Single Shaft BOPP Tape Log Slitter

- Easy Operation

- Economic Cutter

- Bilingual system

- Cooling Sytem

- Specification

- Video

Single Shaft BOPP Tape Log Slitter

Last update time:21/03/2022

In the shipping and inventory management industries, BOPP tapes are among the most extensively utilised. Their strong, solid seals and resilience to severe temperatures have earned them a reputation.

Jota Machinery manufactures adhesive tapes constructed from high-quality adhesive with the tack and adhesion strength needed to seal cartons and make them pilfer-proof.

We use single shaft tape log slitters to slit BOPP tapes. Let’s have a look at the following article to learn more about the BOPP tape log slitter.

- What is BOPP?

- What is BOPP Tape?

- What are the advantages of adhesive tape?

- What are the features of Bopp Tape?

- What are the types of adhesive tapes?

- What is BOPP Adhesive Tape Slitter?

- Difference between BOPP and OPP Tape?

- What are the applications of BOPP Tape?

- What should I consider before buying a BOPP Tape?

- What raw material is used in the manufacturing of a cello BOPP tape?

- How does a single Shaft BOPP tape slitter work?

- What is the cost of tape log slitting machine?

- Where can I find the best Log slitter in China?

What is BOPP?

Biaxially Oriented Polypropylene (BOPP) is an acronym for Biaxially Oriented Polypropylene. BOPP film is stretched flat (that’s the “biaxially oriented” portion); polypropylene is a thermoplastic polymer, which means it’s pliable at some temperatures but solidifies when cooled.

BOPP film is widely utilised in a wide range of packaging applications, including snack food packaging and soft drink labels. BOPP film technology is also found in a number of popular packaging tapes.

What is BOPP Tape?

Adhesive tapes are the most often used adhesive packaging tapes in the medium to heavy-duty carton sealing, shipping, inventory management, and logistics industries.

This tape is made up of a backing and an adhesive component that is used to bind objects with a surface bond.

A cellulose film usually serves as a backing for adherents manufactured from chemically processed petroleum by-products, which are responsible for the tape’s stickiness.

BOPP tape is also called Cellophane tape. These tapes are largely used in the labelling industry and include basic cellophane tape, masking tape, packaging labels, and, perhaps most famously, transparent tape.

Polypropylene’s unique molecular structure and resin stability provide exceptional mechanical and optical qualities to the tapes.

Polypropylene also has abrasion resistance, chemically reactive substances resistance, burst resistance, and moisture resistance.

The film’s surface is simple to print and coat, making it ideal for custom printed BOPP packing tapes. When needed, the tape can be readily slit.

Figure 1: Adhesive Tape

What are the advantages of adhesive tape?

- Its tough structure and strong tensile strength make it an excellent packaging and labelling material.

- Abrasion, dampness, and a variety of chemical solvents are all resistant to it.

- It’s simple to coat, print, and even laminate, making it ideal for custom packaging tape production.

- The material is also burst-resistant and has a low elongation (about 150 percent on average). It’s also simple to slit.

- Because the material is a thermoplastic polymer, it can be used at both high and low temperatures.

- Although not all manufacturers publish tensile strength data, industrial packaging tape should be able to withstand longitudinal pressures of roughly 27 pounds per inch and transverse pressures of around 44 pounds per inch.

- BOPP tapes, which are made of thermoplastic polymer, can be used in both low and high temperatures.

- Hot melt synthetic rubber is a common adhesive because it seals quickly, reliably, and consistently.

What are the features of Bopp Tape?

These adhesives adhere to the surface quickly and have extra qualities such as UV, shear, and heat resistance. The following are some of the noteworthy features that go well with the tapes:

- High gloss and excellent clarity.

- Dimensional stability and flatness are perfect.

- Anti-wrinkle and anti-shrink.

- It’s non-toxic and biodegradable.

- Temperature resistant in both low and high temperatures.

- UV, heat, and moisture resistance are all features of this product.

What are the types of adhesive tapes?

When it comes to BOPP, there are a few different categories to look at to see what works best for you. BOPP Tapes are divided into three categories.

Transparent:

It can be used in products that require a lot of visibility. In the pharmaceutical sector, for example, some drugs must be handled with caution. The BOPP Tape makes it easier to seal those products while also ensuring that they are visible.

Colored Tape:

This type of tape is useful for tracking inventory levels. It ensures that all inventory dispatched has an identifying property that may be used to identify it. In this instance, the coloured BOPP Tape will need to effectively differentiate products.

Customized:

Many people want their business to be known. They want consumers to be aware of their products; in this scenario, brand recognition is critical. Customized/printed tapes can be really useful in this situation. It makes it easier for customers to recognise the goods and the brand that delivers it.

As a result, the above are examples of how the tape can be beneficial to many types of organisations.

Figure 2: Types of Adhesive Tapes

Aside from the cassettes mentioned above, industries use a variety of different tapes. This tape will be compared to OPP Tape in this section (Oriented Polypropylene).

What is BOPP Adhesive Tape Slitter?

Cutting and slitting is the essential parts of tape slitter and Jota provides you this service in the form of one machine.

You don’t need to invest money on different machines for cutting and slitting. you can use cello tape log slitting machine.

This cello tape slitter has a single shaft that slit the tape log at a point. With the help of a single shaft shaft cello tape log slitter, the low volume orders are done in time and no time is wasted.

The cello BOPP tape log slitter has the following parts.

Automatic cutting system

This machine has an automatic cutting system that converts the mass tape rolls into the rolls of desired form.

For instance, you want to make rolls for cello tapes, this machine will help you cut the paper rolls into the desired shape.

Wall thickness

Your BOPP cello tape log slitter has a wall thickness of 37mm

Work rate

It can work 24 hours a day. This feature is a huge want of the customers as it saves both cost and time.

The cello tape slitting machine can make cello rolls of about 57mm thickness.

However, the wall thickness of the machine is 37mm which is ideal for maintaining balance. Otherwise, the working of the machine may disrupt and the whole process will be affected.

With the aid of tail cutting and automatic glueing, the process of making cello tapes becomes easier.

CNC System

Moreover, a CNC system monitors the small functions of the machine to let you know of the tiniest possible error.

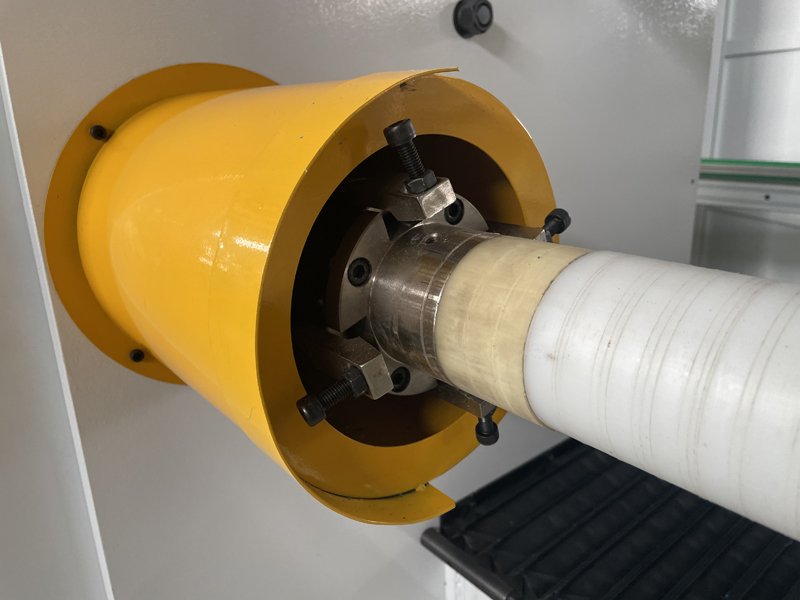

Figure 3: BOPP single shaft tape log Slitter

Difference between BOPP and OPP Tape

OPP Tape is a heat-resistant, lightweight, transparent, and unscented tape. It aids in the insulation and protection of surfaces.

BOPP Tape, on the other hand, has “high tensile strength,” is durable, and comes in a variety of sizes.

The main difference is that, whereas OPP Tape is used for insulation and sound dampening, BOPP Tape has a wider range of applications.

The BOPP is superior when it comes to securely packaging items and easily identifying them.

Additionally, the BOPP Tape is your best bet if you want to ensure that packages are not harmed by components such as water vapour.

However, if you need to utilize tape for electrical or surface protection, the OPP Tape is a good option.

What are the applications of BOPP Tape?

BOPP Tape has become a valuable resource in a variety of sectors. Here are a few examples:

Industry of shipping and sealing

It is necessary to ensure that items that must be delivered are properly sealed.

As a result, these tapes can be used to protect them from external elements such as water vapour. This tape does it all, from sealing hefty cartons to keeping lightweight shipments safe.

Inventory Management

This tape can be used to determine how much inventory a company has despatched.

Because the BOPP Tape has such a distinctive appearance, it helps prevent theft and loss. This makes identifying and labelling any goods much easier.

Miscellaneous Industries

This tape is also used in the jewellery, electronics, and publishing industries. It ensures that the products are packaged safely and that there are no damages.

Figure 4: Applications of BOPP Tape

What should I consider before buying a BOPP Tape?

BOPP Tape takes the lead when it comes to giving a wide range of benefits. However, before you decide to buy it from a corporation, there are a few things to keep in mind:

Quality Control

It is a term used to describe the process of ensuring

You must guarantee that your chosen ‘BOPP Tapes manufacturer’ is committed to quality control.

This is because these details provide you with a better understanding of the business and how it runs.

Certifications like “ISO 9001” keep a close eye on the “creation” and “production” of products like BOPP Tape.

Employee Safety

It is critical to provide a safe working environment for employees.

Look for a BOPP Tape manufacturer that employs safe working practices in their facilities. This is something that the certification ‘ISO 45001’ emphasises.

Furthermore, given the present pandemic, it is even more critical that employees work in surroundings that do not jeopardise their safety.

Food and Drug Administration Authority Certification

The BOPP Tape manufacturer you choose should be certified by the “Food and Drug Administration Authority.”

BOPP Tapes are also used on culinary and pharmaceutical products; therefore, this is critical. As a result, confirming that the tape is safe to use is crucial.

You should also seek a BOPP Tape manufacturer that has garnered honours or recognition for previous accomplishments.

This helps to demonstrate the manufacturer’s integrity and dedication to ‘qualitative processes.’

To summarise, it is a priceless instrument that provides numerous advantages. It provides high-quality packaging for products, is widely available, affordable, and well-known in the industry for its adhesive properties.

Figure 5: things to consider for BOPP tape

What raw material is used in the manufacturing of a cello BOPP tape?

Although natural rubber is still used in some pressure-sensitive tapes, the bulk is now produced with synthetic materials.

Cello tape’s backing is often made of cellulose acetate, a synthetic derivative of cellulose derived from wood pulp or cotton seeds.

The cellulose is treated chemically with acetic acid and anhydride, and the side of the tape that will not receive an adhesive coating is treated with a release agent to allow it to be wound and unwound without sticking together.

Although the exact composition varies by manufacturer, chromic chloride and poly-stearic carbonate are two typical ingredients.

The adherend side of the backing may be prepared with a solvent or aqueous dispersions such as nitrile rubber or chlorinated rubber before applying the adhesive.

Some manufacturers employ as many as 29 basic components that go through multiple phases of processing to create the finished glue compound.

Acrylic resins, which are petroleum by-products that are broken down into alcohols and acids before being fused into a polymer complex, make up the general adherend.

After that, the substance is combined with mineral spirits or a hydrocarbon solvent to make an aqueous emulsion that is applied to the backing.

Figure 6: Raw Material

How does a single Shaft BOPP tape slitter work?

Single shaft tape log slitter is suitable for low volume production and reduces your cost by reducing labour.

Following is the working principle of the Automatic BOPP Self Adhesive Tape Slitting Machine.

- It starts with slitting the tape roll.

- The machine includes cutters for slitting the mother paper roll, a web guide for edge tracking, and slitting/cutting.

- To slit the enormous mother roll, place it on the shaft.

- A mobile trip for online guide tracking is provided by the portable tape roll stand.

- We offer a variety of cutting processes for various material rolls. Round disc cutters may cut a variety of materials, including paper rolls, plastic sheet rolls, electric films, and new energy films.

- The electric tapes or sticky tapes are coated with pressure-sensitive acrylic, and the material electric tapes are protected by the centre rewinding process.

- If you’re looking at BOPP tape slitting machines, you’ll want to know which cutting knife processes are optimal and how to keep jumbo roll tension under control.

- The electric tapes or sticky tapes are coated with pressure-sensitive acrylic, and the material electric tapes are protected by the centre rewinding process.

- When one of the rollers is in use, the other is used for core loading and roll changing. It boosts productivity.

- Surface rewinding is the other option. Two bottom rollers, one of which is motorised, and a top pressure lay-up roller.

- On the bottom, there are two drum rollers, and on the top, there is a pressure roller. It creates a tightly wound loop that can be used to rewind the paper. A steel drum roller and a rubber friction roller are the two types of bottom drum rollers used by our expert.

Please contact our specialised sales team to send multiple jumbo roll samples so that we may conduct a test and learn more about the material’s qualities before recommending slitting machines. Someone else will make a decision if you don’t.

Figure 7: Working of Single Shaft Tape Slitter

What is the cost of a tape log slitting machine?

The cost is also determined by the machine’s size. For example, if you want to buy a jumbo log slitting machine, the price of a jumbo tape roll will affect the price of its little till roll.

Furthermore, the price will fluctuate based on market conditions.

The price of a cello BOPP tape log slitting machine varies depending on the country.

The cost of tape logs varies depending on market conditions. It is currently $15,000 worth of cost.

You should also think about the tape log roll’s quality. More end consumers would be attracted by consistent quality.

The cost of your log slitting machine is mostly determined by its characteristics and the region from which you purchase it.

You can acquire an estimate for a cello tape slitting machine by contacting us directly or contacting well-known jumbo tape roll vendors in your area or from around the world.

Figure 6: Cost of Cello Tape

Where can I find the best Log slitter in China?

After ten years on the market, Jota’s cello tape log slitting machines are accessible in more than 50 countries.

All of the electric appliances on the ATM paper slitting machines are well-known brands such as NSK bearing, Schneider electric switcher, Taiwan AirTac cylinder, and many more.

Jota Machinery provides all essential services and technical support in the event of any issues.

You might be able to find a solution locally, but we are always there for your help. We double-check that you’re covered for all of your services.

You may also find several industrial districts on the outskirts of a city, at least one manufacturer of tape log slitters can be found there.

We Jota could also supply the following related machines, if you are also interested in any type, please feel free to send us an inquiry:

- Hot Melt Thermoplastic CFRP CFRTP Prepreg Manufacturing Machine

- Fully Automatic Toilet Paper Maker

- Automatic Facial Tissue Making Machine

- Plastic Film, Fabric, Aluminum Foil Slitting Rewinding Machine

- Paper Sheeter

- Paper Tube Making Machine

- CFRP CFRTP FRP Prepreg Slitter

- Paper Drinking Straws Machine

- Label Die Cutting Machine

- Flexo Printing Machine

- Cardboard Tube Cutting Machine