1400mm Fully Automatic Thermal Paper Slitting Machine

- fully automatic intelligent machine line for thermal cash rolls.

- More till roll output capacity in 8h

- No need dedicated operator, labor cost -95%

- Core feeder, slitter rewinder, conveyor, packager

- Optional inline printing and buffer

- Specification

- Video

PARAMETERS

| Item | 1400mm Fully Automatic Thermal Paper Slitting Machine |

| Unwinding Width | 1400mm |

| Unwinding Diameter | 1200mm |

| Max. Rewinding Diameter | 300mm |

| Min. Slit Width | 15mm |

| Max. Speed | 300m/min |

| Unwinding Shaft | 3” air expanding shaft |

| Rewinding Shaft | 0.5”, 1” are available (or as your request) |

| Voltage | 3 phase, 380V, 50Hz |

| Torque | 100Nm |

| Power | 20Kw |

| Weight | 4000Kg |

| Overall Dimensions (L*W*H) | 5500mm x 2200mm x 1880mm |

| SPECIFICATIONS |

| 1400mm Fully Automatic Thermal Paper Slitting Machine is able to make thermal receipt paper roll, ATM roll, ECG roll, carbonless copy paper roll, POS till roll, adding machine roll, etc. |

| FEATURES |

| Siemens PLC and MCGS touch control screen, all the parameters can be set on the screen. |

| Master motor is Siemens Inverter Motor, controlled by Inovance AC drive. |

| Shaftless unwind stand, hydraulic driven automatic jumbo roll loading. |

| Ultrasonic web guide for printed paper. |

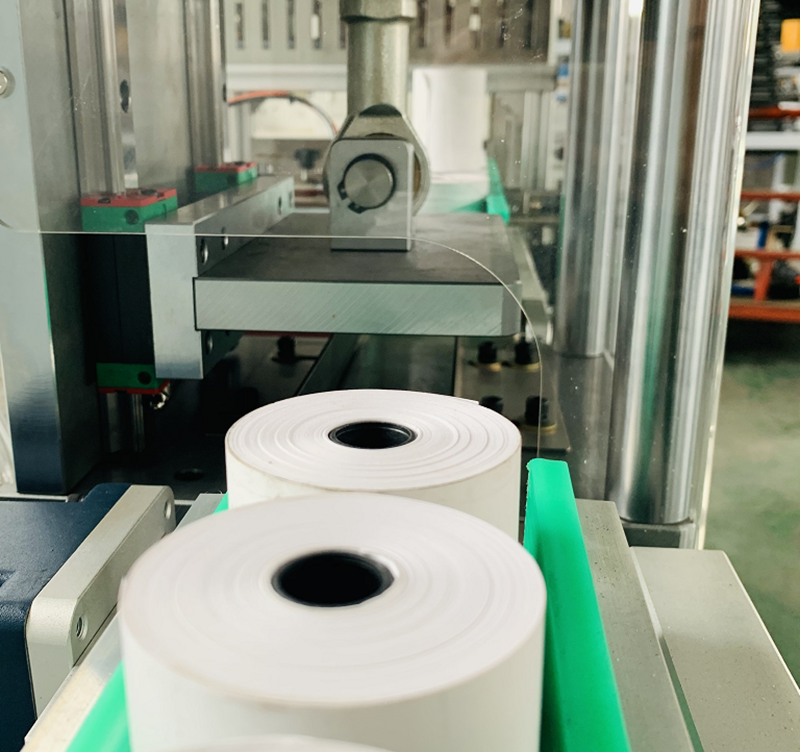

| Automatic vacuum core sucker. (Patented) |

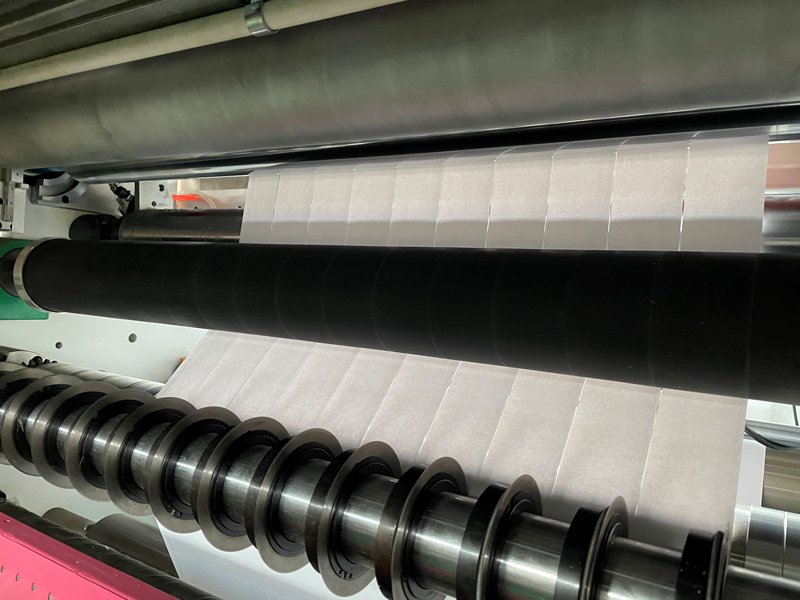

| Upper and lower circular knives shear cutting. |

| Automatic tucker quickly triggers rewinding. |

| 2 sets loadcell sensor and fully automatic tension controller for constant tension control. |

| Rotary encoder measures slit length automatically. |

| 90° vertical lay-on roller and banana roller ensures no overlapping problem. |

| Automatic finishing line: breaker, hammer, and conveyor. |

| Automatic Hot Shrink Packager (Another packing method available) |

1400mm Fully Automatic Thermal Paper Slitting Machine

Are you a wholesale supplier of cash register receipts? Would you like your slitter rewinder that customizes various POS receipt sizes?

Well, if so, why don’t you become the main supplier of thermal paper rolls in your local town, city, or country. Get the best, fast, most precise, and fully automatic thermal paper slitter.

Let the 1400mm fully automatic thermal paper slitting machine help you save on labor costs by 95 percent! Yes, the machine is fully automatic and doesn’t need an operator. All you have to do is preset the width and diameter you’d like to cut into thermal paper rolls and let the magic happen.

If you’d like to know more about the 1400mm fully automatic thermal paper slitting machine, then read on. Here’s a list of the 10 most commonly asked questions about Jota’s 1400mm fully automatic thermal paper slitting machine.

1. What Are the Specifications of the JT-SLT 1400FA Thermal Paper Slitter Machine?

It’s a fully automatic thermal paper slitter rewinder, with a “one-stop” production.

- More till roll output capacity in 8h

- No need for a dedicated operator, labor cost -95%

- Core feeder, slitter rewinder, conveyor, packager

- Optional inline printing and buffer

The 1400mm fully automatic thermal paper slitting machine offers an unwinding width of 1400mm, with an unwinding diameter of 1200mm. The slitter also comes installed with a motor that provides a maximum speed of 300m/s. At the same time, the 1400mm fully automatic thermal paper slitting machine can create slits as small as 15mm, which means you’ll easily produce ATM receipts, parking tickets, etc.

2. Is the JT-SLT 1400FA Fully or Semi-Automatic?

The 1400mm fully automatic thermal paper slitting machine is fully automatic, which does everything from the core feeding stage, the slitting process, and the packaging. You don’t need a worker handling the machine’s operation. It comes with an automatic setup screen where you preset the width sizes you need to cut and let it do the magic.

The only process that requires a human touch is placing the plastic cores on the bowl feeder. Once they’re in there, everything else is automatic. The plastic cores are automatically pushed into the staging conveyor.

The cores are then sucked into the rewinding station through the vacuum core sucker. Here’s a video on how the cores are sucked into the rewinder, which is entirely automatic.

As if that’s not enough, the 1400mm fully automatic thermal paper slitting machine makes things even easier for you. Before the slitting process, the machine features a fully automatic knife positioning system. This helps reduce your operation time and further improve the machine’s efficiency.

3. What Makes Your Cash Register Slitter Machine Unique and Different from Others?

Here are some reasons why Jota Machinery is the leading and number one cash register slitting machine.

A team of qualified engineers

Jota Machinery is reputable for manufacturing machines that are very accurate and precise. We have a team of engineers of the highest caliber. The R&D usually does everything in its power to make sure you get the best machines. We’re all about perfection and efficiency.

For instance, the 1400mm fully automatic thermal paper slitting machine ensures perfect slitting of rolls with consistent, flawless results and constant line speed. The machine’s also available in an adaptable model to suit your requirement.

CNC department for testing the machines

We also have the CNC department to ensure quality. Here’s where we do all kinds of tests to ensure nothing goes wrong. The CNC department carries out tests from the perspective of our target market.

We operate like we’re the suppliers of thermal paper rolls. This helps us learn of potential mistakes or issues our clients may incur. We don’t have to wait for feedback from clients because the CNC tests will show us exactly where to improve.

However, we still value our clients’ feedback and comments. In essence, your response and assessments are what we live for. Jota’s engineers are always ready and willing to help you out – even if it means customizing the entire slitter machine to fit your exact needs.

The latest technology

Jota’s 1400mm fully automatic thermal paper slitting machine is equipped with the latest technology in the market.

For instance, Jota’s 1400mm fully automatic thermal paper slitting machine works at a higher speed by AC Frequency Inverter Motor. This minimizes the time required for production and lead time. Jota Machinery thermal paper slitting machine ensures perfect slitting of rolls with consistent flawless quality and constant line speed.

We manufacture thermal paper slitting machines depending on your preferences. You can reach us for customized designs of your fully automatic thermal paper slitting machines.

Cost-effective slitter machines

At Jota Machinery, we regard your budget. We ensure that our thermal paper slitting machines are affordable. This subsequently will guarantee you profitable margins for your paper mill business.

The affordability of our thermal paper slitting machines also ensures that you save operating costs. The fully automatic thermal paper slitting machine is fully automated. This means that you will save costs associated with manual operations.

4. Does Your Cash Register Slitter Machine Offer Rewinding and Unwinding Features?

Of course, yes. The 1400mm fully automatic thermal paper slitting machine is a fully automatic machine that includes slitting and rewinding capabilities. The slitter unwinds a width of up to 1400mm, hence the name.

The machine also offers an unwinding diameter of 1200mn, with an unwinding shaft equipped with a 3-inch air expanding shaft. Here’s a video of the 1400FA unwinding stand. So check it out and see how the machine slits, rewinds, and unwinds.

5. How Does the JT-SLT 1400FA Thermal Paper Slitter Machine Work? What’s the Step-by-Step Process?

The 1400mm fully automatic thermal paper slitting machine is fully automatic, meaning that from the core feeding process to the final packing stage. And in terms of step by step process on how it works, here are a few videos giving you an overview:

- Jota’s 1400FA production line process

- A summary of its automatic process

- Automatic core sucker for the 1400FA slitter

- The machine also offers thermal paper printing

- Jota’s 1400FA Jumbo roll loading process

- Heavy jumbo rolls unwinding stand

6. What’s the Waste Outlet Like? Should I Be Worried About the Maintenance Process?

1400mm fully automatic thermal paper slitting machine has a special waste outlet in the waste trimming part.

Connect the hose to the waste outlet. The waste edges pass through the hose with the siphon fan’s huge vacuum suction.

Usually, after the finished till rolls are broken apart by cylindrical roller and flattened by the small press, the finished till rolls’ edges become neater, then they are about to enter the downstream packing.

In addition, different thermal paper slitting machines require other maintenance protocols. This is because they are all configured differently. Adhere to all safety protocols before the start of maintenance procedures on your thermal paper slitting machine.

Use our operators’ manual to guide you. This will help you avoid making grave mistakes when cleaning the thermal paper slitting machine. It also ensures that you avoid minor and major accidents.

7. How Customizable or Flexible is the JT-SLT 1400FA Slitter Machine?

Flexibility is Jota’s middle name. Our engineers take it personally to make sure you have the exact kind of machine you want. We understand the importance of having a thermal paper machine that fits your specific needs, as per the type of business you’re running.

Some of the configurations that you can put in mind may include the mode of control of the thermal paper slitting machine. You can also consider some configurations, such as hydraulic-driven automatic jumbo roll loading. All these serve to push the fully automatic thermal paper slitting machine slightly higher.

Therefore, we have flexible and open-minded designers and engineers to talk to for your design specifications. You can configure the thermal paper slitting machine to include a printer at the end of the thermal paper roll production.

The machine’s flexibility, the 1400mm fully automatic thermal paper slitting machine comes installed with a Master Control system. This gives you the freedom to adjust the thermal paper slitting machine’s speed, torque, and tension.

8. Do You Ship Cash Register Slitter Machines to the United States?

Yes. Even though we don’t have agents in the United States to help with the installation process, we can ship the 1400FA cash register slitter machine via DHL or TNT express. And then, we can Zoom to take you through the installation and working process of the thermal paper slitter machine.

In terms of timeline, we usually estimate an average of 3-4 weeks to have the machine delivered. But the timeline will also depend on your State. So yes, we can ship to the U.S.

9. How Much Does the JT-SLT 1400FA Cost? Should I Worry About the Taxes?

At Jota Machinery, we are business-centric. It means we understand your situation and we’d like to charge you the machine’s price as per your financial capability. So it’s best to contact us if you’d like to negotiate.

It’s worth noting that the slitter machines differ in their qualities and customizable requirements. Customized configurations for your thermal paper slitting machine will likely lead to slightly higher prices.

Parameters such as unwinding width and unwinding diameter will determine the overall price. The lesser the parameters, the lesser the overall price of your thermal paper slitting machine.

Components like the rewinding shaft and the unwinding shaft are customizable. This is achievable by increasing the rewinding shaft. Adjusting the components will lead to slightly higher prices for your thermal paper slitting machine.

Nonetheless, we are fair. You don’t have to worry about taxes, even though they’re included in our process of determining the machine’s pricing. That’s why Jota considers all your financial needs, so we may settle on a price that’s reasonable to you. Just know that Jota Machinery always has your business’ best interest at heart.

For instance, if you’re a startup, feel free to visit us. We will offer you the best fully automatic thermal paper slitting machine prices in the market.

Therefore, feel free to contact us, and let’s chat about the cost implications of your orders and purchases.

We advise you to go through our product catalog before making your order. This will help you in making the right decision.

10. Do You Offer Post-Purchase Services on the JT-SLT 1400FA Slitter Machine?

Yes, we do. At Jota Machinery, we ensure that we give you comprehensive guidance on how to operate our fully automatic thermal paper slitting machine. We have the option of dispatching our technicians to your location.

You can also send your technicians to our factories in China. This is ideal in making them understand the operation of the thermal paper slitting machine.

Our skilled team of employees offers a fully automatic thermal paper slitting machine after-sales service. Here are three services Jota offers.

- Consultations

At Jota, we offer consultations meant to ensure production growth. This can be achieved either directly from the Jota Machinery team or through the provision of access to our suppliers’ vast knowledge and expertise.

Some of the nitty-gritty of our post-sale relationship involves the following:

- Assessing the suitability of thermal paper slitting machines for customer requirements.

- Advising on the efficiency of production of fully automatic thermal paper slitting machine.

- Identification of the most appropriate solutions for customer needs.

- Recommending the required maintenance actions for the thermal paper slitting machine.

- Workforce Training

Apart from consultations, Jota Machinery also offers workforce training. Jota Machinery is always happy to offer on-site training for thermal paper slitting machines. this can be carried out either by our local team or with the help of our key suppliers.

When workforce training is empowered, your employees will become very productive. The best thing about Jota’s workforce training is that we can tailor your thermal paper slitting machine to suit your company’s various skills and levels.

- Tests, Trials, and Repairs

As if consultations and workforce training aren’t enough, Jota’s post-purchase services include tests and trials. We understand that machines may experience technical challenges, which may pose some difficulty whenever you’d like to repair. them them

With Jota Machinery, we don’t leave you alone to struggle with the repairs, which may cost you lots of money. Instead, we facilitate the testing of your thermal paper slitting machine. We also evaluate your needs to ensure your machine is always running as per your requirements.

As you can see, this helps us create a relationship that’s deeper than the conventional buyer-seller relation.

Therefore, we highly encourage you to contact us for more info on our 1400mm fully automatic thermal paper slitting machine. You don’t have to buy to develop a relationship with us. At Jota Machinery, we’re a friendly bunch, and we always welcome new clients to try our products even before purchasing. This is to have an idea of what you’re buying.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine