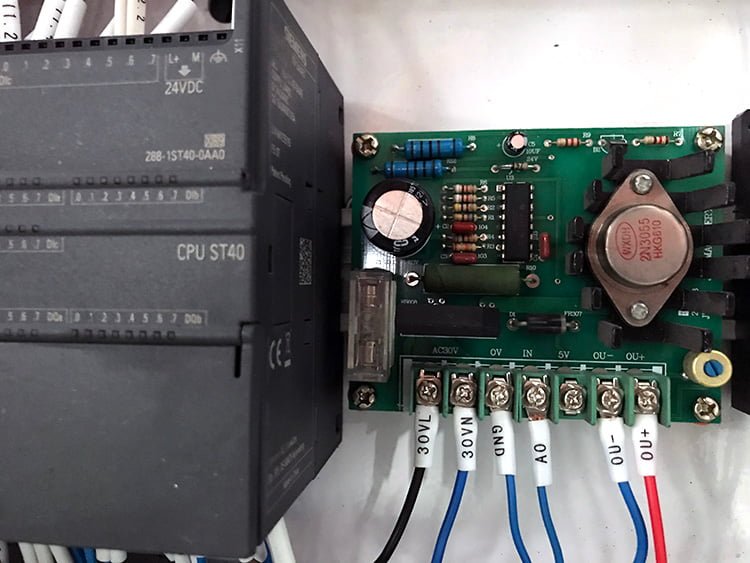

Tension data feeds back to the tension control board for processing, then reports to Siemens PLC, PLC sends the command to electromagnetic brake for execution.

Tension Control Board

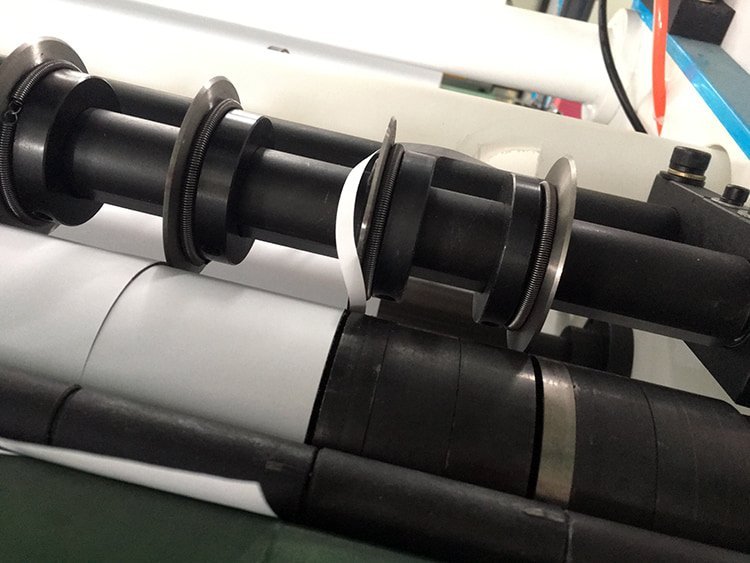

In the slitting section, JT-SLT-900 thermal roll slitting machine introduces shear cutting, proactive lower circular knife, and slave upper circular knife, leads to the minimum or no burrs, effectively minimizes waste.

Proactive Lower Circular Knife and Slave Upper Circular Knife

In the rewinding section, JT-SLT-900 cash register paper roll slitting machine utilizes automatic tail tucking system for a quick start, significantly reduces the time gaps from startup to winding beginning, effectively improves production efficiency.

Automatic Tucker

In order to avoid overlapping problems during the rewinding process, the lay-on roller is installed in the JT-SLT-900 cash register paper roll slitting machine.

Without any overlapping problems for small rolls, material waste also could be avoided.

Lay-on Roller

During communication with our previous clients, some of them request us to develop rewinding tightness adjustment function, so our engineers creatively add a precision regulator to JT-SLT-900 POS paper slitting rewinding machine, these clients are really satisfied with a shiny smile now.

Precision Regulator

There are still many secrets about JOTA’s best-selling cash register paper roll slitting machine JT-SLT-900, please speed up your action to send us an inquiry, one-on-one service is waiting for your call in China.

Recently, we Jota has just released fully automatic thermal paper roll slitting packing machine JT-SLT-1400FA, from core feeding to finished roll packing, no need dedicated operator, inline printing function can also be integrated, please send us an inquiry on this website to get more details.

Thermal Roll Slitting Machine Ultimate FAQ Guide

- How to start thermal till rolls business?

- How much investment do you need to start thermal roll business?

- Is the ROI of thermal paper roll business high?

- What can you do if you don’t understand mechanical operation as a newcomer?

- Who is the thermal roll’s terminal customer?

- What are the common sizes of thermal roll paper?

- What is the inner core size of thermal paper roll?

- What is the thickness of thermal paper?

- Is there any blue display thermal paper besides black ones?

- What other business can you do to share the same POS roll sales channels?

- Can you cut different widths on the same thermal paper cutting machine?

- Is the thermal roll slitting machine able to mark redline on roll tail?

- How does thermal roll slitting machine count winding length?

- What are the sizes of thermal paper slitter rewinder’s rewinding shaft?

- What are the unwinding widths of thermal roll slitting machine?

- Why does the thermal paper roll overlap during the winding process?

- Does cashier paper slitting machine need automatic tension control system?

- Does thermal paper slitter need PLC and touch screen?

- Can thermal paper roll production efficiency be improved?

- Is cash register roll making machine safe during production?

- What is the dimension and weight of thermal roll slitting machine?

- What if thermal paper slitter expires warranty period?

- How do you know thermal paper roll production cost?

- Can thermal roll machine be used to cut other materials?

- Do you need a printing machine except for a thermal roll slitting machine?

- Do you still need automatic packaging line to pair with thermal roll slitting machine?

- What are the packaging methods for thermal till rolls?

- Do thermal paper rolls need to be stored in a dark place?

- Is thermal paper roll environmentally friendly?

- Do you need to wash hands after touching thermal paper?

- Will thermal paper be replaced by other materials?

- What is the output of thermal paper roll slitting machine?

- How long is thermal roll slitting machine’s service life?

- How often does thermal roll slitting machine’s blades need to be changed?

- Can you get service from Jota if you bought other brands thermal roll machine?

- What other value-added services can you get for Jota thermal paper slitter?

- Can you provide thermal paper jumbo roll?

- Can you distribute Jota thermal paper cutting machine?

- Can you apply for Jota cash register roll making machine’s agent?

How to start thermal paper rolls business?

Thermal paper rolls business is a low-input, high-profit business, such business doesn’t need large workshop.

The factory area required is just 100 square meters, you can even use your backyard as a factory.

To start make small roll of thermal paper or rolls lottery or POS paper rolls, you need a thermal paper roll slitter, paper or plastic core, thermal paper jumbo roll, and some packaging films, bags, or a shrink film packaging machine.

As a professional supplier, we Jota can provide you with one-stop solutions.

First of all, your local thermal paper market should be researched and analyzed by you carefully, and where is the thermal cash register paper rolls source from?

Mainly, There are two ways:

- Working as a trader, To buy finished thermal cash register paper rolls directly from China or India, then distribute them locally. 2. Working as a manufacturer: to buy a thermal paper slitting machine and convert the thermal mother rolls into small rolls then distribute it. It is with the advantage of delivery time and quality are controllable

- If it is the former, congratulations, you have found a new world of thermal paper roll business. If it is the latter, then you need to further investigate the cost of the paper rolls, workers’ salary, and factory rent, etc. Because you need to face some competition in the future. Of course, Jota Machinery is pleased to support you with your thermal paper business starts. As a professional thermal paper solution, we provide a full set of thermal paper solutions from A to Z. Would you please just send a message to get more related information like the current price of thermal paper, and the cost of each item.

If you find that in your local market, the thermal paper roll business is a new virgin land, then you only need to buy a thermal paper roll slitting machine, one air compressor and Thermal paper mother roll, plastic core, or paper core to start the business.

You probably need a space of at least 100 square meters, Voltage: 3-phase 380V industrial power is needed. (Different countries have different voltage requirements, but you need a 3-phase, 4 wire power supply.) Then you need a forklift for transporting thermal paper mother rolls, an air compressor provides working air source, 0.6Mpa is sufficient. You also need 2-3 staff to operate the thermal paper slitting machine and the finished thermal paper roll packaging.

In a word, Jota machinery has a powerful ability and experience to support your thermal paper roll business, just send us an inquiry.

How much investment do you need to start a thermal roll business?

The thermal roll business is a popular business everywhere.

To start your thermal roll business, take our most economical thermal paper roll slitting machine as an example, you need a start-up capital of about USD30000: a thermal paper roll slitting machine, 3 tons of thermal paper mother jumbo rolls, 2- 3 staffs salary, and some rents for a workshop.

But as your business grows, you need enough cash flow to support your company flowing. Firstly, you need to buy thermal paper jumbo rolls in cash. Now the global thermal paper price is rising every day. The price of thermal paper fluctuates every day. You need to prepare a certain amount of cash for that.

To buy one 20GP paper as an example, it can load about 16tons. one ton of thermal paper price USD1800, Sum up to USD28800.00. Plus Shipping freight, it is approximately USD35000.00. The entire paper operating cycle is almost 90 days, and you probably need approximately USD100,000 to complete the cash flow of your factory.

In addition, you also need to pay labor salaries and factory rent, the amount of which depends on your local situation.

Now you probably have a general idea of the investment. For the factory running, you need about USD100,000-USD200,000 to support the smooth operation of the factory.

As your business continues to increase, our customers in the Middle East and Africa will basically come back in one year and buy a second thermal paper roll slitting machine. At the same time, they will also buy a thermal cash roll finishing production wrapping line to improve their production efficiency. This fee will be a bit more, about USD50000.00

Jota machinery is a professional thermal paper roll slitting machine manufacturer in China, we can recommend proper solutions to you, just contact us now!

In the beginning, you need about 100 square meters of ground to start.

The manpower is about 1-2 people, the voltage requires 3 phase 380V or 3 phase 220V industrial power.

The overall investment is around USD$45,000.00, including a cash register paper roll slitting machine, a conveyor, shrink film packing machine, thermal paper jumbo rolls, paper/plastic cores, etc.

Is the ROI of thermal paper roll business high?

Thermal paper roll business ROI should be divided into products and your own positioning, there is a difference between thermal POS rolls and ATM thermal paper roll.

If your product is ATM thermal paper rolls, the width is 80mm, and there are printed patterns, the profit is still very high, which can reach more than 30%.

What can you do if you don’t understand mechanical operation as a newcomer?

As a professional supplier of thermal paper slitting machines, we provide a full range of services.

We have a professional sales team, each team member understands English and can serve you 7x18h.

The cash register paper roll slitting machine will be debugged before leaving the factory, you only need to plug in the electricity and gas source in your factory.

Please refer to the following video:

In addition, if you have any questions, you can contact us to solve any problem asap via WhatsApp video call.

If it still doesn’t work, we can send our engineers to your site for commissioning, but you need to pay round-trip airfare, hotel fee, and daily salary of USD$100.00.

Who is the thermal roll’s terminal customer?

Thermal rolls are widely used in many fields, many terminal customers need to buy thermal rolls, mainly include:

- Shopping malls

- Supermarkets

- Street convenience stores

- ATMs and POS machines in banking systems

What are the common sizes of thermal roll paper?

Thermal roll paper sizes are determined by 4 aspects:

- Thermal roll paper width

- Thermal roll paper diameter

- Thermal roll paper length

- Inner core diameter

Generally speaking, thermal roll paper size is marked by roll width x roll diameter, most common sizes are 57mmx50mm and 80mmx80mm.

57mmx50mm thermal roll paper is used on POS machines and 80mmx80mm thermal roll paper is used on ATM machines.

What is the inner core size of thermal paper roll?

The inner core can be paper core, plastic core, or PP plastic honeycomb core, depending on the needs of your local market.

The inner diameter size is 0.5″ (13mm), 1″ (25.4mm), other specifications can be customized according to your requirements.

What is the thickness of thermal paper?

The thickness of thermal paper is generally 48gsm, 55gsm, 65gsm, the most commonly used are 55gsm and 65gsm.

Is there any blue display thermal paper besides black ones?

Depending on the chemical raw materials, the display color of thermal paper is black or blue.

The color rendering durability of black is generally within 3 years, if you have higher requirements, it can be achieved within 10 years.

What other business can you do to share the same POS roll sales channels?

Many of our customers are engaged in the self-adhesive label printing business, and they are also making swipe machine roll, POS roll.

Thereby they can share the same sales channels, thus reducing operating costs.

Can you cut different widths on the same thermal paper cutting machine?

Yes, you can cut different widths on the same thermal paper cutting machine, it can be achieved by replacing or rearranging the spacers.

You can also purchase an additional lower blade shaft to easily change the slit width.

Is the thermal roll slitting machine able to mark redline on roll tail?

Yes, Jota cash register roll making machine is customized with redline marking function, you just need to set it on the Siemens touch screen, the redline on roll tail will be automatically marked by ink wheel.

How does thermal roll slitting machine count winding length?

The winding length control is preset in the machine’s PLC, when the specified winding length is reached, the machine will automatically stop.

The winding length count is realized by rotary encoder installed on thermal roll slitting machine.

What are the sizes of thermal paper slitter rewinder’s rewinding shaft?

Thermal paper slitter rewinder‘s rewinding shaft size depends on paper core or plastic core size.

The rewinding shaft outer diameter is mainly 12.7mm or 25.4mm, special size rewinding shaft can also be customized to your requirements.

What are the unwinding widths of thermal roll slitting machine?

Jota thermal roll slitting machine’s unwinding width has several types:

- 500mm 2/3 plies carbonless copy paper slitting machine

- 700mm coreless thermal till roll making machine

- 900mm economical thermal paper slitting machine

- 1100mm plotter paper slitter

- 1400mm high-end thermal paper kraft paper tape slitting machine

You can choose a suitable thermal paper roll slitting machine according to your thermal paper jumbo roll width.

Why does the thermal paper roll overlap during the winding process?

There are 2 reasons that lead to thermal paper roll overlapping problem.

- 1st reason

There are some thermal paper slitting machines whose design are not reasonable enough, so the paper rolls will bite each other, wasting materials and increasing costs;

- 2nd reason

The operator does not know enough about the machine itself and is not familiar with tension control, which causes paper biting during the winding process.

These problems can be solved after operators are familiar with machine operation.

In the past years, many customers have this problem, we have conducted in-depth research and optimization, Jota thermal paper roll slitting machine does not have this problem.

Does cashier paper slitting machine need automatic tension control system?

The automatic tension control system is very important for the thermal paper rolls slitting machine, because the machine often needs to accelerate and decelerate at high speed during the operation, and the tension must be consistent at all times.

The automatic tension control system ensures that the material tension is always consistent in the machine running process.

Does thermal paper slitter need PLC and touch screen?

Many years ago, Jota thermal paper slitter machine did not have PLC and touch screen, so it needs to install a lot of time relay and solid-state relay.

With PLC and touch screen, the operation is simpler and the machine downtime rate is also reduced.

Can thermal paper roll production efficiency be improved?

Jota economical cash register roll making machine’s standard working speed is 110m/min, the maximum speed is 150m/min.

A thermal till roll length is only 10m-55m, which limits the maximum speed performance.

If speed is too fast, after slitting and rewinding 10m-55m thermal paper, the operator is still loading plastic/paper core for next circle, which means the thermal roll machine needs to wait for operator, it is a waste of time.

Besides, faster speed means that tension control requirement is higher, the total thermal till roll making machine price will be higher too.

When producing some 80×80, 80×210 rolls, the speed can be increased to 200m/min on high-end models.

But once the speed of the machine is fast, and the accessories wear is also fast, which affects the life cycle of the machine.

Is cash register roll making machine safe during production?

Our machine has CE certification, and many drive motors and cutter blades have safety covers, which are very safe.

Blades Safety Cover

The machine adopts synchronous belt drive, the noise is not more than 80 decibels.

What is the dimension and weight of thermal roll slitting machine?

Jota thermal roll slitting machine uses 37mm thickness frame to ensure its stability at high speed running process.

37mm thickness frame

The dimension is approximately 1800mm x 1750mm x 1500mm, and the weight is 1200Kg.

The machine can work in the space above the second floor.

What if thermal paper slitter expires warranty period?

The warranty period of our machine is 1 year, but the technical support is whole life.

No matter where you are in the world, we can solve the problem through the network, e-mail, and video call;

Any accessories can be sent by DHL, TNT, FEDEX express delivery.

How do you know thermal paper roll production cost?

As your most professional thermal paper business solution provider, we can provide this service, please contact our sales, we will make a business plan for you.

Can thermal roll machine be used to cut other materials?

No.

Generally, other materials’ winding shaft diameter is 3″, and thermal paper roll rewinding shaft diameter is 0.5″ and 1″.

However, some special materials can be cut, and we have experience.

Please consult our sales for details.

Do you need a printing machine except for a thermal roll slitting machine?

If you can add a flexo printing machine, it helps you make greater profits.

The printing machine is mainly used to help your end customers print back logos or advertisements.

Jota also manufactures flexo printing machines for thermal paper, please watch below flexo printing machine video for reference.

Do you still need automatic packaging line to pair with thermal roll slitting machine?

Sure!

In fact, the thermal paper slitting rewinding machine only needs one person to operate, and the most wasteful manpower and time-consuming is the back packaging.

Jota’s automatic packaging line can be equipped with 2-3 slitting machines at the same time, helping you reduce labor costs, improve efficiency, and earn greater profits.

What are the packaging methods for thermal till rolls?

There are many ways of packaging thermal paper till rolls, the simplest is heat shrinkable film packaging, as well as golden film wrapping, silver film wrapping, paper packaging, and bag type packaging (pillow type packing machine).

Jota can provide all the above solutions, please submit your inquiry to us then wait for Jota’s prompt reply.

Do thermal paper rolls need to be stored in a dark place?

Considering the special nature of the thermal paper material, do not place it in direct sunlight, otherwise, it will easily fade.

But it doesn’t need to be placed in a dark place deliberately, just indoors.

Is thermal paper roll environmentally friendly?

The thermal paper we provide comes from world-class manufacturers, does not contain BPA, no harm to the environment, no harm to the human body, non-carcinogenic.

Do you need to wash hands after touching thermal paper?

There are color-developing substances on the thermal surface.

It is better to wash your hands after touching the thermal paper.

Will thermal paper be replaced by other materials?

So far, no material has been found to replace thermal paper.

However, with the rise of mobile payments, the thermal paper market will be affected, but will not be replaced in the short term.

What is the output of thermal paper roll slitting machine?

In 8 hours, 10,000 rolls of 57×50 thermal till rolls can be produced by Jota thermal paper slitting and rewinding slitter rewinder, which is almost 100 cases (100 rolls/case).

How long is thermal roll slitting machine’s service life?

The machine needs to be maintained once a month, lubricate the oil, keep such normal maintenance, 10 years of service life is possible.

We have many customers with Jota thermal POS paper slitting machines for 15 years.

How often does thermal roll slitting machine’s blades need to be changed?

Depending on your production time, it is generally necessary to replace the blade in 6-12 months.

We provide slitting upper blades of high specification materials, please contact our sales.

Can you get service from Jota if you bought other brands thermal roll machine?

Yes, we can provide you with thermal paper information service, as well as some accessories, such as upper blades and cylinders.

We also provide automatic packaging lines, which are independent and can be used in conjunction with your current paper cutting machine cash register.

What other value-added services can you get for Jota thermal paper slitter?

We provide consulting services, including global thermal paper market and price comparison, and provide packaging solutions, such as automatic packaging lines, packaging machines, and packaging consumables, POF film or golden film.

We also provide mechanical parts service, no matter you have any problems in the operation process, you can always contact us, we use a variety of channels to provide you with services.

Can you provide thermal paper jumbo roll?

We have good contact with various world-class manufacturers in China, and we can provide the most real-time thermal paper prices.

We have very good channel advantages.

Many large domestic thermal paper mills are our customers.

We have very close cooperation, and their prices are better than the prices you asked outside.

Please believe in professional power!

Can you distribute Jota thermal paper cutting machine?

Yes, we have better services for middlemen, not just price.

The win-win business is sustainable.

Can you apply for Jota cash register roll making machine’s agent?

Welcome!

So far, our machines have been sold in 50+ countries around the world on 5 continents.

If you have certain industry knowledge and service capabilities, we can communicate in detail.

In order to let you know more about we Jota company, please watch the following video for reference.

We Jota could also supply following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine