Leading Thermal Paper Slitter Rewinder Machine Manufacturer

- Specially designed for making 3 layers thermal paper

- There is each separate tension controller for each unwinding stand

- Small size and economic

- Support customize

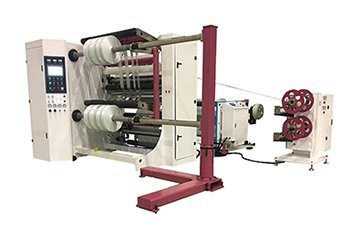

JT-SLT-500 3 Layers Thermal Paper Roll Slitting Rewinding Machine

JT-SLT-500 3 Layers Thermal Paper Roll Slitting Rewinding Machine is always Jota’s core product from the very beginning.

Jota thermal paper slitting machine’s iconic clients include Navigator, SS Labels, K.M.S Group, etc.

When you are shopping in the supermarket or having dinner at a restaurant and swiping your credit card, there is a small cash roll of paper, which is very popular nowadays. It is thermal reception paper or thermal cash register receipt paper. There is a great demand for this kind of paper in the current market, and it penetrates all aspects of your life. Therefore, the thermal paper slitting converting should be a good business for you, it is with a small investment and quick return.

As a professional thermal paper slitter rewinder machine supplier, after 20 years of industry precipitation, we could now provide a full set of thermal paper cashier receipt solutions chain from A to Z, from base thermal paper mother roll, paper core (plastic core), thermal paper slitter rewinder Machine, thermal paper printing machine, cash roll finishing wrapping line, and packaging film, we could provide a full set of professional solutions.

Submit your requirements now, we will recommend a suitable thermal roll slitting machine to you.

Jota Machinery: Your Trustworthy Thermal Paper Slitting Rewinding Supplier in China

Jota is a reliable thermal paper slitter rewinder supplier, we have our own factory and CNC center.

We are able to offer a one-stop solution for your thermal paper roll business.

To OEM your desired thermal paper roll machine, please submit your request to get a quote.

Machining Material

- Visible high-quality components

- Famous brands such as Siemens, Yaskawa, Delta, Schneider, Mitsubishi

- Self-supporting CNC processed sheet metal, precision parts

- Assembly raw materials provided by long-term cooperation suppliers

Installation and operation user manual, wire connection diagram, tension controller guide.

Installation and operation video tutorial.

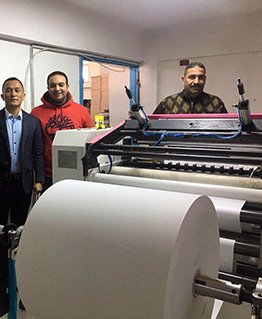

One-on-one remote video call assistance.

On-site installation and operation guidance.

- Factory

- Customer

- Specs

| Max. Unwinding Width | 500mm |

| Max. Unwinding Diameter | 900mm |

| Max. Rewinding Diameter | 160mm |

| Min. Slitting Width | 25mm |

| Max. Machine Speed | 150m/min |

Around 30-45 days, mainly depends on machine type.

Sure, it is our honor to work for you.

We will offer you some parts as backup, in case any part is broken within one year, we will sent you for free.

Sure, if we have client in your country, we will offer.

JT-SLT-500 3 layers thermal paper roll slitting rewinding machine

Last Update Time:27/03/2022

There is a good reason why numerous enterprises and e-commerce websites persistently update and improve their FAQs pages. It is to create awareness hence, promote the brand.

On top of saving lots of support tickets and pre-sales calls, FAQs pages are a great way to promote your products alongside the brand and give your customers an in-depth understanding of products.

Some of the freshmen don’t know how to do or how to solve the issue when operating our slitting machine then we made a page for frequent troubleshooting and solution. Kindly check this page

For example, these FAQs on Jota’s JT-SLT-500 3 layers thermal paper roll slitting rewinding machine, are eye-openers to many great potential buyers.

What are the specifications of the JT-SLT-500 3 layers thermal paper roll slitting rewinding machine?

Anyone looking for a fitting three plies carbonless copy paper roll slitting rewinding machine should look its way because it is a good model. It is a fully automatic thermal paper slitter rewinder on a one-stop production.

The aim of the machine is to be specially designed for making no-carbon copy paper, NCR paper rolls, and carbonless copy paper.

The following are some of its specs;

- The maximum speed of the machine is 150m/min

- The maximum unwinding width is 500mm

- The maximum reminding diameter is 160mm

- The maximum unwinding diameter is 900mm

- The minimum slitting width is 25mm

This machine is used in rewinding and slitting all types of thermal paper consisting of ATM paper, self-adhesive trade marks, cash register paper, fax paper, and non-woven cloths.

What is the working process of the 3 layers thermal paper roll slitting rewinding machine at Jota machinery?

Looking at an overview of some of the high-quality materials, carbonless copy paper is utilized.

Also referred to as the CCP, the carbonless copy paper is usually coated and comprises three layers of paper.

The CCP can disseminate information through the top, middle, and bottom sheets. On the side of the NCR paper structure of the machine,

The CCP contains some ink microcapsules on the downward side of the sheet top beside a reactive layer of clay on the bottom, upper, and middle of the sheet.

The time writing pressure is applied to the CCP, a reaction between the clay layer and ink microcapsule takes place, leaving a permanent duplicate mark.

Just like the final product contains three different layers, so does the machine fit out with three unwind stands, with every stand having a self-reliant tension controller.

As the working process continues, the CCP jumbo rolls are unrolled from the three autonomous unwind stands.

After going through the NIP and drive rollers, they go in the slitting section before forming a finished roll in the rewinding shaft. Alternatively, it can make thermal paper rolls; however, its main implementation is on the carbonless paper copy rolls.

What distinguishes you from other thermal layer paper roll slitting rewinding machines?

Research shows that 58% of customers are not trustworthy. Meaning as a brand, you are always in competition for your buyer’s dollar.

Today’s market is very competitive, so you’ve got to stand out if you are to succeed. Here are the top tips that have seen us through at Jota Machinery in our quest to remain relevant in the market.

- Remarkable customer service

Do you know that only 67% of consumers will remain after poor customer service? That is according to research.

With the rise of many thermal paper roll slitting rewinding machines, we can’t afford to lose customers because of poor service.

That is the reason why, at Jota machinery, excellent customer service is the core of our company’s focus.

Therefore, that means, our engineers sometimes willingly travel overseas at your request in maintenance guidance and time troubleshooting of the winding machines.

As a result of our commitment to serving our clients, a handsome percentage of them consider our customer service as a true test of our company adequacy.

At Jota, we consider our customer service strategy as part and parcel of our review management, and that is why we have been able to sustain more than 1,000 clients since we started producing these machines.

- A strong online presence

Only 3%of customers do not go online when looking for a product, meaning the remaining 97% check their products online before purchasing.

As a result, we have built a very robust online presence which has been a huge stepping stone in the success of our industry.

We have tons of information on our blog about the products we sell relevant information such as pricing, sales, services, manufacturing, etc.

- Latest technology

It is vital to note that there are positive facets of brand competition. Competition is the best way to know if your products are on high demand.

And that is where Jota has successfully managed to thrive. 3 layer thermal paper roll rewinding machines are equipped with the latest technology in the market.

A good example is the cutting-edge technology manufacturing that is fully automated thermal paper slitter winder, from small roll packaging to jumbo roll unwinding.

At the same time, our three layers thermal paper roll winding machine operates at high speed using AC Frequency Inverter Motor. That, in turn, reduces both lead time and the time for manufacturing.

For that reason, one of the benefits that we have because of embracing new technology is the competitive advantage that we have over our less tech-savvy rivals.

Due to technology, we now have the drive to constantly improve the quality of our products to ensure that you get the best of 3 layers thermal paper roll slitting rewinding machine.

How does the JT-SLT-500 3layers thermal paper roll slitting rewinding machine work? What is the step-by-step process?

JT-SLT-500 3 layers is a fully automatic machine that takes three steps to make the thermal paper rolls.

The principle that is used in the rewinding and slitting machine to cut the Jumbo paper rolls into diminutive thermal roll sizes of your choice.

The materials needed are; a rewinding and slitting machine, jumbo thermal roll, and a single forklift.

Step 1

Hoisting the jumbo roll. Here, you can use some mechanical equipment or forklift when lifting the jumbo rolls onto the slitting machine.

Some of the most common jumbo rolls sizes are as follows; 795mm by 5800m, 790mm by 6000m, 636mm by 6000m, 565mm by 6000m, 558mm by 5500m, and finally 405mm by 6000m.

Select the right jumbo roll size depending on your requirements. The most popular thermal paper brands are OJI (Japan), Koehler (Germany), Appvion (America), Hansol (South Kores), and APP (Indonesia).

Step two.

Balancing the blade. This step requires that the blade distance measure 79mm. Ensure that the measurement is exactly 79 without exceeding or reducing even with a 1mm distance.

Step 3

Power up the slitting machine. Ensure that the jumbo rolls have enough stability in the shaft before starting the engine.

The machine will naturally cut the 405mm jumbo roll into five distinct 79mm parts. Remain on the lookout for the digital counter to observe the length of the rolls.

After it gets to 75m, reduce the speed of the machine because the rolls will almost be reaching their 80mm mark in diameter.

And since it is a dire requirement that experienced workers handle these operations, Jota machinery elite staff takes great pride in its 20 years of experience in manufacturing thermal paper machines.

Do the JT-SLT 500 3 layers thermal paper roll slitting rewinding machine promising? Is there any future in using the machine?

Technological advancement gives Jota an upper hand in delivering the best to its customers and has thus, increased the profit margin because of the many sales.

For example, the jota thermal slitting machine’s symbolic customers include S.S Labels, K.M.S group, the Navigator, and many more.

These are some of the digitalized companies that esteem technology and will continue to do so. Take a good look at this example,

Having some delicious dinner at a restaurant, or just normal shopping in the supermarket, if you have noticed, there is usually a small cash roll of paper that is currently very popular.

The small cash roll of paper is thermal cash register receipt paper or thermal reception paper.

Therefore, as technology increases, there is a likelihood of high demand for this kind of paper in the market. That is because it will penetrate all aspects of many people.

Therefore, since it will be used by many in the future, Jota’s thermal paper slitting converting business is very promising.

With the many years of expertise in manufacturing professional thermal paper slitter rewinding machines, we are certain that there will be a surge of these products in the market later on.

Apart from JT-SLT-500 3 layers thermal paper roll slitting rewinding machine, what other products does Jota manufacture?

The manufacture of numerous varieties of products at Jota revolve around different types of thermal slitting machines, which include;

- JT-SLT-1400FA Fully Automatic Thermal Cash Register Roll production line.

- Semi-Automatic Thermal Roll Production Line JT-AUX-900

- High-Efficiency Cash Register Paper Roll Slitting machine

- JT-SLT-700 Coreless Cash Register Paper Winding Machine

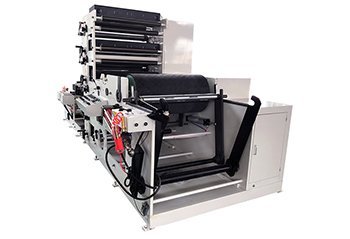

- Automatic Printing Slitting Machine

- Water Activated Tape Printing Slitting Machine

- Paper core machine

What are the shipping ways of transporting the JL-SLT-500 3 layers from your company to our premises or the market?

There are three different ways by which you can import your machine;

- The first one is organizing Jota carriers for the job for you.

- If you are friendly with the technicalities and methods of shipping, then you can decide on the importation by yourself.

- If you do not have enough experience in the industry, you can decide to hire a veritable freight forwarder to transport to your facility.

Whichever way you choose, Jota promises that you receive the machine at your facility without any defect. And that is achieved by proper packaging and taking care of any other security risk if need be.

And so, although one can cause train, sea or air, the most common route is the sea, because ships can carry very heavy machines safely besides, it is also cost-effective.

What are the profits of using this product?

Because of the many merits of manufacturing the JT-SLT-500 3 layers thermal paper roll slitting rewinding machine, a huge number of global customers have extraordinary profits from the industry.

A simple logic how you can make an astounding profit is as follows;

For example, if you start producing small paper rolls from two slitting rewinding machines that you have, the chances are high that you will increase your output hence a high sales margin.

Furthermore, you can cut papers with Jota machines and make money. There is no process there, it is just cutting paper using the machines, and that’s it.

To strengthen the financial muscle of your business, you may find it interesting to incorporate these business plans.

- Intensive marketing of the JT-SLT-500 3 layers thermal paper roll slitting rewinding machines.

- Enlist professional operators.

- Assess your profits.

- Select the best manufacturing location perfect for your target market.

- Buying raw materials and the machine.

What qualities are a good JT-SLT-500 3 layers thermal paper roll slitting rewinding machine?

To know if the machine is going to serve you better or is of good quality, you must consider these attributes:

- Ease in operation

- The speed of production should be high.

- Cost-effective

- The cost of maintenance should be reasonable

- Easy to install

- Adaptability – the machine should adjust to any changes, especially in technological advancement.

Is it possible to customize the three layers thermal paper roll sitting rewind machine?

At Jota, almost everything revolving around machines is possible. Meaning it is possible to customize your machine.

It would help if you simply liaised with our engineers, and they will do it depending on your needs and specifications.

A good example is where you may want to deal with a vast mother roll or need your knife-edge for a more hard material; everything will be done according to your demands.

In general, Jota professional staff manufacture very precise and accurate JT-SLT-500 3 layers thermal paper roll slitting rewinding machines that meet the need of all levels of customers.