Poster Paper Sheeting Packing Line

- Fully Sheeting Packing Ideal Solution

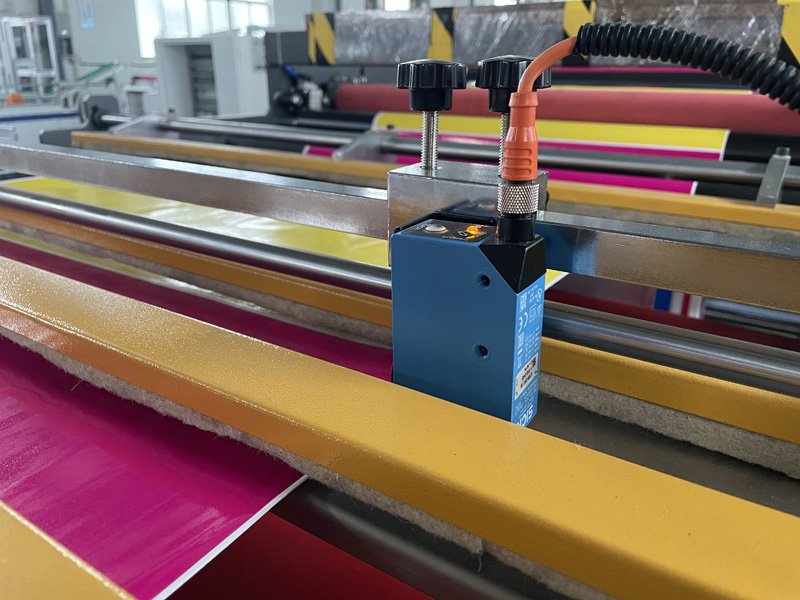

- Famous Brand Photocell for Tracking Printed Material

- Customize Long-Short Sheeting Program for Poster Paper

- Hydraulic Loading Station to Unload Sheets

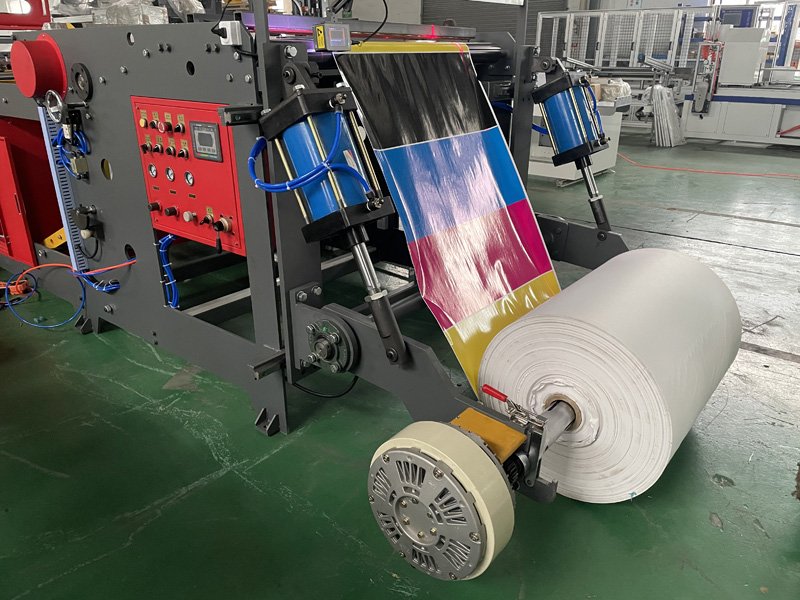

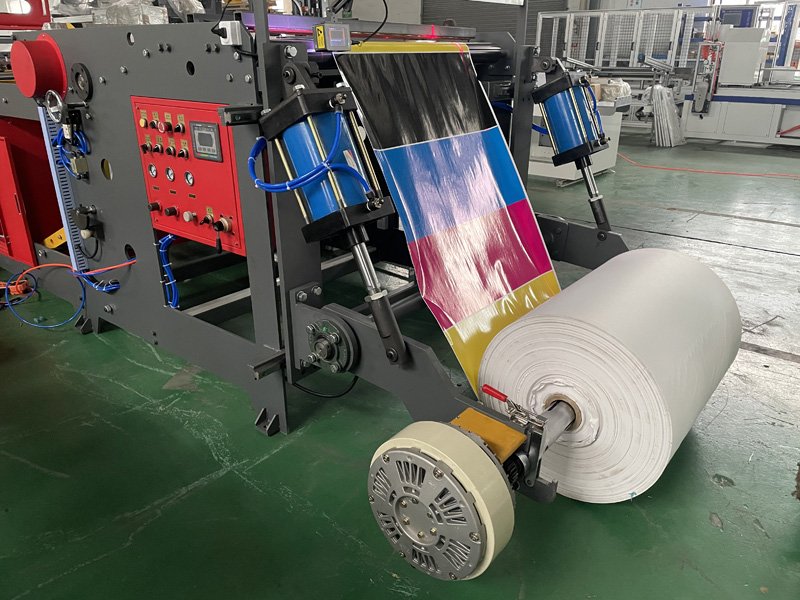

- CCD Camera For Web Guiding

- Specification

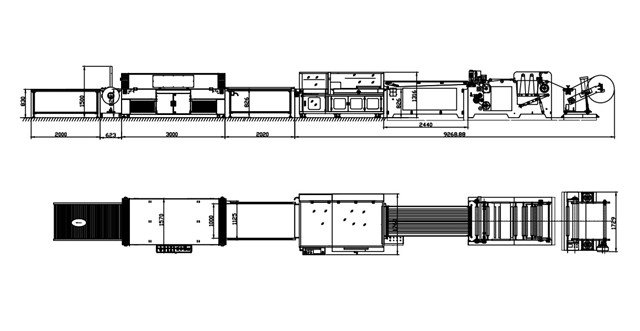

- Drawing

- Video

| Parameter of Sheeting Machine | |

| Max Sheeting Width | 1000mm |

| Max Unwinding Diameter | 1000mm |

| Max Sheeting Length | 6000mm |

| Unwinding Shaft | 3-Inch Air Expanding Shaft |

| Precision | ±0.5mm |

| Dimension (MM) | 6300×1500×1500 |

| Voltage | 380V/50HZ |

| Max Speed | Long Short Sheeting:30m/Min Or 15 Cuts/Min Plain Paper:90m/Min Or 45 Cuts/Min |

| Weight | 3000KG |

| Parameter Of Packing Line | ||

| Item | Sealing Machine | Oven |

| Max Packing Size | L: No Limitation W+H≤950mm H≤250mm | L*W*H 2000*900*250mm |

| Max Seal Size | L: No Limitation W+H≤1000mm | L*W*H 2600*1000*300mm |

| Packing Speed | 1-10 Bags/Min | 0-30m/Min |

| Power And Voltage | 220V/50HZ & 3kw | 380v/50-60HZ & 20kw |

| Max Current | 6A | 40A |

| Air Supply | 5.5kg/Cm3 | / |

| Weight | 950kg | 950kg |

Poster Paper Sheeting Machine with Packing Line

In November of this year, we exported this poster paper sheeting packaging line. This paper sheeting machine can be said to be a customized machine for customers in the advertising industry.

At the 2019 label exhibition, we brought our thermal paper slitting machine and paper sheeting machine to attend the exhibition. During the exhibition, a customer in the advertising industry took a fancy to our paper roll to sheet machine. He asked us that the poster paper needs to be long and short. After cutting the long material, still need to cut the short material. This is also the audit requirement for this cross-cutting machine.

After the exhibition, we wrote the short and long-cut program and debugged it. When we sent the trial video to the customer, the customer was very satisfied. After communication back and forth, we finally received the deposit.

In 2020, we took the packaging machine to participate in the label exhibition. The customers of this poster paper sheeting packaging line came to our booth again and told us they also need a packaging solution We added a customized packaging machine on the original basis, so this line appeared.

In about November, our equipment has been delivered to the customer. Below is the feedback video from this client.

In the paper milling industry, a paper sheeting machine is a critical piece of equipment.

This is because paper sheets are required for practically all of our daily activities.

From the cheeseburger, you order at your favorite spot to the paper you use to do your project, everything matters. Paper sheets are useful in our everyday lives.

That is why Jota Machinery guarantees you a paper sheeting machine with a packing line designed specifically for your business.

Have a look at the following questions to answer your queries.

- What is a poster paper sheeting machine with a packing line?

- How does a poster paper sheeting machine with a packing line work?

- Which industries use paper sheeting machines with packing lines?

- What raw material does a paper sheeter machine use?

- Does a paper sheeting machine with a packing line works at high speed?

- Can I print with my paper sheeting machine with a packing line?

- How can I make posters with a paper sheeting machine?

- What are the parameters of a paper sheeting machine with a packing line?

- What is important to consider before buying a paper sheeter machine?

- Who is the best manufacturer of paper sheeting machines with packing lines in China?

What is a poster paper sheeting machine with a packing line?

Cutting paper or other similar materials into particular lengths is known as paper sheeting. Cutting paper into particular widths is also part of the process.

A paper sheeter machine, on the other hand, is a device for cutting paper. It can be programmed to cut materials or paper to precise lengths and widths.

Paper sheeter machines are designed to cut huge jumbo rolls into smaller sheets of paper. They may take enormous rolls and cut them into smaller sheets for a variety of applications.

Sheeters can be used to feed rolls of material or to transform the output of an extruder, calendar, laminator, or other web equipment.

The majority of the sheets cut by a paper sheeter are used as finished goods.

The additional feature of this machine is that you can dd packaging line in this machine as auxiliary equipment.

In this way, you can take the benefit of sheeting and packaging in one place.

Types

We offer two types of sheeter machines at Jota Machinery.

- The scissor-type sheeter machine is the first. It contains a cutting mechanism in which the blade moves up and down, cutting the paper sheet. It’s great for cutting larger-width paper sheets.

- The rotary knife sheeter machine is the second type of paper sheeter machine. The slitting process used by these two types of sheeter machines differs.

Figure 1: Poster Paper Sheeter Machine

How does a poster paper sheeting machine with a packing line work?

Large rolls are cut into various sizes of paper sheets using a paper sheeter machine.

Rolling packing materials may be included in these paper sheets. Paper, paper-plastic, and multi-color laminated materials are examples of rolling packaging materials.

Consider the many sections of a paper sheeter machine to better understand how it works. Although the paper sheeter’s working mechanism may differ slightly.

They all have a nearly identical functioning mechanism. The following are the various sections of the paper sheeter machine.

The section where you unwind

Once a huge roll of a specified material is loaded into a paper sheeter machine, the operation begins.

Jumbo roll is a term used to describe a huge role. The unwind feeds the jumbo roll into the slitter.

Following that, the jumbo or master roll is slit into several widths. The paper sheeter machine, unlike other machines, cuts the slitted paper into multiple lengths.

Unwinding the jumbo paper roll is how the unwinding portions of a paper sheeter machine work. The jumbo paper roll is fed into the unwinder drum to do this.

Both the two-drum winder slitter machines and the four drum winder paper slitter machines are made by us.

The hydraulic shaftless jumbo roll loading system is installed on the drum winders.

Section of transmission

The slitted jumbo roll is readied for slitting during the transmission phase of the paper sheeter machine.

Our paper sheeting machine has been developed to match your paper sheeting requirements.

We have a customized sheeter, for example, that can cut two rolls at once. On the left, one roll, and on the right, another.

The material feeding segment of the transmission section has been optimized. The cutter head’s mechanical structure for thin paper has also been improved.

Section for Slitting

The paper sheeting machine’s slitting and sheeting components are combined.

This ensures that the process runs smoothly while producing high-quality paper sheets.

The jumbo paper roll is slitted into suitable rolls in the slitting area.

The widths of these rows correspond to the sort of paper sheet that will be generated.

Section of Sheeting

The unwinder paper roll is cut into various sizes throughout the sheeting process.

It can cut paper sheets into various lengths and widths depending on the setup. It can cut paper into A2, A3, A4, and A5 sizes with a paper sheeter machine.

Our paper sheeter machine can also be used to cut a variety of materials.

The scissor kind of cutting or the rotary style of cutting can be used on the A4 paper sheeting machine.

Cutting paperboard with a rotary sheeter machine. For cutting newsprint, a scissor-type reel to sheet cutting machine with a width of 1600mm is used.

You can also integrate the printing method, such as flexographic printing, in this area.

This can be accomplished by connecting the paper sheeting machine to flexographic printing machines.

You can also add different-width PE coating and lamination equipment to the paper sheeting machine.

Section of control

Our paper sheeter machine’s control system is centered. This means you’ll be able to control your paper sheeter machine’s many functions from a single location.

You won’t need many control locations for your paper sheeting machine’s numerous portions.

A program control system is included with the paper sheeter machine. The control monitor may show all of the parameters.

You can also utilize the control monitor to automatically start and stop the paper sheeting machine.

When it comes to machine management systems, the monitor incorporates the most cutting-edge technology available.

A powerful Wein view PLC, Touch Screen, and meter counter are used in our A4 paper sheeting machine.

The control monitor can show all of the working parameters. Only the material thickness and beginning tension parameters need to be set up.

Section of Waste Disposal

A specific waste exit has been installed in our automatic paper roll to sheet cutting machine.

You must connect the hose to the waste outlet in order for it to function properly.

With the syphon fan’s massive vacuum suction, all of the waste edges travel through the pipe.

Our paper sheeting machine’s air blower is designed specifically for thinner materials.

This ensures that your machine stays clean throughout the manufacturing process.

Working of Paper Sheeter Machine

Which industries use paper sheeting machines with packing lines?

Sheeters can also be found in the packaging and manufacturing industries. The following are a few of the uses.

- Glass processing laminates

- Medical devices are wrapped.

- Products made of composite materials.

- Interiors of automobiles that have been thermoformed

- Cutting with a die

- Laminating

- Printing on a computer.

Slitters can also be added to your paper sheeter machine. The slitters will aid in the cutting of your paper’s width. In addition, the length can be shortened to precise measurements. You can use your paper sheeter machine with a variety of various add-ons.

Figure 3: Uses of Paper Sheeter Machine

What raw material does a paper sheeter machine use?

The advantage of a paper sheeter machine is that it may be used with a variety of materials. It’s a machine that’s both versatile and simple to operate.

The sheeter machine can be used to sheet a variety of products. These are some of the items available:

- Packaging Paper Made of Cardboard

- Wrapping paper for hamburgers made of foil.

- Wrapping paper for hot dogs

- Wrapping paper for French fries

- Wrapping paper with a coating

- Plastic film with foil

- Various fabrics

Our paper sheeter machine can handle small rolls and cut them into sheets of any length.

A4 paper sheeting machines, for example, are designed to handle high-volume activities.

They can withstand the rigors of a 24-hour-a-day, seven-day-a-week operation in an industrial setting.

Figure 4: Raw Material

Does a paper sheeting machine with a packing line works at high speed?

When it comes to high-speed paper sheeting machine manufacture, we use cutting-edge technology.

The capabilities of the paper sheeting machine are designed to increase manufacturing capacity.

The paper sheeting machine’s automatic operation promotes efficiency. This is accomplished by a centralized control system that ensures that any machine failures are minimized.

Before an issue with the paper sheeting machine system becomes catastrophic, it can detect it. At the end of the day, it ensures that operations run smoothly and without incident.

Increased jumbo paper roll widths are guaranteed with an improved unwinding shaft.

This implies that you can cut numerous sheets of paper at once.

The high-speed paper sheeting machine, in fact, can produce seven A4 paper sheets at once.

This is in addition to a 200-cut-per-minute cutting speed. You’ll like the quickness.

High-speed working

Can I print with my paper sheeting machine with a packing line?

No, our paper sheeter equipment is not capable of printing.

Our paper sheeter machine does not have the ability to combine printing capabilities. Because printing is a continuous process, this is the case.

The sheeter, on the other hand, is a machine that can be turned on and off.

The sheeter machine slices the paper sheetfed in intervals when it is turned on and off. It is also modified on a regular basis to cut various types and sizes of paper sheets.

This makes integrating printing with the paper sheeter machine problematic.

An off-line printing machine is an ideal option to integrate printing capabilities. Before slitting and sheeting, this can be used to print on the paper sheet roll.

Another option is to have offline printing equipment that can print on already printed paper sheets.

It’s worth mentioning that the paper sheets can be printed in a variety of ways.

As a result, you’ll be able to use a wider range of printing processes on your paper sheets.

You have the option of printing on both sides of the paper sheeter or only one side.

This is dependent on the needs of the customer and how the paper sheeter is used.

You can reach out to us for assistance with the paper sheet printing process.

How can I make posters with a paper sheeting machine?

Yes, you can make posters with your paper sheet machine. The cutters installed in the paper sheeting machine are able to cut the paper rolls in various sizes.

You can set the dimensions of posters on the PLC control system and your required posters will be ready in no time.

With the help of the packing line, you can also pack your posters decently.

Our paper sheeting machines are among the best on the market, offering extremely high sheeting precision.

We ensure that you get the most bang for your buck by using better manufacturing procedures. We guarantee excellent production output and efficiency in service.

The finest part of the paper is that we are willing to consider your ideas for setup and customization. We can incorporate these into the final paper sheeting machine that we supply to you. It’s crucial, especially when it comes to addressing your unique business requirements.

Figure 6: Posters with paper sheeter machine

What are the parameters of a paper sheeting machine with a packing line?

Our paper sheeting machines provide a variety of settings. This is because we work hard to create a paper sheeter machine that is tailored to your needs.

The specifications are tailored to your company’s requirements.

The following are some of the most typical parameters of our A4 paper sheeting machine:

- A maximum unwinding width of 1050mm is available on our paper sheeter machine.

- It also has a 1200mm maximum unwinding diameter.

- The automatic paper roll to sheeter cutting machine has a sheeting length of 0-999mm.

- It also features sheeting that ranges from 50mm to 1050mm in thickness.

- Our rotary paper sheeter machine can cut at a maximum speed of 350 cuts per minute.

- Our paper sheeter machine has an accuracy of 15mm. This means it can precisely cut your paper sheets to the desired widths and lengths.

- Our A4 paper sheeting machine’s rated frequency is 50Hz or 60Hz. It will be determined by the specifics of your order.

- The rated voltage is 380V/220V, three-phase, four-wire.

- The paper sheeter machine’s unwinding and rewinding shafts can be customized. A 3″ (76mm) air expanding shaft is available.

- The dimensions of our A4 paper sheeting machine are 3000mm x 2000mm x 1300mm.

- The weight is estimated to be around 4000 kilograms.

What is important to consider before buying a paper sheeter machine?

Before purchasing a paper sheeting machine, you should think about the following factors:

- Paper sheeter machines come with a variety of features. As a result, it’s critical that you think about the type of paper sheeter machine you’ll need. The type of cutting put on the paper sheeter machine, for example, is something you should think about.

- Varied types of sheeter machines also have different functions and configurations. Select a machine that meets your company’s requirements. We will advise you on the best machinery to utilize at Jota Machinery.

- You should also consider the cost of the sheeter machine. Different things can influence the pricing.

- Paper sheeter machines are used for a variety of applications. You would have to pay more if you require a fully integrated automatic paper roll to sheet cutting machine. Different capacities are available for automatic paper roll to sheet cutting machines.

- Paper roll to sheet cutting machines with a higher capacity cost more than those with a lower capacity. The ability to manufacture a large number of small-size paper sheets is referred to as high capacity. The price of a machine is also determined by how it is integrated.

- The price of a paper sheeting machine is also determined by its configuration. The functioning mechanisms of the paper sheeting machine are among the configurations.

- Another factor to consider is the paper sheeting machine’s flexibility. The versatility of a paper sheeting machine might include features such as printing integration. Another factor to examine is the machine’s capacity to operate with various materials.

- The type of automatic paper roll to sheet cutting machine you require will have a significant impact on the way your organization operates.

- It’s critical that you have all of the information you need regarding the machine you want. Paper sheeter machines come in a variety of capacities, specs, configurations, and parameters.

Who is the best manufacturer of paper sheeting machines with packing lines in China?

For all of your paper sheeting machine needs, Jota Machinery is the place to go.

We work with a variety of different paper sheeting machines. When it comes to paper sheeting machines, we are known for our excellent client service.

We want to build a long-term relationship with you, unlike other paper sheeting manufacturers.

From the time you place an order until it is installed, we will be ready to help you.

We’re also accessible to make sure you’re getting the most out of your paper sheeting machine.

Figure 7: Paper sheeter manufacturer

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine